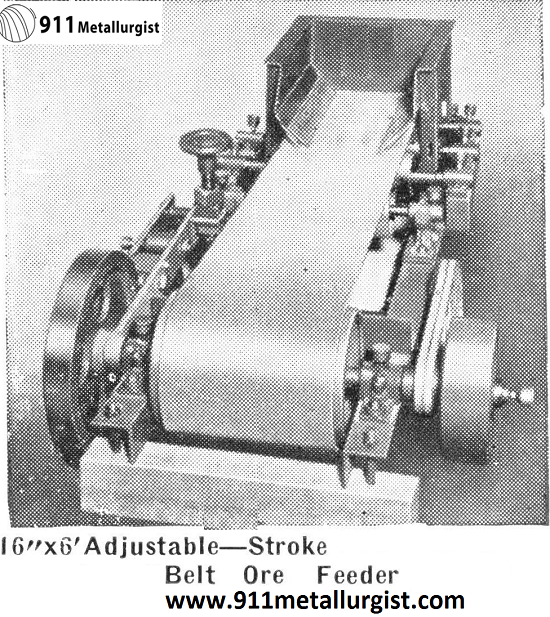

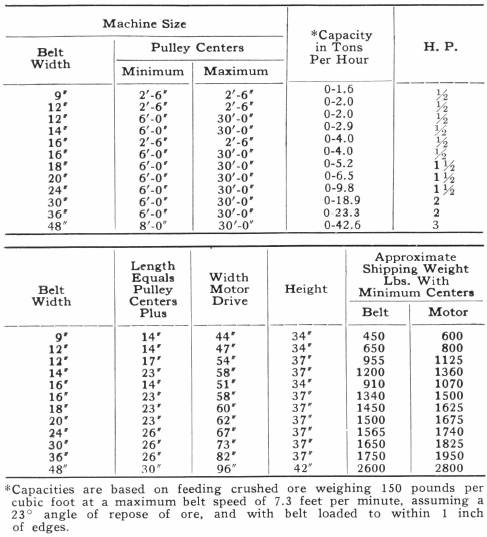

Adjustable-Stroke Belt Ore Feeder

The Adjustable -Stroke Belt Ore Feeder is preferred for feeding the grinding mill because of its smoothness of operation, uniformity of discharge, and regulation of feed. It is so arranged that it can be installed to draw the feed from the bottom or the front of the ore bin. Various lengths are available to fit the various requirements.

The tonnage of feed can be regulated by a wide range of belt speeds or by regulating a sliding gate fitted on the front of the feed hopper, or if necessary, an adjustable opening is built into the ore bin to give further control.

The frame is made of structural steel and supports a steel hopper, head and tail shafts and the necessary closely spaced flat belt idlers which are located under the feed hopper to support the ore in the bin. A heavy rubber belt ensures long life. Variable belt speeds ranging from 0″ to 15′ per minute are accomplished by the use of an adjustable feed control which is regulated by a handwheel conveniently placed on the frame away from belt.

Additional data gladly furnished upon request.

