The principal object of this paper is to present data on the development of the revolving convex round table as a concentrator for the through 0.07-mm slimes from the ores of the Butte district, although some brief notes on the earliest recorded use of this type of concentrating table in the ore-dressing plants of the Lake Superior region and of the Butte district are also presented.

The revolving convex round table belongs to the class of concentrating tables known as film-sizing tables, these tables using the relative transporting power of a film, or thin sheet of water, as it flows over a quiet inclined surface, to separate the minerals of a sorted product.

The grains of heavy mineral move down the slope of the table deck slowly, or, in some cases, not at all, after the initial force of the feed entry is expended, since, being smaller, they are acted upon only by the slowly moving portion of the water which is in contact with the surface of the table; on the other hand the grains of light mineral (gangue), being larger, are exposed to the more rapidly moving water of the upper current and are therefore moved much faster down the slope of the table.

The speed with which the coarser grains of gangue material move down the slope of the table is also accelerated intermittently by the action of the waves of pulp flowing down the table. The coarser grains of gangue material are submerged, partly in the slow-moving under current and partly in the swifter upper current, and their speed of travel is greater than that of the former and less than that of the latter. Observations made on the action of the pulp on the table have shown that these coarse grains of gangue material are subject to distinct blows from the waves of pulp which momentarily increase the speed of these grains.

The speed at which the under current, or friction film, moves is dependent upon the character of the surface of the table, a rough surface retarding the flow of this current while a smooth surface accelerates the flow.

The revolving round table is a development of the stationary Cornish buddle, one of the oldest forms of slime concentrators, and it is a fact of great interest that a machine so closely related to one of the oldest forms of concentrating machines should be selected as the right machine for an important position in the flow sheet of our latest milling practice on copper sulphide ores in Montana.

The origin of the buddle seems to be lost in obscurity, and there is considerable doubt as to whether Cornwall or Germany first introduced this method of concentration. Cornwall has laid claims to having taught the art of tin mining and metallurgy to the Germans, and a story is related by one Matthew Paris, a Benedictine monk, by birth an Englishman, that a Cornishman who fled to Germany on account of a murder which he had committed, first discovered tin there in 1241, and that in consequence the price of tin fell greatly. This would seem to point to the probability of the buddle having originated in Cornwall.

Georgius Agricola in his De Re Metallica devotes considerable space to descriptions of dressing implements which were similar to the early forms of the box buddle. These consisted merely of a wide inclined stationary trough, with twigs or riffles placed so as to catch the heavy particles, the principle being the same as that used in Cornwall to-day. Agricola was born in 1494, and therefore this method of dressing or concentrating ores evidently dates back earlier than this time.

In the third century B. C. the Greeks practiced a system of milling and concentrating, using a method of washing the crushed ore which was very similar in some respects to the box buddle.

Edward Ardaillon in Les Mines du Laurion dans l’Antiquite gives the following details:

“From the mills it (crushed ore) was taken to washing plants, which consisted essentially of an inclined area, below which a canal, sometimes with riffles, led through a series of basins, ultimately returning the water again to near the head of the area. In washing, a workman brushed upward the pulp placed on the inclined upper portion of the area, thus concentrating there a considerable proportion of the galena; what escaped had an opportunity to settle in the sequence of basins somewhat on the order of the buddle.”

The square or box buddle of Agricola’s time would hold about 600 lb. of material when full. Owing to the necessity of returning the lower two- thirds of the material deposited to be re-treated on the same buddle, also to the amount of labor required to operate it, this form of buddle is practically obsolete everywhere.

The round buddle works on the same principle as the box buddle, and could be described as a series of box buddles arranged radially, with their feed ends in the center.

To obviate channeling of the ore, arms are attached to the rotating feed gear, and on these arms are hung strips of brattice or coarse cloth, which gently drag over the deposit, and thereby keep the surface even. This type of buddle is in use both in the concave and the convex forms. In Cornwall it is very extensively used in tin dressing, also in Derbyshire, Isle of Man, and Cumberland for concentrating galena ore.

The Cornish buddle or building table, which was used almost exclusively as a concentrator for tin ores in Cornwall during the early days of tin mining in that district, was usually from 18 to 20 ft. in diameter and was built in the form of a circular tank with sides 18 in. deep, the bottom sloping gently from the center to the circumference. In the center of the tank or table was a mound with a conical top, the mound being from 5 to 6 ft. in diameter. Pivoted in the center of the mound was a vertical shaft which revolved. This shaft carried a pulp distributor and four wooden arms which extended out over the buddle, the arms being equipped with brushes made of cocoa matting frayed at the ends or wisps of brush which dragged lightly over the sand as it accumulated in the buddle. These brushes kept the surface of the charge trued up and hence’ assisted the work of concentration very materially by preventing channeling.

During the process of running a charge in a buddle the water and slime were drawn off at points on the circumference which were equipped with sliding doors perforated with auger holes. As soon as the buddle became filled, the foreman examined the contents, marking off with the point of his shovel four or five concentric circles on the surface of the charge, their relative position depending on the richness of the mineral within each.

The buddle crew then shoveled the outer ring, which was mostly slime, into a launder which delivered it to a settling pond; the next ring was thrown into a waste tailing launder, the intermediate rings were shoveled into wheelbarrows and carried to other buddies for re-treatment, while the inner ring of all, containing about 25 per cent, black tin, was sent to the calciners.

The total result of this first buddling was that about one-quarter of the waste was removed from the pulp treated; another small part was sufficiently enriched to be sent to the calciners, while probably more than one- half of the whole had to be re-treated.

This method of buddle treatment has been supplanted in the more progressive plants by the use of Frue vanners and revolving round tables.

American milling practice has always been averse to the use of concentrating machines which operate intermittently, or machines which produce a large amount of middling material for re-treatment, therefore, the revolving round table, which at once overcame so many of the difficulties of the operation of the stationary buddies, made rapid headway in American mills in displacing stationary buddies, kieves, and other intermittent machines.

Round Table Practices

The milling practice in the Lake Superior district has been described in papers read before the Institute by Charles W. Rolker, H. S. Munroe, and F. G. Coggin. As nearly as the writer can learn the first revolving round table was introduced in the Lake Superior region, being installed in the Atlantic mill by a Mr. Jenkins, a Cornishman who had had considerable experience in the tin-ore dressing plants of Cornwall; and later it was in general use in the district. The round table most largely used was the design of W. J. Evans, the distinctive feature of which was the “dead-head” at the center, from 6 to 8 ft. in diameter, one-half of which was used for distributing the slime and the other half for distributing clear water.

The part played by the revolving round table in the flow sheet of the Michigan mills was to treat the spigot discharges of the settling tanks receiving fine product from the stamp mills, the material coming to the tanks as overflow material of the hydraulic classifier.

Before the advent of the reciprocating table, the round tables were used to produce a finished concentrate; two decks on a shaft were generally used, the middling from the upper deck being re -treated on the lower deck or on a separate system of tables.

The writer is informed by C. H. Benedict of the Calumet & Hecla company that the present practice at its mills is in no case to make a finished concentrate on the round tables, these tables being always followed by Wilfley tables, either two, three, or even six decks of the round tables being dressed up on one Wilfley table.

Round tables are in use at the C. & H., Tamarack, Ahmeek, Osceola, Isle Royal, and Mass mills. Ordinarily there are three decks on one shaft except at the C. & H. mills, where there are four decks on a shaft. The tables make 1 rev. per minute, and in new installations cement deck surfaces are used to replace the wood deck surfaces of the older installations.

The slope of deck surface in general is 1.5 in. per foot although a slope of 1.25 in. per foot is sometimes used on fine material. The tonnage fed per deck ranges from 15 to 20 tons per 24 turns and the recovery made is ordinarily from 40 to 50 per cent. On low-grade ores the ratio of concentration may reach as high a figure as 80 into one and is never less than 30 into one. With classifiers now in use the maximum size of grain going to the round table is about 0.25 mm.

The revolving round table used at the present time by the Calumet & Hecla Mining Co. consists of four decks mounted on a shaft. The table is driven from the top by means of a crown gear and pinion and is timed to make 1 rev. per minute. The total height of the table from crown gear to floor line is 21 ft. and the spacing between the decks is 3 ft. 8 in. The decks have the usual umbrella frame, the supporting braces consisting of 2-in. angle irons. The frame is so designed that the supporting braces occupy very little of the space between the decks. The circumference of the decks is stiffened by 3-in. angle-iron rim segments bent to the proper curve. The deck surface used is cement laid on-wood, the cement being about ½ in. thick.

Each deck is equipped in the center with a cone with a 45° slope and a base diameter of 3 ft. The feed pulp is delivered on one side of the table only from a special form of feed box which delivers the pulp against the face of the 45° cone. The decks are in general given a slope of 1.5 in. in 1 ft.

Early Use of Revolving Round Table in Butte District

From C. W. Goodale’s paper on the Concentration of Ores in the Butte District, Montana, it would appear that the Colorado Smelting & Mining Co. was the first to install round tables in the Butte district. The plant started operations. Round tables were installed in the initial flow sheet of this mill, but were afterward discarded in favor of Frue vanners.

In the concentrator of the Montana Copper Co. the reverse is the case, as Frue vanners were first installed and later were replaced by round tables.

Use of the Round Table at Great Falls for Sand-Slime Feed

Construction work on the first concentrator of the B. & M. C. C. & S. Mining Co. at Great Falls, the concentrator being put into operation in March. A second concentrator was completed and put into operation. Convex revolving round tables were installed for the treatment of the fine sand and slime which overflowed the Evans hydraulic classifiers.

The round-table practice at Great Falls, preceding the development of the table as a concentrator for through 0.07-mm. slime, did not differ greatly from the round-table practice in other Montana mills; usually the feed ranged in size from 50 mesh (0.36 mm.) to zero, with from 3 to 5 per cent, of coarser material due to the imperfections of the hydraulic classifiers employed, or to the overloading of these classifiers. No very close classification of feed was attempted, nor was any attempt made to produce a waste tailing from the round tables, the tables being guarded by the vanners. The use of the Wilfley table, under the conditions of round¬table operation, rapidly superseded the use of the round table for the following reasons: (a) A cleaner grade of concentrate was produced which contained as high or higher a percentage of the copper fed to the table; (b) a large tonnage of fairly low-grade tailing could be produced from a feed no more closely classified than the feed sent to the round tables, thus eliminating the re-treatment of this material on vanners; (c) the Wilfley table acted as a classifier in that it made a Separation between the sand and slime fed to it.

It is probable that good work could be obtained from round tables when fed with sand ranging in size from 60 mesh (0.25 mm.) to 200 mesh (0.07 mm.). Under these feed conditions, the very fine slime being eliminated from the feed, the tables should produce a large amount of low-grade tailing product.

The Round Table for Fine Slime

The use of the revolving convex round table as a concentrator for a through 0.07-mm. slime feed was originated by J. M. Callow of the General Engineering Co., Salt Lake City, in an exhaustive series of tests made by him on the concentration of overflow slime at the Boston & Montana concentrator, Great Falls.

This is believed to be the first time that so fine a feed had been treated alone on a round table; the writer has looked up all available literature on the subject but can find no record of a feed which did not contain a large percentage of coarser sand, the feeds usually varying from 0.35 mm. down.

