EF1 – Dry Grinding – for the same range of work, dry grinding requires 1.3 times as much power as wet grinding.

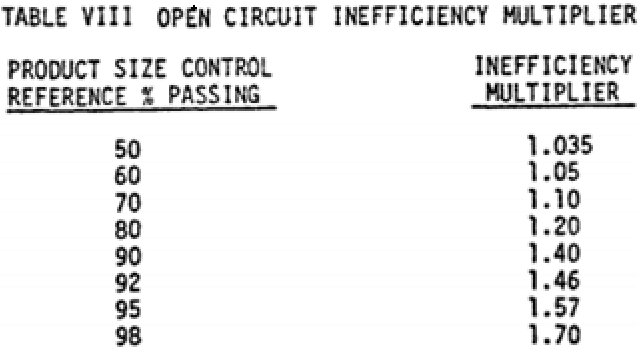

EF2 – Open Circuit Grinding – when grinding in open circuit ball mills, the amount of extra power required, compared to closed circuit ball milling, is a function of the degree of control required on the product produced. The inefficiency factors for open circuit grinding are given in Table VIII.

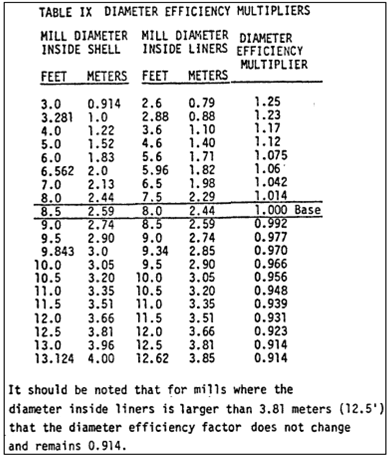

EF3 – Diameter Efficiency Factor – using the base mill diameter of 2.44 meters (8′) inside liners, the diameter efficiency factor can be calculated from the following:

Table IX gives a tabulation of the EF3, factors for some of the more common mill diameters in both the imperial and metric measuring systems.

Note: In selecting mills for new operations, where this factor is less than 1.0 it is sometimes neglected and is used as a safety factor. In the example it will be applied.

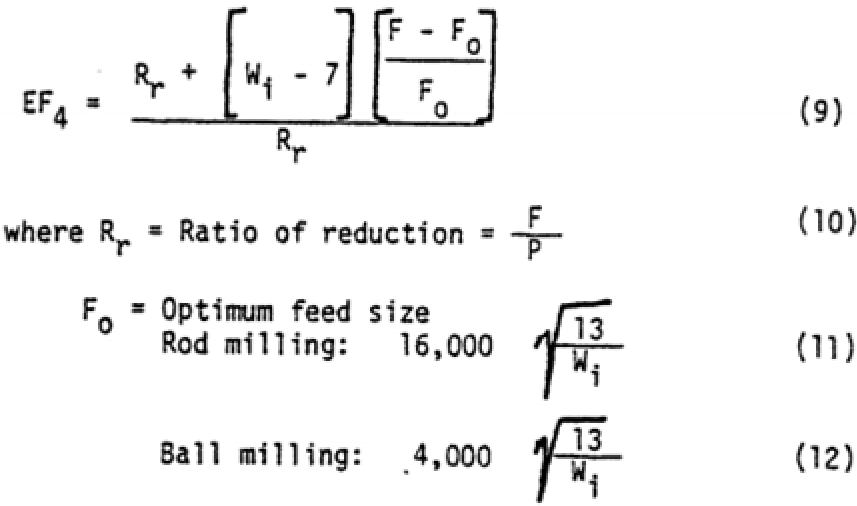

EF4 – Oversized Feed – when being fed a coarser than optimum feed, this factor applies to rod milling and ball milling. However, the most frequent use is found in conjunction with single stage ball milling. This is the one efficiency factor that is related to Work Index as is seen in the following equation:

When available, use the Work Index from a grindability test at the desired grind for Wi in equation 9. For equation 11, use either the Work Index from an impact test or a rod mill grindability test, whichever is higher. For equation 12, use the Work Index from a rod mill grindability test, since this more represents the coarse fraction of the feed; if not available then use the ball mill grindability test results.

