Processing Heap Leachable Gold Ore by Cyanidation

Oxide ore (low grades) will be unloaded on the heap leach PAD. Lime must be added during the discharge in order to control pH. Harvesting must be performed after the ore discharge is completed in order to avoid compaction caused by the trucks during the leach cell construction.

After the leach cell is harvested, the irrigation system shall be installed and leaching will start with a cyanide solution of 50 ppm CN at an irrigation ratio of 10 L/h-m2 for a period of 60 days.

The pregnant solution is collected in the operations pond and then pumped to the Carbon in Columns Plant (CIC) where gold and silver are adsorbed on activated carbon. The gold and silver and then eluted at high temperature and pressure, using a cyanide and caustic soda solution. The result is a more concentrated solution of Au and Ag, which is sent to Merrill Crowe process plant (MC).

The Merrill Crowe process has three stages: clarification of the solution with filters, dissolved oxygen removal through de-aeration towers and precipitation of Au and Ag through the addition of zinc powder.

The precipitate from the filter presses is sent to retort furnaces for drying and removal of mercury.

The dry precipitate is blended with fluxes and smelted in an electric submerged arc furnace, obtaining the Dore bars (Gold and Silver).

The excess of water in the process can be treated in the Reverse Osmosis Plants (RO).

Processing Gold Ore by Milling by Cyanidation

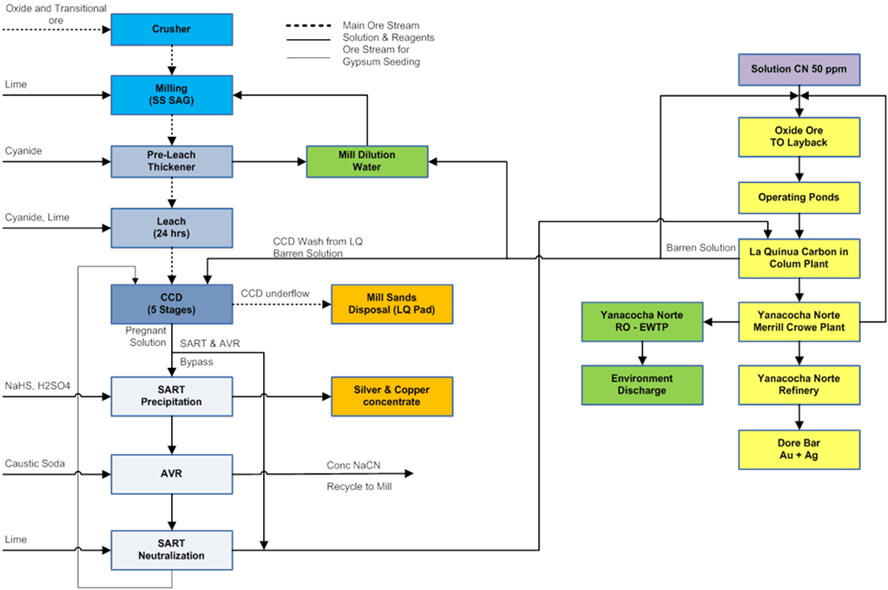

Oxide, transitional and deep transitional ores (high grades) will be processed in the Gold Mill plant according to their content of CuCN, %SS, gold and silver. Run of mine is transported from the pit by trucks and deposited on the crusher feed Hopper. The material is screened and crushed to 100% passing 4 inches and conveyed to a crushed ore stockpile.

The crushed ore is conveyed to the grinding circuit, where it will be ground to a nominal size of 80% passing 180μm (p80 -0.18mm). The circuit will consist of a single stage semi-autogenous grinding (SAG) mill in closed circuit with hydrocyclones. At this point, lime is added in order to control the pH and avoid the generation of hydrogen cyanide gas (due to the contact with the process solution, which contains cyanide).

The milling product is thickened in the pre-leach thickener and the solids in the U/F reach 60%. The overflow solution goes back to the mill and the thickened pulp is pumped to the leach tanks where cyanide concentration is controlled according to the requirements and type of ore that is being processed.

Leached slurry will be washed in a Counter Current Decantation circuit (CCD) for solid/liquid separation where a pregnant solution and mill sands are obtained. The sands will be pumped to the tailings storage facility.

Pregnant solution from the CCD circuit will be collected in the pregnant solution tank and pumped to the SART circuit if it contains high levels of copper and silver, or pumped directly to the carbon in columns for gold recovery.

Sulfidization, Acidification, Recycle and Thickening Circuit (SART) product is marketable as copper and silver concentrate.

After the pregnant solution is pumped to the Carbon in Column plant, it will go to the Merrill Crowe plant and then to the Refinery for the obtention of Dore bars.