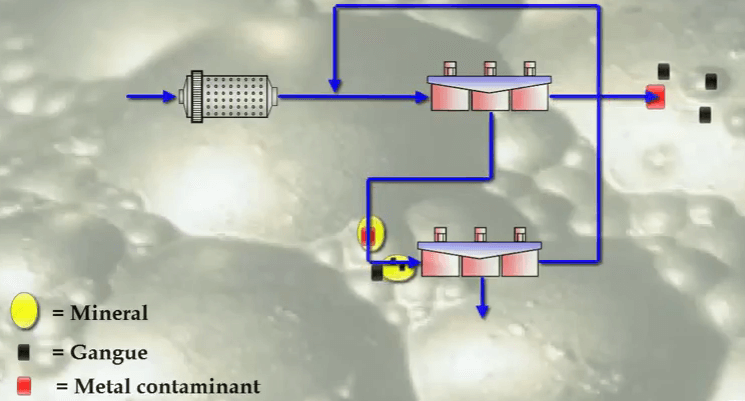

This covers the recovery of entrained solids with water and the relationship between mineralogy and flotation performance; both are described in terms of flotation kinetics. The starting points for the relationship between mass and water recovery other products of a flotation rate test.  In addition to concentrate mass, metal or mineral and floatable gangue. If the mass of water in each concentrate has been measured, then a fourth set of kinetics can be added which defines water recovery. This is useful if dealing with ultra-fine material or silicate gangue which has been recovered mainly by entrainment by water carry over to concentrate rather than being recovered by true flotation.

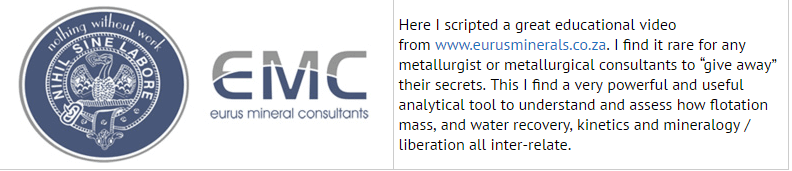

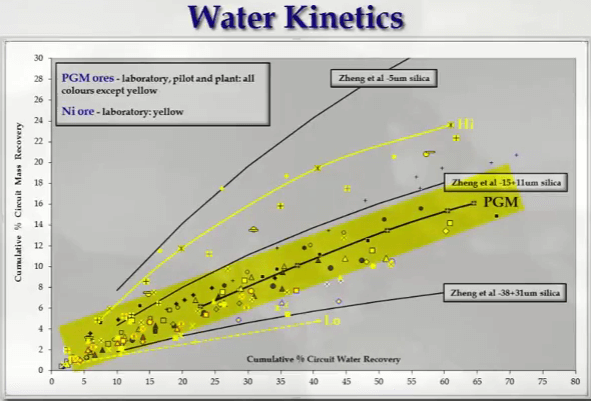

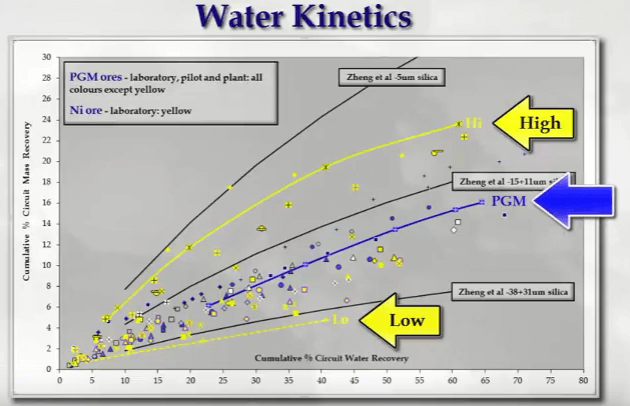

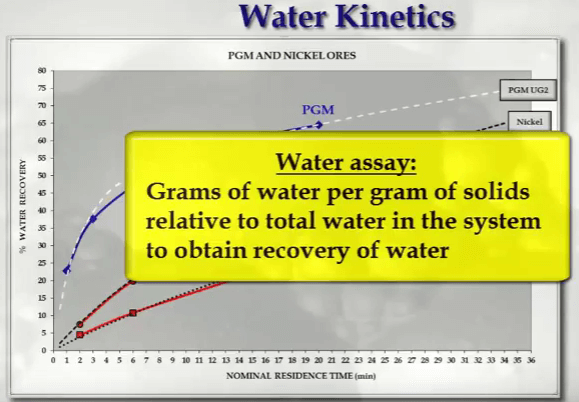

In addition to concentrate mass, metal or mineral and floatable gangue. If the mass of water in each concentrate has been measured, then a fourth set of kinetics can be added which defines water recovery. This is useful if dealing with ultra-fine material or silicate gangue which has been recovered mainly by entrainment by water carry over to concentrate rather than being recovered by true flotation.  Knowing the kinetics of water recovery is also useful as one means of classifying frothers. The graph shows the relationship between mass and water recovery for PGM ores in colours other than yellow and twenty two variability samples for a nickel ore in yellow.

Knowing the kinetics of water recovery is also useful as one means of classifying frothers. The graph shows the relationship between mass and water recovery for PGM ores in colours other than yellow and twenty two variability samples for a nickel ore in yellow.

