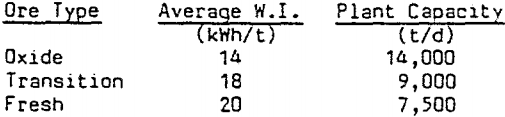

Brief Geology in Relation to Work Index Variation

To understand the need for a SABC Grinding Circuit it is pertinent to briefly describe the geology.

Gold mineralisation at Kidston occurs in the marginal areas of an oval breccia pipe. Gold and silver are disseminated within the breccias and veins formed after brecciation.

The ore is hosted within granodiorite, polymictic, and volcanic breccias comprised of quartz, feldspar, and sericite-muscovite with minor amounts of chlorite, carbonates, kaolinite, and sulphide minerals, mostly pyrite.

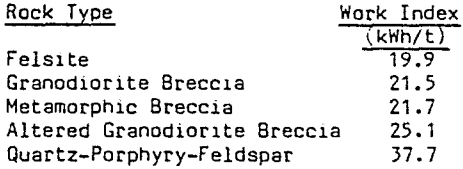

Comparative work index determinations undertaken on various rock types show that even with the predominant fresh ore type significant variations in grindability also occur, viz:

SABC Test Procedures

To obtain reliable results from the tests stable milling conditions were essential. This involved monitoring parameters such as power draw, bearing pressure, feed rate and mill speed, and prescribing strict limits.

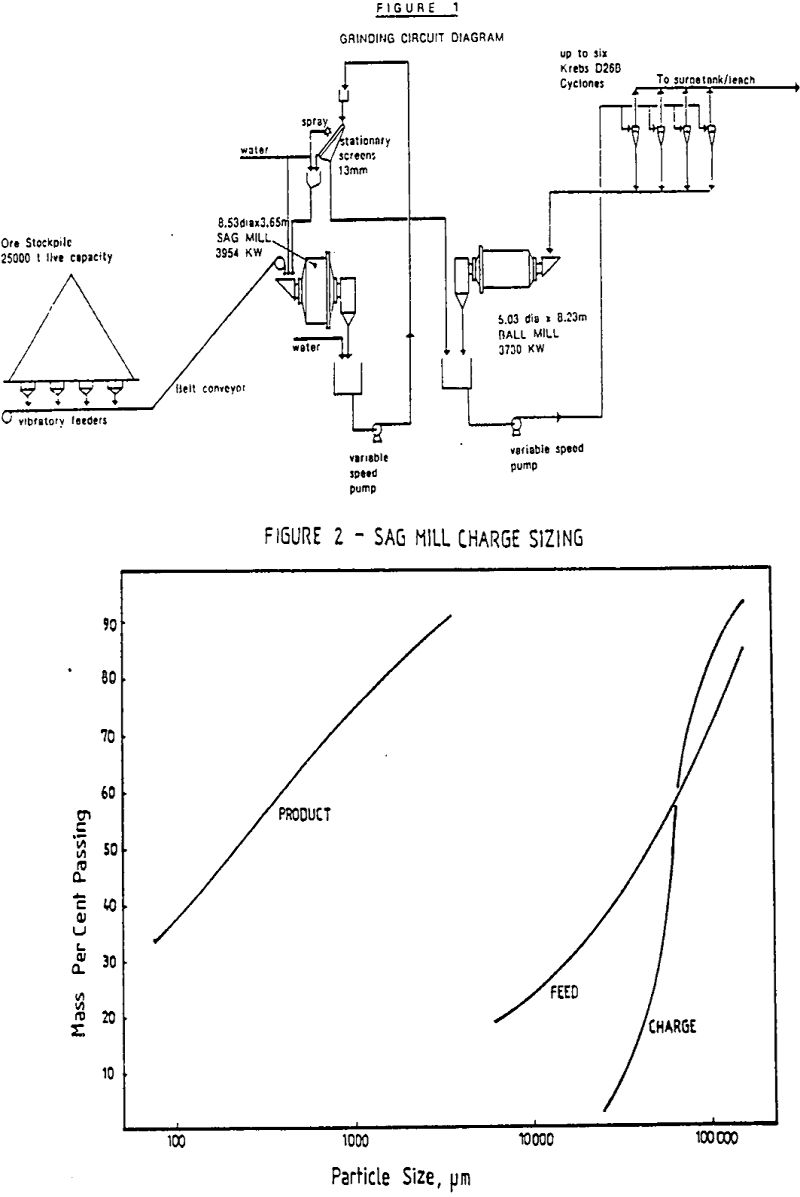

Under normal operating conditions the scat conveyor was operated in open circuit while the stationary screens were operated in closed circuit. Scats from the conveyor system were discharged onto the ground and transported to a low grade stockpile by front end loader.

