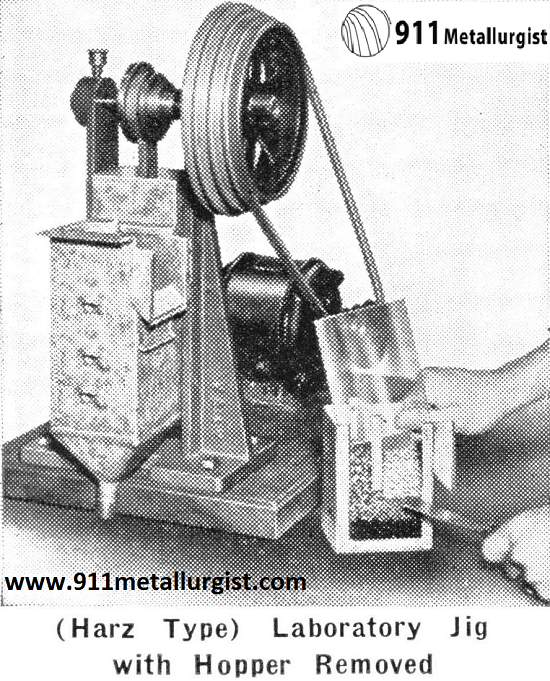

Laboratory Jig (Harz Type)

There are many ores, such as zinc, lead, iron, and fluorspar which can be treated economically in jigs handling very coarse feeds; either to make a high grade concentrate or to discard a coarse, clean tailing. The small (Harz Type) Laboratory Jig accurately tests the possibilities of such an ore.

|

|

The entire screen compartment is removable at the end of a test, and has a glass side, through which the bedding can be observed. By removing the glass, it is easy to separate the concentrate, middling, and tailing layers for analysis. The speed and the length of the plunger stroke are adjustable through an eccentric and a 4-step cone pulley.

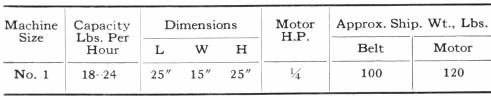

Small Laboratory Jig Capacity

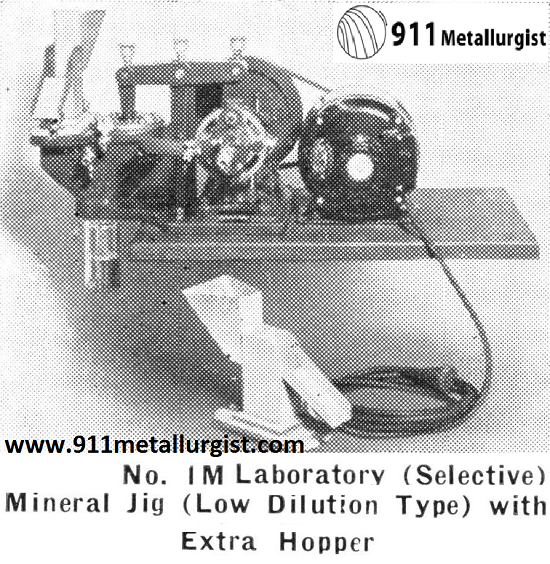

Small Laboratory Jig, (Selective) Mineral

This Laboratory Mineral Jig, is a laboratory unit built in the same manner as the commercial (Selective) Mineral Jig. The rotating water valve, timed to admit water only on the plunger upstroke, is on the end of the eccentric shaft. The shaft is mounted on two adjustable bearing stands with bronze bushed bearings and the eccentric itself is adjustable. A sturdily constructed walking beam mechanism actuates the plunger which is sealed with a rubber diaphragm.

The construction of the screen compartment differs from that of the commercial unit in that the entire top part of the jig is removable, which makes for ease of cleaning in the laboratory.

Two wing nuts hold the compartment in place and allow its quick removal, while a gasket makes the seal watertight.

