Where gold is associated with arsenic, antimony, tellurium, and certain other minerals, it is often only partly soluble in cyanide solution. The difficulty is usually more of a physical than a chemical one but special methods of treatment may be required.

Gold Leaching & Processing of Arsenic Ore

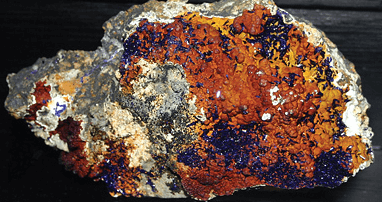

Mispickel (Arsenopyrite: FeAsS).6

When this mineral occurs‘in a gold ore, a proportion of the gold is frequently in intimate association and only rendered open to cyanide attack by previous roasting. With a “sweet” roast, the calcine usually yields a high gold extraction with low lime and cyanide consumption.

Mispickel in the raw condition in an ore, when agitated with strong concentrations of lime or other alkali in the presence of air, can yield alkaline arsenites, thus:

(FeAsS)2 + 2Ca(OH) + 130 = 2FeSO4 + 2HCaAsO3 + H2O

This reaction is a strong deoxidizer, inimical to gold solution by cyanide; therefore minimum amounts of lime and cyanide should, be employed in order to delay such reaction provided the gold is substantially free. If high concentrations of lime are used, the associated gold may be released, but difficulty may ensue in dissolving the gold owing to lack of oxygen.

Leaching and Recovering Gold from Antimony Minerals

Stibnite (Antimony Sulphide, Sb2S2)

This mineral in an ore acts as a weak acid, combining with alkalis to form salts, of the order of M1/3SbS2 and M1/3SbS4 alkaline sulphantimonite and sulphantimonate, especially in the presence of iron sulphides, using high concentrations of lime or alkalis. It is therefore indicated that minor amounts of lime be used in solution, sufficient to provide a permanent alkaline pH for protection of the small amounts of sulphantimony compounds formed, otherwise attacked by the latent acidity of the ore to liberate antimony pentasulphide and hydrogen sulphide, which would act as powerful cyanicides.

Use of low-cyanide-strength solutions is also advisable in order to minimize the speed of disequilibrium of the alkaline cyanide ions. The ore should be pulverized only to a sufficient degree to render the gold particles open to cyanide attack, thus presenting a minimum stibnite surface area for interferent reactions.

https://www.911metallurgist.com/sulphide-gold-ore-alkaline-pressure-oxidation/

Some stibnite gold ores are more amenable to cyanidation when previously subjected to surface oxidation in the pulverulent condition, with the formation of a sulphate film, which on contact with water yields an insoluble basic sulphate. The oxidation may also open up the fissure planes, setting free the associated gold. This oxidation may be secured by “weathering” the ore pulp, but in some cases, the agitation of the wet pulp with small amounts of lime and sodium peroxide, together with injected air prior to the addition of cyanide, may be effective.

If an antimonial ore or concentrate is roasted before cyanidation, this calls for meticulous temperature and air control, as reduction to the molten metallic condition can occur, with enfoldment of the gold particles.

The gold ores from this section are of special interest due to the gold’s being in association with stibnite and in some places with scheelite.

When ordinary water-slaked lime was used in the cyanide treatment of tailings from previous milling operation, the gold extraction was fair but the cyanide consumption was 12 to 14 lb. per ton, but by the use of ordinary air-slaked, or agricultural, lime the consumption was reduced to 3.5 lb. per ton.

The present 100-ton treatment plant consists of agitation and decantation equipment—an 18-ft.-diameter mixer vat with paddles and four agitators. Eight-ton batches are fed to the mixer. Sufficient lime is added for the proper degree of alkalinity. Then additional cyanide solution is pumped in to bring the strength to 0. 03 per cent.

The batch is then stirred for 4 hr. and then discharged into an agitator vat. The mixer handles two batches per day. The four agitator vats are 16 ft. in diameter by 8 ft. deep, fitted with stirring gear. Before running a batch into an agitator, a large quantity of sump solution is first pumped in, and the proportion of solution to solid is kept high. After receiving two batches from the mixer and given a double wash, the agitators are discharged, hosed clean, ready for the next batch.

The clear solution drawn off from an agitator is run to two settling vats 16 ft. 6 in. in diameter by 4 ft. deep. The solution stands in settlers until any cloudiness has settled. It is then run through a sand filter and then to the zinc boxes.

An 80 per cent gold recovery was made by the method of treatment described.

