In addition to the operational issues of dust control, confined spaces electrical dangers and poor visibility that we’ve discussed in the previous topic there are two other dangers that are every present in underground environments. These are risks due to rock fall and due to water in flow. In this topic, we’ll have a look at how these are managed, when underground openings are created, it inevitable that loose fragments will remain barely attached to the rock faces. In some cases, these are small and isolated and unrelated to the overall stability but in others they may involve some or all of the rock surrounding the opening. In module two, you were introduced to the rock and rock mass characteristics that are important to the design and construction of underground openings. In this topic we’ll have a look at how these relate to underground mining. The most common situation leading to loose rocks in an underground mine is that of over break during blasting. Ideally, a blast will break up the rock you want to remove but not affect the rock you want to leave behind. Unfortunately, this easier said than done. Inevitably, there are rock fragments that hang up for some period of time after the mac has been removed. The occurrence of loose rocks is generally lower in mines where the rocks are cut rather than blasted. That is cut with a road hitter. Rocks can fall under the action of gravity in any underground space but the risk of rocks falling increases as the depth of mining increases. This is because as we learned in module two the stresses in the ground are redistributed when an opening in the ground is made. This can mean that a loose rock fragment is detached or it can mean that rock fragments are produced from the faces of the excavation. In extreme circumstances in very deep mines, there can even be rock fragments detached from vertical surfaces in mines. The hazards posed by falling rocks are managed by bolting, meshing and track grading and we’ll talk about these shortly. Ideally, openings in underground mines are designed taking account of rock strength and rock mass structure to be inherently stable. However, sometimes they are prone to collapse particularly when for example the unexpectedly bad conditions are encountered. In these situations, it may be necessary to reinforce the roof using bolts or tendons. The purpose of a bolt is not to attach loose rock fragments to the rocks above but to lock the rocks in the roof together so that they act as a beam capable of expanding the opening.

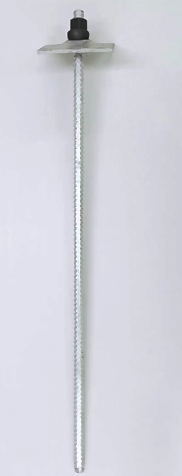

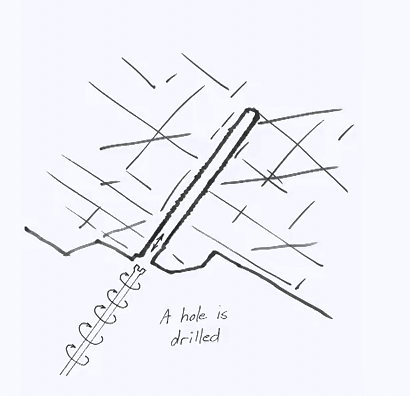

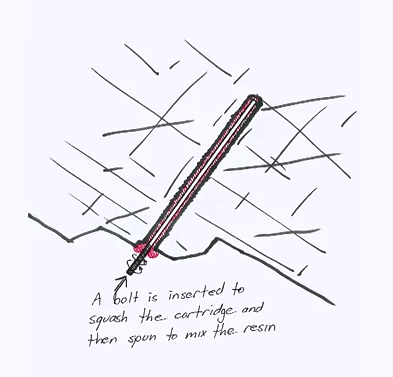

In addition to the operational issues of dust control, confined spaces electrical dangers and poor visibility that we’ve discussed in the previous topic there are two other dangers that are every present in underground environments. These are risks due to rock fall and due to water in flow. In this topic, we’ll have a look at how these are managed, when underground openings are created, it inevitable that loose fragments will remain barely attached to the rock faces. In some cases, these are small and isolated and unrelated to the overall stability but in others they may involve some or all of the rock surrounding the opening. In module two, you were introduced to the rock and rock mass characteristics that are important to the design and construction of underground openings. In this topic we’ll have a look at how these relate to underground mining. The most common situation leading to loose rocks in an underground mine is that of over break during blasting. Ideally, a blast will break up the rock you want to remove but not affect the rock you want to leave behind. Unfortunately, this easier said than done. Inevitably, there are rock fragments that hang up for some period of time after the mac has been removed. The occurrence of loose rocks is generally lower in mines where the rocks are cut rather than blasted. That is cut with a road hitter. Rocks can fall under the action of gravity in any underground space but the risk of rocks falling increases as the depth of mining increases. This is because as we learned in module two the stresses in the ground are redistributed when an opening in the ground is made. This can mean that a loose rock fragment is detached or it can mean that rock fragments are produced from the faces of the excavation. In extreme circumstances in very deep mines, there can even be rock fragments detached from vertical surfaces in mines. The hazards posed by falling rocks are managed by bolting, meshing and track grading and we’ll talk about these shortly. Ideally, openings in underground mines are designed taking account of rock strength and rock mass structure to be inherently stable. However, sometimes they are prone to collapse particularly when for example the unexpectedly bad conditions are encountered. In these situations, it may be necessary to reinforce the roof using bolts or tendons. The purpose of a bolt is not to attach loose rock fragments to the rocks above but to lock the rocks in the roof together so that they act as a beam capable of expanding the opening.  This operation is called roof support or strata control. Rock bolting involves installation of a bolt usually steel or fiber glass into a hole drilled in the rock mass and secured using cementitious grout or polarism. Rock bolt comes in wide variety of forms and systems but for the installation of a simple ipoxorism bonded bolt, step include drilling a hole in the rock, insertion of a two part risen cartridge, insertion of the bolt to squash the cartridge, spinning of the bolt to mix the risen, fitting of the washer and the nut and tensioning of the bolt by a specified amount. Using fast sitting risens bolt can be fully installed in tensions even in overhead positions within minutes. Meshing involves the fixing of sheets of welded steel wire mesh to the excavated rock surfaces using pins or bolts. If pinned deeply enough into the rock mass, the mesh can retain any rock fragments that are approximately larger than the actual size of the mesh. Track grading involves the spraying of small aggregate concrete unto a rock face thereby bonding it together. It is often used in conjunction with meshing. The result is a reinforced concrete skin on the rock face that binds the rock together and can retain rock fragments of any size. You may or not be aware but deep in the ground even the rocks are saturated and the water in the rocks may be under enormous pressure.