SABC Test Results

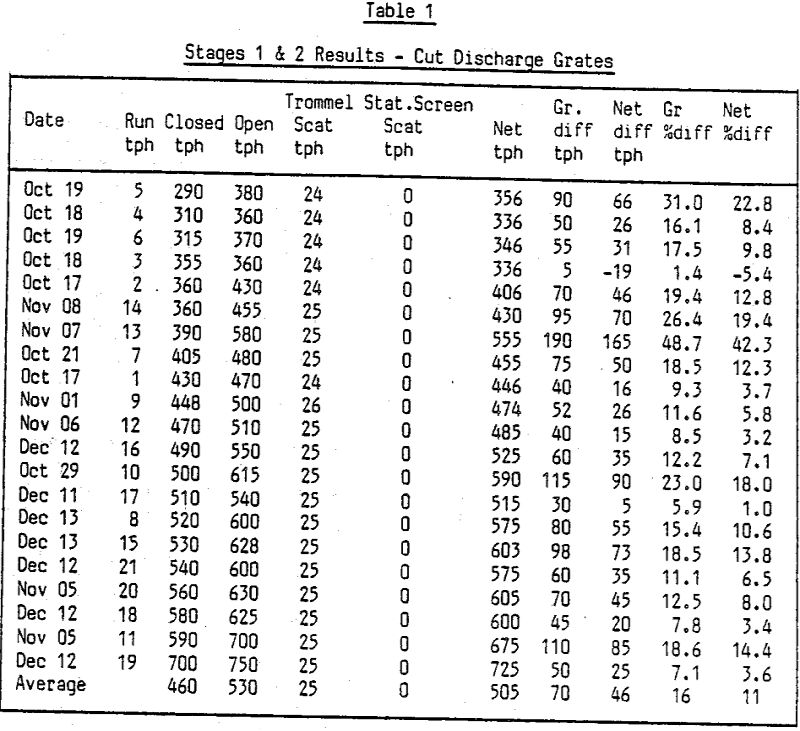

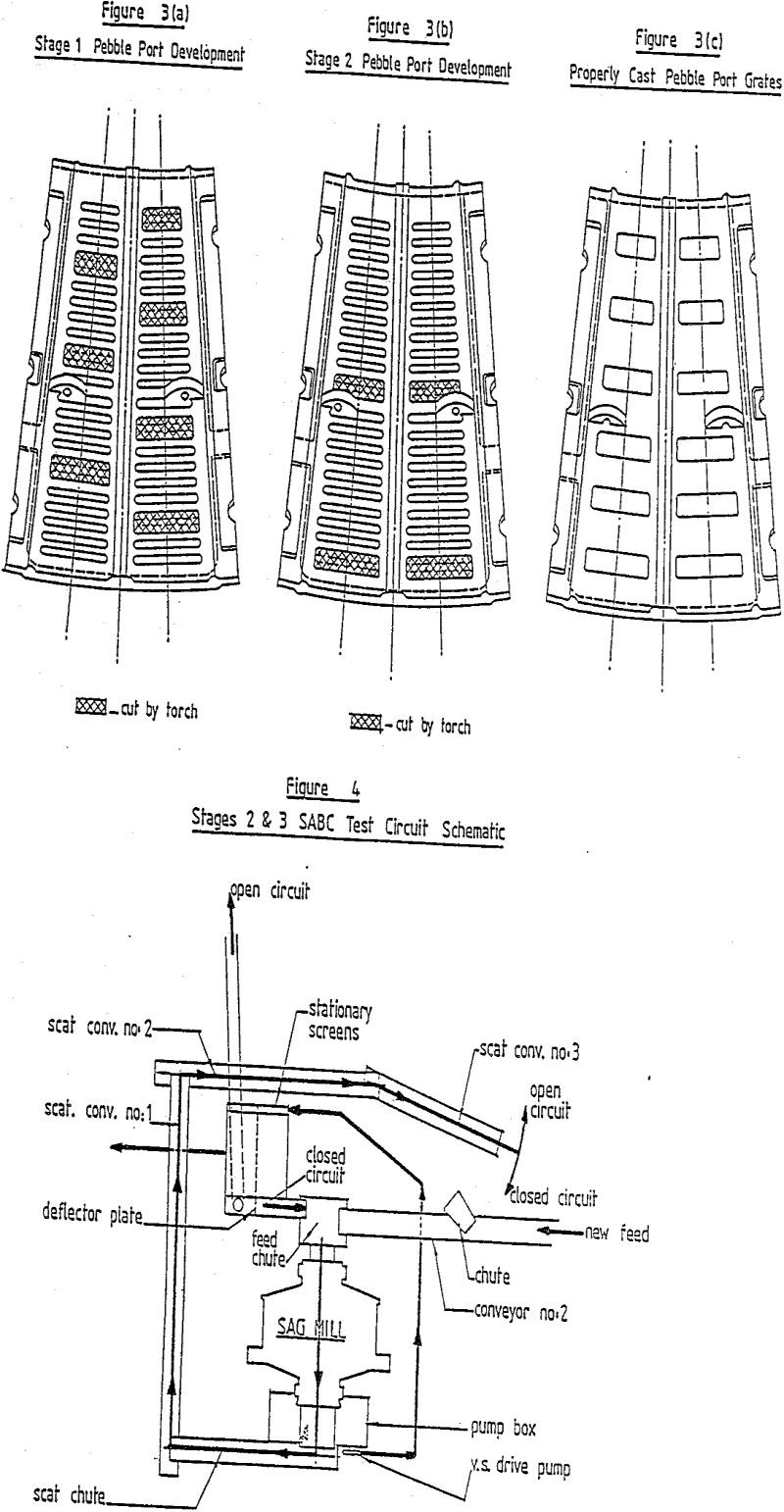

Stages 1 & 2 – Cut Discharge Grates

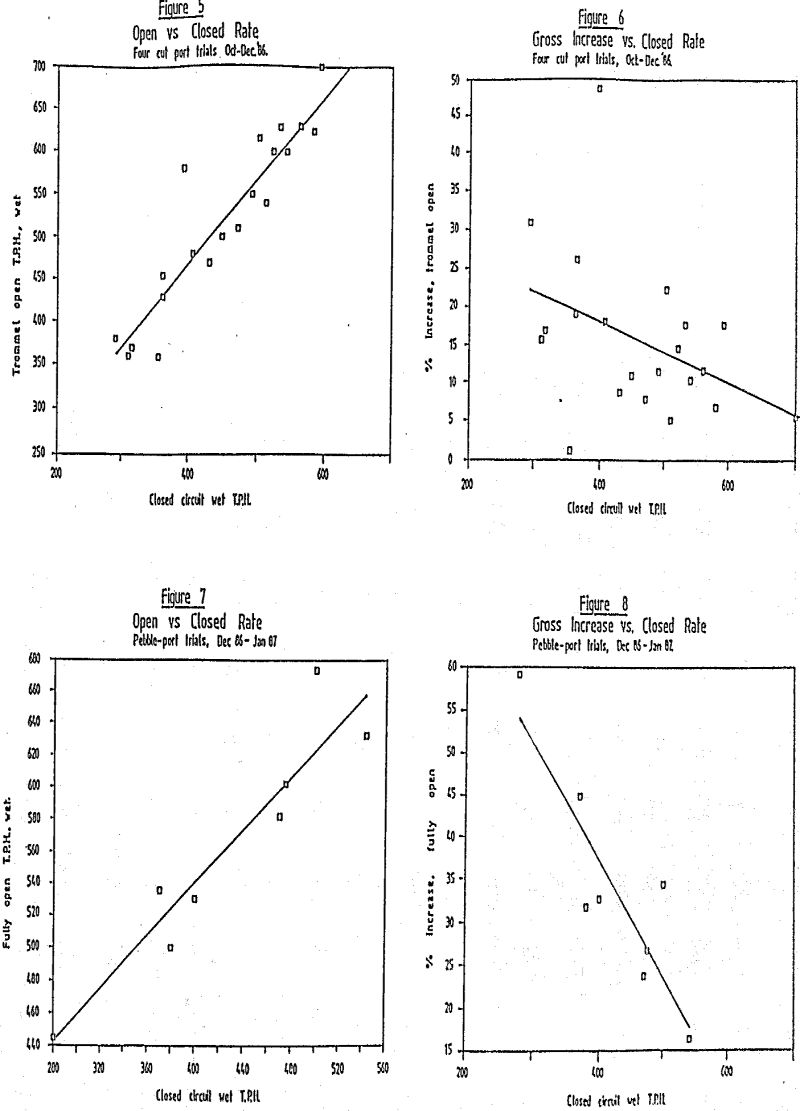

The results of this testwork were encouraging and indicated a 16 percent average increase in feed rate for 21 trials conducted. Refer to the data in Table 1. Note that this was trommel oversize only.

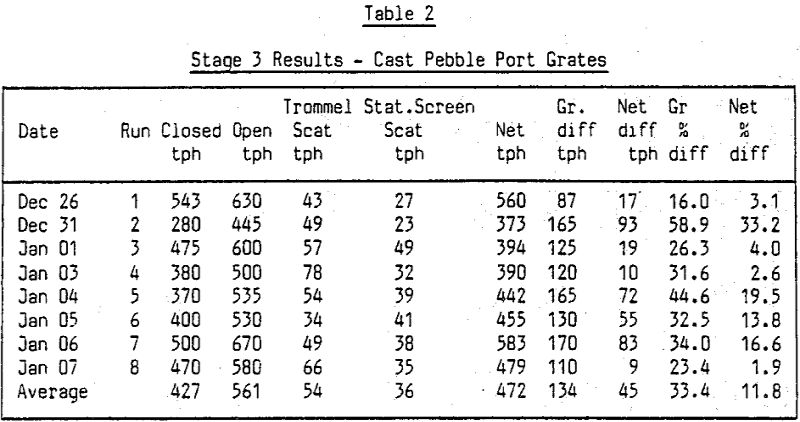

Stage 3 – Cast Pebble Ported Grates

Inserting the budgeted figure of 415 tph gives 553 tph or a 33 percent increase, the difference between these and the results from Stages 1 and 2 being largely attributable to the increased open area with the cast pebble ported grates. (Based on Chino experience a ‘correction’ factor of 0.85 was later applied to these figures to account for the effect of crusher product recycle on SAG throughput for budgeting purposes.)

