Preparing Flotation Reagents

The following flotation reagent mixing system is typical for the flotation reagent mixing systems: A-208, Xanthate and Sodium Silicate. The reagent mix tanks, for the above mentioned reagents, are located on the basement floor. Feed chutes from the main operating floor carry dry or wet reagents to each mix tank. Either reclaim or fresh water is […]

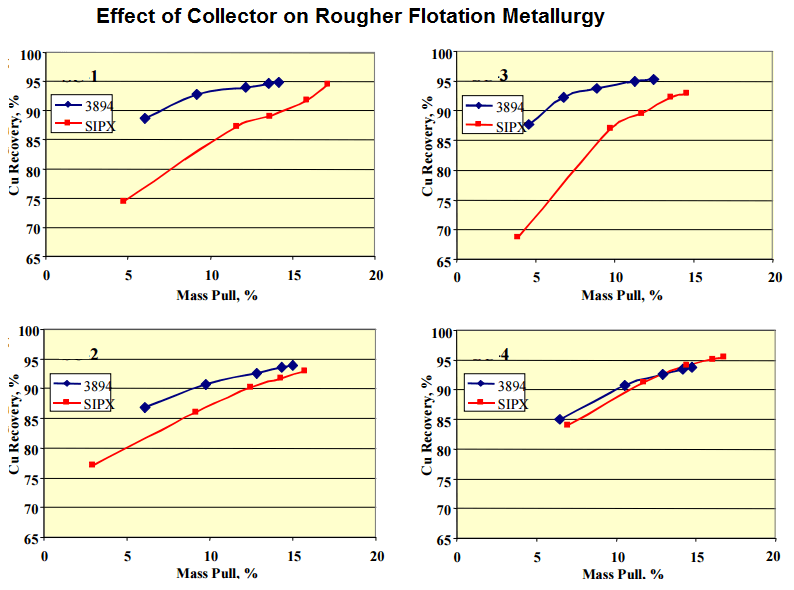

Effect of Collector on Copper Flotation Metallurgy

A pretty clean and relatively easy to treat ore was tested suggesting a collector optimization strategy would probably yield only relatively minor incremental metallurgical improvements. Therefore, collector suite fine-tuning was deemed largely better left for future optimization, possibly when the plant is in operation. In earlier studies Sumitomo had adopted the use of thionocarbamate Cytec […]

Flotation Collector Dosage – Collection of Froth

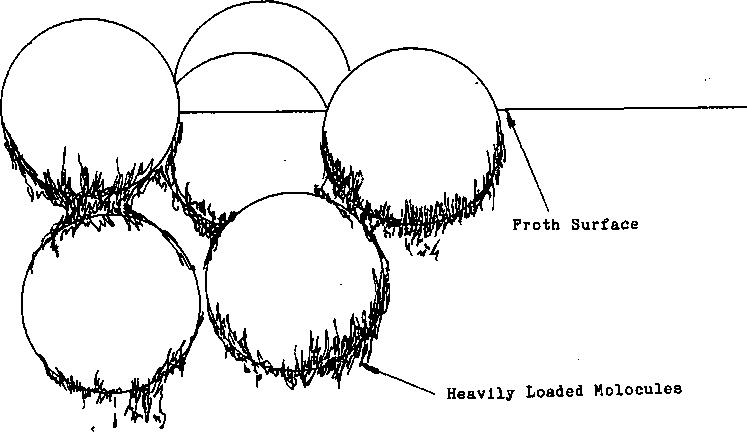

What happens when there is too much flotation collector, how do you know and how can to estimate? The bubble will react as if there is too little depressant. Froth bubbles will get smaller and closer together, but the unlike the depressant it won’t cause the mineral to fall off of the bubble due to overloading. […]

Flotation Collector Manufacturers

There are several Flotation Collector Manufacturers, but may half-a-dozen really good ones. What makes a quality may Flotation Collector supplier is the dependability and consistency of the product. Yes price matters but trusting what you buy it worth a few pennies extra. Now would you select as a Flotation Collector Manufacturer depends on what you need. If you need […]

Flotation Collectors

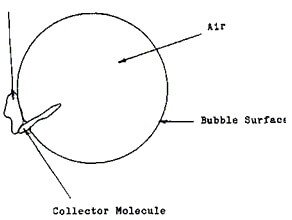

Simply said; a Flotation Collectors is a chemical used to make the surface of minerals, which is metallic, hydrophobic or in layman’s term ‘afraid of water’ or ‘water hating’ as others like to say. This chemical used will behaved, in a way, as a wax would when you applied it to your car. After wax (or […]