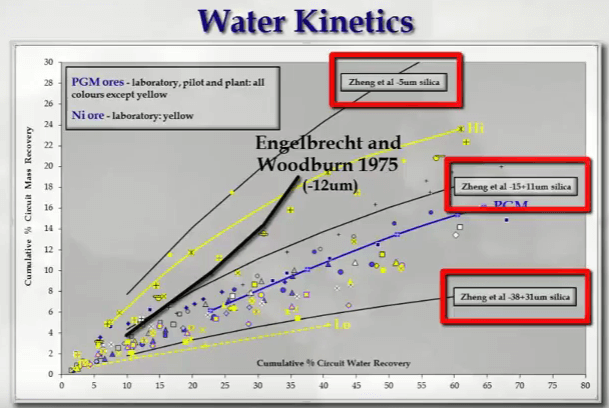

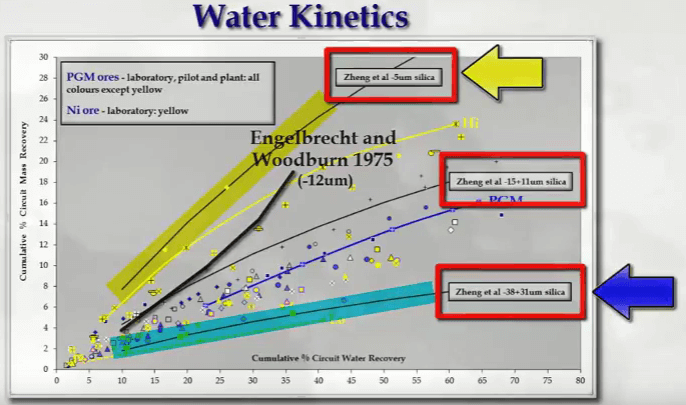

For reference, profiles for different silica size fractions from research conducted by Zheng in 2008 are included.

The mass recovery of less than five microns slimes due to entrainment is high. Where there’s recovery of the coarser is less than thirty eight plus thirty one micron fraction is much lower.  Where PGM data is fairly well bunched despite being sourced from laboratory pilot plant and main plant operations.

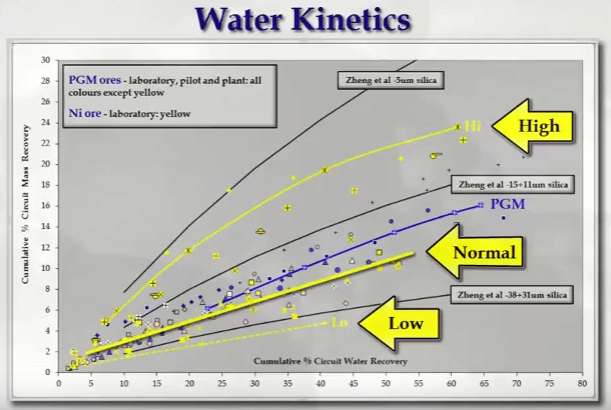

Where PGM data is fairly well bunched despite being sourced from laboratory pilot plant and main plant operations. It can be seen that the nickel samples are divided into ore types which have low, normal, and high gangue floatability.

It can be seen that the nickel samples are divided into ore types which have low, normal, and high gangue floatability.  Two profiles have been highlighted with low and high water and mass recoveries from the nickel deposit and the middle profile from the PGM ores.

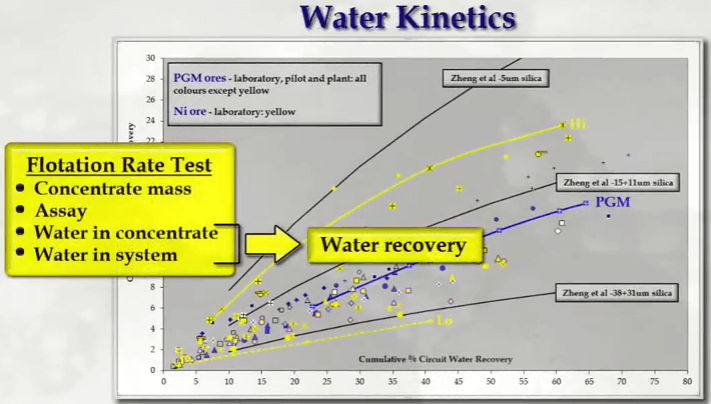

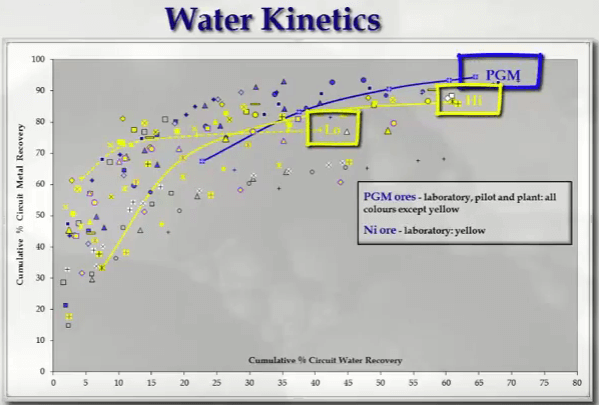

Two profiles have been highlighted with low and high water and mass recoveries from the nickel deposit and the middle profile from the PGM ores.  Here the same data are plotted as metal recovery against water recovery with the same nickel low, high and PGM middle profiles. The profiles are now in different positions relative to each other as the metal recoveries have different characteristics.