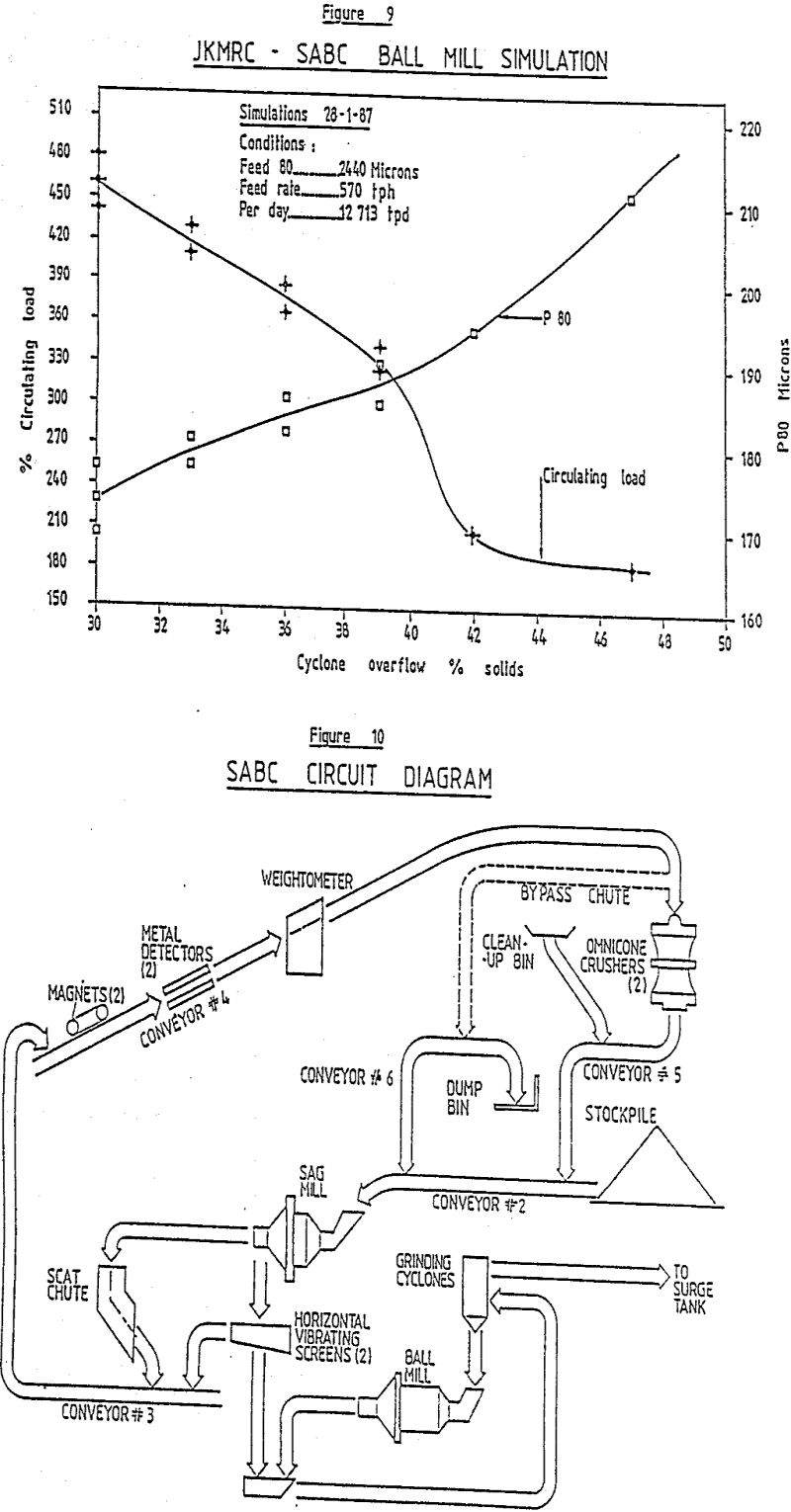

Ball Mill Capacity

The most effective way to test the impact of crusher recycle rate on ball mill capacity would be to insert a test crusher. This would have delayed the project some 4 to 6 months as magnets would still be needed and procurement time would be 3 or 4 months.