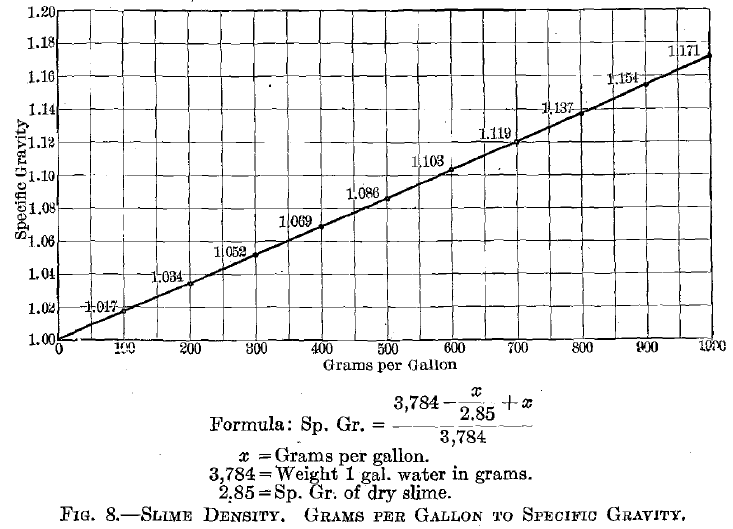

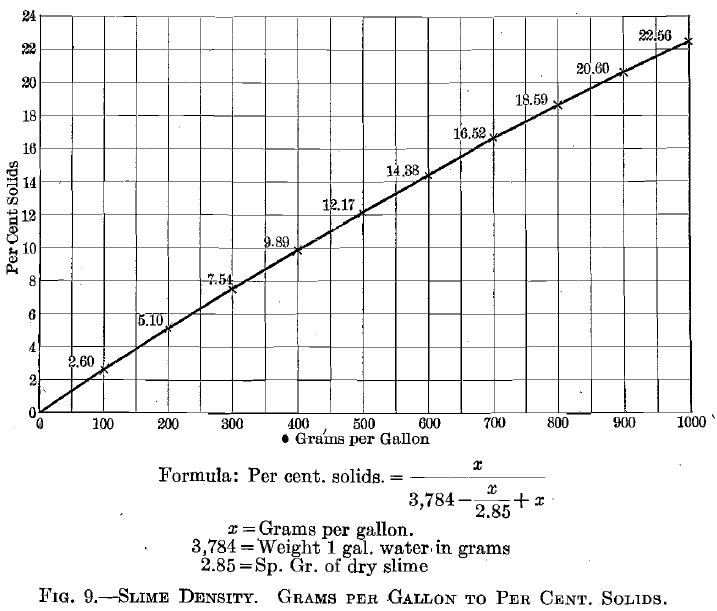

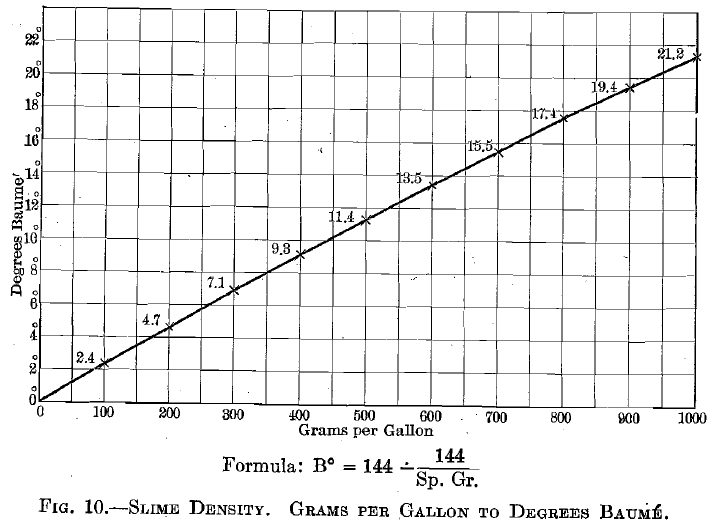

The concentration of the slime was preceded by a dewatering or pulp- thickening operation, the slime as produced in the mill being unwatered in a peripheral overflow tank of Mr. Callow’s design, since well known under the name of the Callow settling tank or cone.

By the use of this unwatering device, preceding the concentrator, the density of the slime was increased from about 70 g. of solids per gallon of pulp (2 per cent, solids) to about 350 g. of solids per gallon of pulp (8.75 per cent, solids) with a loss of only from 2.0 to 2.5 per cent, of solids and copper in the overflow of the tank. The capacity per Callow tank, to obtain the above results on B. & M. slime, was 25 gal. of slime feed per minute or 36,000 gal. per 24 hr. per tank, the tank being equipped with a goose-neck spigot discharge with an opening 3/8 in. in diameter operating under a head of 24 in. A full description of Mr. Callow’s tests will not be attempted in this paper, the general results only being given.

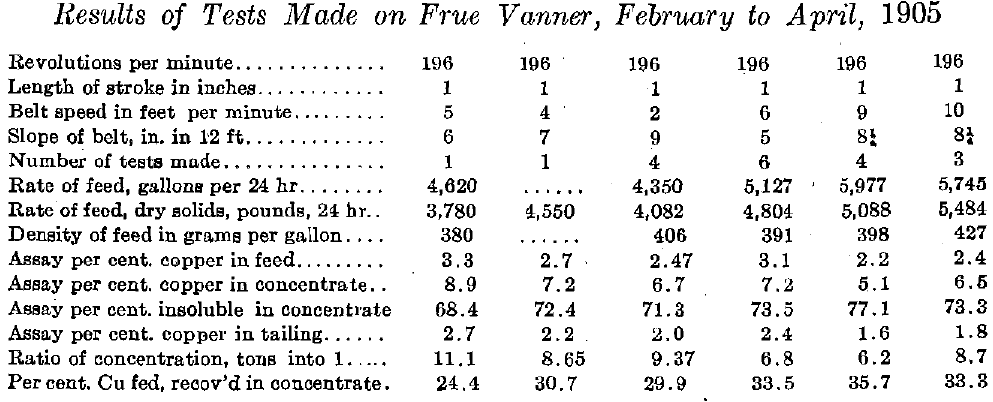

The machines at Mr. Callow’s disposal for trying out the concentration of the thickened slime pulp from his tanks consisted of a smooth-belt Frue vanner, a Wilfley table, and a revolving convex round table.

The round table was not at first considered by Mr. Callow, the first four tests being made on a Frue vanner and the next 16 on a Wilfley table. The copper recoveries made by the Frue vanner and the Wilfley table were in both cases low, especially so in the case of the Frue vanner, which was not equipped with the necessary stroke adjustments for the treatment of so fine a feed, which it must be remembered was about 96 per cent, finer than 0.07 mm. (200 mesh). Mr. Callow then directed his efforts toward finding what could be accomplished by using the revolving round table as a concentrator for the slime and his first results were so satisfactory that the remainder of his tests were made on this table.

No mechanical adjustments were possible except the speed and this remained unchanged from the speed used for the regular sand-slime feed, 1 rev. in 2 min. The Wilfley table and vanner have been developed as slime concentrators since this period but the development of the round table has enabled it to maintain its supremacy in this particular branch of ore dressing.

The tests made by Mr. Callow included tests made on the individual slimes and on various combination of the slimes, the end results of which showed that the Callow tanks would handle from 25 to 30 gal. of slime pulp per minute, thickening this slimy water from a density of about 60 g. of solids per gallon of pulp to a density of about 350 g. (1.5 to 8.75 per cent, solids), overflowing about 90 per cent, of the water contained in the slime and delivering from 95 to 98 per cent, of the solids fed in the pigot discharge for treatment on the round tables.

The revolving convex round table was shown to have a capacity for treating from 4 to 5 tons of the thickened slime per 24 hr., producing from 3/4 to 1 ton of concentrate assaying from 5 to 6 per cent, copper and 71 to 75 per cent, insoluble, and containing about 50 per cent, of the copper in the feed, the ratio of concentration being from 5.5 to 6 tons into one.

It was recommended by Prof. R. H. Richards that an Embrey vanner be tried out as a concentrator for the thickened slime pulp from the Callow tanks, as, in his opinion, the end-shake vanner, to which type the Embrey vanner belongs, would prove to be a superior machine to the side-shake vanner for the concentration of the fine slime.

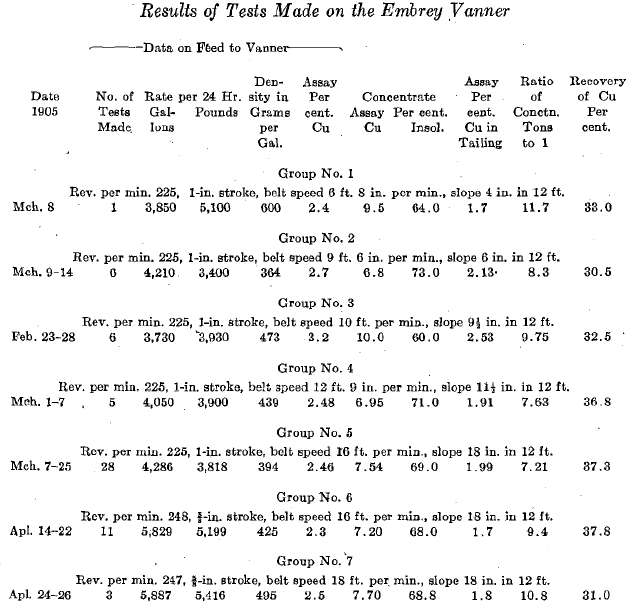

An Embrey vanner was, therefore, installed in the concentrator and thoroughly tested on the treatment of the slime. The results of the tests confirmed Professor Richards’s statement in regard to the fact that the end-shake vanner would develop a higher efficiency than the side-shake vanner in the treatment of very fine slime, the recovery of copper being increased, but the recovery made by the Embrey vanner still fell short of the recovery made by the revolving convex round table and the capacity of the vanner was much lower. The main data received from tests made on the Embrey vanner follow (p. 425).

Some results obtained from tests made in the Frue vanner when equipped with a corrugated rubber belt are also presented.

Construction of Slime Plant

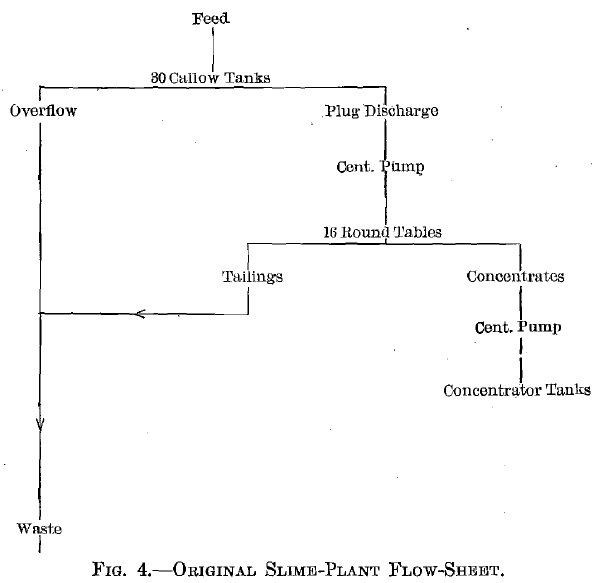

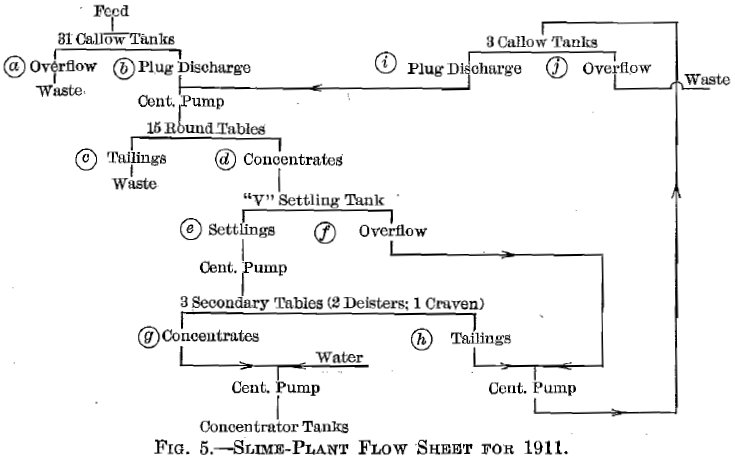

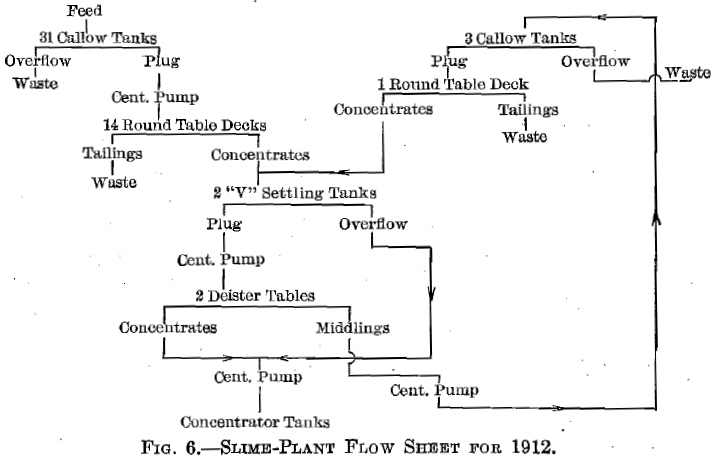

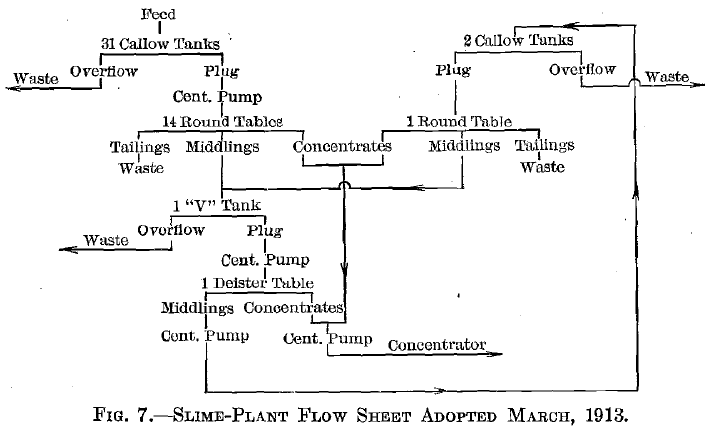

In order to try out Mr. Callow’s flow sheet on a commercial scale it was decided to erect a slime plant with a capacity for treating about 1,000,000 gal. of slime per 24 hr., the pulp carrying about 80 tons of solids. This required an installation of 30 Callow tanks and four four-deck round tables. Construction was started on this plant during the summer and the operation of the plant was started in the fall.

