SRL Pump More Than Pays For Itself in Recovery Of Flotation Concentrate From Thickener Overflow

Problem: Froth building up on surface of concentrate thickener tends to carry mineral values to waste.

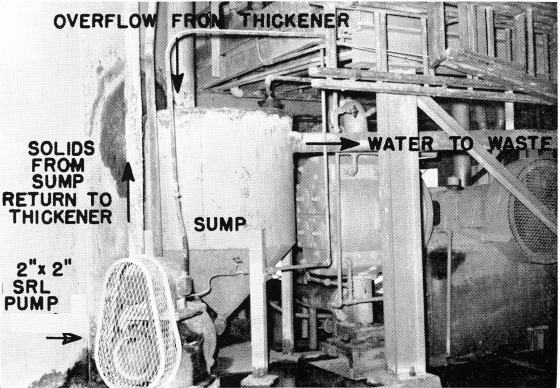

Solution: A small combination sump and overflow box was installed at the base of the thickener tank and a 2″ x 2″ SRL Pump was connected to the conical bottom of the sump.

To recapture the floating concentrate the thickener overflow flows to this combination sump and overflow box. As the thickener overflow flows down the pipe to the sump, the flocs of concentrate lose their entrapped air and the concentrates sink very rapidly to the bottom of the sump. The overflow from the sump goes directly to waste.

The underflow from the sump is pumped by a 2″ x 2″ SRL Pump to the concentrate pump which feeds the thickener. This procedure also saves having to add additional water at this point.

The savings in concentrates recovered at this plant have more than paid for the pump and its total operation without considering the savings effected by using reclaimed water for conveying the concentrates to the thickener.

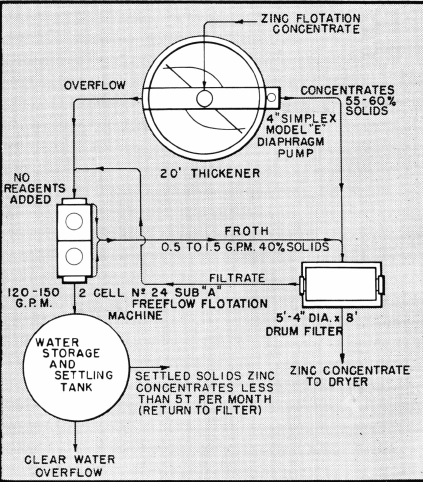

“SUB-A” FLOTATION RECLAIMS ZINC FROM CONCENTRATE THICKENER OVERFLOW

At the American Zinc Company, Mascott, Tennessee, an overload and froth condition on their concentrate thickener resulted in considerable quantities of fine zinc sulphide being carried to the overflow. The thickener feed consisted of cyclone overflow which is free of floculated particles.

To recover this fine zinc a settling tank was used and from 80-100 tons fine zinc per month accumulated and had to be removed.

American Zinc Company installed a 2-cell No. 24 “Sub-A” Flotation Machine between the thickener and the settling tank. Now the fine zinc is recovered without the use of any additional reagents. The flotation froth concentrate goes directly to the filter while the flotation tailing water go to the settling tank. The amount of fine zinc which now must be removed from the settling tank is less than 5 tons per month. The 2-cell flotation unit set adjacent and slightly above the filter, requires small space and has eliminated the need for a larger thickener and substantially reduced the labor involved in cleaning the settling tank. No pumps are required.