An approach based on the following was therefore adopted:

- Feasibility study testwork on Kidston ore

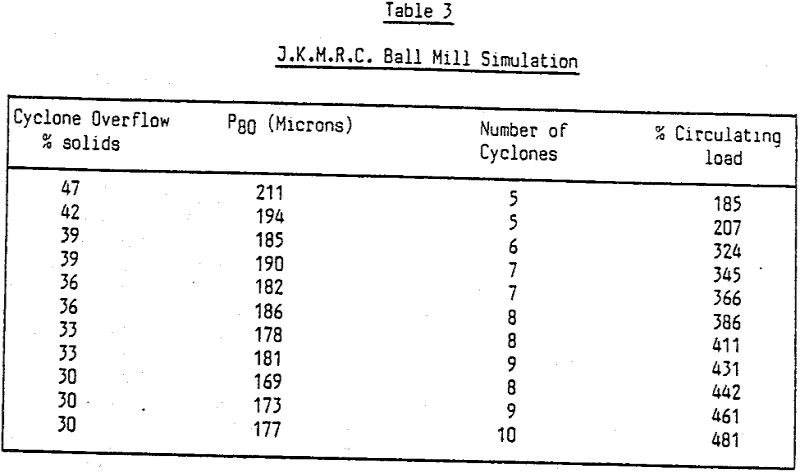

- Ball mill/SABC simulations at JKMRC using their commercially available process models

Since the plant was originally designed for 14,000 tpd (softer oxide ore) at 88 percent availability and 300 percent circulating load, no problems were foreseen with the grind circuit pumps.

Scat Discard Option

As the scats tend to be competent, unaltered (i.e. less mineralised), clast rocks liberated from the softer, altered, breccia matrix, their gold values were substantially lower than those of the feed. A scat discard/low grade stockpile option therefore required consideration. This option proved to be less attractive than the SABC case based on gold recovery calculations derived from laboratory scale leaching of the scats and haulage cost estimates.

SABC Circuit Operation

Most of the commissioning effort centered on problems arising from a higher proportion of minus 25mm metal shards than expected and involved:

(i) Magnetics Recovery

This was maximised by adjustment of the magnet positions and reducing the pebble bed depth by speeding up the conveyor. Although the 11 tonne magnets are not located in the preferred position, that is at a transfer point, metal recovery, as indicated by a metal detection frequency of about one piece per hour, is high.

(ii) Metal Detector Tuning

The detectors, guaranteed to detect a 25mm metal sphere (66 grams for

steel) have been fine tuned to detect ball shards with a mass of 18 grams. This required the detection and elimination of interference sources such as ballast in conveyor walkway lighting, vibration and welding machines.

Semi Autogenous Ball Mill Crushing Circuit SABC

Inco Limited’s, Sudbury operations are located in north eastern Ontario, Canada, approximately 250 miles north of Toronto. Here, Inco has 11 operating mines around the rim of the Sudbury basin. These mines are currently capable of producing approximately 12 million tons of ore annually. Typically, this ore contains pentlandite, pyrrhotite and chalcopyrite in mafic host rocks. The milling facilities are designed to produce 240 million pounds of nickel, as concentrate, annually. This concentrate is further processed through Inco’s smelting and refining facilities to produce nickel, copper and several other metals.