The hutch compartment is cast iron, which is sand blasted and finished with baked enamel so that no crevices or pockets will remain to salt the next test. Two removable screen compartments are furnished, each with a different sized screen and the necessary bedding material. The spare compartment is shown in the foreground of the illustration.

The concentrates fall into a detachable glass jar which screws against another gasket. This feature is of great assistance as the type of product is readily inspected as it accumulates and the necessary adjustments can be made without the necessity of re-running the sample. The possibility of salting at this point is eliminated by the opening in the bottom of the hutch extending through the gasket into the neck of the jar. To release entrapped air from under the diaphragm at the beginning of each run, a small air cock is provided. A siphon arrangement is provided by which the water remaining in the hutch can be drained to a level below the neck of the jar. Thus the jar can be removed without spilling. The jig has a screen size of 1½ by 2¼” and it is designed for use with batch samples as small as 2,000 grams. A sample of this size can be jigged with a resulting pulp which will require additional dilution for subsequent flotation test. Thus no dewatering will be necessary between these two tests. Since cast iron is used throughout, cyanide solution can be fed to the unit instead of water when desired.

The Laboratory (Selective) Mineral Jig is ideal for use in the grinding circuit of a No. 5 Test Plant. It may also be used in the No. 7 Test Plant when handling high ratio ores.

