Talc Market Specifications

Talc has a wide variety of uses and markets, specifications for which call for certain standards of grain size, shape, color, chemical and mineral composition, weight per unit volume, oil absorption and hardness.

The paint industry is by far the largest user of talc, but the roofing, ceramics, paper, rubber, cosmetics, textile and insecticide industries are important consumers.

For paint 98.5 to 99.5 per cent minus 325 mesh particle size is commonly desired and a Gardner-Coleman oil-absorption test range of 30 to 60.

Production Problems

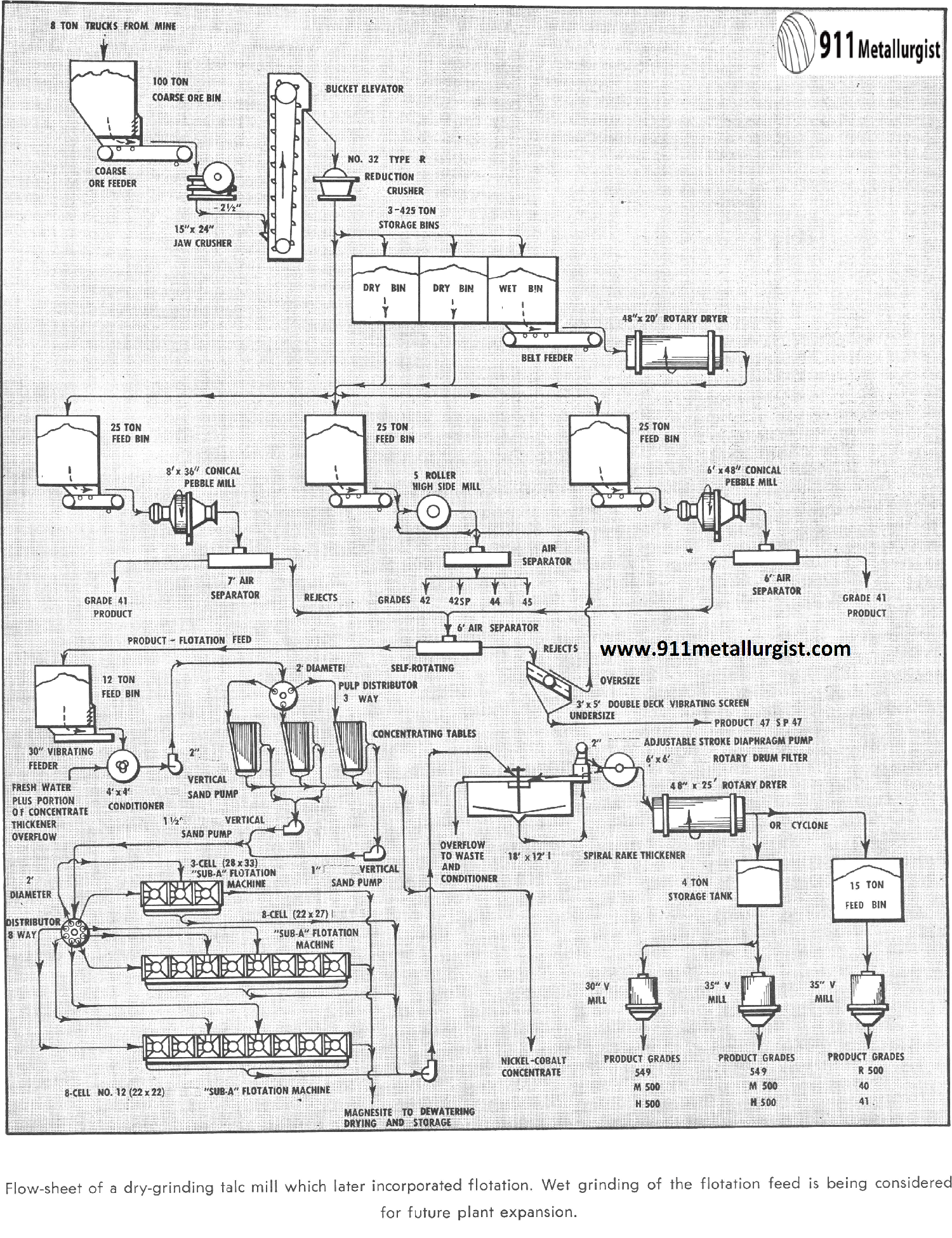

Much of the talc marketed is produced from the crude ore by dry grinding and air classification. Where, however, a talc of exceptionally high purity is desired it can best be produced by flotation. In this case, the cost of drying the concentrate and preparing it for market is the chief concern of the operator.

Reagent Combinations

A wetting agent, such as alkyl sodium sulfonate, made from petroleum products is generally used to float talc from tremolite and silica. Sodium silicate is sometimes used as a slime dispersant.

Talc: Part of 19 “Sub-A” Flotation Cells floating talc. Result: A concentrate approximately 94% talc produced at the rate of ¾ tons per hour. Flotation produces a uniformly pure product at a low cost per ton of ore processed and in addition recovers talc which cannot normally be recovered by dry processes.