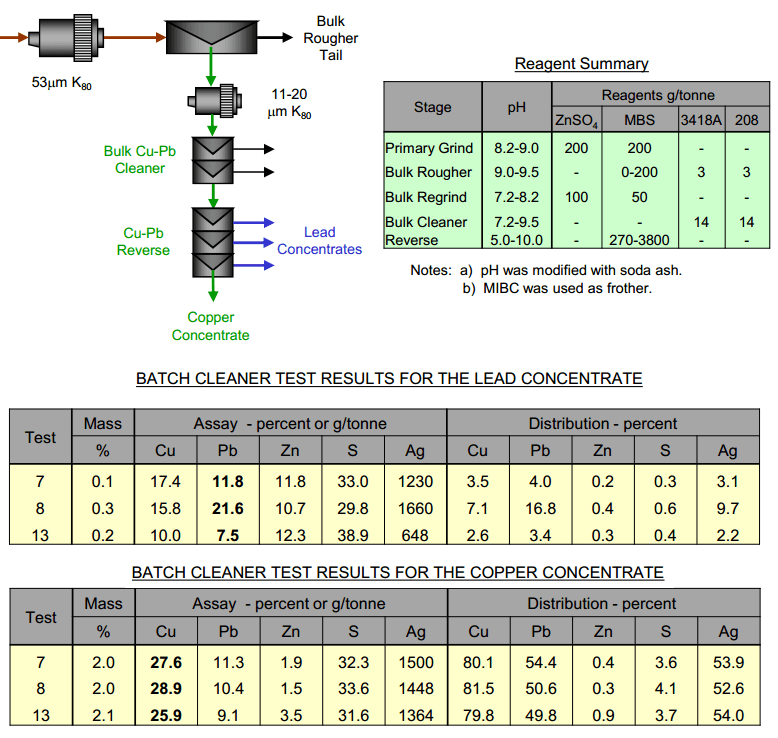

Lead Depression in Bulk Cu/Pb Flotation

A series of tests were completed with bulk copper and lead flotation with the depression of lead and flotation of copper. This alternative utilized MBS as the primary depressant in both the bulk and reverse circuits. The challenge of this scheme is that the lead concentrate will be the tailings of the reverse circuit and will likely […]

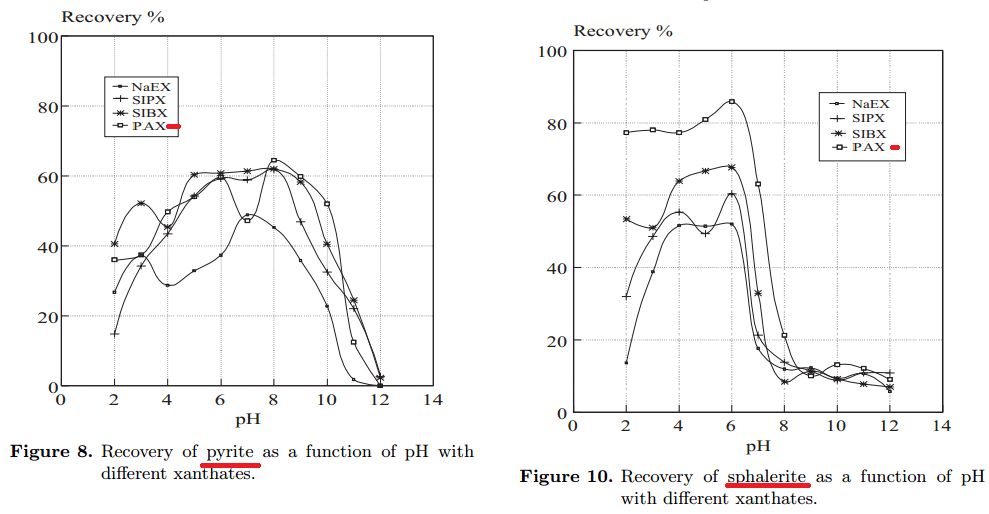

Types of Anionic Collectors of Sulphides

Collectors for sulphide minerals : Anionic collectors are most commonly used for sulphide minerals. By reference to the table (below) it will be note that they are all structurally similar, each having a single sulphur atom double bonded to either a carbon or phrosphorus atom, hence all of the sulphide minerals can be floated with […]

Collectors Strength – Xanthate Family – Recovery Power

A little about collector strength and Xanthates: Some call it selectivity, I call it “how much do you put on”. Even the most selective collector can be rendered un-selective it you add enough. In reverse order of strength (strongest to weakest): PAX SIBX SIPX SEX Methyl Xanthate (uncommon) More about the collecting power of xanthate and […]

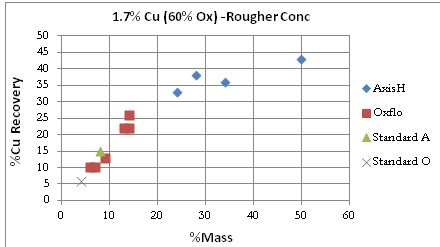

Compare Hydroxamate AM2 Rinkalore CTC3 Oxide Collectors

In this series of tests aimed to Compare Hydroxamate Collectors namely: AM2 Rinkalore and CTC3 we now conclude. All data indicate the CTC3 is a more selective reagent. In all tests, metallurgy was improved. Nowhere were the results produced by CTC3 inferior to AM2. Although AM2’s Lab Recoveries can look “attractive”, the AM2 reagent shows problematic […]

Oxide Flotation Collector | Collector for Copper Oxide Ore

In this flotation tests and evaluation for the best collector for copper oxide “ore” 911Metallurgy continues with material that’s 60% Oxide copper. Sample C: 1.7% Copper about 60% Oxide Cu Rougher Tests: Both reagents appear to behave similarly as the “blue dots” are seemingly a continuation of the trend started by “red dots”. Oxflo and Axis […]