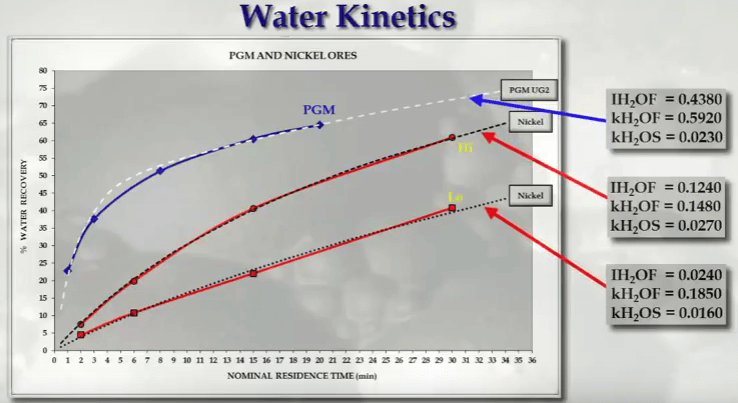

Here the same data are plotted as metal recovery against water recovery with the same nickel low, high and PGM middle profiles. The profiles are now in different positions relative to each other as the metal recoveries have different characteristics.  Water recovery with time is plotted together with the predicted profiles and broken lines obtained by putting the water kinetics into the equation.

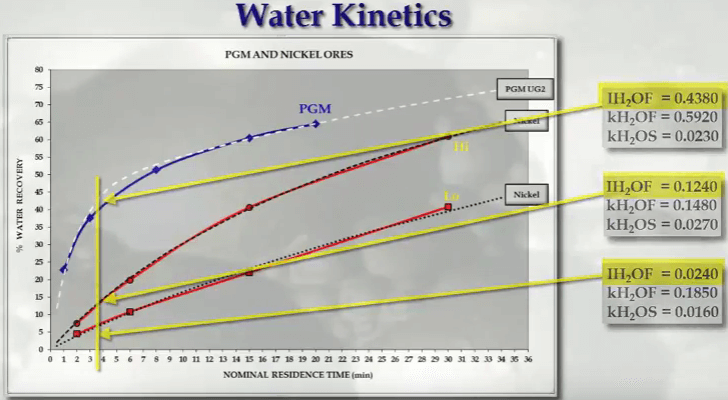

Water recovery with time is plotted together with the predicted profiles and broken lines obtained by putting the water kinetics into the equation.  Note the fast learning fractions are in line with water recovery with lowest fast floating water fraction corresponding to lowest water recovery.

Note the fast learning fractions are in line with water recovery with lowest fast floating water fraction corresponding to lowest water recovery. To calculate the kinetics of water, an assay is required the same as for metals and other elements. This is simply expressed as grams of water per gram of solid in each concentrate and tailings or the percentage of water in the pulp.

