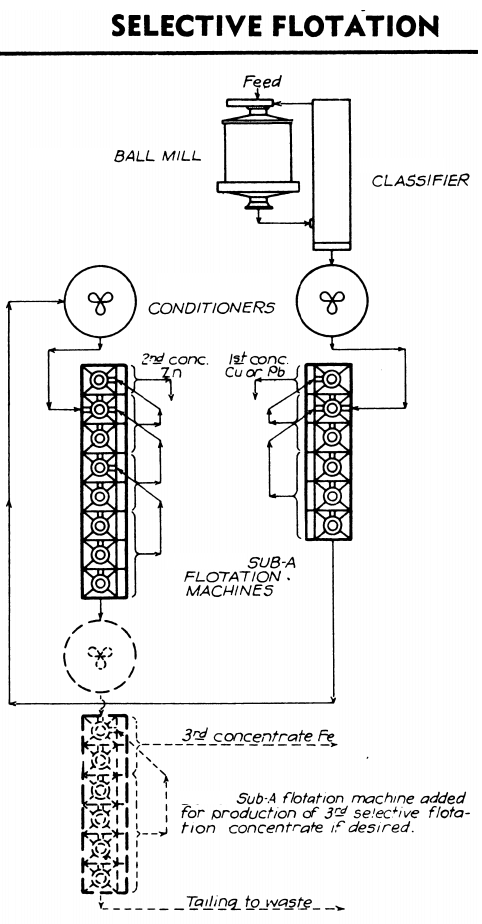

A selective or sequential flotation flowsheet of two or more products. By utilizing selective flotation, two or more minerals in an ore are separated into individual high grade products.

ORE TREATED: The most common of ores treated in this manner are lead zinc, copper-zinc-iron, copper-nickel, but application may be made to other two or three mineral separations. This flowsheet, without a Unit Flash Flotation Cell or a Mineral Jig, is applicable to ores where the values are in the base metals alone.

ADVANTAGES: The various minerals contained in the ore can be concentrated into products each containing a major portion of one separate metal. In this manner, it is possible to secure the greatest net return for each of’the metals, shipping each one to the smelter that offers the best schedule for payment on the metal.

PROCESSING COMMENTS: In many cases, where the minerals are freed at a coarse mesh, savings are made in grinding costs through the use of the proven “Sub-A” Flotation Machine which is the only flotation unit capable of effectively handling coarse feeds.

The sulphide iron minerals contained in practically all base metal ores, may be recovered from the tailings where the product can be marketed for the sulphur or where precious metals are closely associated with these minerals; an additional conditioner and flotation machine make this step feasible. As many as five individual concentrates are being produced from a single ore in actual milling practice.

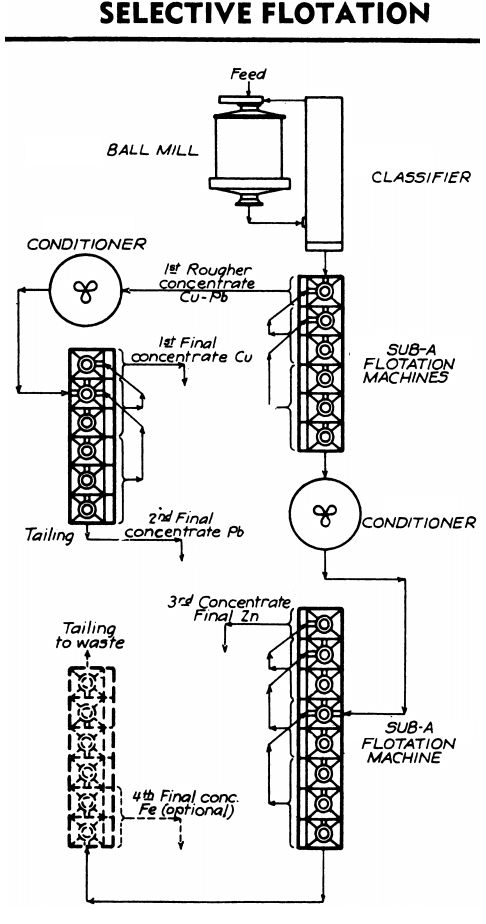

Sequential Flotation Circuit #1

Selective flotation (sequential) flowsheet of three metals

ORE TREATED: Sulphide ores of lead, copper and zinc are primarily treated. This flowsheet can also be applied to other ores wherein the separation of base metals or nonmetallic minerals may be desired.

ADVANTAGES: The first flotation machine in a copper-lead-zinc separation would produce a copper-lead concentrate. This copper-lead concentrate would go to a second machine wherein the copper w’ould be floated off, leaving a high-grade lead residue. Since the amount of copper-lead concentrate being treated would be small as compared to the original tonnage of the mill, excessive flotation capacity would not be required, as would be in the case of this 3 product flotation process Flowsheet wherein the first machine would produce a lead concentrate, and a second machine would produce a copper concentrate, but both machines treating the large tonnage of the original feed.

PROCESSING COMMENTS: In the case of the lead-copper cited above, the floatability of the lead and copper sulphides are so close together as to make a conventional separation impractical. By recovering these two into a single rougher concentrate, their recovery is accomplished and the preferential floating of one can be brought about through depressing the other. This separation is of particular interest as the copper may be recovered first, leaving a high-grade lead residue; whereas in other cases the lead may be floated first, leaving a high-grade copper residue.