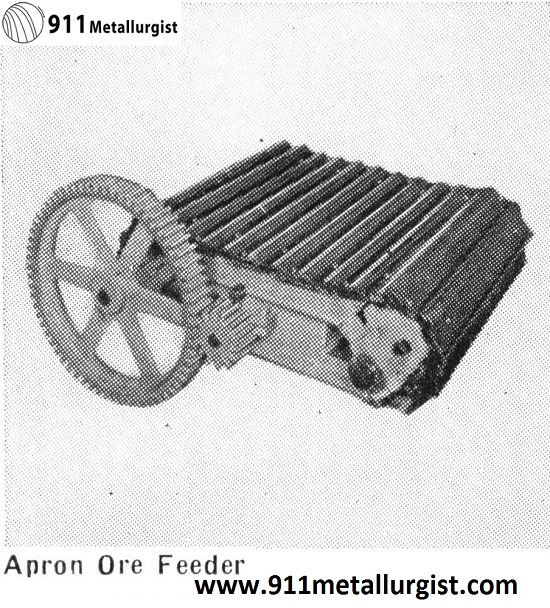

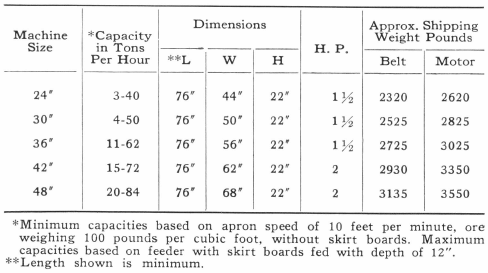

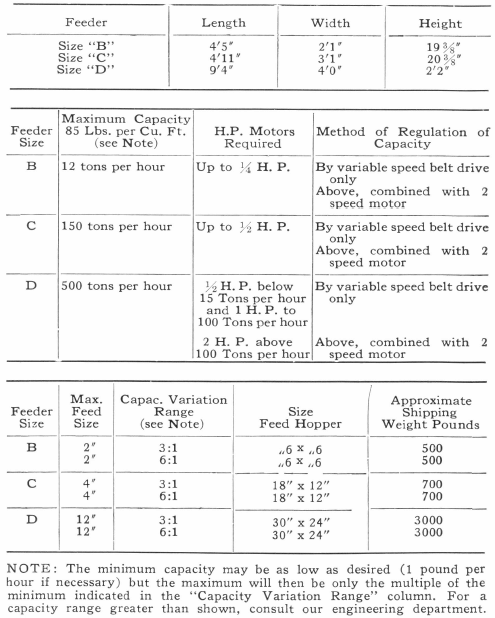

Apron Feeder

The Apron Ore Feeder is especially suited for feeding a uniform flow of lumpy and abrasive ores which would ordinarily damage less durable equipment. It is built to resist damage resulting from sudden impact and from sharp edges of large lumps, and to withstand severe loading conditions. It is an ideal unit for installing under a coarse ore bin to feed a jaw crusher or a gyratory crusher, and due to its slow speed it may be used as a picking belt for removing tramp iron and drill bits before the ore is fed to the crushing unit.

The Apron Ore Feeder is constructed with a steel frame, two strands of roller chain which support double beaded steel pans, sprockets and chain take-ups. Pans can be furnished 3/8″ or ½” thick with or without 2″ high sides. Steel skirt boards can be furnished if desired. Two types of feeders can be supplied: with or without roller-supported chain. Usual drive consists of a gear motor, sprockets and roller chain. Variable feeds are obtained by using a Reeves drive. Minimum center is 4’7″ and can be increased in increments of 18″ to a maximum of 9’1″ center.

Additional data gladly furnished upon request.

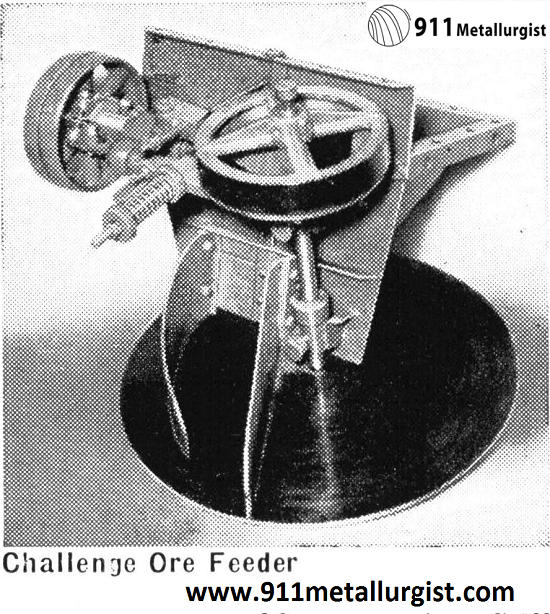

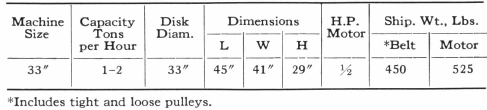

Challenge Ore Feeder

The Challenge Ore Feeder is built for low and moderately sized tonnages. Positive feeding of the ore is assured, as there are no gears or levers in the mechanism which account for lost motion and resulting irregular feed. The clutch mechanism is on the same shaft as the feed disk, and the hopper and disk are made of heavy steel plate. Specify correct hand when ordering. Drive is to a tight and loose pulley from the customer’s line shaft, or for a motor driven feeder a gear-motor can be mounted on a bracket in front of the ore bin.

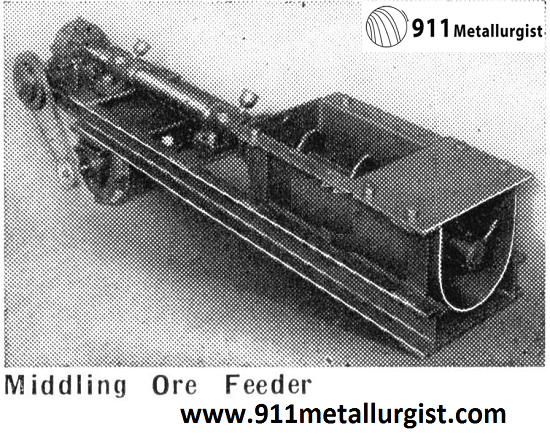

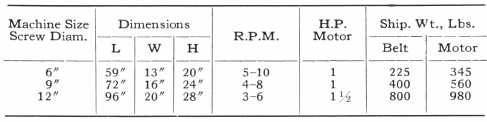

Middling Type Ore Feeder

The Middling Type Ore Feeder is an economical, simple unit for such operations as returning jig tailings or classifier sands to ball mill.