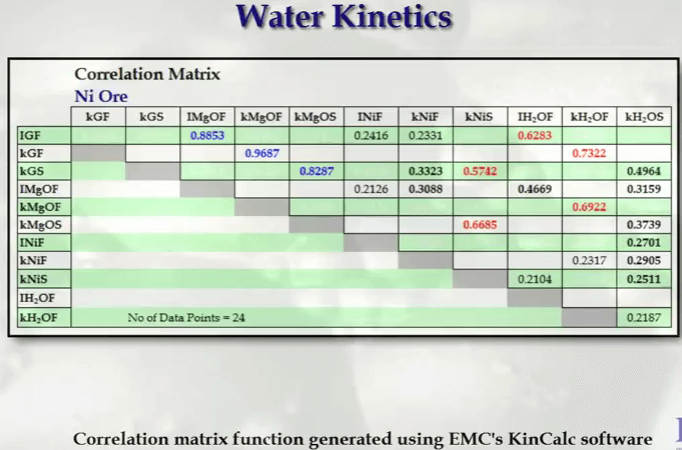

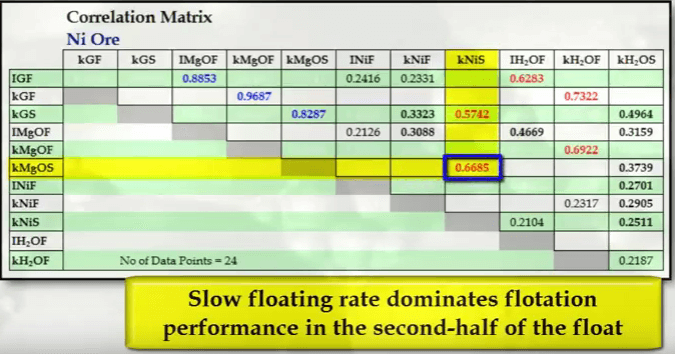

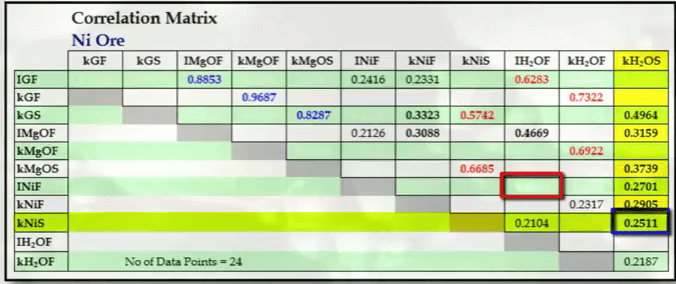

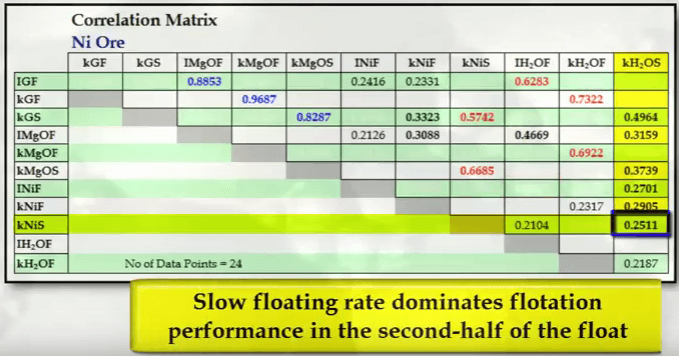

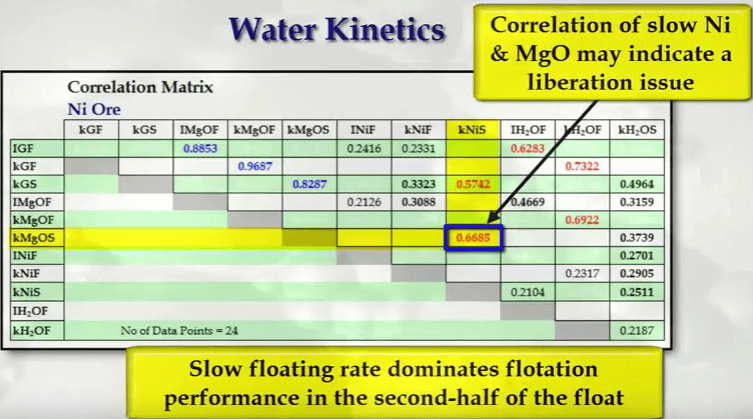

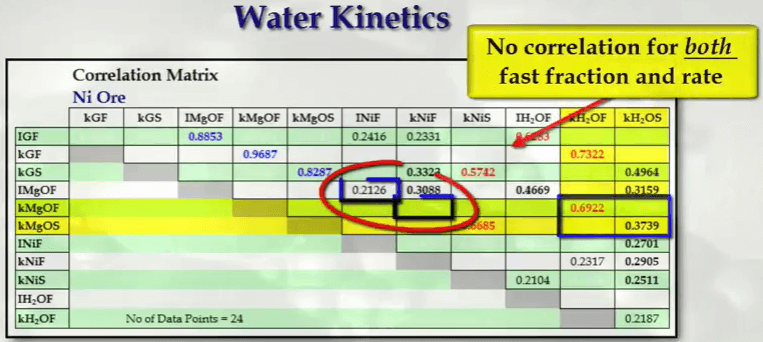

To calculate the kinetics of water, an assay is required the same as for metals and other elements. This is simply expressed as grams of water per gram of solid in each concentrate and tailings or the percentage of water in the pulp.  To illustrate the value of determining water kinetics; kinetic data from a nickel or which has been ground to 80% passing 53 microns has been correlated. I squared correlations less than zero point two has been blanked out.

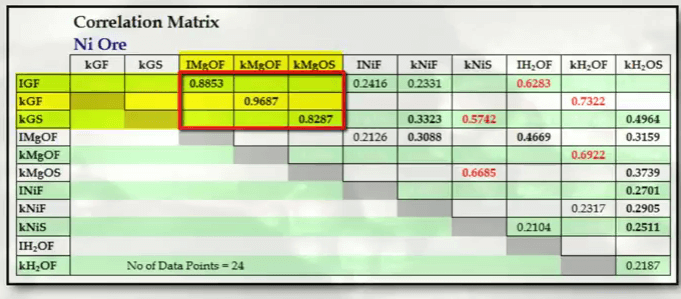

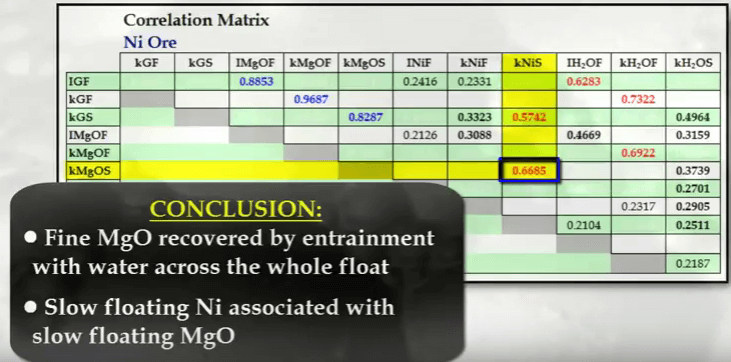

To illustrate the value of determining water kinetics; kinetic data from a nickel or which has been ground to 80% passing 53 microns has been correlated. I squared correlations less than zero point two has been blanked out.  There are high correlations between MgO. and gangue because MgO makes up a large part of floatable gangue. The correlations between MgO and water are significant and spread across fast and slow floating components.

