Table of Contents

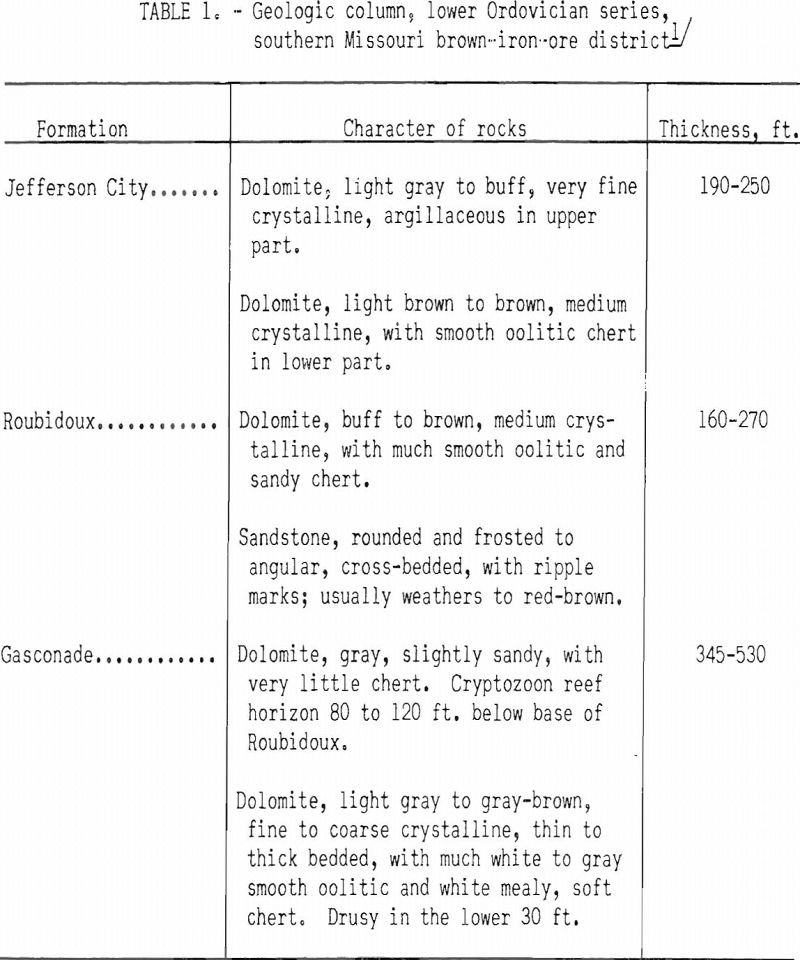

Most brown-iron deposits of southern Missouri occur in residual materials resting on Jefferson City dolomite, Roubidoux sandstone, or Gasconade dolomite, all of the Ordovician system (see table 1). The residual materials, which consist mainly of clay, chert, and iron oxides, are products of weathering of sedimentary rocks younger than the Jefferson City dolomite.

Deposits of brown iron are widely distributed over the extreme southern part of the State. According to Crane, they are of two types: Primary deposits, formed by direct precipitation of iron oxide; and secondary deposits, in which the iron oxides are products of oxidation of marcasite and pyrite. Secondary deposits occur more commonly and have been mined more extensively than primary deposits.

As disclosed by mining, the contents of individual deposits range from a few tons to rarely more than 175,000 tons. Thicknesses range from a few to more than 100 ft., depending on the depth of the host residuum. Outcrops vary in area and shape and are not reliable criteria for judging size or characteristics of ore bodies. The overburden of cherty clay on the deposits ranges from a few inches to about 25 ft in thickness.

Common ore minerals are the iron oxides, goethite, and/or limonite. Gangue materials and impurities in the ore include pyrite, marcasite, quartz and chert (reported as silica in ore analyses), calcite, dolomite, and minor amounts of manganese, copper, and zinc minerals. The phosphorus content of ore shipments seldom exceeds 0.08 pct. but may exceed 0.20 pct, in ores of the Springfield district. The iron oxide minerals occur as hard boulders, tabular ore, pipe ore, and ocher.