It is generally known that antimony can be readily volatilized, and by roasting stibnite (Sb2S2) in an oxidizing atmosphere, antimony oxide can be driven off and condensed. At the same time, anyone who has had experience with such roasting knows that it is a delicate process. To begin with it is impossible to drive off the antimony completely. Furthermore, unless temperature control is very exact, the ore being roasted is liable to be fused into a solid mass, entirely hopeless as regards subsequent roasting or treatment. Provided the roasting is carefully done, the scoria remaining, which contains the gold, also contains a residual amount of antimony which still stands in the way of normal cyaniding, as the gold is, if anything, still more intimately associated with it.

The treatment of the calcines with an alkaline leach for the conversion of the residual antimony oxides to soluble antimonates has been proposed as a method for overcoming the difficulties usually encountered in attempting to cyanide such material.

At the plant of the Consolidated Murchison Co. in the Transvaal, South Africa, where a refractory high-antimony gold ore is being treated, flotation and cyanidation of the flotation concentrates and tailings are being practiced. The association of the antimony and gold is very intimate, and during 1946, while the antimony recovery amounted to 70.6 per cent, only 62.7 per cent of the contained gold was extracted.

Telluride Gold Ore Processing

Solubility of Tellurides

In Bul. C.I.M, and M. June, 1933, under the heading “Gold Tellurides Are Soluble in Cyanide,” W. E. Johnston wrote:

The gold-bearing tellurides behave very much as does gold itself. Finely divided particles are dissolved fairly rapidly; coarser particles more slowly. All tellurides are soft and brittle and also have high specific gravity, with the result that they are extremely finely divided in ordinary mill practice. The ordinary high-lime solution of Kirkland Lake practice is suitable for dissolving of the gold tellurides. Oxygen is necessary but apparently not more so than in dissolved gold.

In E. and M.J., August, 1933, Johnston returns to the problem with the results of experiments. Before detailing these he says that a search of the literature failed to show that anyone had actually conducted cyanidation tests on either specimen tellurides or those concentrated from an ore—meaning Kalgoorlie, Cripple Creek, and Kirkland Lake. Experiments with cyanide on these ores gave the following conclusions, with which A. L. Bloomfield, H. V. Wallace, and John Dixon of Kirkland Lake substantially agree:

- Gold-bearing tellurides do yield their gold to cyanide if they are in a finely divided state and excess lime is used.

- Sodium peroxide greatly reduces the time of treatment required for maximum extraction. It is not beneficial when used in quantities equivalent to commercial use.

- The tellurides are very brittle and, owing to their high gravity, will be retained in the mill circuit for a long time. They will thus be in a finely disseminated state, approximately minus 1600 mesh or the size required to yield a maximum extraction of their gold.

- Up to the present, gold-bearing tellurides have not been found in large quantities in mill tailings or in concentrates recoverable from them.

As in the case of many arsenopyrite ores, however, those carrying tellurium and sulphotellurides often require roasting in order to open up the gold content to attack by cyanide solutions.

Gold Extraction from Carbonaceous Ore

The so-called “graphite” or carbonaceous mineral that exists in certain ores in California, Montana, West Africa, and western Australia has been a source of considerable difficulty in cyanide plants for many years. It usually occurs in graphitic schists adjacent to the ore bodies and with quite an irregular amount of carbon, increasing the difficulty in plant control.

Several different treatment methods have been developed to overcome the premature precipitation of gold by the carbon from cyanide solutions. In West Africa, a post-treatment was given following usual cyanide practice by releaching with sodium sulphide solution, which acted as a solvent for the gold precipitated by the carbon. Results, however, were not satisfactory.

The Silver-Dorfinan process, in which the ore, crushed in water, was treated with small quantities of fuel oil, kerosene, or a combination of both prior to cyanidation, was successfully used at some plants. The oiled graphite lost, to a large extent, its precipitating power.

Roasting was a satisfactory solution, but its cost precluded its use on many low-grade ores.

The later development of flotation for gold ores, has, in most cases, provided a satisfactory pretreatment and has been applied in several ways. Flotation removes most of the freed carbon with the concentrate, which is then roasted prior to cyanidation or shipped to a smelter. McIntyre, using flotation with cyanidation of concentrate, refloated their cyanidation tailing and returned this concentrate to the head of the cyanide circuit when they encountered carbonaceous ore.