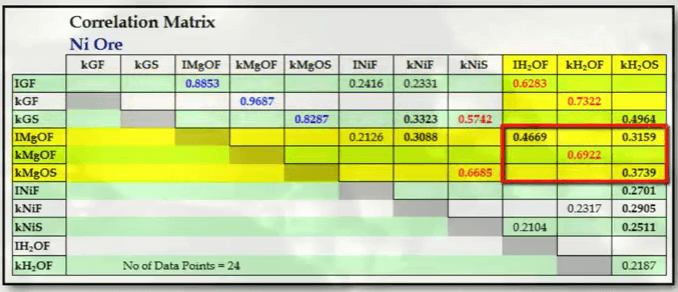

There are high correlations between MgO. and gangue because MgO makes up a large part of floatable gangue. The correlations between MgO and water are significant and spread across fast and slow floating components.  Nickel and water has no correlation for fast loading fraction but this correlate weakly for slow floating rate.

Nickel and water has no correlation for fast loading fraction but this correlate weakly for slow floating rate.  So it seems slow floating nickel is being pulled over with water at the end of the float.

So it seems slow floating nickel is being pulled over with water at the end of the float.  However there is a high correlation between slow floating nickel and MgO.

However there is a high correlation between slow floating nickel and MgO.  So it is evident that slow floating nickel is actually being recovered with slow floating MgO and this could indicate a liberation issue.

So it is evident that slow floating nickel is actually being recovered with slow floating MgO and this could indicate a liberation issue.

Reasonable correlations are seen for both fast and so floating MgO versus water.  There is not a correlation between fast floating nickel and MgO but there is between their slow floating rates.

There is not a correlation between fast floating nickel and MgO but there is between their slow floating rates.

So the conclusion is that fine MgO is being recovered by and entrainment with water across the whole float.

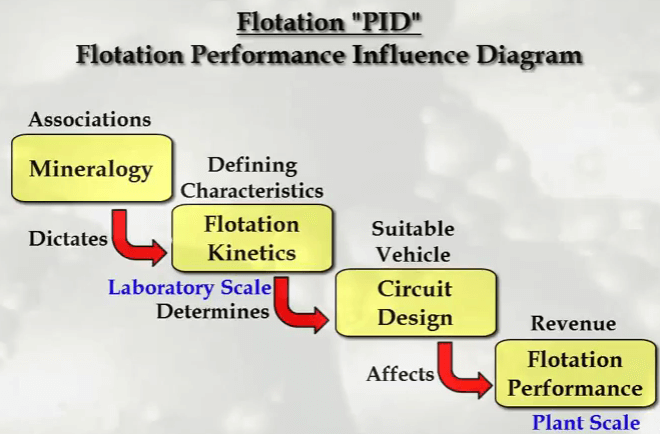

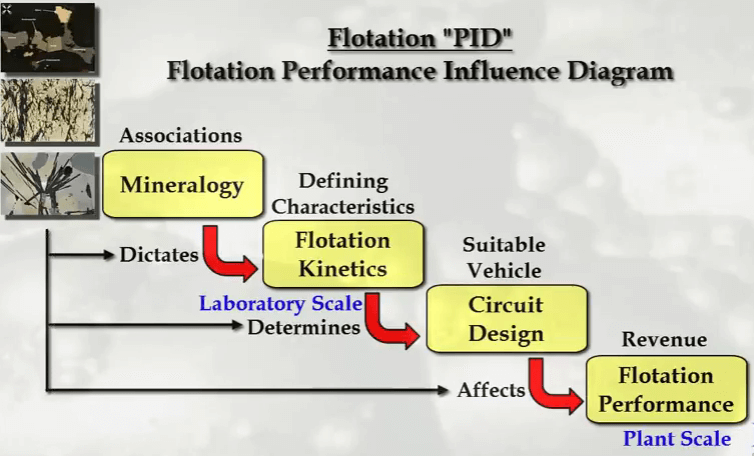

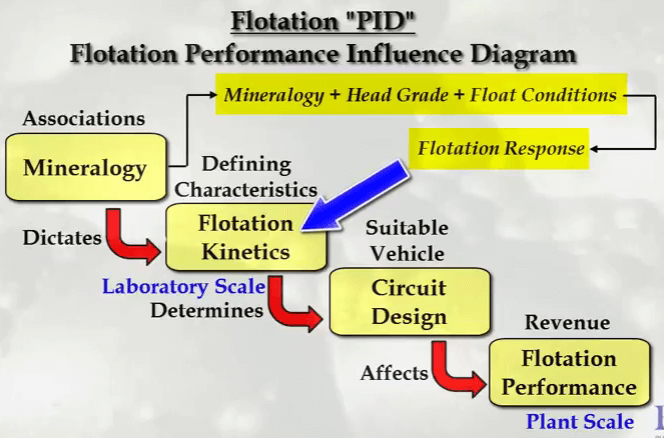

And slow floating nickel is being recovered due to association with MgO and not as a result of entrainment with water.  How kinetics fit into the overall picture of testing and characterizing a new ore through to plant scale performance and concentrate production is illustrated by the flotation performance influence diagram referred to as the flotation PID.