The building was so designed, and the equipment so arranged, that the plant could be readily enlarged to the full capacity required should the results obtained justify this course.

The original dewatering and concentrating equipment of the slime plant consisted of 30 8-ft. Callow tanks and 16 17-ft. revolving round tables arranged as four four-deck tables. The round shaking tables used were the two-deck tables removed from the concentrator at about this time, two double decks being set up one above the other and the shafts connected with a coupling so as to form a four-deck table.

Of the 16 decks installed, four were given a linoleum cover, four a cement surface laid on the original wood surface, and on the remaining eight the original wooden surface was maintained. The circular feed- distributing apron with a 2 in. to the foot slope, previously mentioned, was allowed to remain on the tables. The slope of the deck surfaces was 1.25 in. per foot for the wood and linoleum surface decks and 1.5 in. per foot for the cement surface decks; the speed of all tables was 1 rev. in 100 sec. or 36 rev. per hour. The feed pulp was distributed over one- half of the table and washed with dressing water on the other half of the table, the tables being operated in practically the same manner as when treating a sand-slime feed in the concentrator.

The cement-surface decks installed in the slime plant were the first decks of this character installed at the Great Falls works; cement-surface decks were coming into general use in the Michigan ore-dressing plants at this time and probably had been used at other plants; in fact, John A. Church mentions having installed cement-deck round tables at Tombstone, Arizona.

Mr. Church states that the use of cement for round-table deck sur-

faces was not original with him at that time, he having read of its use although he had not seen tables with this character of deck surface in operation. Mr. Church introduced the round tables in the Tombstone district after seeing the performance of the revolving round tables in the Lake Superior copper mills, where, at that time they were made entirely of wood. The deck slopes used by Mr. Church were as follows: 1.75 in. per foot for all but the finest slime, for the treatment of which the deck slope was reduced to 1.25 in. per foot. A novelty introduced by Mr. Church was the construction of some tables with iron framework, under the impression that the swelling of timbers in such a wet place as a mill might throw the surface out of true. In constructing the above-mentioned concrete-deck surfaces the body of the table surface was made of concrete with broken stones up to 3/8-in. ring and with the cement so scant that the concrete was visibly (and coarsely) porous. A thin skin of pure cement was laid on this, of not much more than paper thickness. Mr. Church states that these tables kept their surface extremely well, better than some all-cement surfaces that he has seen; he thinks, however that the quality of the cement has more to do with the results than the mode of laying on.

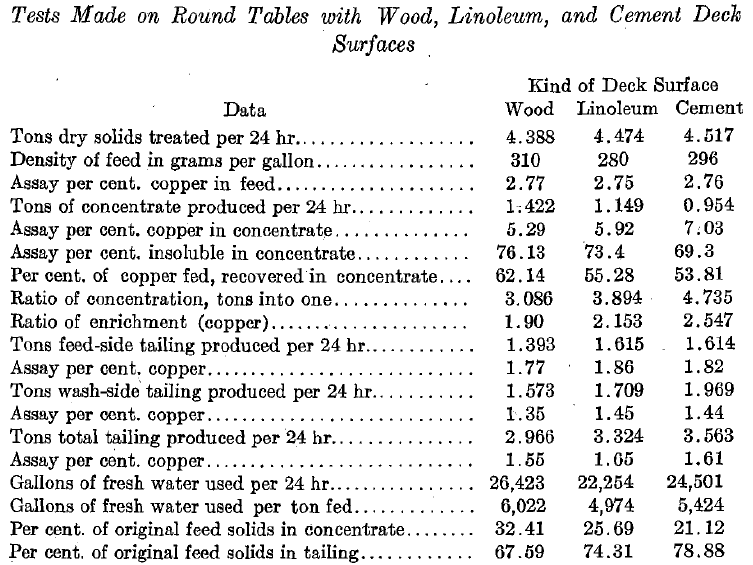

Tests on Wood, Linoleum, and Cement Decks

To return to the Great Falls slime plant. The writer, who was placed in charge of the slime plant during the first year of its operation, carried out a series of tests with a view to determining the relative effectiveness of wood, linoleum, and cement deck surfaces on a round table, two series of tests being made each extending over a 10-day period. During the first test the total feed to the tables was distributed over 12 of the 16 decks, one four-deck table being shut down, while during the second test the 16 decks were used. The first test was called a high-tonnage test and the second a low-tonnage test. Three tables were tested, the deck surfaces being wood, linoleum, and cement, respectively.

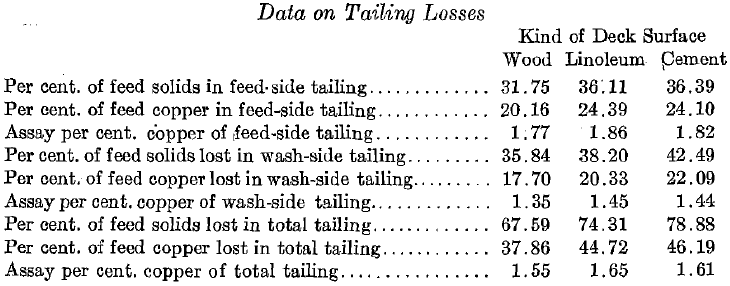

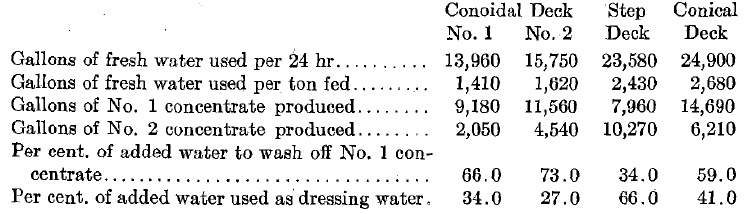

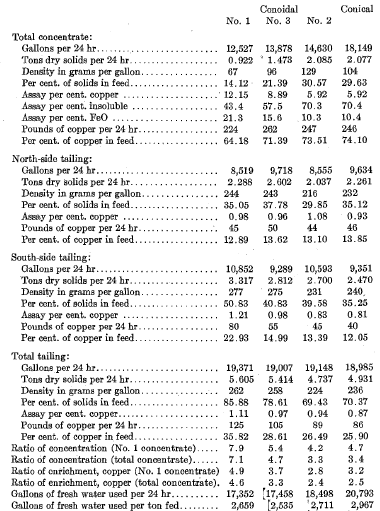

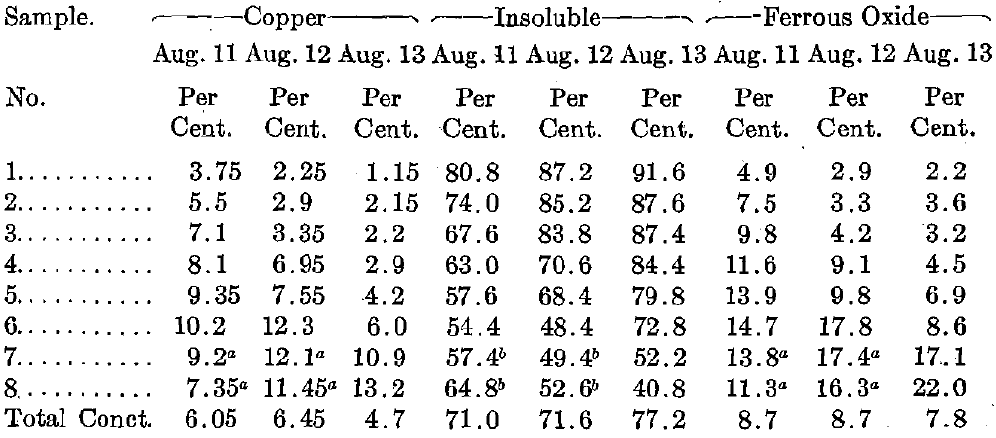

The average results of the high-tonnage tests only are given in detail in the following tabulation.

High-Tonnage Test Results—The tonnage treated per 24 hr. during the above-mentioned tests was approximately 4.5 tons, which was called a high tonnage at the time of making the tests; the writer will show later how the tonnage treated per deck surface has been greatly increased. In considering the above feed it must be remembered that this feed contained a large percentage of colloidal slime in addition to the very fine sands, although at the time the tests were made it had been decided to subject the Callow tanks to an overload in order to secure a greater copper production from the plant, it being more profitable under the existing conditions to operate the plant in this manner.

On January 1, the feed per Callow tank was, therefore, increased from 29.8 gal. per minute to 41.6 gal. per minute, which had the effect of raising the density of the Callow tank overflow from 3.5 to 13.5 g. of solids per gallon of pulp. As the increased overflow loss was made up largely of colloidal slime, the character of the spigot discharge of the tanks (round-table feed) was changed to some extent and in a manner which made it more susceptible to concentration on a round table due to the lesser percentage of colloids in the feed. This accounts for the fact that the table recoveries shown by the test results are from 4 to 12 per cent, higher than the results obtained by Mr. Callow.

A reference to the foregoing table shows that the wood deck surface recovered 6.86 per cent, more of the feed copper in concentrate than the linoleum-covered deck and 8.33 per cent, more than the cement deck surface, but also, that this additional recovery was made at the expense of a more siliceous concentrate and a concentrate with a lower copper value, the wood-deck concentrate assaying 0.63 per cent, less in copper than the linoleum-deck concentrate and 1.74 per cent, less than the cement-deck concentrate. From the above it follows that the wood deck produced a lower tonnage of a lower grade of tailing than the other decks and this is shown to be the case, the wood deck producing 0.358 ton less tailing than the linoleum deck and this tailing assaying 0.10 per cent, loss in copper, and 0.597 ton less tailing than the cement deck assaying 0.06 per cent. less in copper.

It may be well to parallel additional data on the tailing losses from the tables and this is done in the following table:

The tailing made by the linoleum and cement decks does not show a notably higher assay copper percentage than the tailing produced by the wood deck, especially so in the case of the cement deck, the greater loss of copper in tailing being largely due to an increased production of tailing material. For this reason the writer favored the use of cement deck surfaces with a slightly flatter slope than the deck under test (this deck having a slope of 1.5 in. per foot), providing the cement was laid on a rigid framework so that the cement could not crack or get out of true in any way.

Low-Tonnage Test Results—The reduction of the tonnage fed to the decks per 24 hr. from 4.5 to 3.5 tons, improved the copper recovery and reduced the tailing loss on all three decks but had the greatest effect on the work of the linoleum and cement decks, the recovery made by the latter decks approaching to within 3.0 per cent, and 1.4 per cent, respectively of the recovery made by the wood deck, this being partly due to a slight lowering of the grade of concentrate produced in each case.

A comparison of the results obtained in the low-tonnage tests showed that the additional loss of copper in tailing from the linoleum and cement decks was due entirely to the production of a greater tonnage of tailing material than was produced by the wood deck, the linoleum deck discarding 3.64 per cent, more of the feed solids as tailing and losing 2.99 per cent, more of the feed copper than the wood deck, and the cement deck discarding 5.10 per cent, more of the feed solids as tailing and losing only 1.37 per cent, more of the feed copper. These results also favored the use of cement deck surfaces as tending to produce a cleaner grade of concentrate and a lower grade of tailing with a lower consumption of dressing water if rigidly constructed and given the right slope. During the running of above tests the writer noted the fact that no concentration took place on the feed aprons previously described, these aprons having a slope of 2 in. in 1 ft., and also noted that very little settlement took place on the first 8 or 10 in. of the working radius of the table, due to the velocity that the steep slope of the apron and the fall of about 1 in. from surface of apron to surface of table deck gave to the feed pulp.

Central Feed Apron Removed

At the conclusion of the tests, February, the writer removed the feed apron from one of the wood decks, filled in the space with a cement mortar (3 sand, 1 cement), with a finishing coat of neat cement. A slope of but 1 in. in 1 ft. was given to this surface since it was considered that the initial velocity of the feed when discharged from the feed box was sufficient to warrant lesser slope than that given to the remainder of the deck surface. The results of this change showed that a considerable deposit of very clean concentrate could be obtained within 12 in. of the edge of the wash-water cup, the working radius of the table being lengthened about 3 ft. in the direction of the center. Shortly afterward another of the wood decks was changed in the same manner and a new type of feed and wash-water cup was introduced with a view to getting a better delivery of feed on the table. These feed and wash-water cups, which for experimental purposes were made of galvanized iron, were so constructed that the feed and wash water overflowed the rims, falling down the sides on to an apron with 3-in. radius and 15° slope, the outer edge of the apron practically touching the deck surface. These feed and wash water cups, if kept perfectly level and given attention by the operator about twice per shift to remove any foreign material, gave satisfactory service, delivering the feed and wash water to the table with an even distribution.