This operation is called roof support or strata control. Rock bolting involves installation of a bolt usually steel or fiber glass into a hole drilled in the rock mass and secured using cementitious grout or polarism. Rock bolt comes in wide variety of forms and systems but for the installation of a simple ipoxorism bonded bolt, step include drilling a hole in the rock, insertion of a two part risen cartridge, insertion of the bolt to squash the cartridge, spinning of the bolt to mix the risen, fitting of the washer and the nut and tensioning of the bolt by a specified amount. Using fast sitting risens bolt can be fully installed in tensions even in overhead positions within minutes. Meshing involves the fixing of sheets of welded steel wire mesh to the excavated rock surfaces using pins or bolts. If pinned deeply enough into the rock mass, the mesh can retain any rock fragments that are approximately larger than the actual size of the mesh. Track grading involves the spraying of small aggregate concrete unto a rock face thereby bonding it together. It is often used in conjunction with meshing. The result is a reinforced concrete skin on the rock face that binds the rock together and can retain rock fragments of any size. You may or not be aware but deep in the ground even the rocks are saturated and the water in the rocks may be under enormous pressure.  Generally, the storage capacity is small and the rate at which the water can move through the rock is very slow and so the water make the water that flows into the mine is small and manageable. In these cases small galleries, slumps are cut into the rock at low points in the mine and water is collected before being pumped to somewhere where it is not a problem. Sometimes during there are deep geological structures that contain large amounts of water that can flow freely into the mine and degrade pressures. When these are encountered during drilling say for bolts or for blasting they can be at massive and sudden in rush of water that is difficult to stem. In these situations, expanding polarism can be injected into the holes to reduce the flow of proper water into the mines. In extreme circumstances, water pressure can cause regions of the rock mass to burst out when support for the rock mass is removed during mining. These out bursts are very dangerous and they can involve great forces and flood work areas. They are difficult to predict and manage, the risk associated with in rush is an outburst can be managed by good geological mapping and drilling ahead of production. Where there is a history or strong suspicion of water problems it may be advantageous to de-water or depressurize the strata prior to mining. We’re nearly at the end of our journey into underground mining and into mining engineering as a whole. There is not much left to do now but to look at how the process ends and to put some of our forgoing discussion into context for those of you who might like to look into mining engineering a little more deeply. We will do this in our next topic.

Generally, the storage capacity is small and the rate at which the water can move through the rock is very slow and so the water make the water that flows into the mine is small and manageable. In these cases small galleries, slumps are cut into the rock at low points in the mine and water is collected before being pumped to somewhere where it is not a problem. Sometimes during there are deep geological structures that contain large amounts of water that can flow freely into the mine and degrade pressures. When these are encountered during drilling say for bolts or for blasting they can be at massive and sudden in rush of water that is difficult to stem. In these situations, expanding polarism can be injected into the holes to reduce the flow of proper water into the mines. In extreme circumstances, water pressure can cause regions of the rock mass to burst out when support for the rock mass is removed during mining. These out bursts are very dangerous and they can involve great forces and flood work areas. They are difficult to predict and manage, the risk associated with in rush is an outburst can be managed by good geological mapping and drilling ahead of production. Where there is a history or strong suspicion of water problems it may be advantageous to de-water or depressurize the strata prior to mining. We’re nearly at the end of our journey into underground mining and into mining engineering as a whole. There is not much left to do now but to look at how the process ends and to put some of our forgoing discussion into context for those of you who might like to look into mining engineering a little more deeply. We will do this in our next topic.

https://youtu.be/qfJPbd5nyHk