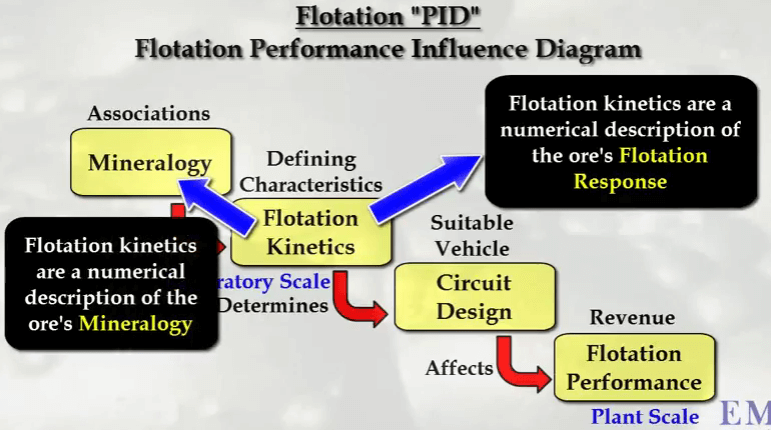

How kinetics fit into the overall picture of testing and characterizing a new ore through to plant scale performance and concentrate production is illustrated by the flotation performance influence diagram referred to as the flotation PID.

Mineralogy measures liberation characteristics and any mineral to mineral and mineral to gangue associations. This gives an indication of how well or how poorly an ore will float. Recovery grade rotation performance is determined by the ores head grade and mineralogy.  Flotation batch and rate tests measure this performance and express it as a set of numbers which are the flotation kinetics of Fast and Slow fraction and rate.

Flotation batch and rate tests measure this performance and express it as a set of numbers which are the flotation kinetics of Fast and Slow fraction and rate.  Flotation kinetics are therefore a numerical description of the ore’s flotation behavior and also a simplified numerical description of the ore’s mineralogy.

