The object of the post agitated leach drum filtration circuit is to recover as much of the dissolved gold and silver as possible. The efficiency of recovery can be increased significantly by utilizing two successive stages of filtration such as the two stage system applied in this plant. Recovery of the precious metals is also improved by the use of spray water solutions on the filters in addition to repulping between the filtration stages.

The filtration circuit, both primary and secondary stages, is designed to the following criteria:

Filtration Rate 175 kg/sq.meter/hour

Wash Ratio 1.6:1

Flocculant Dosage 75 gms/tonne of solids

Vacuum Air Rate 55 cu.meters/hour/sq.meter

Filter Cake Moisture 80% solids

Slurry pH 12.0

Detailed Filtration Process Description and Control

Precious metal slurry flows by gravity line from the last leach tank into the primary filter feed pumpbox at a rate of 35.5 cubic meters per hour and 45% solids. This pump box is composed of two compartments; a feed diverter box atop the pumpbox can be manually switched to direct flow into either compartment. A high level switch top-mounted on each compartment will alarm at the mill control panel annunciator on a high pumpbox compartment level. The dual compartment pumpbox is designed so that flow can be alternated between two pumps on a regularly scheduled basis. The barren gland seal liquid to each pump must also be switched with the pump alternation.

Discharge of each compartment is pumped by its separate pump to a filter distribution box. This box is located on a platform above four drum filters, allowing gravity flow into either or both primary or into either or both secondary drum filters. A diverting gate atop the distribution box will pull the two inflow lines from the filter feed pumps into either of two sections of the distribution box. One section is reserved for the primary filters, and the other for the secondary filters and a bypass. Each filter and the bypass have their own manually operated plug valve at the underside of the distribution box section. The bypass valve should only by used if the need arises to bypass the entire circuit. Flow from this bypass valve will be directed to the Conditioning Circuit.

Discharge of each compartment is pumped by its separate pump to a filter distribution box. This box is located on a platform above four drum filters, allowing gravity flow into either or both primary or into either or both secondary drum filters. A diverting gate atop the distribution box will pull the two inflow lines from the filter feed pumps into either of two sections of the distribution box. One section is reserved for the primary filters, and the other for the secondary filters and a bypass. Each filter and the bypass have their own manually operated plug valve at the underside of the distribution box section. The bypass valve should only by used if the need arises to bypass the entire circuit. Flow from this bypass valve will be directed to the Conditioning Circuit.

Flocculant is added, at the distribution box, to both the primary and secondary filter feed slurry compartments. The ground ore has relatively poor filtration characteristics and it is therefore essential that flocculant be added to the feed slurry to aid filtration. A paddle type flow meter gives a local indication of flocculant flow rate. It should be noted that flocculant is never added prior to a pump, as the shear forces in a pump will break the large flocculant molecules (flocs) down, rendering them useless. Flocculant is best added as close to the filters as possible. In addition, the feed slurry must be maintained at a pH level of 12.0, as controlled in the last leach tank, to maximize the filtration capacity of the filters.