Overflow feed and wash-water cups had been previously used on the round tables, but on these the apron attached to the cup had a slope of 45° and the edge of the apron was usually from 6 to 8 in. above the surface of the distributing apron on the table. On all cement deck surfaces constructed since this time the central distributing apron has been dispensed with, the working radius of the table being extended to the feed and wash-water cup.

Re-treatment of Round-Table Tailing

In June, the writer carried out a series of tests to determine to what extent the recovery of copper could be increased by re-treating the round-table tailing.

The feed and wash side tailings from six round tables (four wood and two linoleum deck surfaces) were fed into four Callow tanks, the plug discharges of the tanks in turn being fed on to a cement-deck round table, while the overflow went to the tail race. The cement-deck table made a low recovery of copper (21.29 per cent.) which when figured back to original slime gave an additional copper recovery of about 2.5 per cent. The concentrate produced was of a very low grade, being not much richer than the original slime.

A test was then made on the re-treatment of the feed-side tailing alone. A better grade of concentrate was obtained than from re-treating the mixture of feed and wash side tailings, but the recovery made was lower. The tests showed conclusively that the amount of original slime copper to be recovered by a re-treatment of the round-table tailing was small, probably no more than would be gained by a first treatment with tables properly designed for the treatment of a slime feed.

Determination of Conditions for Round-Table Treatment of Slimes

Early in the Spring, the writer had an experimental slime table constructed similar to the one described in Richards’s Ore Dressing, vol. ii, p. 1155, with a view to carrying out a series of experiments to determine the proper slope of deck surface, and rate of feed, for round tables operating on a through 0.07-mm. feed. The table, which was 1 ft. wide and 6 ft. long, was made adjustable as to slope by an arrangement of steps which increased the slope by 1/8 in. per foot at one time. A smooth cement surface was used on the table and the various slimes and slime mixtures were tested out under varying rates of feed, deck slopes, etc.

The conclusions reached from the results of the tests were as follows: The table should be 18 ft. in diameter; should have a cement deck surface sloping 1.25 in. in 1 ft.; and should make 1 rev. in 200 sec. A re-treatment of the feed-side tailings on a canvas deck surface was recommended.

During the summer of we carried out a series of tests in the concentrator, using an adjustable segment of a canvas-covered round table. The purpose was to determine the difference in behavior of the various concentrator slimes, as to both settling and concentration, and the proper treatment for each.

The experimental table as originally constructed was a segment of a round table, being the equivalent of one-tenth of an 18-ft. table. The slope of the table was adjusted by raising or lowering the feed end. The surface used on the table deck was No. 6 duck, the woof (cross threads) being laid approximately parallel to the direction of the slope. A large number of tests were made, both on the individual slimes and upon certain slime mixtures such as the slime plant was handling at the time.

The following general conclusions were arrived at: The primary slimes might be mixed, dewatered so as to recover about 98 per cent, of the solids, and then treated on a canvas-deck round table with a slope of 1.25 in. per foot. The table should make 1 rev. in 20 min. and produce a concentrate assaying 7.0 per cent, copper, and a tailing assaying 1.15 per cent, copper. For the lower-grade or secondary slime a slightly greater deck slope (1.375 in. per foot) was suggested, but it was considered probable that the 1.25 in. per foot slope would be found quite satisfactory for the normal mixture.

Dr. Robert H. Richards suggested the use of canvas-deck round tables for the slime plant, the tables to be given a speed of 1 rev. per hour and to be fed over nine-tenths of their entire surface, no dressing water to be used. Acting on this suggestion three round-table decks were covered with canvas (No. 6 duck) and the speed was reduced to 1 rev. per hour. It was expected that the concentrate would be so low in grade as to require a final dressing on another table, but such was not the case, as a very fair grade was produced.

The slime plant practice recommended by Dr. Richards was as follows: A low ratio of concentration, a low-grade concentrate and a high recovery on the round tables; the concentrate to be re-treated and enriched on a secondary table, from which the tailing would go back to the round table. In accordance with this suggestion, the round tables were recommended for use as roughing tables. Dr. Richards also recommended that the Embrey vanner be used as a finishing machine for cleaning up the rough concentrate from the round tables, but up to the present time this part of the plan has not been tried out, Deister, Craven, and James tables having been used as finishing machines.

Variation in Slope of Round-Table Deck

The first round table with a variation in the slope of the deck surface, tried out at Great Falls, with the exception of the change made when removing the central feed aprons, was installed in the slime plant in June.

J. H. Klepinger, Assistant Superintendent, suggested the use of a conoidal deck surface, and proposed to lay a cement surface of this character on one of the wooden decks. As the wooden decks in use were old tables, and as the cement deck would add greatly to the weight which the framework would have to support, it was thought that the structure would break down under the increased load. A compromise was therefore adopted, a cement deck surface being installed which was divided into two sections, at first of the same length radially, the feed apron previously referred to being left in the center, but of unequal areas, the upper deck being concentric to the lower deck. There was a drop of about 1.25 in. between the first and second deck sections. The first or upper deck section was given a slope of 1 in. in 1 ft. and the second or lower deck section a slope of 1.25 in. per foot. The steep feed apron with a slope of 2 in. per foot was afterward removed and the upper deck with its slope of 1 in. per foot was extended to the feed box.

This change gave the upper deck a radial length from the point where it received the feed, to its perimeter, of 5 ft. About 3 in. of radial length was occupied by the slope of the upper to the lower deck, leaving a radial length of 30 in. for the lower deck.

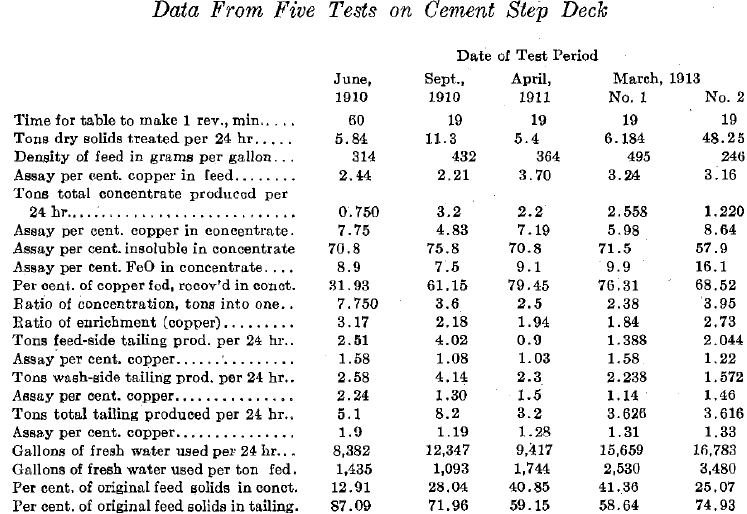

This table was tested in June, being set to make 1 rev. per hour. The results obtained were not satisfactory, a heavy building up of solids occurring on the upper deck which caused a channeling of the feed and consequent heavy tailing loss. The speed of the table was then increased so that it made 1 rev. in 19 min. or practically 3 rev. per hour, the table being again tested in September, and April. In spite of the fact that the tonnage fed to the table in the September test was nearly double the tonnage fed in the June test, the work of the table showed great improvement, the channeling of the feed being nearly entirely eliminated. The April test was made on a lower tonnage, good results being obtained. The table was again tested in March, while the writer was carrying out some tests on conoidal deck tables, the steep feed apron having been removed in the meantime, two tests being made under different tonnage and feed-density conditions. The test results showed that the removal of the steep feed apron further improved the work of the table.

In the two tests, the table was operated as a roughing table, while later, tests the table was fed over about three-quarters of its area and washed with dressing water over about one-quarter of its area; this accounts for the smaller quantity of fresh water used in former tests.

In the April, test the central feed apron had been trued up so that a better distribution of feed was obtained.

In comparing the results of the 3 tests, it can be seen that the work of the table improved greatly with each succeeding; test. In the June test, the slow speed of the table caused channelling even with a light feed. In the September test, the speed of the table and the tonnage were both increased, and although the tonnage was increased rather too much, the work done showed considerable improvement. In the June test and the April test, the tonnages treated by the table were very nearly the same so that the effect of the increased speed can be better observed in these comparisons. The assay per cent, of copper of the feed in the April test was higher than in the June test, but the tailing produced was lower and the work done by the table showed great improvement. It was considered doubtful at the time, however, whether the work by this type of table would surpass the work done by a rigidly constructed cement-deck table with a regular slope of 1.25 in. per foot and so far these doubts have been justified.

The Steel-Frame Cement-Deck Round Table

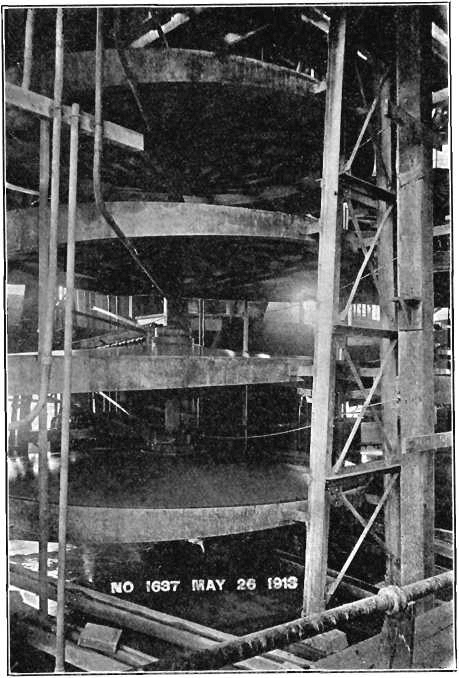

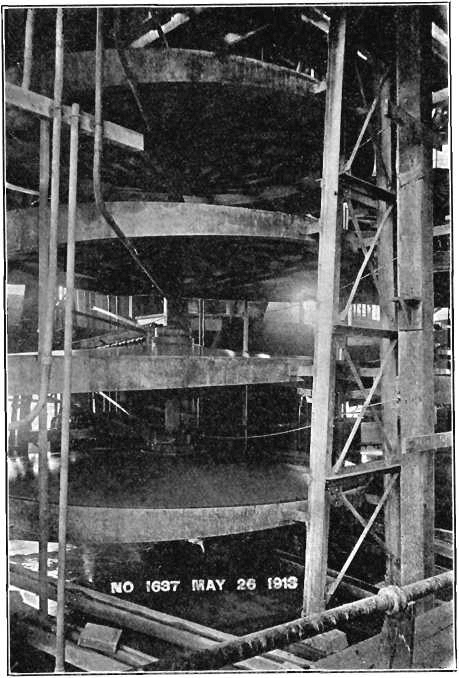

The construction of a four-deck steel-frame cement-deck round table (Fig. 1) was started early, the table being installed in the slime plant and put into commission later.

Of the four decks, the three upper decks were given a slightly rough finished cement surface while the lower deck was cemented in such a manner that canvas could be laid over the cement, the canvas being tacked to strips of wood laid radially in the cement. By this arrangement it was possible to change the deck readily from a canvas to a cement surface if the canvas proved unsatisfactory.

When the steel-frame table was designed it had already been proved that the rough canvas surface was satisfactory for a roughing table designed to produce, with high efficiency, a low-grade tailing and a low- grade concentrate. The disadvantages of the use of canvas were, the cost of maintenance and excessive amount of wash water required.

It was evident that if a cement surface of a character similar to canvas could be utilized, these disadvantages could be eliminated. It was for this reason that three of the decks of the new table were surfaced with cement at the start. The one canvas surface was soon replaced with cement.

The steel frame was a great improvement over the wood-frame construction; the cement decks being rigidly supported, a true conical surface could be maintained and the liability of cracks developing in the deck surfaces was eliminated. The cement decks were made of a mixture of one part cement to two parts concentrator-tailing sand.

The decks had a diameter of 18 ft. and a slope of 1.25 in. per foot, the distance between deck surfaces being 5 ft. The total height from floor to top of center shaft is 25 ft. 2 in. The diameter of the center shaft is 8 in., the shaft consisting of five cast-iron sections, a top and a bottom section and three intermediate sections, the intermediate sections being 5 ft. 1½ in. long.

The tables were equipped with movable sprays for washing off the concentrate. These were supposed to wash cleaner with less consumption of water than stationary sprays. The sprays had a throw of 9 in. transmitted by means of an eccentric and crank and made 4 strokes per minute; the use of movable sprays was afterward discontinued, since no especial advantage was shown over the stationary form.