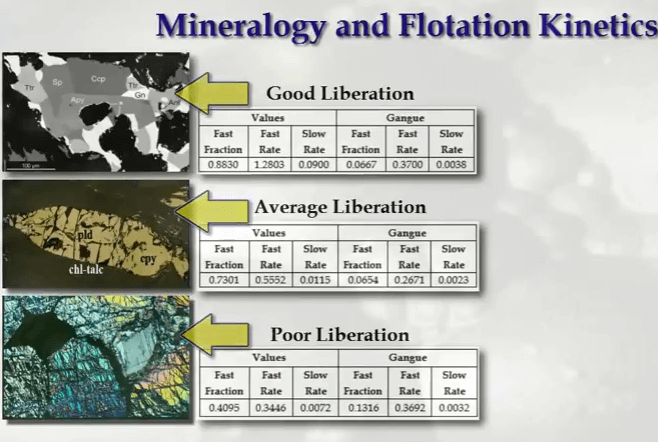

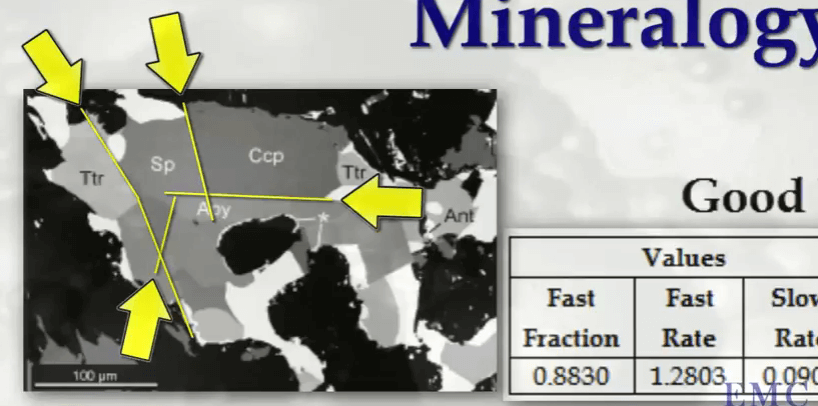

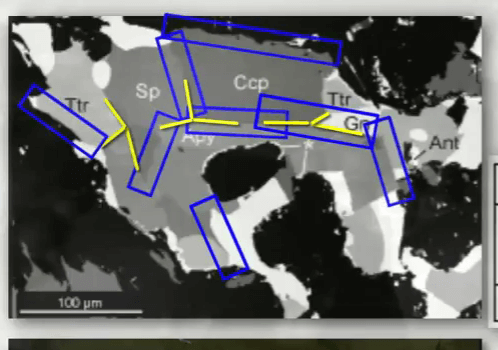

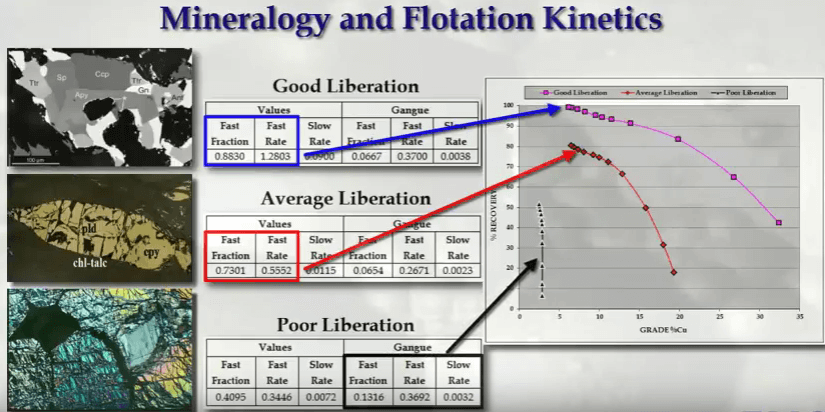

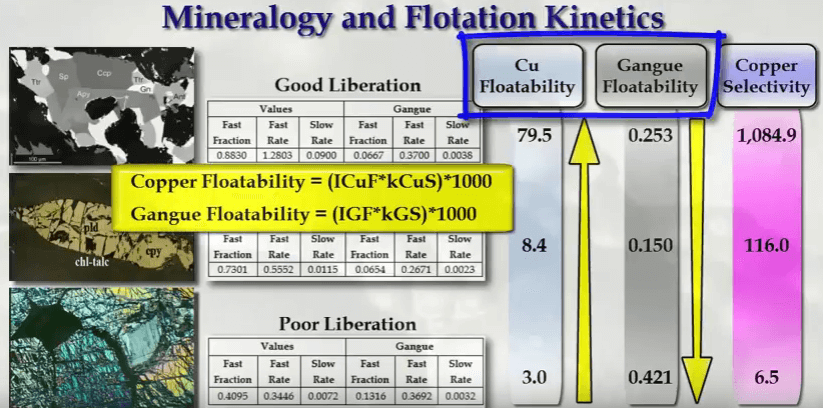

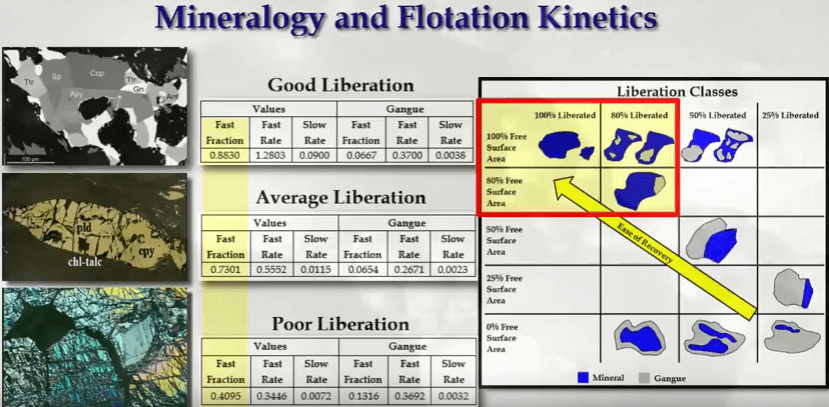

Flotation kinetics are therefore a numerical description of the ore’s flotation behavior and also a simplified numerical description of the ore’s mineralogy.  Here are examples of base metal ores with a degree of liberation is good, average and poor. Sphalerite, Chalcopyrite and Galena are large grains with distinct and straight boundaries between each other and between mineral and gangue.

Here are examples of base metal ores with a degree of liberation is good, average and poor. Sphalerite, Chalcopyrite and Galena are large grains with distinct and straight boundaries between each other and between mineral and gangue.  The presence of triple point junctions is characteristic of an ore which liberates well.

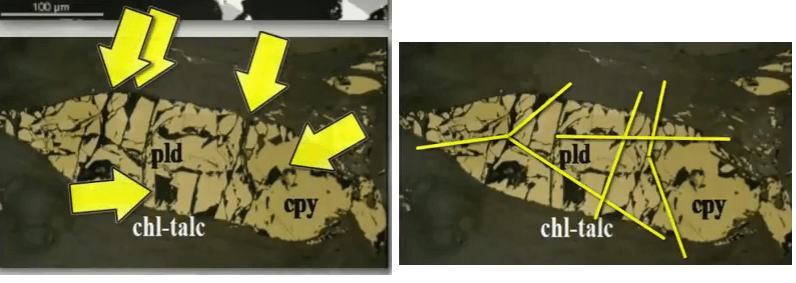

The presence of triple point junctions is characteristic of an ore which liberates well.  On milling, fracture will preferentially occur along the weakest points which are the grain boundaries resulting in a high degree of liberation of mineral. A slightly altered ore has some chloride and talc into growth which has broken up pentlandite and chalcopyrite minerals.

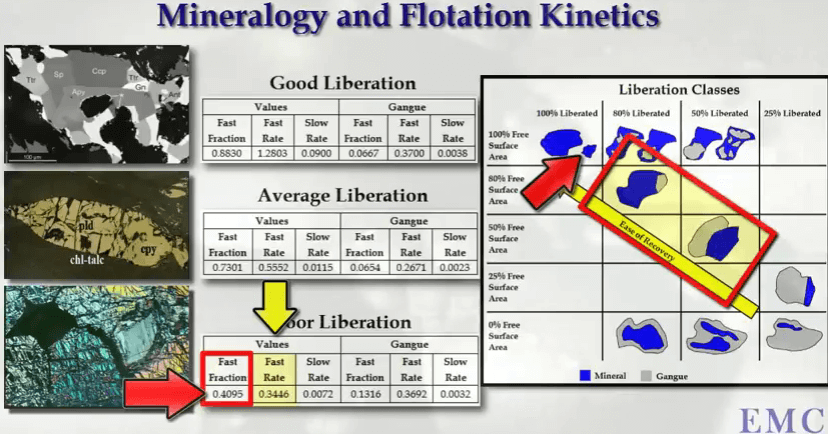

On milling, fracture will preferentially occur along the weakest points which are the grain boundaries resulting in a high degree of liberation of mineral. A slightly altered ore has some chloride and talc into growth which has broken up pentlandite and chalcopyrite minerals. Fracture will occur across boundaries and result in some mineral gangue associations. Finally, in a highly altered ore mineral has been severely intergrown by gangue.