Flocculated slurry from the distribution box is fed to the tank or ‘boot’ of each primary filter at a rate of 18.3 cubic meters per hour. The level in the boot is maintained during operation via a continuous overflow back to the filter feed pumpbox tank. A high level switch at each filter, located at the top of the 8″ overflow pipe, will alarm at the mill control panel if the overflow condition is too high. The solids in the slurry are kept in suspension with a 7.5 HP mechanical variable speed reciprocating agitator located in the bottom of the boot. The 12′-0″ diam. x 18′-0″ long drum, with filter medium or filter cloth wrapped tightly around its surface, is partially submerged in the slurry and rotates at a very slow speed of one to five minutes per revolution. The mechanical variable speed 7.5 HP drum drive is interlocked with its agitator drive. Both drives must be started and stopped locally, and can be run individually; however, a mill control panel stop pushbutton will stop both drives. The periphery of the drum is divided into compartments, each of which is provided with a number of drain lines which pass through the inside of the drum, terminating at one end as a ring of ports accessible to a rotary valve, to which vacuum is applied. Vacuum gauges monitor pressure in the vacuum line. As the drum rotates, each compartment goes through the same cycle of operation. As a compartment is rotated through the slurry in the boot, the applied vacuum draws the liquid in the slurry through the filter cloth into the internal drain lines while forcing the solids to form a thin layer or ‘cake’ on the surface of the drum. As the drum rotates and the cake covered segment rises out of the slurry, the vacuum continues to draw liquid into the internal drain lines. As the cake reaches the highest point on the drum, the cake is thoroughly washed with barren solution flowing through two spray bars from above at a rate of 8.8 cubic meters per hour. A paddle type flow meter can be used in conjunction with the appropriate hand valve to correctly adjust the barren flow rate wash water. The wash water displaces any liquid or pregnant solution entrained in the cake. With the vacuum still applied, the displaced pregnant solution is drawn into the internal drain lines. As the compartment approaches the end of one complete cycle, the vacuum is discontinued and a quick blast of air, from inside the drum, expands the filter cloth, lifting the cake from the media, while a knife blade running the length of the drum scrapes the cake off the filter. This is a continuous cycle, i.e., while the cake is being scraped off one section of the filter, it is forming on another.

The filter cake at 80% solids from both primary filters discharges into a repulper at a rate of 13.3 cubic meters per hour, where it is mixed with barren solution at a rate of 25.7 cubic meters per hour. Paddle flow meter indicates barren flow to the repulper. The repulped slurry, now at 40% solids, flows by gravity to the wash feed pumpbox. This dual compartment pumpbox is identical to the primary filter feed pumpbox, and has its own high level switches, and panel alarms.

Repulped filter cake from both primary filters is pumped at a rate of 39 cubic meters per hour and 40% solids from the wash pump tank by either wash feed pump, depending on which pumpbox compartment is in service, to the secondary filter feed section of the filter feed distribution box. Flocculant is again added to the feed and the slurry flows by gravity to the boot of the secondary drum filters.

Approximately 32.2 cubic meters per hour of pregnant solution is drawn into the drain lines of the filters, and flows into the 6-‘0″ diam. x 7′-0″ primary vacuum receiver where it is pumped to either the thickener or pregnant solution tanks by a 3” filtrate pump.

The second stage filtration process is identical to that of the first stage; however, the 8.8 cubic meters per hour of wash water on the second stage of filtration may be barren solution, reclaim water, or a combination of both. Paddle flow-meters on the barren lines, and on the reclaim lines monitor flow rates. Also, the secondary filter cake is repulped with 33.3 cubic meters per hour of reclaim water as opposed to barren solution, as in the primary filtration system. A flowmeter monitors the flow rate of repulp water.

Repulped slurry from the second filtration stage flows by gravity to the conditioning feed pump box. This pumpbox is identical to the filter feed pumpbox. Repulped slurry is then pumped by either conditioning feed pump, to the first conditioning tank.

Pregnant solution from the secondary stage of filtration flows at a rate of 35.8 cubic meters per hour to a 6′- 0″ diam. x 7’-0″ vacuum receiver and is then pumped to either the thickener or the pregnant solution tanks by a 3″ filtrate pump.

Both receivers have been provided with high level switches which alarm at the mill control panel, and are interlocked with the vacuum pumps to shut down the vacuum pumps if a high level condition in the receiver is experienced.