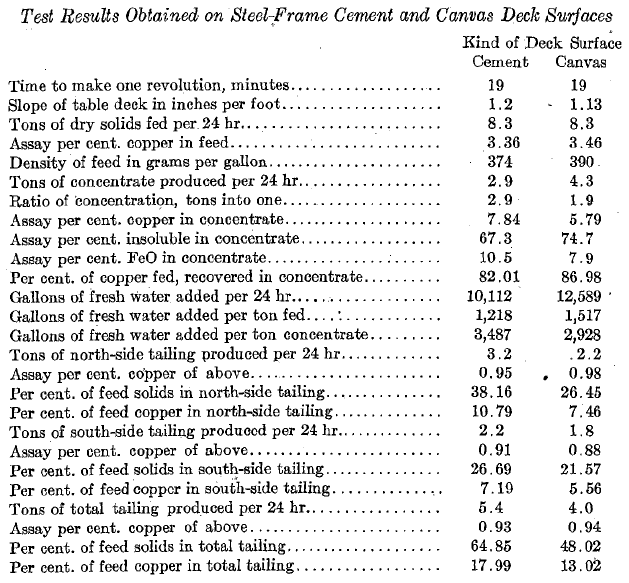

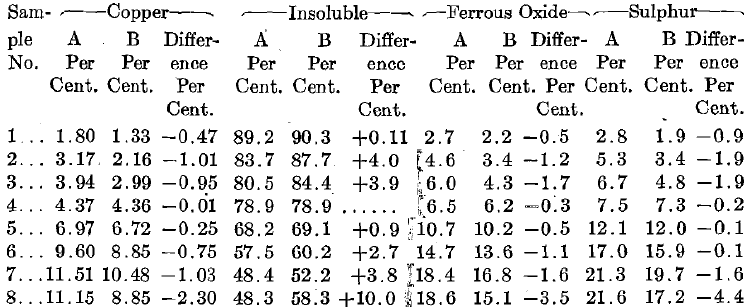

Tests on Cement and Canvas Deck Surfaces

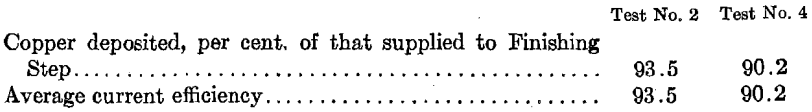

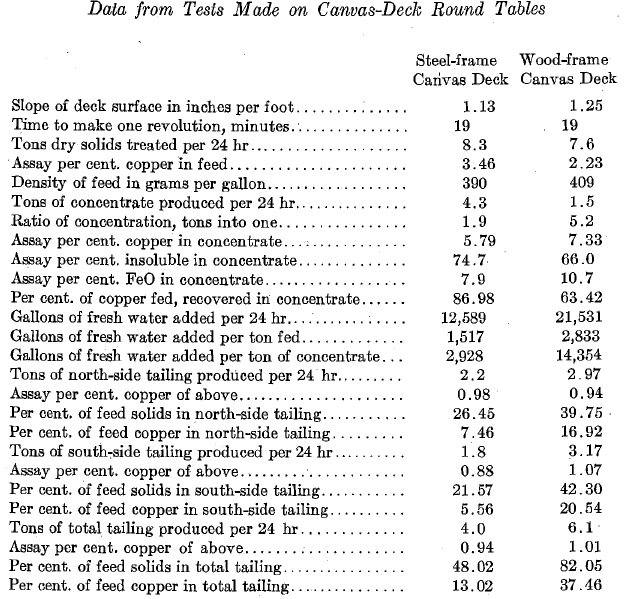

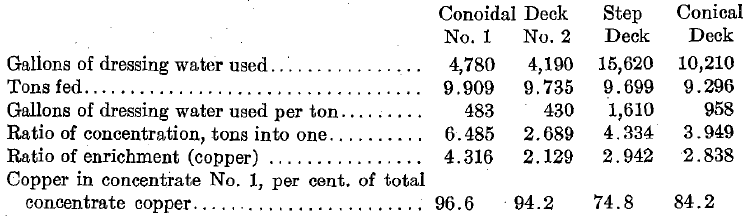

One cement deck surface and the canvas-covered deck were thoroughly tested in April, the results of. the tests being presented below.

It has been stated above that the decks had a slope of 1.25 in. per foot, but it was found from accurate measurements made on April 29, that the actual slope of the cement deck tested was 1.2 in. per foot and of the canvas deck 1.13 in. per foot. The chief data obtained from the tests are placed in parallel columns.

In the following tests the two tables were fed at the same rate per 24 hr., the feed for the canvas deck, however, being slightly higher in assay per cent, of copper than the feed for the cement deck.

The cement deck made a recovery of 82 per cent, of the copper fed in 2.9 tons of concentrate, the ratio of concentration being 2.9 tons into one.

The canvas deck made a recovery of 87 per cent, of the copper fed in 4.3 tons of concentrate, the ratio of concentration being 1.9 tons into one. If these concentrates were sent direct to the smelter in the condition

Deck Surface, cement mortar (2 parts sand to 1 part cement). Slope of deck surface, 1.25 in. per foot. Diameter of decks, 18 ft. Decks make one revolution in 20 min.

Fig. 1.- Four-Deck Steel-Frame Round Table, Great Falls.

in which they were produced by the round tables, the additional cost of fluxing the silica contained in the canvas-deck concentrate, together with the additional cost of loading, transporting, and unloading, would probably more than offset the advantage gained by the extra recovery of 5 per cent, of copper made by the deck.

As, however, the round tables were used as roughing tables, the concentrate produced being cleaned up on finishing tables, the canvas-deck table would appear to have some advantages in making a 5 per cent.higher recovery of copper than, the cement deck. It is noted, however, that the assay value of the total tailing produced by the canvas deck is slightly higher than that of the similar product of the cement deck, the extra recovery of copper made by the canvas deck being traceable to a slightly richer feed.

The assay value of the feed-side tailing produced by the canvas deck is slightly higher than that of the cement deck, while for the wash-side tailing the copper content is lower in the case of the canvas deck.

From the results obtained, it was the opinion of the writer that if the slope of the canvas deck had been the same as that of the cement deck, the advantage gained by the canvas deck in recovering an additional 5 per cent, of copper would have been wiped out in an increased tailing loss without very materially benefiting the grade of concentrate produced. It was, therefore, considered that the cement deck was the equal of the canvas deck in regard to its ability to recover copper mineral and its superior in producing a cleaner grade of concentrate, in using less water, and in possessing a longer life.

Our experience with canvas deck surfaces has shown that the canvas has a comparatively short life, becoming rotten after about nine months’ use. During September, a test had been made on a canvas-deck round table at the slime plant, the canvas being supported on a wooden deck surface with a slope of 1.25 in. per foot; in this case the canvas deck made a cleaner concentrate than the steel-frame canvas deck with a slope of 1.13 in. per foot, but the recovery of copper made was much lower. The comparative results of both tests are shown below.

Tailing products called north and south side tailings when the round tables are operated as roughing tables, as far as the side of the table from which they are delivered is concerned, correspond to feed and wash side tailings of finishing-table practice.

The foregoing comparison is given to show that a clean grade of concentrate can be produced from the canvas deck with an increase of the deck slope. The recovery of copper made by the wood-frame canvas deck, in producing a concentrate similar in character to the concentrate produced by the steel-frame cement deck, is 18.6 per cent, lower than the recovery made by the steel-frame cement deck. This great difference in recovery of copper is partly accounted for by the fact that the canvas deck treated a lower grade of feed than the cement deck. The canvas deck, however, in treating a slightly lower tonnage of a lower grade of feed, made a tailing which assayed higher in copper than the tailing produced by the cement deck.

Referring again to the test results obtained on the steel-frame cement deck and the steel-frame canvas deck. Eight sprays were used to wash off the concentrate from the canvas deck and two sprays on the cement deck; the spray nozzles on the canvas deck, however, had smaller diameters than those used on the cement deck.

A great deal more solid material settled out on the canvas deck than on the cement deck, during the test when a similar tonnage was treated on each kind of deck, the concentrate on the canvas deck amounting to 51.98 per cent, of the total solids fed, while the cement-deck concentrate amounted to only 35.15 per cent, of the total solids fed.

The results of the test indicate that given the same slope of deck surface, a higher grade of concentrate can be produced on a cement deck surface without any greater tailing loss than is incurred on a canvas surface.

In May, the speed of the tables was increased from 1 rev. in 19 min. to 1 rev. in 16 min., the object of the change chiefly concerning an improvement in the work of the canvas-deck table, it being expected that this change would enable this deck to produce a cleaner grade of concentrate with less tailing loss. The tables were tested under the new speed conditions but the results did not show that any advantage was gained.

The work of the steel-frame cement-deck table will be again referred to in connection with tests made on conoidal deck surfaces.

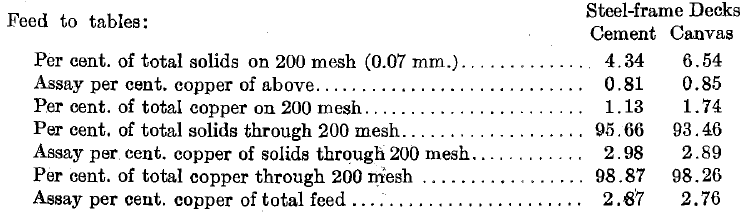

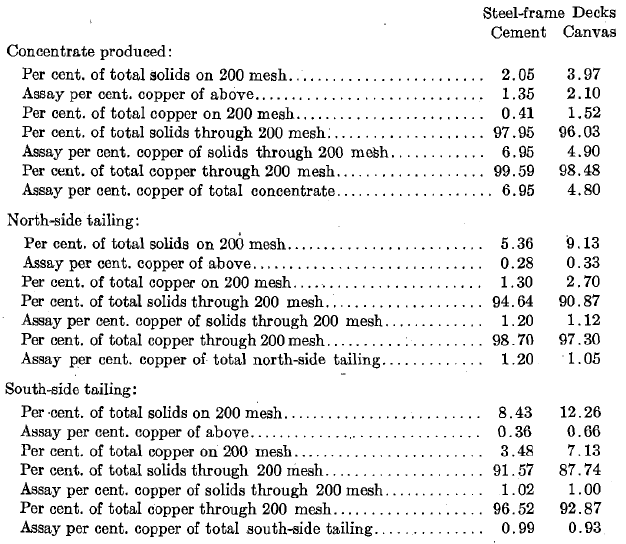

Some of the principal data obtained from the sizing tests made on the feed and products of the steel-frame wood and canvas decks in the above test are given below:

From, the figures above it can be seen that the original feed to the round tables contained from 4.3 to 6.5 per cent, of material coarser than 200 mesh.

The figures given below show the grade of tailing made by the round tables from the material coarser than 200 mesh.

The figures above show that with only 4.34 per cent, of on 200-mesh material contained in the feed to the table, the cement deck makes a very satisfactory tailing, assaying only 0.32 per cent, copper, this figure being comparable with a result of 0.49 per cent, copper obtained in a previous test when the feed to the deck contained 9.09 per cent, of on 200-mesh material. The on 200-mesh tailing produced by the canvas deck was somewhat higher, the amount of on 200-mesh material in the feed being also somewhat higher.

From the results of the above and previous sifting tests the writer concluded that the amount of on 200-mesh material in slime-plant feed should not exceed 4 per cent., and that the work of the tables could be improved if this amount were still further reduced.

Conoidal Deck Round Tables

In May, the question of the use of conoidal deck round tables for slimes again came up for discussion, the subject being brought up by Prof. Henry S. Munroe of Columbia University.

Professor Munroe stated that his object in making the round-table deck conoidal instead of conical, was to make the movement of the pulp on the deck, and the concentration conditions, uniform, in spite of the divergence of the water on the deck as it flows from the center toward the circumference; he, therefore, adopted the plan of gradually increasing the slope of the table from the center to the circumference. Referring to the fact that as the stream of pulp on the table spreads out, the film becomes shallower and the transporting power becomes less, Professor Munroe stated that the most advantageous way to overcome this was to change the deck surface as described above. He stated that the frame and steel top of the round table experimented with at Columbia had a uniform slope of 4°.

The surface of the cement, however, was rounded so that the inclination varied from 3° at the center to 5° at the circumference. The table had a diameter of 18 ft. 5 in., so that the change of inclination was very gradual, something less than a quarter of a degree to the foot, and at the middle point of the profile the curved surface was only about ½ in. above a straight line. This table was designed for the treatment of medium- fine slime, through about 0.15 mm.; for the very fine slime treated at Great Falls, Professor Munroe recommended a slightly steeper slope.

The first conoidal deck surfaces tried out at Great Falls were installed by laying a conoidal cement surface on three of the wooden round-table decks which were still operating in section No. 5 of the concentrator. The tables, therefore, received the regular sand-slime feed of this section, which, as was mentioned earlier in this paper, was very poorly classified, containing grains ranging in size from 0.5 mm. to the very finest slime.

A rough finish and a smooth finish deck surface were tested out under high, medium, and low tonnage conditions. The conoidal deck surface was laid on so that the chord of the arc made an angle of 4° 30′ (1 in. per foot) with the horizontal.

A large number of tests were made and the tables did good work considering the class of feed treated; a good recovery of copper was made in a fair grade of concentrate but no waste tailing could be made by the tables when handling this class of feed. As the flow sheet for future use in this section of the concentrator had already been decided upon, and as this practice could hardly be improved by the use of round tables unless a very close sorting of the feed was resorted to, it was determined to try out the conoidal deck surfaces in the slime plant,where the field was still open,for any suggested improvements in round-table practice.

