The choice of Settling and Thickening test method and procedure depends to some extent upon the temperature of the pulp, its flocculating characteristics, the required supernatant clarity, and the equipment available.

The Long Tube Method may be used for all materials which settle without a clearly defined interface. However, where the feed in question is well flocculated, either naturally or artificially, a simplified test method as indicated below may be used to obtain significant data.

Detailed Procedure of Simple Settling Tests

Simple Settling Tests are conducted to determine clarification performance for a pulp, flocculated naturally or because of chemical additives, of the type which yields a constant suspended solids concentration throughout the supernatant after a period of 10-15 minutes.

- Place pulp in a measuring cylinder and make up to say 1000 ml mark with water. Shake thoroughly after addition of flocculant.

- Allow to settle quiescently and note interface depth as a function of time (seconds).

- Flocculation is a time function following an empirical relationship.

C= k tm where C is the suspended solids concentration. Supernatant samples for suspended solids analysis should be taken after settling times of 10, 15, 30, 60, 90 and 120 minutes. - A log-log plot of this data usually will give a straight line of slope m.

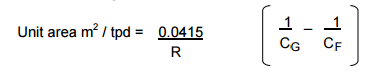

- The static detention time calculated for the desired overflow clarity, and the observed bulk settling rate may be used, with proper scale-up factors that determine sedimentation area and depth requirements.For thickener sizing, the relevant relationship is:

Where R = average settling rate, m/h

CG = Initial Solids Concentration

CF = Final Solids Concentration

R is determined rate x 0.8 scale-up factor

A clarity wedge can very often be used to rapidly assess effectiveness of flocculation or water clarity.