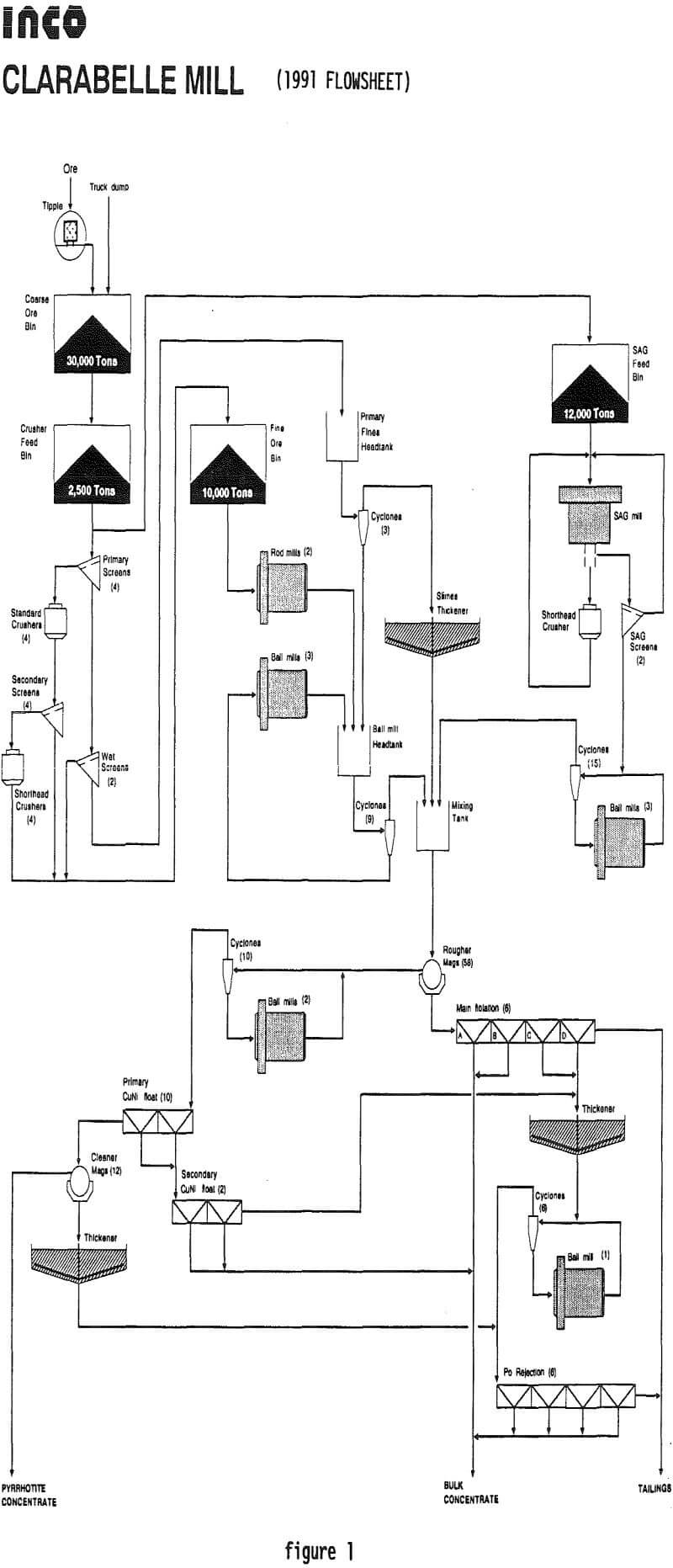

Mills Rationalization

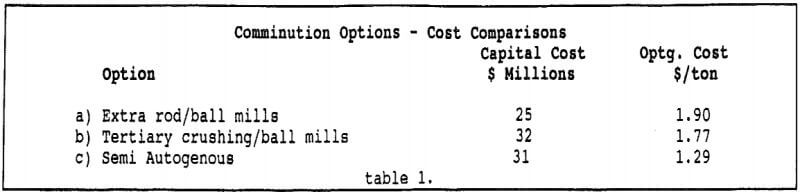

Throughout the 1980’s, several studies were conducted on how to consolidate Inco’s milling facilities. With the 1987 decision to go to bulk smelting along with a commitment to reduce sulphur dioxide emissions, a milling alternative with an economic payback emerged. By increasing comminution circuit capacity, installing 1350 cubic foot flotation cells for bulk flotation and using existing grinding and flotation equipment for improved pyrrhotite cleaning circuits, all mine production could be handled at Clarabelle Mill. Frood-Stobie Mill could be shut down and only the dewatering and filtration facilities at Copper Cliff Mill would remain active.

Pilot Plant Studies

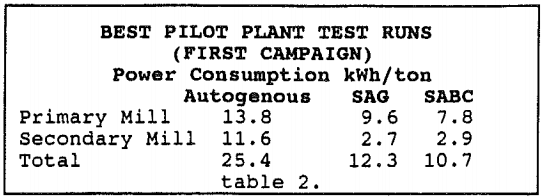

Bench scale tests and pilot plant campaigns were conducted to design a flowsheet and size equipment for a primary grinding circuit to handle 24,000 t.p.d.of ore. The initial pilot plant campaigns consisted of sixteen test runs.

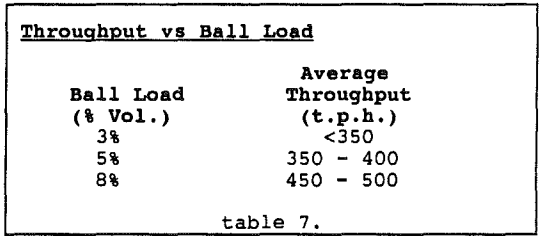

Whereas bench scale tests had suggested Sudbury basin ore to be relatively easy to break by impact, the pilot plant work showed the opposite to be true. In the initial test runs, using SAG milling alone, no combination of ball charges could be found to give an overall power efficiency as low as was determined by the bench scale tests. An examination of the SAG mill charge revealed a buildup of material in the minus 3 inch plus 2 inch size range.

Construction and Start Up

The project schedule called for a 18 month construction period, with equipment coming on line in several phases. In January, 1990, the first major process equipment to be brought into production were the 1350 ft cells for the bulk flotation circuit. Pyrrhotite regrind and cleaning were phased into production beginning in May 1990 with subsequent shutdown of similar circuits in Copper Cliff Mill in August.

