The Laboratory Sieve Shaker will quickly and efficiently size laboratory products, thus allowing the determination of various important treatment factors. Results of sizing tests and analyses of sized products will determine such important factors as the following:

- Size at which valuable mineral is freed from the gangue.

- Whether tailing losses occur in coarser or finer fractions so that measures can be taken to reduce tailing losses.

- Fineness of grind secured in the milling circuit.

- Efficiency of classifier, vibrating screens, and other units in circuit.

- Necessary steps to secure higher recoveries or lower milling costs.

- Numerous other points of value to the research engineer and mill operator for improving treatment methods.

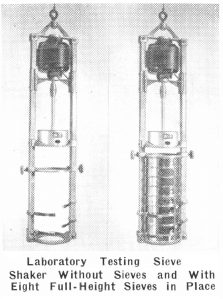

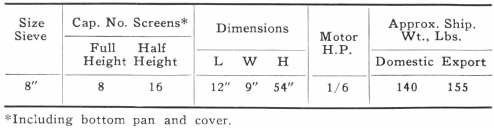

Efficient grinding and milling depend upon accurate screen analysis. The actual screen operation is performed by this Laboratory Testing Sieve Shaker with greatest possible speed. The gyratory motion of the shaking mechanism is such that the sample passes through very rapidly while spring attachments tap the sides of the sieves to prevent particles from adhering or agglomerating. The final product is received in a bottom pan which is firmly clamped into the machine. The high efficiency and low first cost of the Laboratory Testing Sieve Shaker make it indispensable in any laboratory. Capacity of unit is eight full- height or sixteen half-height standard 8″ Tyler Sieves, with cover and bottom pan.

A time switch is available for stopping the mechanism at any predetermined time interval up to thirty minutes. This is essential when standardizing and making comparative screen analyses.

SIEVE, Brass Cloth on Heavy Tinned Frame—Suitable for metallurgical and general purposes. Will nest in any combination. Prices are for sieves only, not including pan or cover. 8 inch diameter.

SIEVE BOTTOM PAN, Tinned—For No. 57310 Sieves.

SIEVE COVER, Tinned—For No. 57310 Sieves.

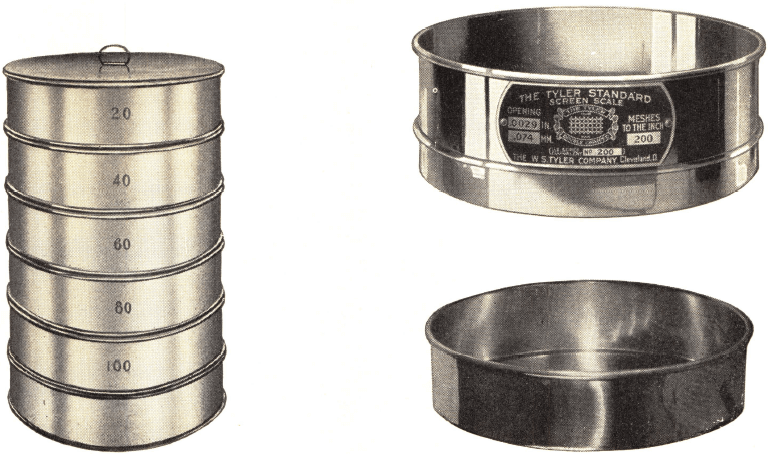

SIEVES, Tyler Standard Screen Scale—The Tyler Standard Screen Scale has as its base an opening of .0029 inch, which is the opening in 200 mesh, .0021 inch wire, the standard sieve, as adopted by the U.S. Bureau of Standards, the openings increasing in the ratio of the square root of 2 or 1.414. To provide for closer sizing, the series is extended with intermediate sieves to progress in the ratio of the fourth root of 2 or 1.189.

These sieves are standard for the A. S. T. M. for precision testing for the fineness of materials, being covered by A. S. T. M. Standard Specifications E-11-26, “Sieves for Testing Purposes.” They also come within the tolerances of the U. S. Bureau of Standards specifications for testing sieves, and each sieve is marked with the U. S. Series equivalent number in addition to the opening in fractions of an inch and millimeters, and the number of meshes to the inch.

These sieves are made with a seamless brass frame and specially woven brass cloth. The finer meshes are of phosphor bronze. Diameter, 8 inches; height, 2 5/8 inches; depth to cloth. 2 inches. Nested type. Each sieve in individual carton. Without pan or cover.

In the following listing, sieves with from 1.050 inch opening to .0029 inch opening run in accordance with the Tyler Standard Screen Scale.

SIEVE BOTTOM PAN, Brass—For No. 57330 Sieves.

SIEVE COVER, Brass—With ring. For No. 57330 Sieves.

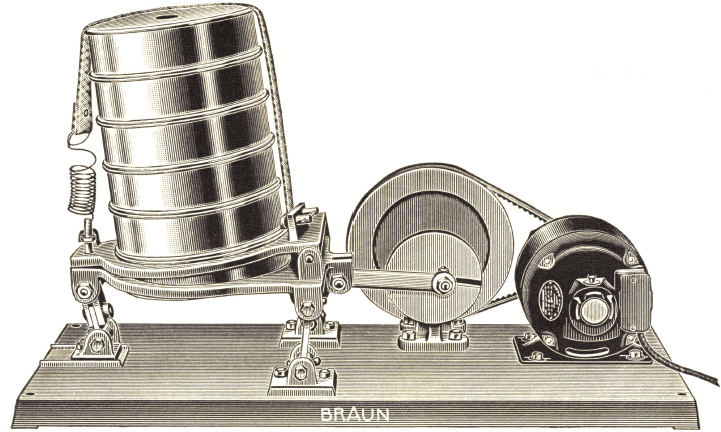

SIEVE SHAKER, Braun-Porter—The Braun-Porter Sieve Shaker is portable, light in weight, strong and sturdy and built to meet requirements of continual use in the laboratory or in the field. It was primarily designed and built for field use by paving inspectors and contractors, as well as for use in the testing laboratory.

It is mounted upon an aluminum alloy casting. It can be used successfully upon the platform of an auto truck or other temporary foundation.

The operation is a backward and forward motion combined with an up and down motion, the latter of which provides two distinct bumps. A heavy bump after the forward throw forces the material through the sieve, while the upper bump provides a whipping action of the material, keeping it stirred up and insuring all particles will contact the surface of the sieve. The construction is such that the sieve itself does not receive the bump directly, thus minimizing wear and tear on the sieve.

From one to six sieves can be shaken at one time with the Braun-Porter. The forward and backward stroke and also the intensity of the bump can be easily regulated for various tests. This shaker will give results comparable to those obtainable with larger and more expensive shakers.

Overall dimensions, 11 inches x 31 inches. Complete with electric motor, ¼ h.p. A.C. without sieves. Shipping weight 100 pounds.

Braunco Time Switch—Can be set to stop the motor automatically after any desired length of test up to 30 minutes. Settings can be made to one minute intervals.

SIEVE SHAKER, Braun-Porter, with gasoline engine—Same as No. 57400 except that it is equipped with a gasoline engine instead of electric motor for use where electricity is not available. Shipping weight, 200 pounds.