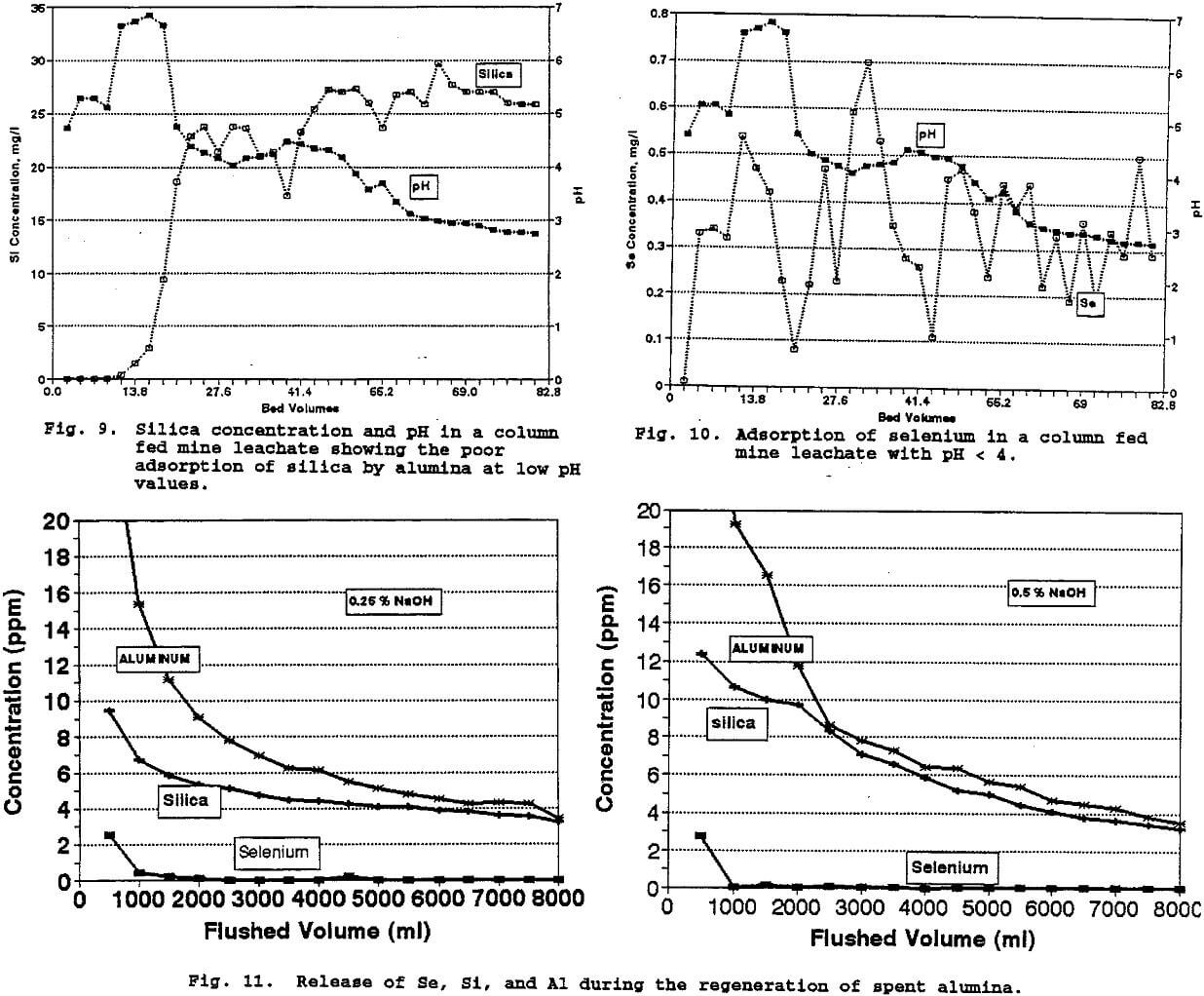

Regeneration of the spent alumina was accomplished by using 0.25% NaOH and 0.5% NaOH. Figure 11 shows the release of selenium, silica, and aluminum when regenerating the adsorption columns that had received the mine leachate. In this case, the regeneration was performed in an upflow mode using 30% bed expansion. As expected, the losses of aluminum during regeneration

increased with increasing NaOH strength. These results indicated that the removal of silica and selenium from the spent material was possible by using a NaOH concentrations as low as 0.25%. More selenium was released from fixed-bed columns receiving synthetic selenite solutions than from columns receiving synthetic solutions. Batch regeneration tests indicated that similar release of selenium could be accomplished with one hour of contact with a 0.25 % NaOH solution.