Sulphide copper ores are normally concentrated by flotation while the oxide ores undergo hydrometallurgical treatments. The mixed sulphide-oxide copper ores may be processed by combined methods such as flotation followed by leaching and precipitation of the oxidized portion, or vice-versa. Also a Leach-Precipitation-Float Process (LPF Process) has been successfully applied.

However, when oxide or mixed ores have calcareous gangue and acid consumption is too high, sulphidization or ammonium leach have to be applied. When these fail to give simple and economical solutions, no metallurgical alternatives are left. This is the case when the Segregation Process provides new possibilities, since both oxide and mixed ores with or without calcareous gangue can be economically processed and reasonable recoveries of accompanying gold and silver obtained. As it is known, in standard hydrometallurgical treatment of copper ores, silver and gold values are generally lost.

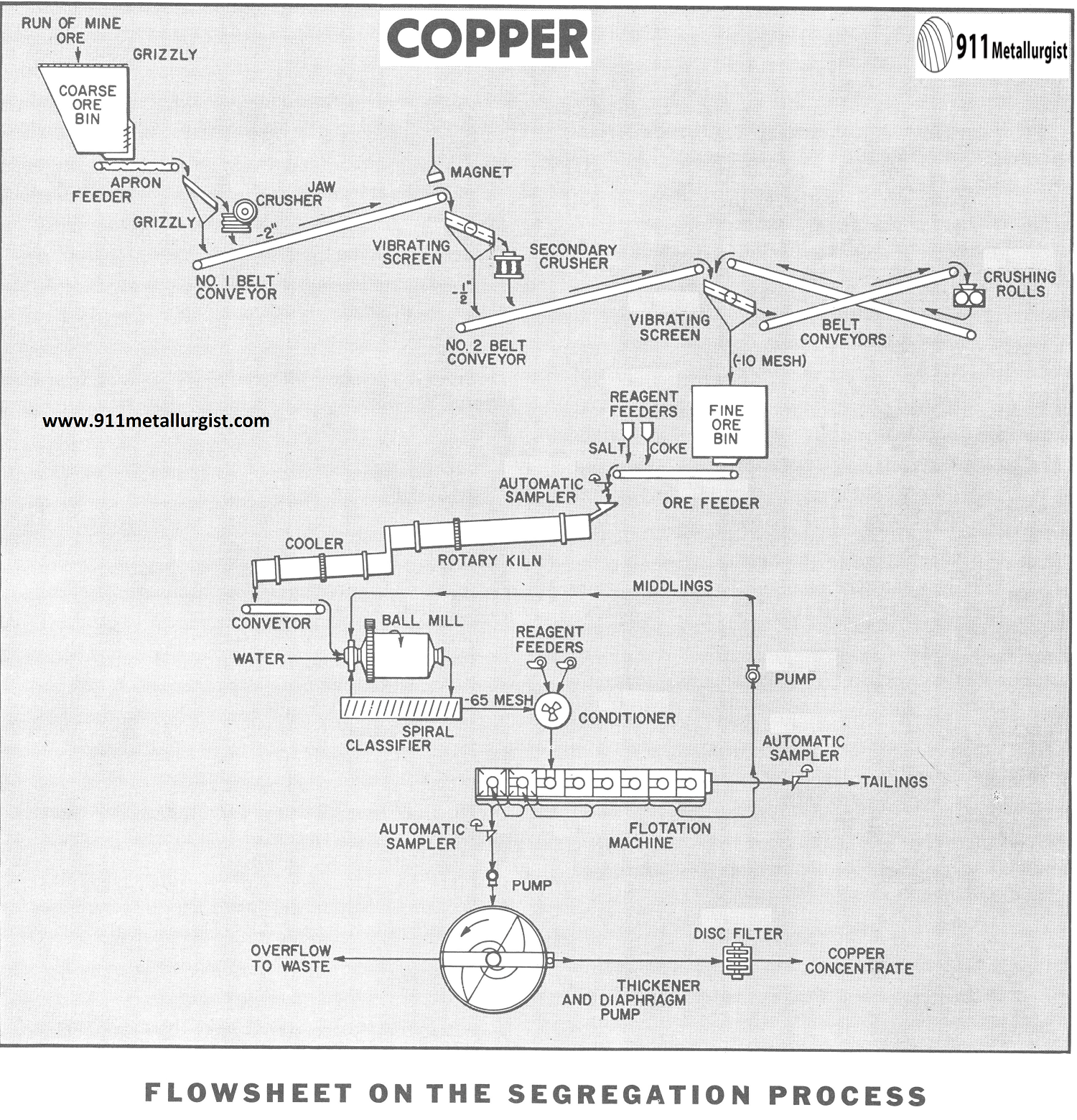

The Flowsheet

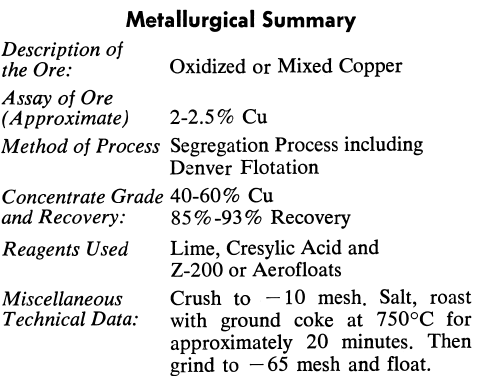

A typical flowsheet for this process calls for three- stage crushing of original ore to a minus 10 mesh product; mixing of crushed ore with small quantities of common salt and fine coke and roasting of this mixture in a kiln at 750°C in a controlled atmosphere. During the roasting, volatilization of copper oxides is effected, due to the presence of chlorides and moisture, and then reduction of volatile copper compounds on the surface of coke particles takes place. Thus copper values, originally disseminated in ore particles “segregate” to the surface of coke particles. The segregated ore is then wet ground in a ball mill and floated in a conventional way. The segregation process does not affect sulphide copper minerals and they float together with the segregated charge in a common concentrate.

CRUSHING AND SCREENING