The unit consists of a trough in which a helix turns, forcing the ore out the end of the feed trough. Simple construction, minimum floor space, and ease of cleaning make the Ore Feeder an ideal unit for a great number of feeding problems. The rate of feed can be varied by simply changing either the motor or the reducer sheave. The length of the trough can be arranged to feed even dilute pulps or middling products. The helix is so constructed as to allow very rapid replacement, it being only necessary to remove two small bolts.

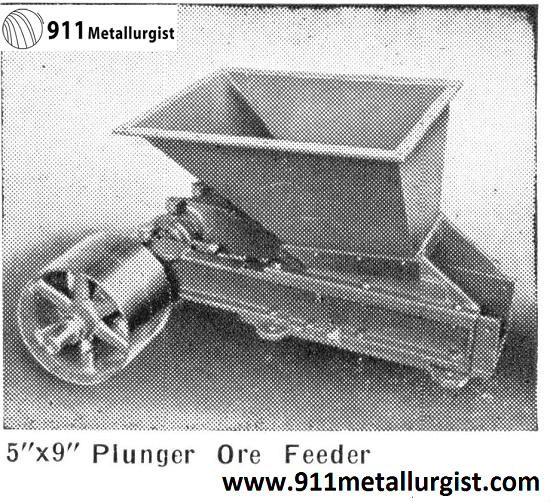

Plunger Ore Feeder

The Plunger Ore Feeder includes a strong cast iron frame supporting a small welded steel hopper, and the plunger bearing. The unit is built so that a feed chute can be easily attached to the discharge opening. The stroke is adjustable and can be regulated easily. These ore feeders are low priced and recommended for small tonnage.

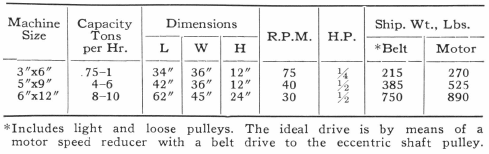

Adjustable-Stroke Variable Speed Belt Ore Feeder

When higher rates of feed than those supplied by the Adjustable-Stroke Belt Ore Feeder are required, or where the belt speeds range from 10 to 50 feet per minute the Variable Speed Ore Feeder has application.

The feeder is constructed the same as the Adjustable-Stroke Belt Ore Feeder except that a standard variable speed mechanism with reduction gears and constant-speed motor are used to drive the head shaft of the feeder. Any belt speed can be obtained

within a 2 to 1 speed variation by turning a handwheel mounted on the side of the variable speed transmission.

The photo shows a constant-speed belt ore feeder employing a constant-speed motor, direct coupled to a worm gear speed reducer which in turn drives the head shaft through a sprocket and roller chain drive. This type of feeder may also be used as a picking belt. Dimensions and shipping weight are the same as for the Adjustable Stroke Belt Ore Feeder.

Additional data gladly furnished upon request.

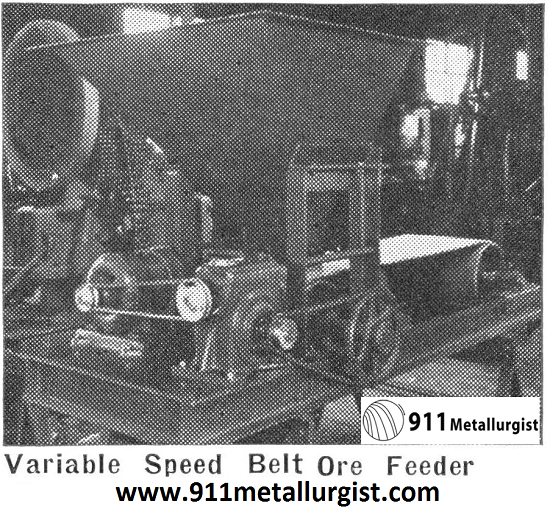

Hardinge Recording Feeder “Feedometer”

The Hardinge Recording Feeder feeds and weighs the material from a bin or surge hopper, and consists of a traveling belt on a pivoted frame suspended from the hopper. Any variation in weight on the belt will tilt the frame, thereby moving the feed gate through appropriate linkage. As the feed on the belt increases, the frame tilts down slightly and the feed gate opening is decreased. If the weight on the belt becomes less, the frame tends to rise and the gate opens wider. A constant weight is thus maintained regardless of conditions. A variable speed drive for the belt, is used to vary the rate of feed. Once set this feeder will maintain a constant rate of discharge by weight, irrespective of changes in character of the material being fed.