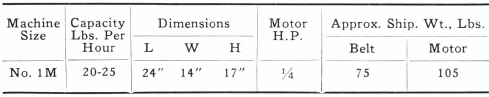

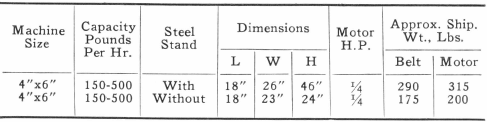

Small Plant Jig Capacity

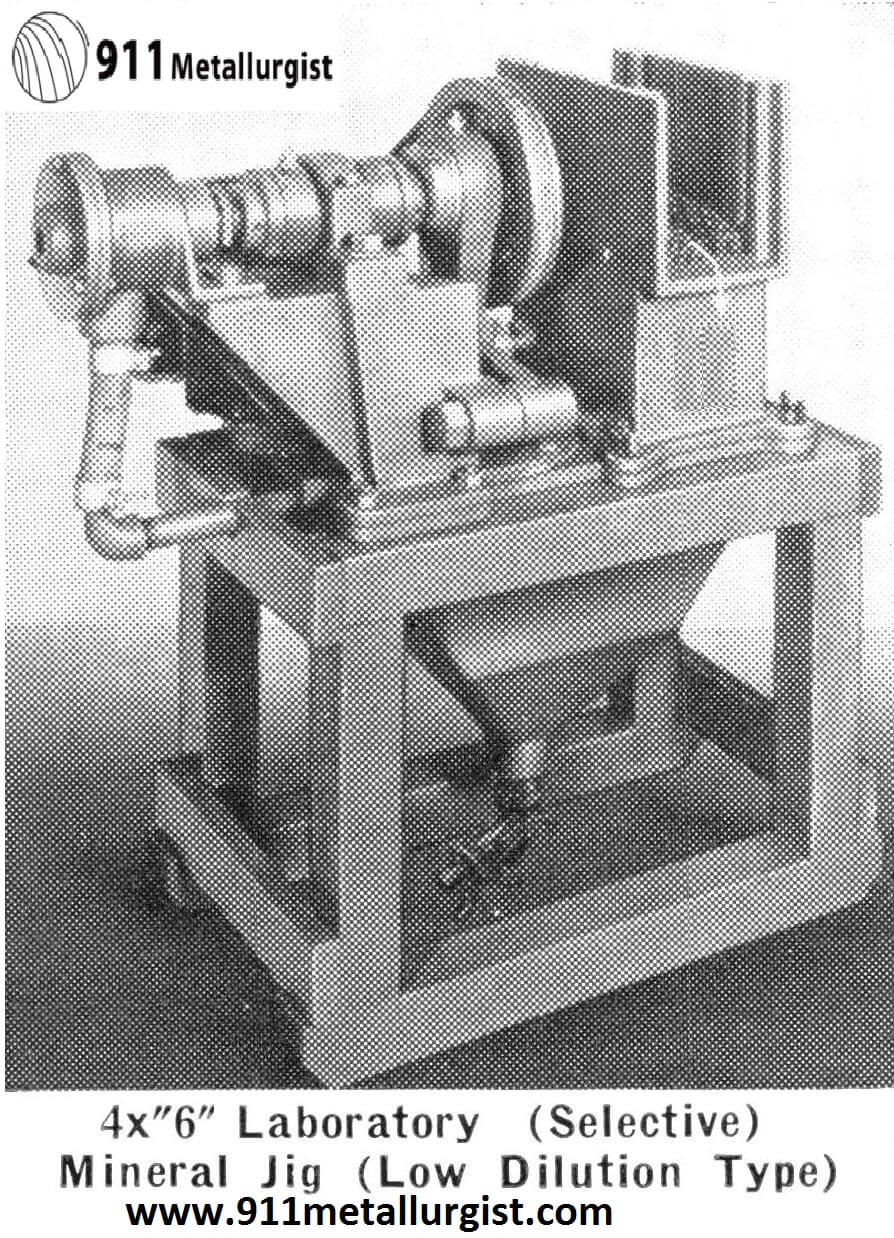

Small Laboratory Jig, (Selective) Mineral 4″ x 6″

Laboratory (Selective) Mineral Jig, size 4″x 6″, is between the commercial size 8″x 12″ Simplex (Selective) Mineral Jig and the No. 1M Laboratory (Selective) Mineral Jig, due to its applicability to both commercial and test work.

Although the 4″x 6″ Laboratory (Selective) Mineral Jig is ideal for many uses in commercial work, it also has considerable merit as a unit for use in pilot mill operation and in large batch laboratory tests. It is suited for non-metallic or open-circuit work in the laboratory, especially where a large quantity of concentrate must be obtained.

This size jig is most desirable for trial installation in large tonnage mills to determine the desirability of a jig in the circuit, as it can operate on small quantities of material of the same size as that handled by the commercial size jig.

The 4″x 6″ Laboratory (Selective) Mineral Jig has a single hutch compartment and a reversible screen compartment constructed of cast iron so that cyanide solutions can be fed to the unit instead of water when it is desired.

The rotating water valve is timed to admit water only on the plunger up-stroke and is located on the end of the eccentric shaft. The eccentric shaft is mounted in a ball-bearing double-pillow-block type bearing. An adjustable eccentric is used for varying the movement of the rubber diaphragm. The upper trash screen consists of a four mesh woven-wire cloth. Two lower wedge-bar screens are furnished with each jig, one with 2 millimeter openings and the other with 5 millimeter openings.

When the jig is used on continuous tests a steel stand is recommended for mounting of the jig. The steel stand is arranged with a shelf for holding a glass jar which accumulates the jig concentrate as it discharges from the hutch. The jar allows the inspection of jig product during test.

Small Plant Jig Capacity

LABORATORY JIG —There are many ores, such as tungsten, manganese, zinc, lead, iron and fluorspar where jigs can be used economically, either to make a high-grade concentrate or to discard a coarse, clean tailing.

Denver Laboratory Jigs are self-contained units for accurately testing the coarse concentration possibilities of an ore. The entire jigging compartment is removable at the end of the test. This removable hopper has a glass side, through which the bedding can be observed. By removing the glass, the concentrate, middling and tailing layers can be easily separated for analysis. The hutch product is drawn off through a drain opening.

Water can be added either above or below the plunger, which is the improved single-acting type. The interior design eliminates any possibility of conflicting cross currents.

The speed as well as the plunger stroke are adjustable. Both a coarse and a fine screen compartment are furnished with each machine.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.