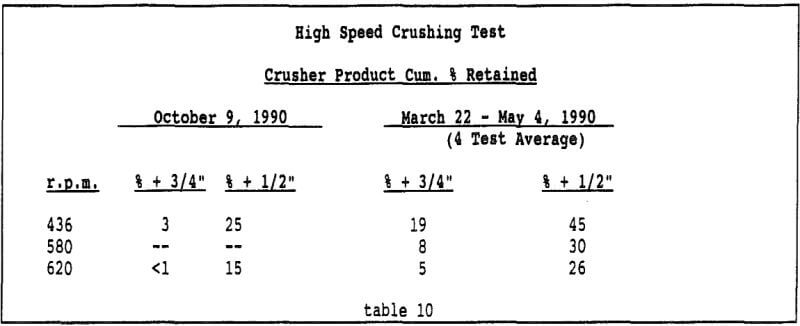

The SABC circuit design is to accept minus 8″ run of mine ore from a 12,000 ton silo. Two Forano pan feeders discharge from the silo onto a 48″ belt which feeds the 32′ x 13.5′ mill. The mill is powered by two 5500 hp D.C. motors. Nominal mill speed is 10.7 r.p.m. (78% critical) with a top speed of 11.3 r.p.m. The mill discharges through a grate with 3″ pebble ports onto a 14′ dia. x 13′ trommel screen with ¾” openings.

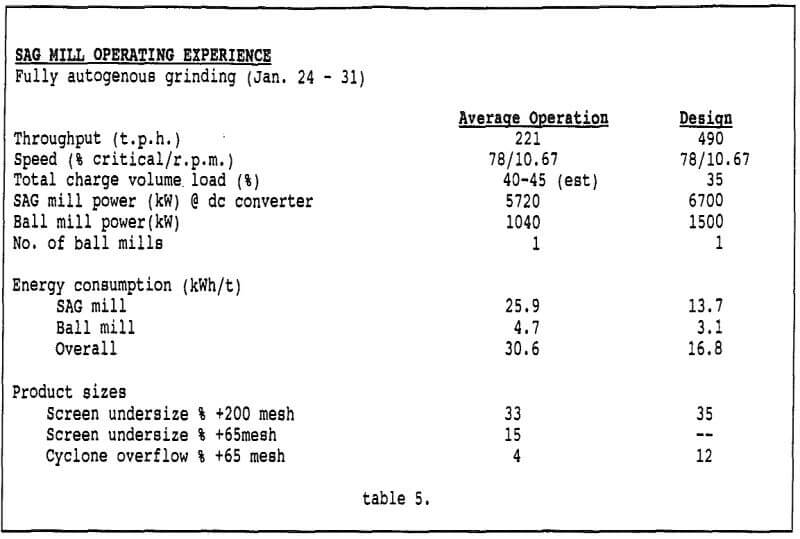

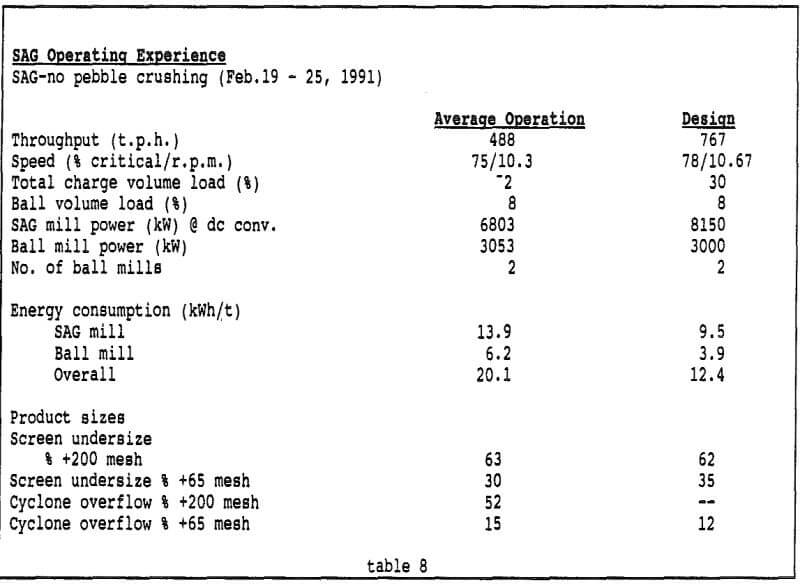

On January 19, 1991 the mill was brought on line as a fully autogenous mill without pebble crushing. The mill was difficult to operate in that it quickly overloaded and required extensive grind out periods.

For these reasons, the circuit was modified just prior to start up to allow for the SAG mill trommel undersize material to be added to the pebble crusher sump. This minus ¾” material was added to the sump via a 4″ bleed off line from the SAG mill trommel undersize pump discharge line.

The operators had difficulty learning to predict how the SAG mill would respond to changes in ore size and hardness, mill speed, pulp density and ball charge and had trouble maintaining steady-state operation. The mill was often overloaded and on several occasions, excessive grindouts occurred causing much ball breakage.