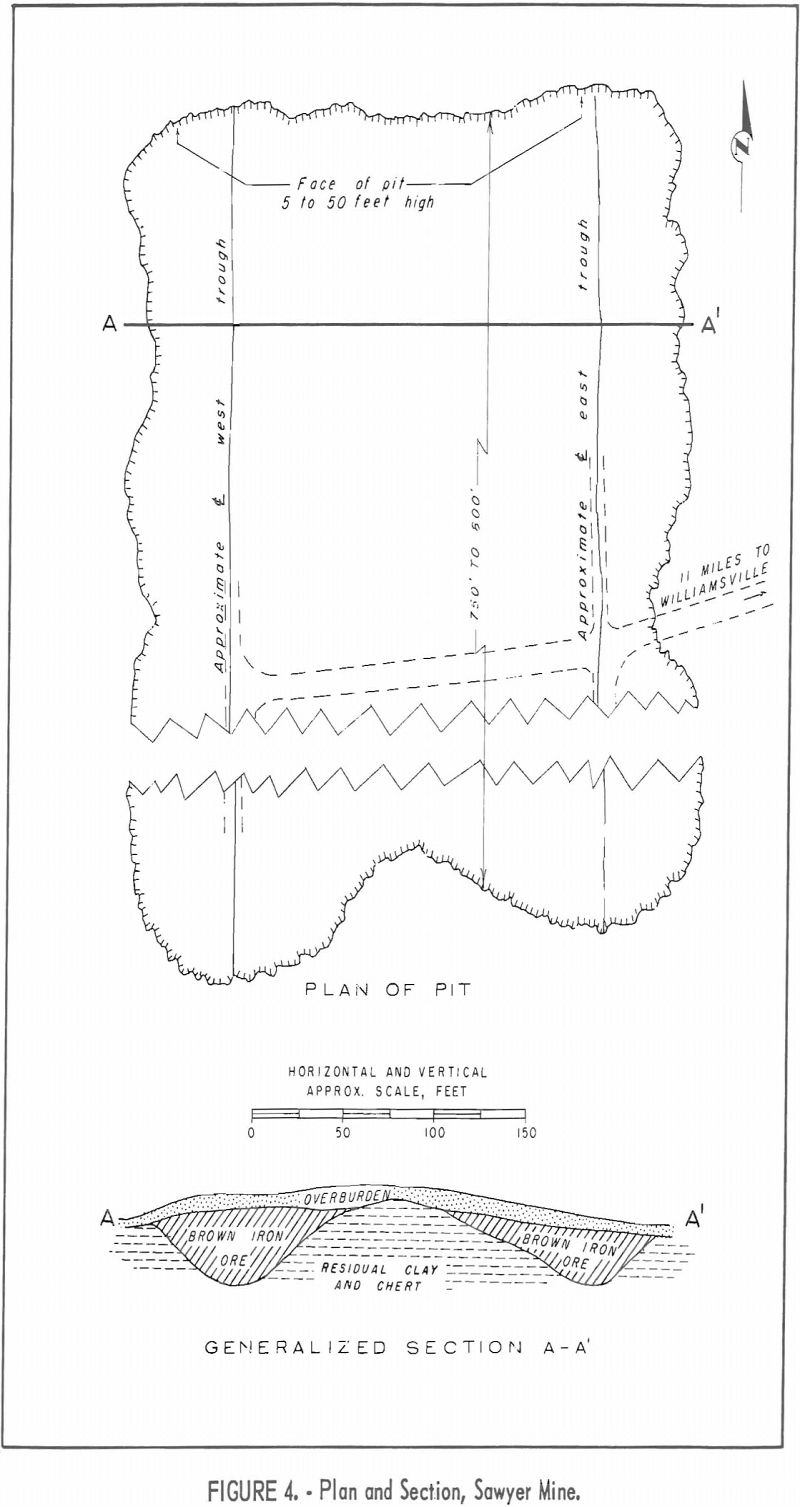

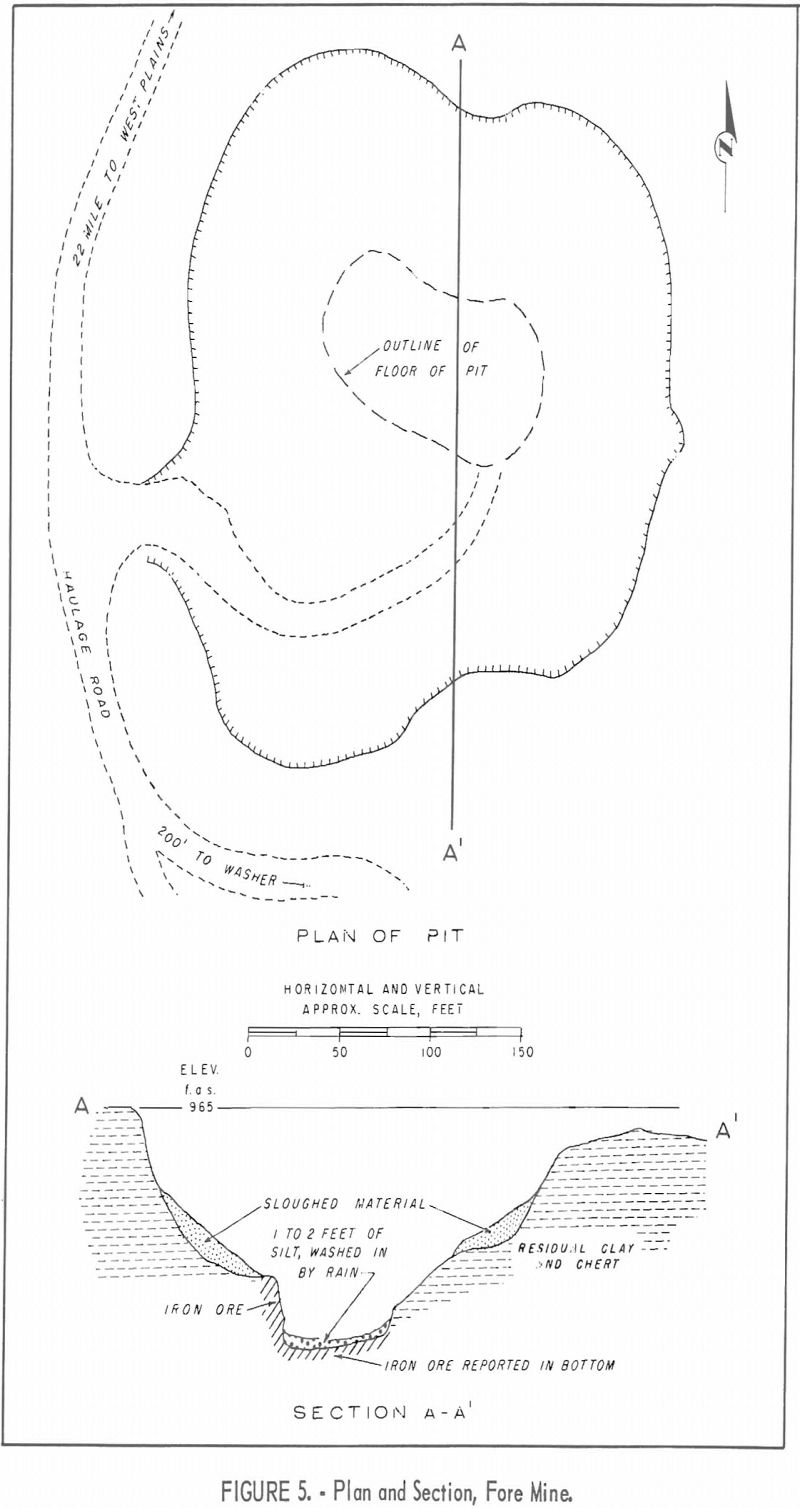

The brown-iron deposits at the Sawyer and Fore mines are of secondary type. Both are on or near the tops of broad ridges.

The deposits at the Sawyer mine are in two parallel, north-south trending troughs in residual material resting on the Roubidoux formation (fig. 4). Within the mined area the troughs are about 200 ft. apart, but exploratory drilling in 1959 indicates that they unite north of the pits. The deposits are more than 1,400 ft. long, from 50 to 100 ft. wide, and averaged 32 ft. in thickness at the center. The iron occurs as goethite and limonite, ranging in particle size from fine claylike ochre to boulders weighing a ton or more. Residual chert and clay are the common gange materials. Overburden reportedly averaged about 8 ft. in thickness.

The Fore deposit is in residual material resting on the Jefferson City formation. The 90-ft. deep pit resulting from mining operations is circular and approximately 250 ft. in diameter at the surface. It tapers in depth to an oval with an east-west length of approximately 120-ft. and an average width of 50 ft. (fig. 5). The ore was similar to that at the Sawyer mine, except that it contained some unaltered iron sulfides. There was no overburden on the deposit.

Prospecting and Exploration

Exploration by Wayne County Mining Co. was done with a Hossfeld prospecting drill with churn-type action. The mobile outfit, including a

gasoline-power unit, weighs about 1,300 lb. and is reportedly capable of drilling to depths of 100 ft. Water is hand- or hose-fed into the drill hole; the cuttings are returned to the surface through hollow drill rods. Detachable 2-in.-diameter tungsten-carbide-tipped bits were used on 1-½-in.- diameter rods. The drill was normally operated by one man. Ore bodies at the Sawyer mine were partly outlined during 1956 with the Hossfeld unit by drilling thirty-six 2-in.-diameter holes averaging 28 feet in depth

Prospecting and development work at the Fore mine was done before the Four Mining Co. began operating the property. Two shafts reportedly were sunk into the deposit, one about 50 ft. and the other about 30 ft. In addition, several pits from 3 to 10 ft., deep were dug to outline the deposit at the surface.