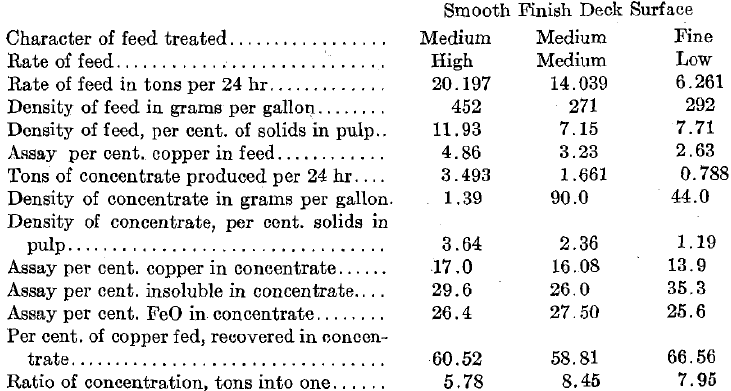

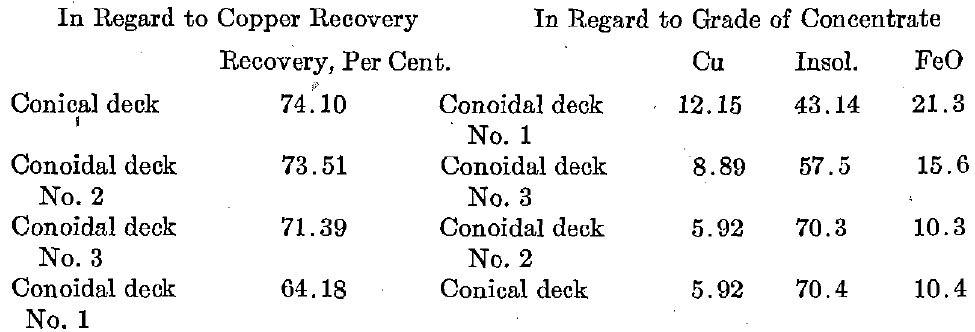

Results with Sand-Slime Feed on Conoidal Deck

Before presenting data on the use of conoidal round-table deck surfaces in the slime plant, a few of the test results obtained from the operation of the tables in the sand-slime section of the concentrator will be presented to illustrate the character of the work done by the tables.

An explanation of the “Character of feed treated” in the preceding tests is as follows; Medium feed is a mixture of all spigot discharges of the feed tank; fine feed is the product of the last three spigot discharges of the feed tank. The spray water used for washing off the concentrate was afterward greatly reduced by using five spray nozzles of smaller diameter instead of eight.

The high-tonnage test above mentioned was run to produce a slightly poorer grade of concentrate than we had been getting in previous tests on high-tonnage feeds and in this respect the test was successful, the change in the concentrate being practically the only variable with the exception of a slight drop in the rate of feed. By increasing the insoluble content of the concentrate 3 per cent, the recovery of copper in concentrate was raised 10 per cent.

In the medium-tonnage test made on a fine feed a very clean grade of concentrate was produced and a fair recovery of copper made, the recovery being as good and the grade of concentrate better than in the low- tonnage test on the same class of feed.

The high-tonnage test results showed a fair recovery of copper in a fair grade of concentrate, the recovery of copper being higher than in the medium-tonnage test immediately following although the grade of concentrate is not so good. The lower copper recovery of the medium- tonnage test is due to the fact that a lower grade of feed was treated, and the cleaner concentrate to the greater quantity of dressing water used. In the low-tonnage test a higher recovery of copper was made, but the grade of concentrate produced was much poorer, the grade of the feed treated being much lower.

In closing a report on the above tests the writer suggested that the conoidal deck round table be given a trial in the slime plant as it presented possibilities of development into a useful table for the treatment of very fine slime.

In the slime-plant practice prevailing at this time, the conical deck round tables were being used as roughing tables, the tables being fed over their entire surface, with the exception of the part reserved for washing off concentrate, and discharging tailing material from the total perimeter with the above exception. The round-table decks used had a slope of 1.25 in. per foot. This slope, with a favorable density of feed, had been proved to give a maximum recovery of free-mineral grains, the coarser grains being recovered on the upper part of the deck and the very minute grains toward the perimeter of the deck. In recovering the very minute mineral grains, however, the tables also recovered a large amount of gangue material, this having been determined by qualitative experiments carried out at the suggestion of C. W. Goodale, in which samples of the concentrate on the deck surface were taken for each foot from the center of the table to the perimeter. These experiments, which will be described later, developed the fact that the concentrate deposited on the lower half of the deck was of a very low grade, and within 12 in. of, the perimeter of the deck was practically a tailing material. In the opinion of the writer, the conoidal deck with its very gradual increase in slope presented possibilities for overcoming the above defect. The first Munroe conoidal deck round table with cement surface (Fig. 2) was installed in the slime plant and ready for operation on Dec 3. The

Deck surface, cement mortar (2 parts sand to 1 part cement). Slope of chord of arc = 1.25 in. per foot. Diameter of deck, 17 ft. Table operating to produce a finished concentrate, a middling for re-treatment, and a low-grade tailing product. One revolution in 16 min.

Fig. 2- Conoidal Deck Round Table, Great Falls. Conoidal Deck No. 1

table was installed with a total slope of 6° (1.25 in. per foot), as, from our preliminary experiments made in section No. 5, this slope seemed to be the most satisfactory. Hence, the chord of the arc of the conoidal deck made the same angle with the horizontal as the surface of the conical deck.

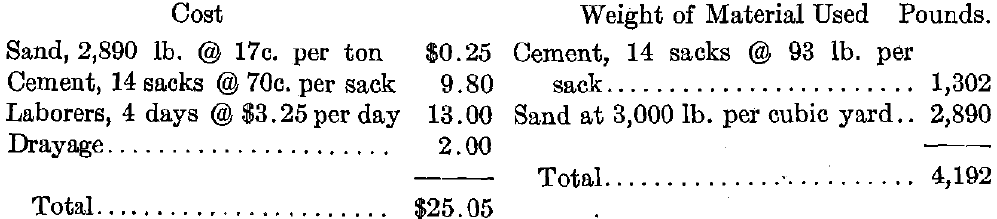

The cement mortar used for the deck surface consisted of two parts of sand to one of cement, the surface being given a rough finish similar to the surface of the steel-frame conical decks. The conoidal deck was laid on one of the wooden decks in the slime plant, the following figures representing the cost of the work and the weight of materials used:

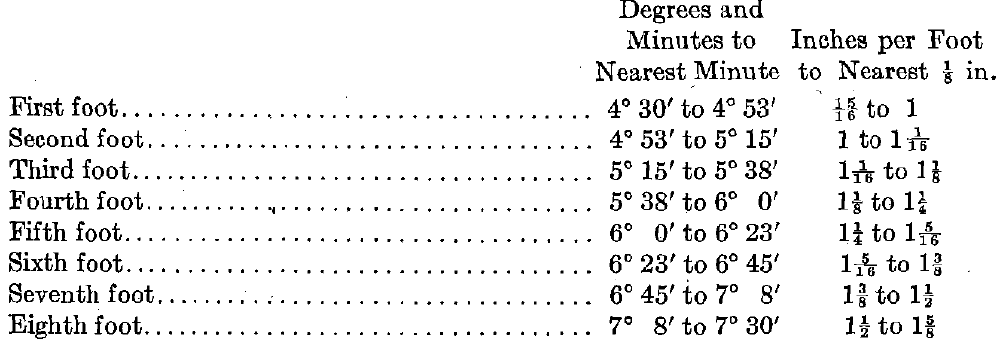

The total slope of 6° which was given to the conoidal deck surface gave the following slope values for each foot of deck surface from the center of the table to the perimeter.

The deck had a diameter of 17 ft. and an available radial width of working surface of 7 ft. 3 in. The table was timed to make 1 rev. in 20.5 min., or 70.24 rev. per 24 hr.

This table was tested against a steel-frame cement-deck table of the following specifications:

The table tested was the upper deck of the steel-frame four-deck conical table. This deck had a slope of 1.25 in. per foot and the cement surface of the deck had a similar finish to that of the conoidal deck. The deck had a diameter of 18 ft. and an available radial width of working surface of 7 ft. 9 in. The table made 1 rev. in 16 min., or 90 rev. per 24 hr.

During the months of December and January, a large number of comparative tests were carried out on the conoidal and the conical decks, the details of which, although very interesting, the writer is obliged to omit in order to keep the length of this paper within reasonable limits. During this period the tables were operated both as roughing tables producing a waste tailing product and a rough concentrate for re-treatment on Deister tables, and as finishing tables producing a waste tailing, a middling for re-treatment on Deister tables, and a finished concentrate, both systems of operation being carried out under various feed- density conditions and various tonnage conditions.

The operation of the tables to produce a finished concentrate, a middling for re-treatment, and a waste tailing resulted from a consideration of the assay results obtained on samples of rough concentrate taken at regular intervals between the center of the deck and its perimeter. From these results it was evident that a considerable percentage of the rough concentrate could be recovered in a concentrate which would be equal in grade to the finished concentrate turned out by the plant after re-treating the total round-table concentrate on Deister tables.

The adoption of this latter system would mean a reduction of the load on the Deister tables and a lowering of the re-treatment loss.

The middling for re-treatment was washed off the lower 3 ft. 6 in. to 4 ft. 6 in. of the deck, by a jet of water, into a separate launder which immediately preceded the finished-concentrate launder. The nozzle used for directing the jet of water was attached to a flexible connection so that the amount of material produced for re-treatment could be varied as desired.

Another method used for producing a clean concentrate and a middling for re-treatment was as follows;

The corner of the feed box nearest to and preceding the concentrate wash-off jets was partitioned off and used as a small wash-water box, fresh water being added at this point and allowed to flow over the concentrate just before it reached the wash-off sprays; the material washed off the deck in this manner was sent to the Deister tables for re-treatment. Either method gives very satisfactory results.

Conclusions from Preliminary Tests on Conoidal and Conical Decks:

It was evident from the results obtained both in the roughing tests and in the finishing tests that a conoidal deck with an overall slope of 1.25 in. per foot and a conical deck with an overall slope of 1.25 in. per foot will not yield similar end results under similar feed conditions, the conoidal deck requiring a denser feed pulp.

The tabular comparison (p. 447 ) illustrates very clearly that if we feed a dense pulp to the conoidal deck and a more dilute pulp to the conical deck, practically similar end results may be expected; this refers to the tables as installed at this time. To produce similar end results it was found that the feed to the conoidal deck must be thickened to a density about 75 per cent, greater than that of the feed to the conical deck.

Since it might not be found advisable to thicken the table feed to a density of 500 g. of solids per gallon of pulp (12.2 per cent, solids) the next best thing to do would be to flatten the conoidal deck; that is, to reduce the overall slope from 1.25 in. per foot to 1.125 or 1 in. per foot, the latter slope, in the opinion of the writer, being the extreme limit in this direction for the class of feed which was being treated in the slime plant at this time.

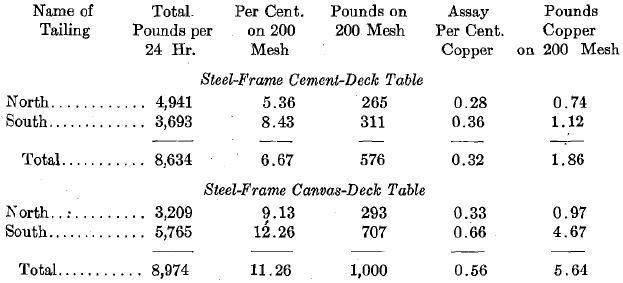

Comparative Results of Roughing Tests on Conoidal and Conical Decks:

NOTE.—North-side tailing = tailing usually produced from feed side. South-side tailing = tailing usually produced from wash side.

Under the “deck slope’’ conditions of the tests, with feed conditions similar, the tables operating to produce a rough concentrate and a waste tailing, the following end results are obtained:

(a) The conoidal deck will deliver from 17 to 25 per cent, less of the feed solids in the concentrate than the conical deck.

(b) The concentrate produced by the conoidal deck will assay from 1.5 to 3.0 per cent, higher in copper, 6 to 12 per cent, less in insoluble and 3 to 5 per cent, higher in iron than the concentrate produced by the conical deck.

(c) The concentrate produced by the conoidal deck will contain from 6.5 to 8.0 per cent, less of the copper fed to the table than the concentrate produced by the conical deck.

The same relative conditions maintain for any other method of operating the tables, hence, if we wish to operate conoidal and conical decks in parallel under similar feed conditions to produce similar end results: For any given density of feed the conoidal decks must be installed with a less overall slope than the conical decks.