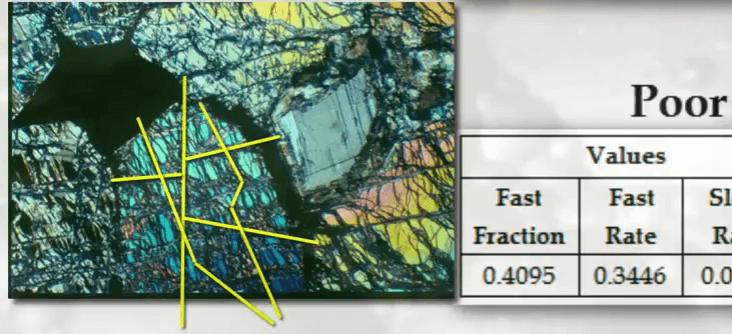

Fracture will occur across boundaries and result in some mineral gangue associations. Finally, in a highly altered ore mineral has been severely intergrown by gangue.  Milling will generate few liberated mineral particles which in any case will be fine and there for slow floating. With the majority of particles being a mixture of mineral gangue associations and liberated gangue.

Milling will generate few liberated mineral particles which in any case will be fine and there for slow floating. With the majority of particles being a mixture of mineral gangue associations and liberated gangue. For this example, I’ve given each ore a head grade of one per cent copper and generated recovery grade profiles by inputting the kinetics into the equation. The kinetics are descriptive of floatation performance.

For this example, I’ve given each ore a head grade of one per cent copper and generated recovery grade profiles by inputting the kinetics into the equation. The kinetics are descriptive of floatation performance.  Better liberation and high recovery of mineral is described by high fractions and rates. Similarly, very floatable gangue which results in low upgrading and concentrate grade is described by high fractions and rates of gangue.

Better liberation and high recovery of mineral is described by high fractions and rates. Similarly, very floatable gangue which results in low upgrading and concentrate grade is described by high fractions and rates of gangue.  For convenience both recovery grade profiles and kinetics can be evaluated on a relative basis using a single metric of floatability.

For convenience both recovery grade profiles and kinetics can be evaluated on a relative basis using a single metric of floatability.  Combine the two including fast floating rate and a measure of copper selectivity relative to floatable gangue is obtained. Flotation kinetics is also a numerical description of the ore’s liberation characteristics of both mineral and gangue.

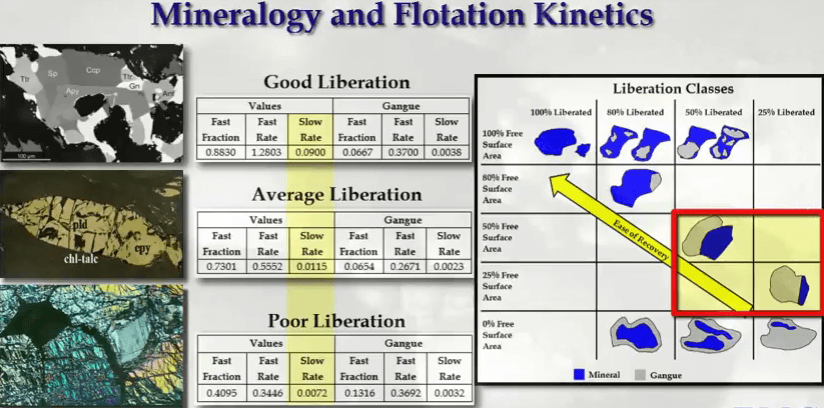

Combine the two including fast floating rate and a measure of copper selectivity relative to floatable gangue is obtained. Flotation kinetics is also a numerical description of the ore’s liberation characteristics of both mineral and gangue.  The fast floating fraction is a proportion of feed material that is 80% liberated with 80% free surface area or better; this applies to metal mineral and gangue.

The fast floating fraction is a proportion of feed material that is 80% liberated with 80% free surface area or better; this applies to metal mineral and gangue.  The low value of fast fraction for the highly altered ore means not only that the proportion of 100% liberated materials is less, but also since a fast floating rate is similarly very low but this fraction most likely consists of fines which are slow floaters as well as more material across these two classifications.

The low value of fast fraction for the highly altered ore means not only that the proportion of 100% liberated materials is less, but also since a fast floating rate is similarly very low but this fraction most likely consists of fines which are slow floaters as well as more material across these two classifications.  The slow floating rate depends on the characteristics of material in this section of the liberation classes. This ends the short course on the relationship of flotation kinetics with entrainment and mineralogy. Next in the series will be the basics of using flotation kinetics to diagnose, understand and optimize floatation performance.

The slow floating rate depends on the characteristics of material in this section of the liberation classes. This ends the short course on the relationship of flotation kinetics with entrainment and mineralogy. Next in the series will be the basics of using flotation kinetics to diagnose, understand and optimize floatation performance.