One or all of the following features may be incorporated:

- A visual feed rate indicating meter that reads direct in pounds, tons, kilograms per hour or other units.

- A totalizer that records cumulative weight fed and a reset recorder that totalizes batch or partial runs.

- A printing attachment that prints on a card the cumulative weight delivered in numerals, also a reset device for recording the batch weight and corresponding transaction or serial number. The card or paper slip on which the weights are recorded is locked in position during the run.

- A recording chart for the control room located at a distance from the feeder. This chart indicates the rate of feed and changes in rate fed. Each chart roll will make a record covering a month’s operation and is divided into hours and fractions thereof.

- Remote control of the feed rate and direct tonnage indicator of the feed rate in an infinite number of steps, through push button control and dial indicator

- Interlocking system for two or more feeders when used as proportioning devices to maintain a constant ratio of feed rates, with means to incorporate feed rate records of two or more feeders on the same chart.

- No-load cut-off attachment and signal to stop the feeder and prevent a false record being made when the feed bin becomes empty or the feed bridges over in the bin. When material again enters the feed hopper the feeder will start up automatically.

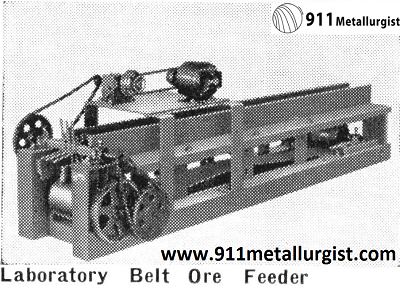

Laboratory Ore Belt Feeder

Feeding ore at the rate of 100 to 200 lbs. per hour requires very careful control for uniform results in continuous laboratory test work. Because of its accuracy the Laboratory Belt Ore Feeder is ideal for this application.

The step cone pulley drive provides means of changing belt speed skirt boards may be spaced any distance desired from center to edge of belt depth of material may be varied as spread on the belt. These three adjustments provide an easy means of regulating the feed rate to cover the normal capacity range required. Higher speed sheaves available to provide greater capacity.

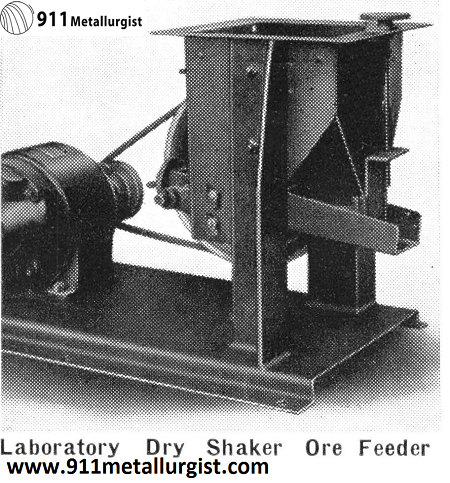

Laboratory Dry Shaker & Ore Feeder

Accurate tests often demand a constant, uniform feed of dry material. This is particularly true when feeding to a concentrating table or jig. The Laboratory Dry Shaker Ore Feeder is a simple, economical unit for these applications. The steep, sloping sides of the hopper drop the material to be fed onto a shaking pan feeder. The depth of the material on the pan is regulated by an adjustable gate, and speed of cam shaft and length of stroke of the shaking pan are also variable. This feeder is furnished for motor and V-belt drive, or for drive from a concentrating table.

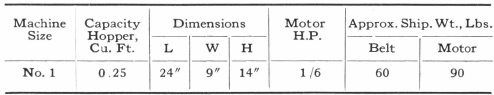

Capacity

Laboratory Hopper & Ore Feeder

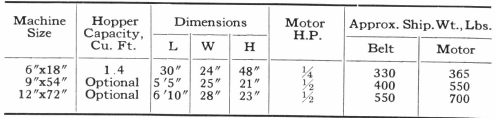

This all steel Laboratory Hopper Ore Feeder is particularly designed for use with the No. 5 and No. 7 “Sub-A” Continuous Laboratory Flotation Test Plants. It is of welded steel construction with speed reducer and motor on a single base.

As the hopper for feeding the ore is directly over the conveyor belt, it is often furnished as a single unit. The hopper is equipped with an adjustable gate to regulate the amount of ore fed to the belt. The hopper feeder and conveyor belt as a single unit is compact and easily portable and therefore may be readily moved to change direction of feed whenever desired.

Let us make recommendations for your feeder installation.

Capacity

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.