It was considered possible that by flattening the chord of the conoidal deck by 1/16 in- per foot at a time, using an experimental deck section, a slope might be found which, while giving a recovery equal to that made by the conical deck, would produce a better grade of concentrate than is produced by the conical deck. The writer considered that the building of a conoidal deck for regular operation with an overall slope of 1.125 in. per foot was justifiable and this was done later.

A conoidal deck with an overall slope of 1.0 in. per foot was first constructed, this table doing very satisfactory work if the table feed did not get above medium density and did not contain more than 2 or 3 per cent, of fine sand. A preliminary test was made on this table on Feb. 28, when the feed to the table had a density of 468 g. of solids per gallon of pulp; the density of feed was too high, the table making an extraction of 85.6 per cent, of the copper fed, in a concentrate assaying 4.12 per cent, copper. Other tests were made later on this table using less dense feed with better results, as presented in the following pages.

In a general way it would seem that it makes very little difference which type of deck is used as long as we use a slope on each type of deck which is most suitable for the average density of feed handled at the slime plant. This conclusion is subject, however, to results to be obtained by using a flatter conoidal deck, as stated on a preceding page, as it was considered possible that the recovery made by the conical deck might be reached in a better grade of concentrate.

In tests A and H, when a high density of feed was used, averaging 480 g. of solids per gallon of pulp, the writer considered that the work of the conoidal deck was superior to that of the conical deck in spite of the fact that the former made a recovery of copper lower by 6.82 per cent, than the other, 73.78 against 80.70 per cent, (averages of tests A and H). (A and H tests on conical deck are not included in the preceding table, but data on tailings are given in the following table.)

This was on account of the fact that the conoidal deck sent to tailings 20.4 per cent, more of the feed solids than the conical deck, the tailings having similar assay values. This means that the conoidal deck produced much less material for re-treatment, the additional loss from this deck being entirely due to additional tailing production and this tailing product being of a lower grade than the tailing made in the re-treatment system. An examination of the following figures will make this point clear.

The results obtained from both the conoidal and the conical deck indicated that considerable improvement could be made in the round¬table practice if the slimes were roughly classified preceding table treatment.

The main difference in the work of the two tables under discussion, both having an overall slope of 1.25 in. per foot, may be explained as follows:

The conical deck, as installed, is capable of retaining upon its surface a considerable percentage of the very finest mineral grains contained in the slime, but in doing so also retains a large percentage of the fine sand, the result being that a concentrate high in insoluble material is produced and a high recovery of copper made.

The conoidal deck, as installed, cannot retain upon its surface a high percentage of the very finest mineral grains, but in losing these fine mineral grains the deck also gets rid of a high percentage of the fine sand, the result being that a clean grade of concentrate is produced, but the recovery of copper made is lower than that made by the conical deck.

From the behavior of the two types of table deck under varying feed densities it would at first seem that the work of the two types of tables under constant feed conditions could be made similar either by increasing the slope of the conical deck or by flattening the conoidal deck. The test data on the second conoidal deck installed in the slime plant will threw some further light on this subject.

Professor Munroe’s idea in adopting the conoidal deck surface, as previously stated, was to make the movement of the pulp and the concentration conditions uniform in spite of the divergence of the water as it flows from the center toward the circumference, which was accomplished by gradually increasing the slope of the table and, therefore, the speed of the film of water. This condition allows the use of a flatter slope than would be practical on a conical deck.

A heavy deposition occurs at the center of the table, but with a slope VOL. XLIX.—29 at this point of 4° 30′ (15⁄16 in. per foot), which is the slope of the table tested, this deposition has been very clean mineral. The writer considers that it would be safe to make the slope at the center of the table 4° or possibly a shade less if the density of the feed is kept at about 350 g. of solids per gallon of pulp (9.25 per cent, solids). With a 3° slope at the center of the table, as suggested by Professor Munroe, a good deal of fine sand is deposited with the mineral if the slime contains 2 or 3 per cent, of on 200-mesh material, and it is difficult to clean this concentrate with dressing water.

The second conoidal deck installed at the slime plant, known as conoidal deck No. 2, was given an overall slope of 4° 45′, or 1 in. per foot, this giving a deck surface inclination varying from 3° 30′ at the center to 6° 15′ at the circumference, or very nearly the slope which is recommended by Professor Munroe.

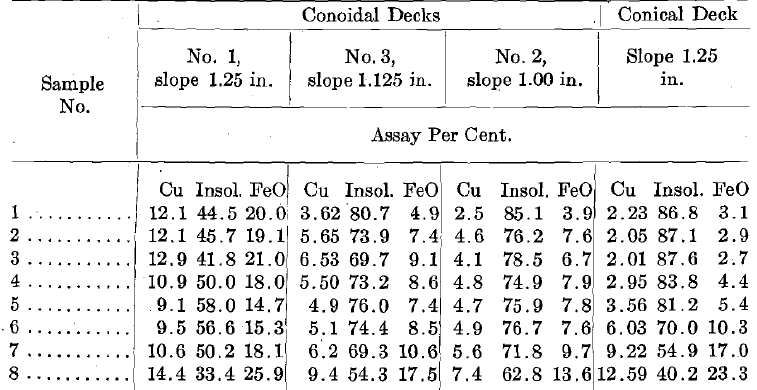

The above deck was tested during the period April 26 to 29, in parallel with conoidal deck No. 1, the steel-frame conical deck, and the step-deck previously described in this paper.

During the test an endeavor was made to keep the tonnage fed to each table and the density of the feed uniform.

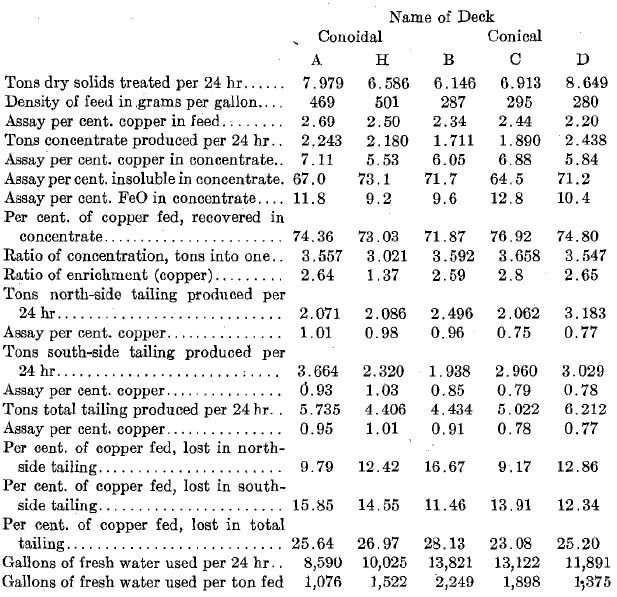

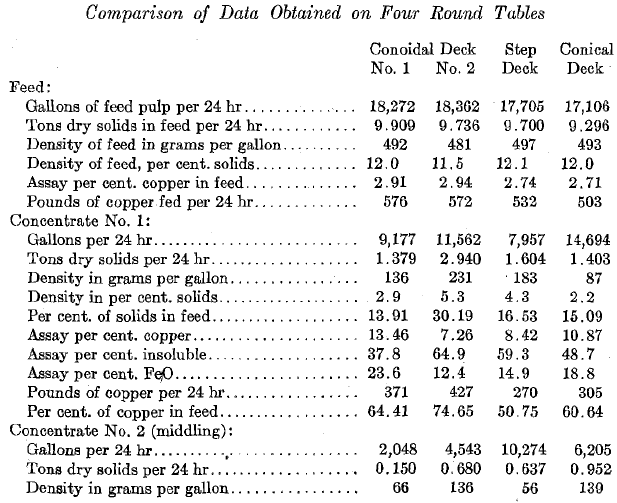

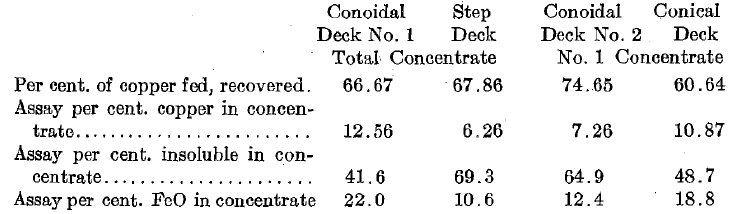

The comparative results obtained from the tests made on the four tables are shown below:

Discussion of Results of Four-Day Test on Conical and Conoidal Decks:

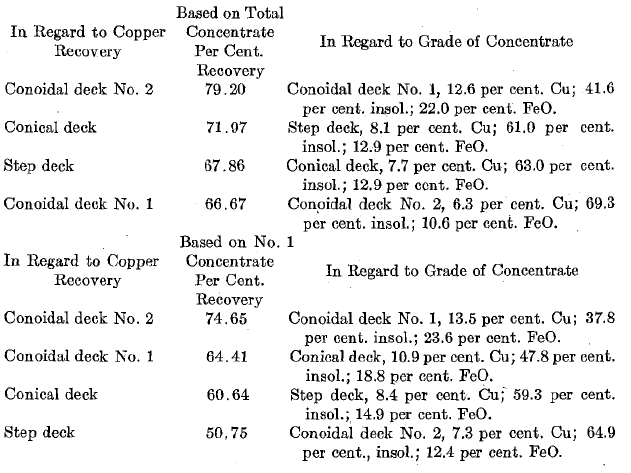

The four-day test results place the decks in the following order in regard to efficiency.

Before discussing the above results some figures will be given showing the fresh water added on the tables during the test period.

Most of the water used as dressing water finds its way into No. 2 concentrate (middling), some of it, however, going to south-side tailing and some to concentrate No. 1.

The order of the decks as regards efficiency in copper recovery made in concentrate and as regards grade of concentrate is about what should be expected. Had less dressing water been used per ton fed to the conical deck the copper recovery made by this deck would undoubtedly have been raised to the level of the recovery made by conoidal deck No. 2, but the grade of the concentrate would have been correspondingly lowered. The gallons of dressing water used per ton fed and some further comparative data are shown by the following figures.

It should be noted that the total concentrate produced by conoidal deck No. 1 (chord of arc on 1.25-in. slope) is of a much better grade than the No. 1 concentrate produced by any of the other decks, while the recovery of 66.7 per cent, of the copper made by this deck in total concentrate is greater than the recovery made by the other decks in No. 1 concentrate, with the exception of conoidal deck No. 2, which on account of its flat slope at the head of the deck, makes a 7 per cent, higher recovery in No. 1 concentrate than is made by conoidal deck No. 1 in total concentrate, the concentrate being, of course, of very much lower grade.

The total recovery made by conoidal deck No. 1 and the grade of concentrate produced will now be compared with the recovery in concentrate No. 1 made by conoidal deck No. 2 and the conical deck. As the step deck made a concentrate No. 2 of high enough grade to be considered in the finished-concentrate class, its recovery in total concentrate and grade of concentrate will also be placed in comparison.

The No. 2 concentrate or middling made by conoidal deck No. 1 and by the step deck are the only ones which can be considered as concentrate, the concentrate No. 2 from conoidal deck No. 2 being of much lower grade than the feed, and the middling from the conical deck being of about the same grade as the feed.

Conoidal deck No. 3 was installed in the slime plant. The deck was given a cement surface of finish similar to that on the other two conoidal decks installed in the slime plant.

This deck varied from the first two conoidal decks installed in that the chord of the arc was laid on a slope of 1.125 in. per foot instead of 1.25 in, per foot for conoidal deck No. 1, or 1 in. per foot for conoidal deck No. 2. This was the only variable.

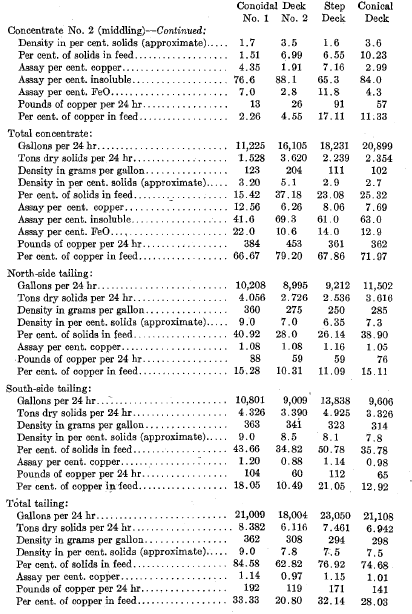

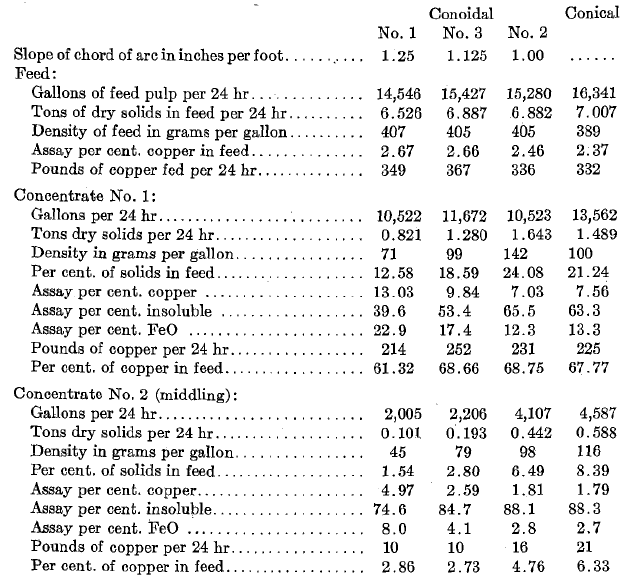

The three conoidal decks and the steel-frame conical deck were tested in parallel during the eight-day period, the results obtained from these tests being presented below. The conoidal- deck results have been placed in the order of decreasing slope of deck surface. This arrangement brings out more clearly the differences in the work of the conoidal decks, and also places the results of conoidal deck No. 2 by the side of those of the conical deck, the work done by these tables being very similar.