The run of mine ore is fed from the coarse ore bin and crushed in three steps: first in a Jaw Crusher to a minus 2″ product; then in a cone crusher to a minus ½” product and finally in Crushing Rolls to minus 10 mesh. In the first two stages the fines are scalped in a grizzly and Vibrating Screen respectively and the last stage is performed in a closed circuit in order to insure granulometry of the segregation plant feed.

SEGREGATION TREATMENT

The minus 10 mesh ore is mixed with approximately 1% of common salt and the same quantity of fine coke. Granulometric size of common salt is not important, although for better mixing fine salt is preferred; the coke should be ground to at least 48 mesh. Also, for proper segregation, the ore must contain some 2-3% of moisture.

The prepared ore is fed to a refractory lined, rotary kiln, which is heated to 750°C. A contact time of about 20 minutes should be given and control of kiln atmosphere is essential. The segregated ore is then cooled to normal temperature in a rotary cooler in order to avoid re-oxidation of metallic copper.

GRINDING AND CLASSIFICATION

The segregated and cooled ore is fed to a one – stage closed grinding circuit which consists of a Ball Mill and Classifier. The ore is ground to a minus 65 mesh product, so that segregated copper particles are liberated from the coke and so that the sulphides present in the ore are liberated from the accompanying gangue. Since the following flotation step should be carried out in an alkaline circuit and since the ore has the tendency to acidify in the segregation process, some lime should be added to the circuit to obtain a pH between 9 and 10 and protect the grinding circuit from corrosion.

FLOTATION

The ground ore is conditioned in a Conditioner with collector and frother reagents.

These are of standard type used for flotation of native copper and sulphide copper minerals. Standard Flotation is used. In order to prevent gangue flotation and concentrate contamination, small quantities of sodium silicate may be useful. If the upgrading of concentrate is difficult, regrind of concentrate can help, previous to new flotation.

CONCENTRATE DEWATERING

This is carried out in the standard way in a Spiral Rake Thickener and Disc Filter.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.