EF5 – Fineness of Grind Factor – this applies to fine grinding when the 80% passing size of the product is finer than 75 micrometers (200 mesh). The equation to determine this is:

EF5 = P + 10.3/1.145 P…………………………………………………………………..(13)

EF6 – High or Low Ratio of Reduction Rod Milling – the equation to be used, unless Rr is between Rro = -2 and Rro = +2 is:

EF6 = 1 + (Rr – Rro/150)²………………………………………………………….(14)

where Rro = 8 + 5L/D………………………………………………………………..(15)

L = Rod Length

This factor always applies to low ratios of reduction but its application to high ratios of reduction is not always needed, but should be used for mill size selection whenever Wi from the rod mill and ball mill grindability tests exceed 7.0.

EF7 – Low Ratio of Reduction Ball Hill – the need to use this factor does not occur very often as it only applies to ball milling when the Ratio of Reduction is less than 6. This shows up particularly in regrinding concentrates and tailings. The equation for this is:

EF7 = 2 (Rr – 1.35) + 0.26/2 (Rr – 1.35)……………………………………………..(16)

EF8 – Rod Milling – a study of rod mill operations shows that rod mill performance is affected by the attention given to preparation and feeding a uniform top size feed size to the mill and the care given to maintaining the rod charge. This efficiency factor has not been definitely determined. In selecting rod mills based upon power calculated from grindability tests, the following procedure has been recommended:

- When calculating rod mill power for a rod-milling-only application, use an inefficiency factor of 1.4 when the feed is to be prepared with open circuit crushing, and use 1.2 when the feed is to be prepared with closed circuit crushing. The mill diameter, low or high ratio of reduction, and oversize feed factors also must be applied to the calculated grinding power.

- When calculating rod mill power for a rod mill-ball mill circuit, do not allow for improvement in the ball mill performance due to receiving rod mill feed. If the rod mill feed is produced with open circuit crushing, apply a 1.2 inefficiency factor to the power calculated for the rod milling stage only. If the rod mill feed will consistently be the same size, such as produced with closed circuit crushing, do not apply a rod mill inefficiency factor. The mill diameter, low or high ratio of reduction, and oversize feed factors should be applied to the calculated grinding power.

EF1 Dry Grinding.

EF2 Open Circuit Ball Milling.

EF3 Diameter Efficiency Factor.

EF4 Oversized Feed.

EF5 Fine Grinding in ball mills to product sizes finer than 80% passing 200 mesh (75 micrometers).

EF6 High or low ratio of reduction rod milling.

EF7 Low Ratio of reduction ball milling.

EF8 Rod Milling.

Example Rod Mill Design Calculations

Rod Mills

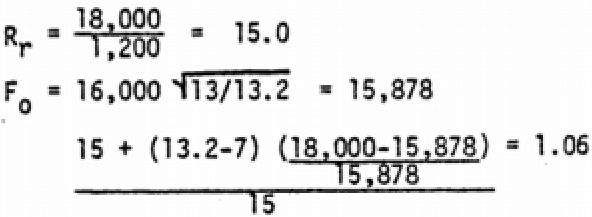

F = 18,000 micrometers.

P = 1,200 micrometers.

Wf = 13.2

W = 10 x 13.2/√1,200 – 10 x 13.2/√18,000 = 2.83 kwh/s. ton

Efficiency Factors:

EF1 does not apply.

EF2 does not apply.

EF3 determine after power calculations is completed.

EF4 Feed size is coarser than 16,000 micrometers,

EF5 does not apply.

EF6 will not apply as ratio of reduction will be within Rro ±2.

Rro determined after mill size selection.

EF7 does not apply.