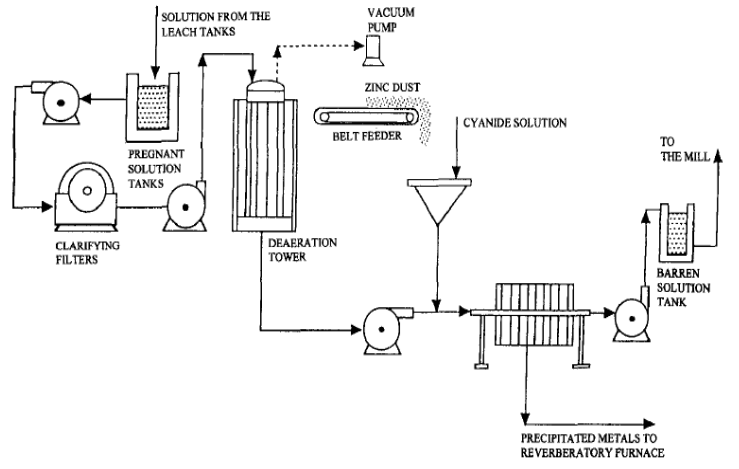

The vacuum applied to all drum filters is produced by three 6300 normal cubic meters per hour liquid ring vacuum pumps. Under normal operating conditions two vacuum pumps will be running and one held as a spare. Each filtration stage has its own vacuum receiver; however, both receivers are connected to the large 16″ diameter common vacuum header of all three vacuum pumps. In addition to the receivers, the vacuum pumps also supply vacuum to the deaeration tower in the Merrill Crowe Circuit.

The liquid-ring type vacuum pumps utilize 70 cubic meters/hour of fresh water as the liquid compressant. As the liquid compressant passes through the vacuum pump, it will undergo a temperature increase of about 15 degrees fahrenheit. The pumps are designed to operate with a water temperature of 60 degrees fahrenheit. Since cooler water tends to increase pump capacity, the compressant is circulated through a closed loop cooling system to maintain this operating temperature.

Liquid compressant and air exits each vacuum pump through a silencer. The silencer exhausts the air to the exterior of the plant and discharges the liquid compressant by gravity into a common drain line feeding the sealed cooling water sump. The 3″ cooling water sump-pump pumps the warm liquid compressant to the 3 meter diameter x 3 meter cooling water surge tank. The cooling water circulating pumps pump the liquid compressant from the surge tank through an inline filter, through a plate heat exchanger and back to the vacuum pumps. Fresh water is added to the surge tank on an as-needed basis to ensure an adequate supply of liquid compressant to the vacuum pumps. Reclaim water is used as the cooling media in the heat exchanger. Temperature gauges mounted at the compressor inlet and outlet lines to the heat exchanger provide a local indication of performance.

Each vacuum pump must be started locally and may be stopped locally or remotely from the mill control panel. On a start, compressant water is allowed to flow into the pump by a fail close spring return solenoid actuated ball valve which is interlocked with the starter. A pressure regulator drops the water inlet pressure from 30 to the required 15 psig inlet pressure to the pumps. While running, high pressure and low pressure switches regulate water flow into the pumps by controlling a solenoid valve feeding water to each 10″ air inlet. A flow meter monitors water flow into the pumps, and pressure gauges monitor water pressure into each pump inlet prior to the solenoid valves. A low pressure switch downstream of the solenoid actuated ball valve, will stop the pump if water pressure is below 5 psig, indicating insufficient water supply. The level switches at both vacuum receivers are interlocked with all vacuum pumps to shut them all down if either receiver has a high level condition. Purge water to the pumps is regulated by a flow orifice plate.

Due to the characteristics of the ore and the continuous use of lime in the process, it is anticipated that scaling of the drum filter cloths will occur. If excessive scaling of the cloth occurs and hinders filtration, the portable acid wash system (explained further in the reagent section) can be used to dissolve the scale. A weak (3%) hydrochloric acid solution can be sprayed, through a 1/2″ diameter S/S spray bar, onto the surface of the rotating drum at a rate of about 3-5 USGPM (10-20 l/min) to dissolve the calcium scale. It should be noted that the drum filter that requires acid washing must be taken out of service during the washing stage. Refer to the start-up and shutdown sequence for the acid washing procedure.

https://www.911metallurgist.com/leaching-circuit-operation-startup-and-shutdown-procedure