|

Deflectors Deflectors

Helps redirect material toward middle of panels

Best suited for conventional lower open area screen panels

|

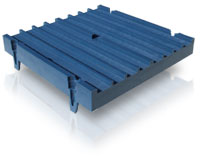

Cutter Panel Cutter Panel

Small surface humps situated slot against flow for static flume applications

- Particularly effective for dewatering and heavy media recovery.

- Small angled surface humps direct water down and into the apertures – slot against flow.

- Superior impact resistant capabilities.

- 30mm thick, 12″ x 12″, with either 4-pin or 4-snap fastening options.

- Slots are 1mm x 304mm.

- Available in standard or low durometer polyurethane.

|

HerringboneEffective for static sieve applications where heavy media recovery is critical HerringboneEffective for static sieve applications where heavy media recovery is critical

- Openings in 1mm x 22mm and 3mm x 21mm

- Increases the effectiveness of drain rates

- Offered only in polyurethane

|

|

Restricted Flow – Restricted Flow –

Effective in fine sizing applications

Controls material flow rates

Intensifies dewatering and washing effect

Breaks up lumping

|

Skid Bars Skid Bars

Keep oversize material off the screen panel surface and reduces wear

One-piece construction

Rubber and polyurethane configurations

|

SVR SVR

Elongated material alternative to standard VR design

50 different configurations and opening sizes

Ideal for applications where elongated material does not cause specific problems

|

|

|

|

|

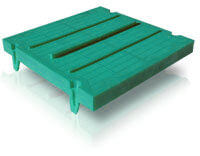

SSP (Static Screen Panel)

Molded with ridges to intensify dewatering

- Ideal for smaller materials, such as sand and fines

- Opening sizes from 0.25 mm x 9 mm up to 1.2 mm x 14.5 mm

|

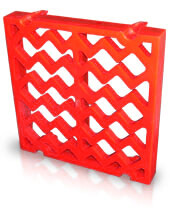

VR

Innovative zigzag design minimizes material entrapment or pegging

“Spring-like” vibrating action rejects over-size material

135 different configurations and opening sizes

|

Solid

Well suited for high impact and heavy wear

Typically installed at feed end of screen

Can also be used on discharge end as discharge lip

|

Slotted

For draining liquid or where elongated material is acceptable

Openings from 0.1mm x 9mm up to 178mm x 216mm

150 different opening size options

“With flow” or “against flow” slot directions

|

Dams Dams

Used in wet applications to slow material and increase washing effect

- One-piece panels with 1-, 2-, or 3-inch dams

- Larger dams available for custom applications

|

Square

The most common opening style.

Openings from 1mm to 200mm

250 different size designs

|

Round

Highly effective in primary scalping operations

Openings from 60mm to 230mm

13 different opening sizes

|

Continuous Slot Continuous Slot

Most commonly used in coal industry

- Six different slot widths from 0.5mm to 2.5mm

- Increased wear life over stainless-steel profile wire

- Offered only in polyurethane

Continuous Slot

Surface Configurations

With our injection molding process, special surface features, such as dams, skid bars, and deflectors, are part of the original panel construction-not a laminated add-on-for greater strength and longer life.

|

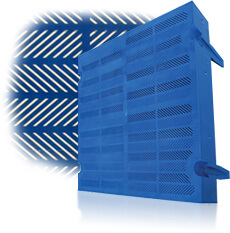

VST

Vector Slot Technology – slots at 45 degree angles enable the efficient recovery of heavy media

The VST’s unique design with slots at 45 degree angles creates speed vectors in the Z axis of a vibrating screen. This, along with ridges molded into the surface reduces racing, the tendency of particles or slurry streams to ride or race unhindered across the top of the screen panel.

- Lower tendency to plug

- Available in .65mm and 1mm slotted openings with a .85mm version coming soon.

|