EF8 The rod mill feed will be prepared by closed circuit crushing and the rod mill will be in a rod mill-ball mill (or pebble mill) circuit with no intermediate concentration stage so no EF8 factor need be applied. If it were just a rod milling circuit or if there were an intermediate concentration stage between the rod and the mill a 1.2 factor would apply.

Conversion short ton to metric tonne 1.102

Kilowatts to horsepower 1.341

2.83 x 1.06 x 1.102 x 1.341 = 4.43 Hph/metric tonne

4.43 x 500 = 2215 HP

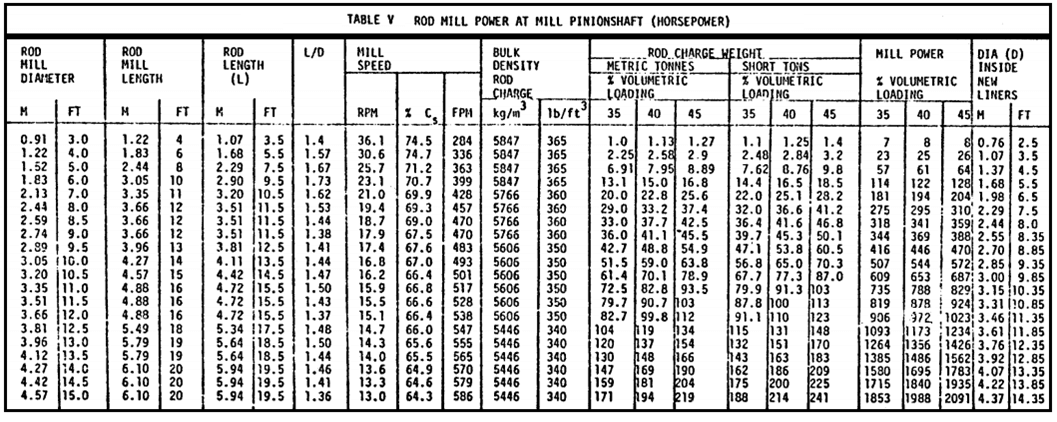

Referring to Table V two mills will be required. The preliminary rod mill selection would be a 3.66 meter (12 foot) inside shell 3.46 meter (11.35 foot) diameter inside new shell liners. Referring to Table IX the EF3 (Diameter Efficiency) factor is 0.931.

2215 x 0.931 = 2062 HP

Referring to Table V the 3.66 m x 4.88 m rod mill with 4.72 m (15.5 ft.) long rods calculates to draw 972 HP when carrying a 40 percent rod charge with a worn-in bulk density of 5606 kg per cubic meter (350 pounds per cubic foot). 1031 HP is required. Therefore, increase mill length by 0.3 meters (1 foot).

972/4.72 x 5.02 = 1034 HP

Therefore, use two 3.66 meter (12 foot) diameter inside shell 3.46 meter (11.35 foot) diameter inside new shell liners by 5.18 meter (17.0 foot) long overflow rod mills with a 40 percent by mill volume rod charge with 5.02 meter (16.5 foot) long rods.

Rro = 8 + 5 x 5.20/3.46 = 15.25

Rr = 15.0

Therefore, EF6 assumption is confirmed.

These mills are required to prepare ball mill feed. With pebble milling the pebble portion of the product does not go thru the rod mill thus the rod mill feed rate is reduced by 30 metric tonnes per hour (6% of 500 metric tonnes per hour).

2062/500 x 470 = 1938 HP

1938 ÷ 2 = 962 HP

Therefore, use two 3.66 meter (12 foot) diameter inside shell 3.46 meter (11.35 foot) inside new shell liner by 4.88 meter (16 foot) long overflow rod mills with a 40 percent by mill volume rod charge with 4.72 meter (15.5 foot) long rods.

Rro = 8 + 5 x 4.72/3.46 = 14.8

Rr = 15.0

Therefore, EF6 assumption is also confirmed here.