Weights of Minerals and Materials

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.

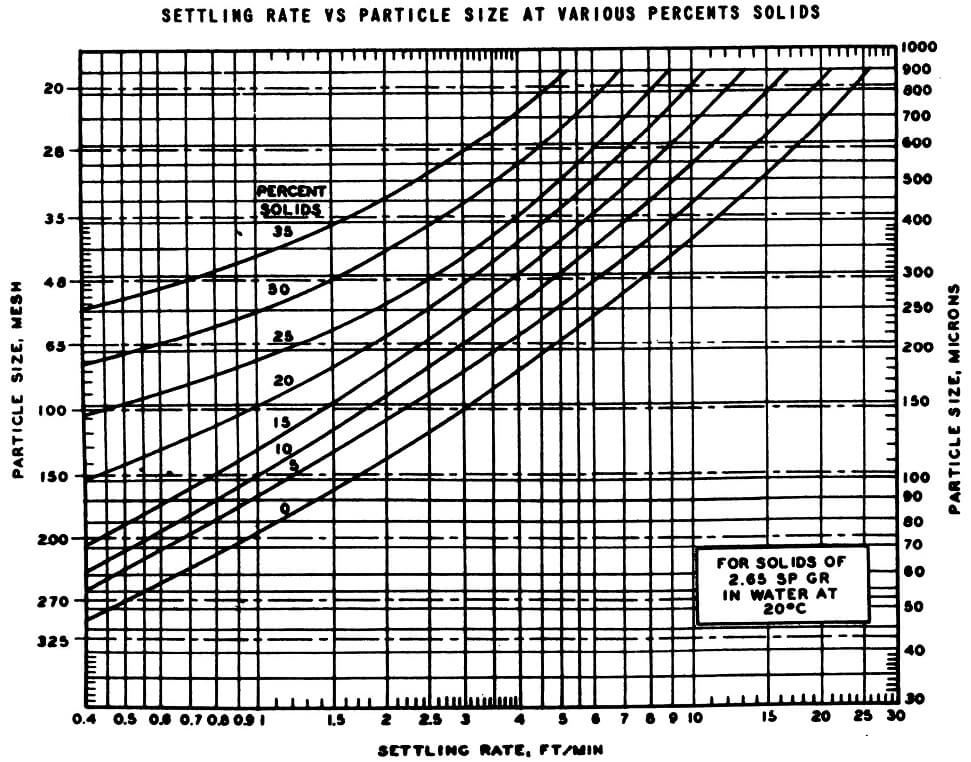

What is the Settling Rate by Particle Size at Various % Solids Density

Settling Rate by Particle Size

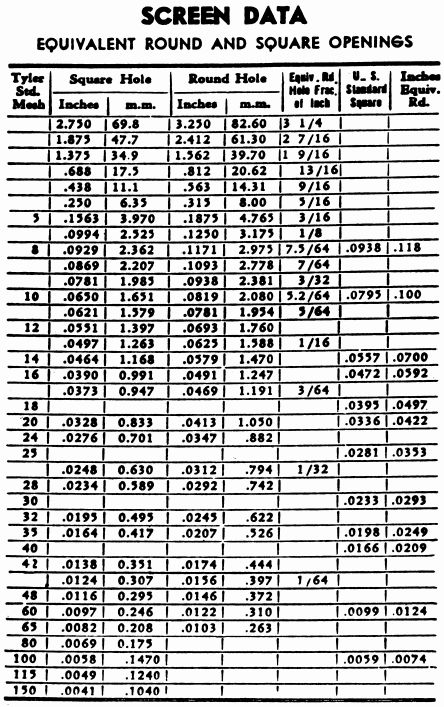

Equivalent Round and Square Screen Openings

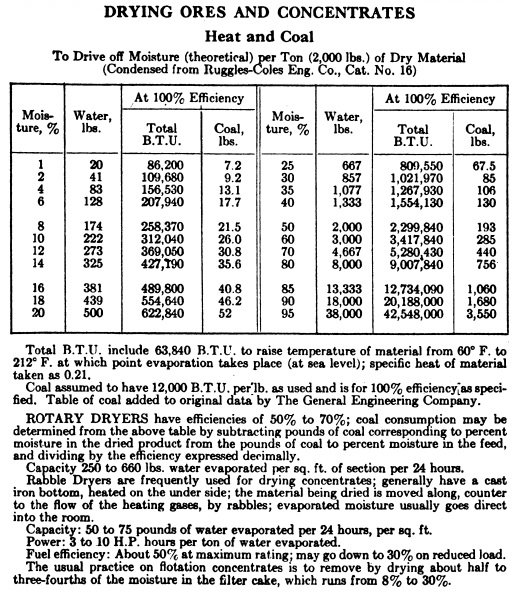

BTU Energy Required to Dry Ores and Concentrates

To Drive off Moisture (theoretical) per Ton (2,000 lbs.) of Dry Material. Total B.T.U. include 63,840 B.T.U. to raise temperature of material from 60° F. to 212° F. at which point evaporation takes place (at sea level); specific beat of material taken as 0.21. Coal assumed to have 12,000 B.T.U. per’lb. as used and is […]

