The Integral Lift Vertical Worm Gear-Box Speed Reducer is used on Center and Side Air-lift Agitators, Hydroclassifiers, and on thickeners in many mills and industrial plants where it is necessary to have a simple, compact, totally – enclosed, self-lubricated reduction unit. This unit is widely used to step down speeds of high-speed motors to the slow speed required by many ore dressing and industrial machines. It has particular application on mechanisms where a positive lifting device is necessary to prevent the stirring arm, or rakes, from sticking due to rapid settling of solids during power interruptions or overloads. Other uses are for metal skimming, mixing, blending, dissolving, emulsifying, saponifying, sulphonating, causticising, washing, scrubbing, and many other uses.

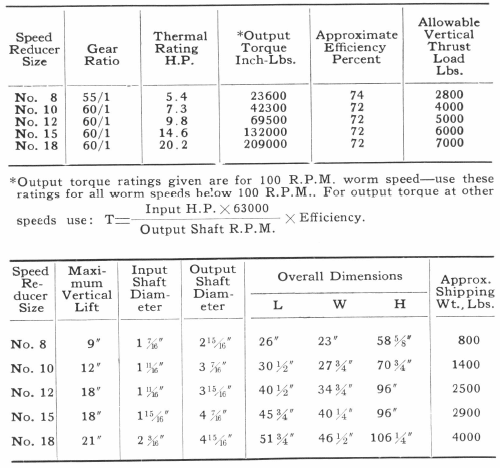

A high-grade bronze is used in the machined, cut-tooth, worm gear and the worm and worm shaft are machined from an alloy steel shaft—hardened, ground, and polished. The worm ring gear is bolted to the quill which transmits the torque to a splined vertical output shaft. The output shaft may be raised or lowered by means of a handwheel located on the top of the gear case. Oversize tapered roller bearings assume vertical loads, while ball bearings on the worm shaft take thrust loads in either direction as well as radial loads. Ample use of leather oil seals prevents oil leakages and protects the bearings from dirt. All parts are precision machined to close tolerances, and wearing parts are generously lubricated to give long wearing life and freedom from repairs. This is important in helping to keep costs low in plants where several units may be used on various machines.

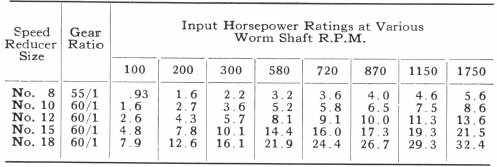

The horsepower ratings given in the table below are for service with 8 to 10 hours duty, and free from recurrent shock loads. For service with 8 to 10 hours duty where recurrent shock loads occur or 24 hour service where no shock loading is experienced, the horsepower ratings must be reduced by dividing by 1.2. For service with 24-hour shock load duty, the horsepower ratings must be reduced by dividing by 1.33. For operation requiring intermittent service where the maximum cycle of operation calls for not more than 15 minutes running in a two-hour period, the horsepower ratings may be divided by 0.7. In no case must the thermal rating be exceeded.