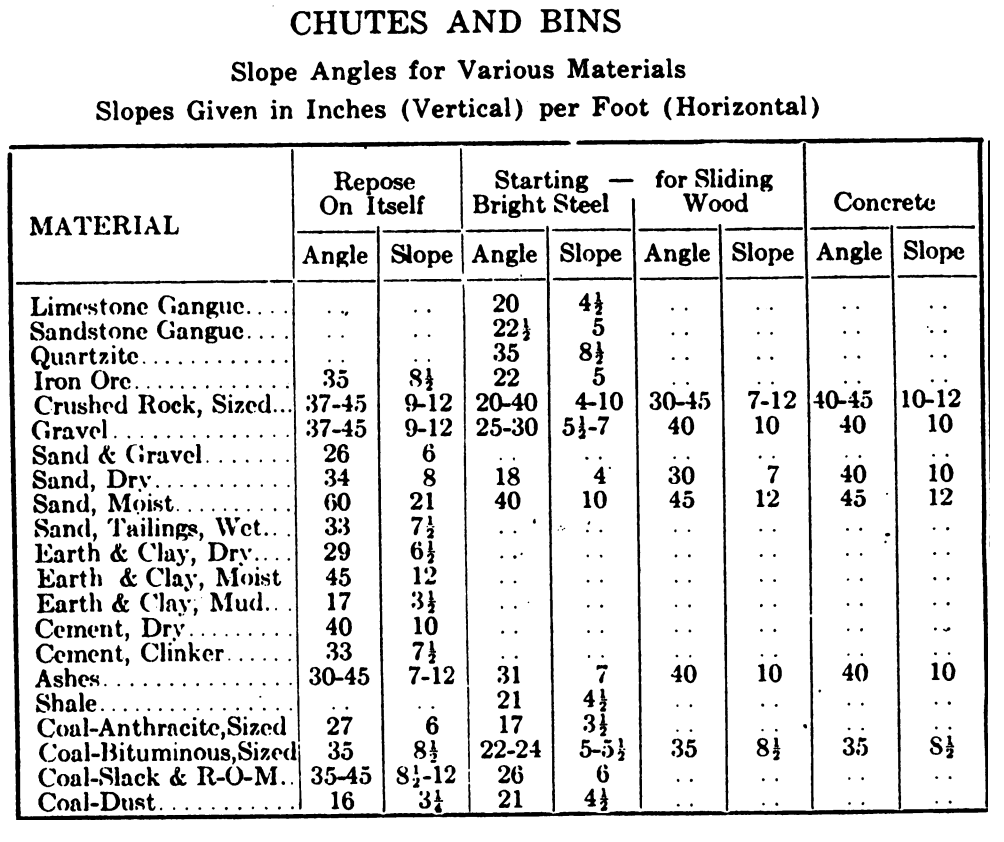

After starting sliding angle is 2°- 3° less.

In practice, sliding angles are 5°- 10° more than above.

Capacity of chutes is determined largely by the opening to the chute.

In gates and other openings or restricted spaces in which pieces of rock are intermittently passing, the width should be at least 3 to 4 times the diameter of the largest pieces, to prevent arching, and in the running chute probably at least 6 times, to prevent arching and reduce side friction. Velocities in the case of round pebbles will tend to approach those of free fall under gravity, while sliding masses have the free fall velocities materially reduced by friction on the bottom.

Spiral chutes of steel, for which slopes have been determined for packages, sacks, and bulk materials, deliver vertically with minimum breakage.