Graphite is present in the gold-silver ore in the Timmins Ochali Mining Co, mill in Columbia. It was noted that considerable carbonaceous schist occurs in the run-of-mine ore, not all of which is detrimental. However, small quantities of graphitic schist act as a precipitating agent and are found to reprecipitate values from the solution in the agitating circuit. To remedy this, diesel fuel oil is added at 125 drops per minute to the classifier sand discharge. The oil acts as a collector for the graphite, coating and inhibiting its precipitating properties. A collector ring placed around the thickener feed well collects the graphitic froth which floats to the surface. This is skimmed off several times a week and stored. In two and a half years, less than a ton of it has been collected. The small amount of graphite that gets by passes harmlessly through the circuit and goes out to tails.

E. B. Leaver and J. A. Woolf of the U.S. Bureau of Mines described a number of experiments on California carbonaceous ores in T.P. 481, 1924, and some of their further work on the same subject was published in R.I. 2998, U.S.B. of M., 1930.

Cyanidation and concentration of gold and silver ores

List Gold Refractory Process Methods

The use of roasting for the oxidation of sulfides has declined over the years. However. Resolute Mining resurrected the Syama project in Mali by converting the process from a whole-ore roast to flotation followed by concentrate roasting. The roaster is a circulating fluid-bed unit. Resolute installed a scrubber on the gas exiling the electrostatic precipitator to remove sulfur dioxide, hence, obviating environmental issues associated with arsenic evolution.

Biological oxidation continues to be an important option for sulfide oxidation. In 2003. GRD Minproc undertook the basic engineering design for the Laizhou gold project’s bacterial leaching system in Shandong Province, which used the Bac l ech technology to treat 200 tpd of sulfide concentrates. This was the first commercial application of bacterial leaching for gold recovery in China. Since that time, at least seven further plants have been developed in China using technology supplied by BIOX ” and CCGRI (Changchun Gold Research Institute). The BIOX’ technology (recently acquired by Outotec) has also been applied further at Kokpatas. Uzbekistan, and at Bogosu. Ghana. The latter plant was originally designed and constructed by GRD Minproc and commissioned in 2007 to process 850 tpd of concentrates. The leach train includes 1500 m3 live capacity leach tanks with 300-kW agitator drives and these are the largest reactors of this type in the industry. Dunne (2012) reports that a biological oxidation plant has been installed by Olimpiada Mining in Russia having a capacity of 1000 tpd. The technology has been provided by BIONORD®.

The Albion Process described by Hourn et al. (2005). has been adopted at two refractor) gold projects (i.e.. Las Lagunas tailings reclaiming project, Dominican Republic, and European Goldfields, Romania). A further project incorporating the technology was commissioned in 2014 at the Ararat Gold Plant (GPM Gold) in western Armenia. The process consists of ultraline grinding of ore or concentrate followed by oxidative leaching at atmospheric pressure in agitated tanks. The leach residue is then processed via conventional CIP. The key control parameters arc the particle size of the leached solids, the temperature and acidity of the leach and the oxidation potential. Ultratine grinding is undertaken in an IsaMill*. The Las Lagunas plant was owned and operated by Pan Terra Gold and processed the refractory tailings from the Pueblo Viejo mine that was operated by Rosario Dominicana. The refractoriness of this ore is complex and w as the focus of many studies. The Pueblo Viejo project was acquired by Barrick Gold Corporation in 2006. who have built new facilities using POX technology to treat the primary sulfides. The new facilities are discussed in more detail later. The Albion Process , now marketed by Glencore Technology, has successfully increased gold and silver recovery from around 30% using conventional CIP to >80%. The process includes an M5000 IsaMill’ (grinding to P80 < 10-12 um) and five 600-m leach reactors fitted with oxygen injection lances. The initial plant had a capacity of 28 t/h of sulfide concentrates and has reportedly been expanded.

The leachox Process is another recently developed hydrometallurgical approach to the treatment of refractory gold ores. The technology is owned and marketed by Maclgwyn Mineral Services (MMS) based in the United Kingdom. This process has been installed at the Vasgold project in Kazakhstan, and the development, design, construction, and commissioning have been described by Flatman et al. (2010). While this process has reportedly been applied at a number of small, developmental sites, the Vasgold facility is significant and has been designed to process 1200 tpd of sulfide concentrates. The plant incorporates the ultratine grinding of flotation concentrate to dm of 4 pm and oxygenated leaching in agitated tanks recirculating through Aachen reactors. Metallurgical performance and operating data for the plant are not available in the public domain.

Pressure oxidation (POX) remains a further option for the oxidation of refractory sulfides. Several projects have been recently constructed: the Killita Project in Finland, the Amursk Project in Russia, the Pueblo Viejo Project in the Dominican Republic, and the MOPU expansion at Lihir.