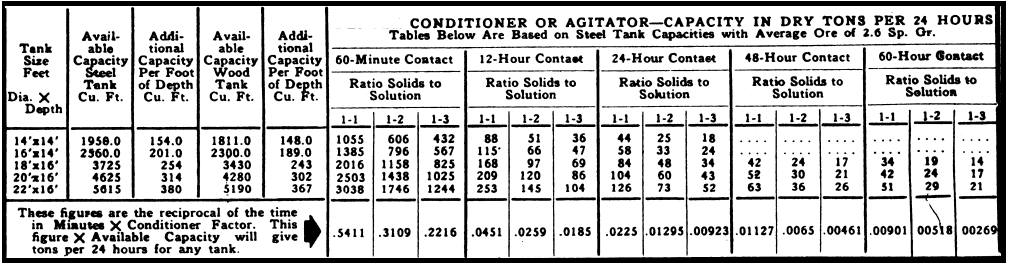

Calculate the Capacity of an Agitator & Conditioner

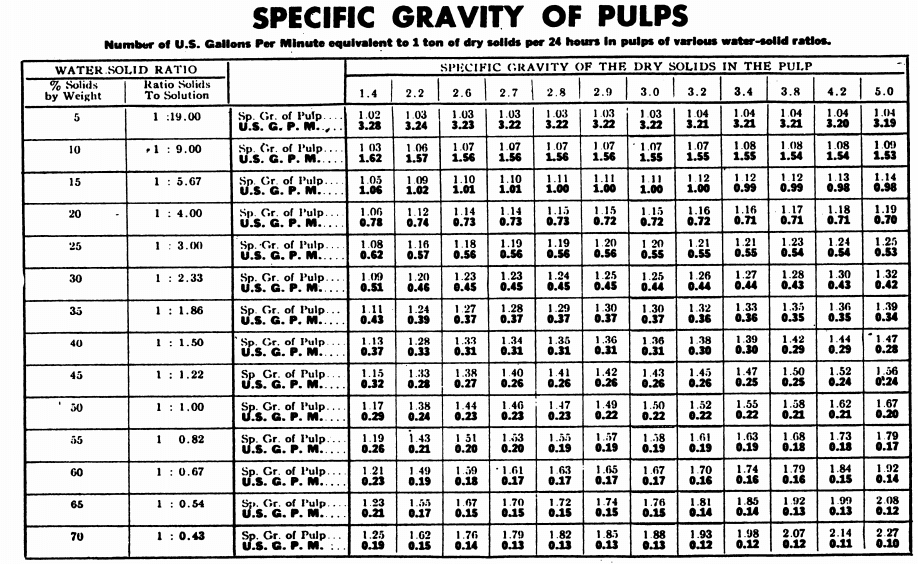

Example 1) It is desired to give 48 hours of contact on 100 tons per 24 hours of 2.7 specific gravity ore in a pulp of 40% solids (1:1.5). What size agitators will be needed? Total volume equals 59.85 –> from our Pulp Density tables. Tons feed equal 100. 59.85 time 100 equals 5,985 cu. ft. (total […]

Mineral Processing Pulp Density Charts and Tables

Reproduced from Denver Equipment Handbook

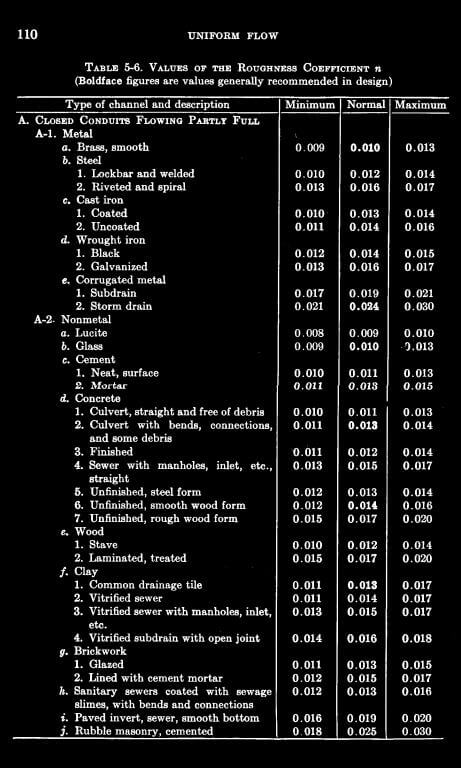

Hydraulics and Fluid Dynamics Tables and Charts

Handbook of Tables for Applied Engineering Science + CRC Handbook of Tables for Applied Engineering Science

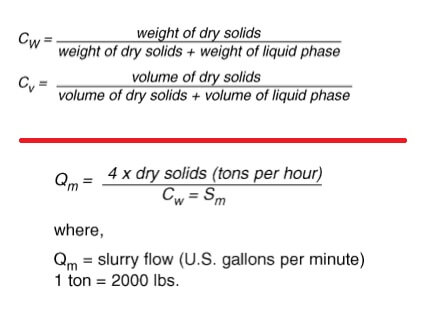

Calculate Slurry Flow / Volume

An example of how you can calculate the slurry flow/volume of a given SG, %Solids and Tonnage. EXAMPLE: 3,400 tons of dry solids is processed in 24 hours in water with a specific gravity of 1.0 and the concentration of solids by weight is 33% with the solids having a specific gravity of 3.7 then […]