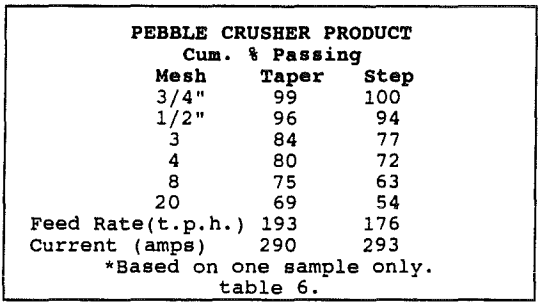

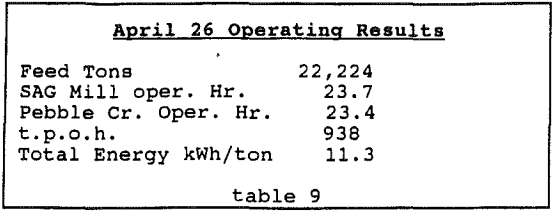

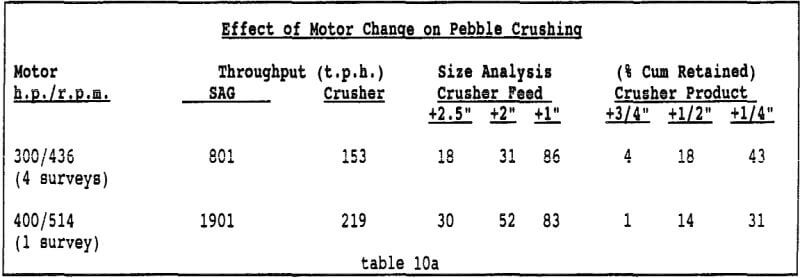

On March 11, the pebble crushing circuit had its first sustained run. Throughput rates immediately started to increase and power requirements dropped. For the remainder of March, throughput averaged 810 t.p.o.h. SABC circuit availability dropped to 33%, mainly due to screen undersize pumping problems. The pebble crusher was available for 69% of the time during SAG mill operation. Power requirements dropped to 15 kWh/ton.

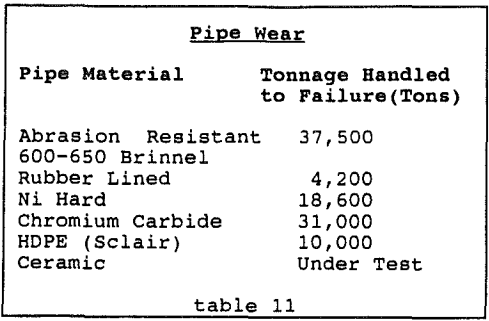

In mid-April, a new problem emerged. Extreme wear problems became apparent on the crusher pebble pumping pipelines. First the pump intake nipples wore out. The combination of sharp edged crushed pebbles and the turbulence of the pump intake injection water wore through the bottom of the rubber lined pipe spool. To reduce this problem, water was injected into the pump intake via a line installed through the sloped bottom of the sump and directed into the pump inlet. Water still had to be injected into the pump intake piping to prevent plugging, but lesser quantities could be used, thus reducing the turbulence and wear.

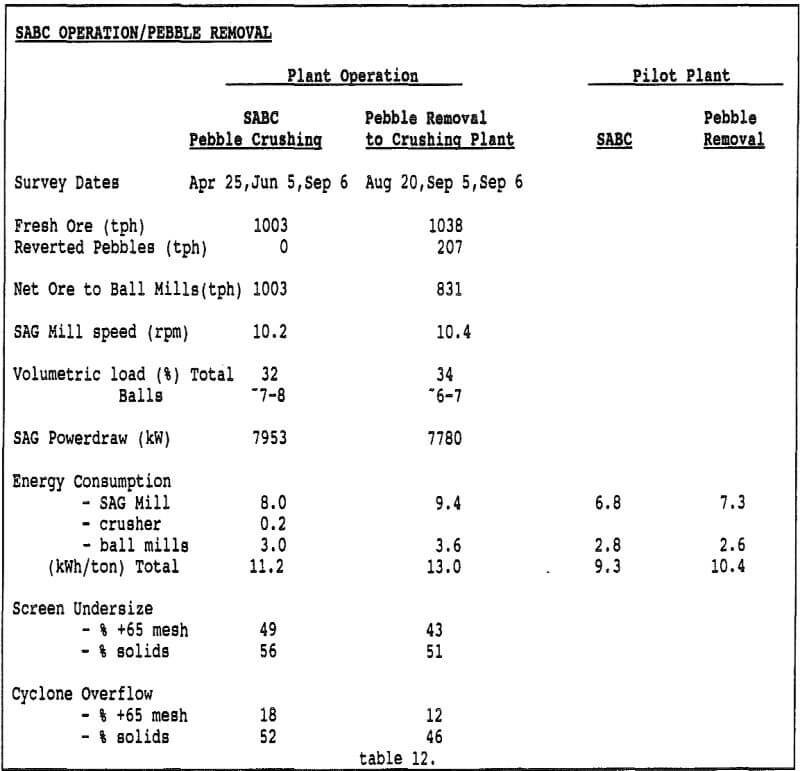

During the four week vacation shutdown period, a temporary conveyor system was installed to by-pass uncrushed pebbles back to the crushing plant feed bin. This would permit the SAG mill to operate, by-pass the pebble crushing circuit which was a bottleneck because of the wear and pumping problems, yet still remove the majority of the impact resistant pebbles so that close to design tonnages could be obtained.