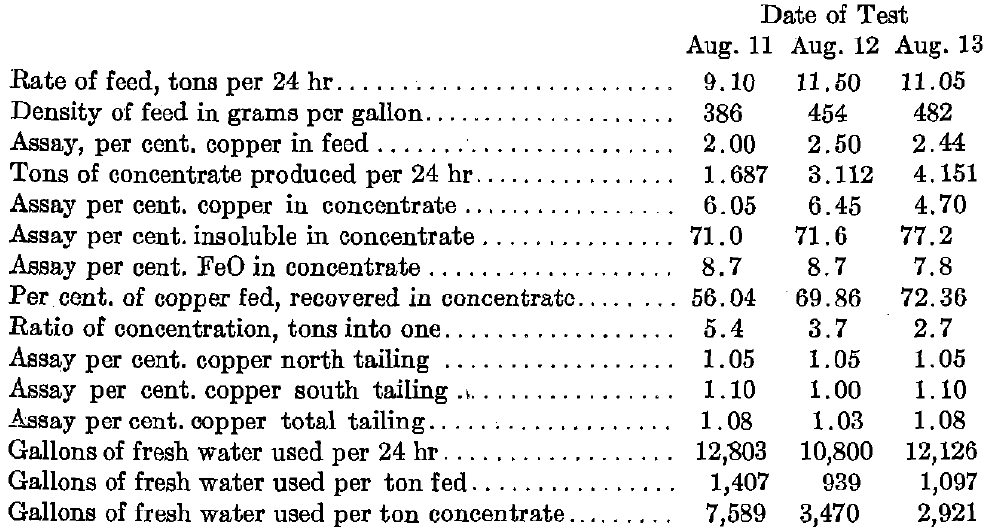

Comparative Results on Four Round Tables:

Discussion of Results of Eight-Day Test:

The following tabulation shows that the test results arrange the different decks in just the order which should be expected both in regard to copper recovery and grade of concentrate produced.

Order of Deck Efficiency Based on Total Concentrate:

The work of the conical deck is practically identical with the work of the conoidal deck No. 2. The conoidal deck results illustrate very clearly the effect of the slope on the work of the table, the grade of concentrate produced being lowered by a decrease in slope while the recovery of copper is raised. Conoidal deck No. 3, with the chord of its arc laid on a slope of 1.125 in. per foot, was designed to produce a cleaner grade of concentrate than the conical deck, with its slope of 1.25 in. per foot, at the same time making practically the same recovery of copper. The tests showed that the results desired were very closely approximated, conoidal deck No. 3 recovering 71.39 per cent, of the copper fed in 21.39 per cent, of the total feed solids while the conical deck recovered 74.10 per cent, of the copper fed in 29.63 per cent, of the feed solids. In considering these results it must be remembered that the conical deck had a radial width 6 in. greater than the radial width of the conoidal deck and that, therefore, in order to make the results strictly comparable, the deposit on the lower 6 in. of the conical deck should have been washed into the tailing launder.

Order of Deck Efficiency Based on Concentrate No. 1:

The above tabulation shows that the conical deck and the conoidal deck No. 2 did very similar work in producing a finished concentrate, the conical deck making a slightly cleaner grade of concentrate and a slightly lower recovery of copper.

The tabulation also shows that conoidal deck No. 3 made a higher recovery in a much cleaner grade of finished concentrate than the conical deck, recovering 68.66 per cent, of the copper fed, contained in 18.59 per cent, of the original feed solids, while the conical deck recovered 67.57 per cent, of the copper fed, contained in 21.24 per cent, of the original feed solids.

After making a few tests on the first conoidal deck installed in the slime plant, the writer became impressed with the fact that the conoidal deck surface presented possibilities for producing a cleaner grade of concentrate than is produced by a conical deck with a slope of 1.25 in. per foot while at the same time making as high a recovery of copper, and that a conoidal deck could be installed which would yield just such results as are recorded above for conoidal deck No. 3. The recovery made by a conical deck can, of course, be increased by a slight flattening of the slope, the increase in recovery being made at the cost of lowering the grade of the concentrate, or the grade of concentrate may be enriched by a slight increase of the slope, the enrichment being made at the cost of a lower recovery of copper. Thus, at first glance, it might appear that by merely juggling with deck slopes or feed densities, the feed density being fully as important as the slope, the results obtained upon any conoidal deck could be duplicated upon any conical deck, or vice versa. While the writer is not yet prepared to state emphatically that such is not the case, it may be stated that a conoidal deck can be installed which will make a cleaner grade of concentrate and as high a recovery of copper as a conical deck with a slope of 1.25 in. per foot. It may be possible that further experiment may develop the fact that a combination of the two types of deck surfaces will be beneficial, making the deck semi- conoidal, semi-conical, the upper part of the deck being conical.

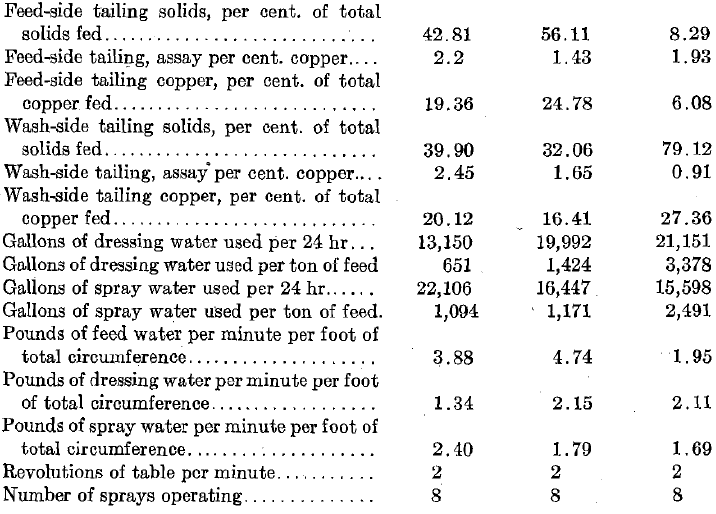

Qualitative Sampling of Concentrates Across Conical Deck:

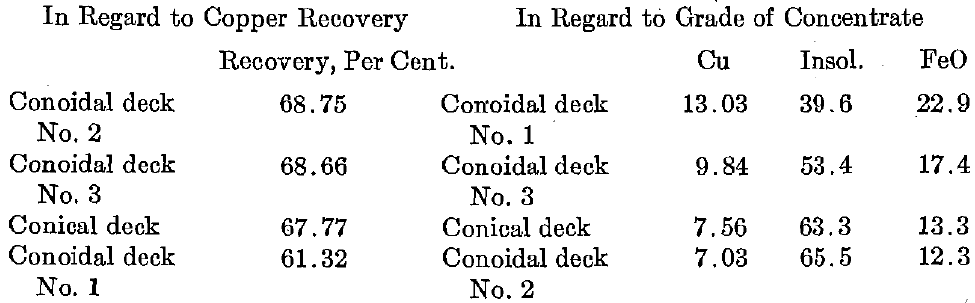

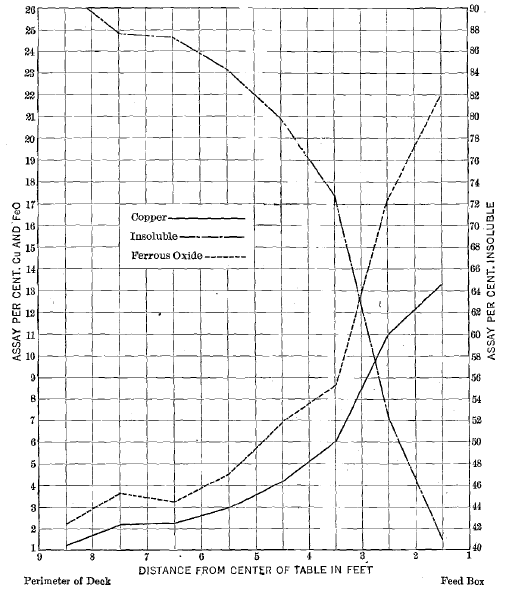

Early in August, at the suggestion of Mr. Goodale, obtained qualitative samples of the rough concentrate on the deck of the steel-frame conical table for each foot of deck surface from the center to the perimeter. The assay results on these samples showed that the concentrate deposit at the head of the deck was considerably richer than the finished concentrate produced by the slime plant, while the deposit nearer the perimeter of the deck was of very low grade. The table was tested on August 11, 12, and 13, being sampled quantitatively preceding the qualitative sampling of the concentrate, two or three revolutions of the table being allowed to elapse before the qualitative samples were taken.

The density of the feed was increased with each day’s sampling, the light density of the first day making a lighter tonnage of feed to the table than was the case on the two following days. The quantitative results of the tests will first be presented:

On August 11, the table was receiving a low grade of feed and, therefore, making a lower percentage recovery of copper than would be made with a richer feed. The feed was also more dilute than on the two following days, which may have helped the tailing loss to some extent. On August 12, a slightly richer and denser feed was treated and an increase made in the recovery of copper in concentrate, the grade of the concentrate being slightly better as regards copper value than that made on the preceding day.

On August 13, the table feed had about the same assay value as on the preceding day, but had a greater density. The percentage of copper in feed recovered in concentrate showed a further increase, chiefly due to the lower grade of concentrate produced. (In a test made on the above deck in May, a 73 per cent, recovery of copper was obtained in a concentrate assaying 7.03 per cent, copper, 69.1 per cent, insoluble, and 9.4 per cent. FeO. This recovery was made on a feed assaying 2.91 per cent, copper, and with a rate of feed of 6.2 tons per 24 hr., as against 11.05 tons per 24 hr. in the present test.)

The following tabulation shows the results obtained on the qualitative samples of rough concentrate.

During the test of August 13, the end of the feed box was partitioned off to prevent new feed from coming on the table at the head of the sampling line, therefore, in this case a uniform increase in copper and iron percentages and a uniform decrease in insoluble content of the concentrate was obtained from the perimeter to the feed box. The samples were taken along a line on the table immediately preceding the wash-off spray, so that the samples may be said to represent the rough concentrate produced by the table.

Analyses of Rough Concentrate from Steel-Frame Conical Table:

Sample No. 1 taken from first foot above perimeter of table; sample No. 8 taken from first foot below feed box.

(a) The lowering of the copper and FeO percentages at this point was caused by new feed coming on the table.

(b) The increase in insoluble content at this point was caused by new feed coming on the table.

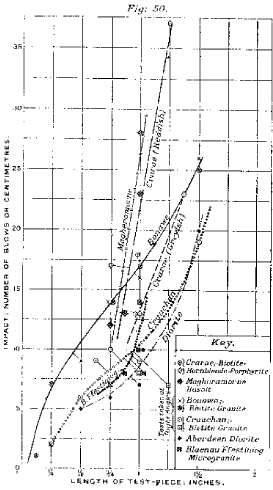

The results obtained on August 13 are shown graphically in Fig. 3. The curves illustrate the results obtained when the new feed is excluded from the two upper samples.

The results showed that in using the conical round tables as roughing tables, which was the regular slime-plant practice at the time the samples were taken, a grade of concentrate was being produced on the upper part of the deck which was of a better grade than the usual run of finished concentrate, and that in removing this concentrate from the deck it was remixed with a large quantity of very siliceous material from the lower part of the deck.

Another set of qualitative samples was obtained during a two-day test made, the material on the deck surface being sampled just preceding the wash-off spray and also on a radial line diametrically opposite the wash-off spray. In the tabulation (p. 461) “A” samples are those taken immediately preceding wash-off spray, and “B” samples those taken on a radius diametrically opposite the wash- off spray. Plus and minus signs indicate that results on “B” samples are greater or Jess than results on “A” samples.

Another set of qualitative samples was taken, including samples taken on each of the three conoidal decks which were in operation at this time and on one of the steel-frame conical decks.

Fig.- 3. Curves Showing Grade of Concentrate for Each Foot of Deck Surface of Steel-Frame Cement-Deck Round Table.

Insoluble curve, one-half scale of Cu and FeO curves.