The iron content of samples taken from the drill holes on the Sawyer and from the pits and shafts on the Fore was estimated visually.

The reserve of crude, unmined ore in the Sawyer deposit is estimated to be 80,000 long tons averaging 38 pct. iron Lack of reliable data precluded estimating reserves of unmined ore in the Fore deposit.

Mining and Processing

The open-pit method of mining was used at both mines, Drilling and blast blasting was unnecessary, as power loaders were able to dig the ore without its being otherwise loosened.

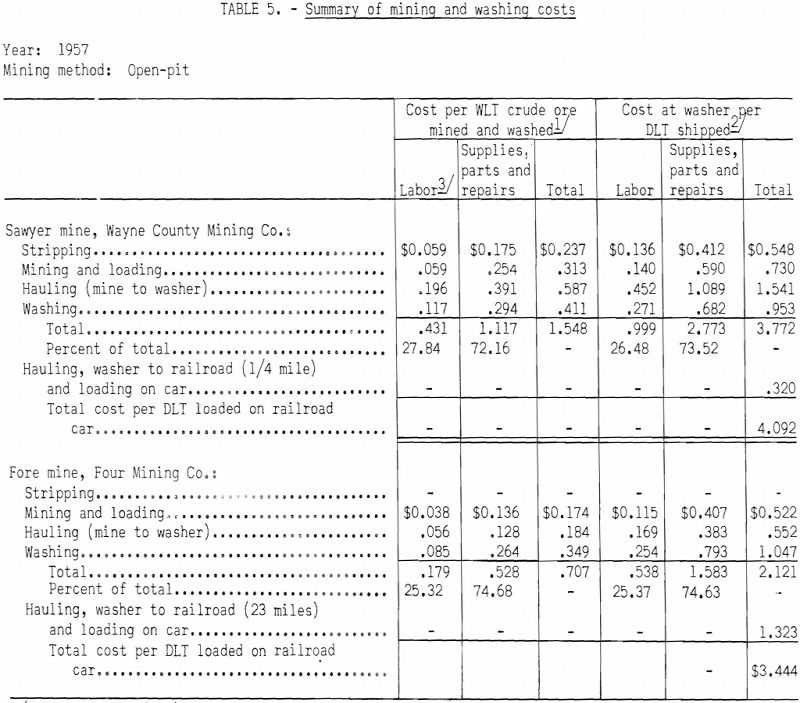

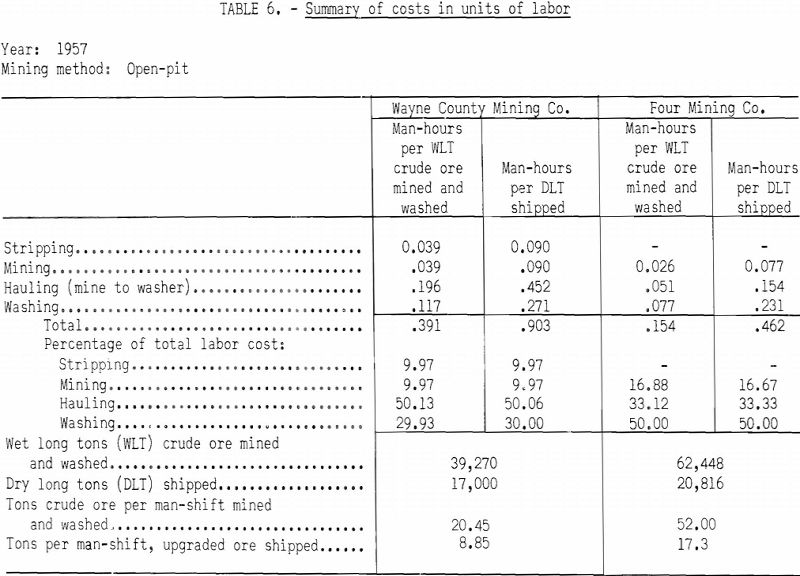

The ease of mining and the efficient use of a small labor force, plus mechanization of all phases of the operations; caused labor costs to be low as compared to the total cost of production.

Overburden at the Sawyer mine was removed with a bulldozer; the ore at the Fore mine outcropped at the surface. Most truck loading at the Sawyer mine was done with a crawler-mounted front end loader equipped with a 2-½- cu.-yd.-capacity skip; a front-end loader with a 1-½-yd.-skip was used part of the time and for standby purposes

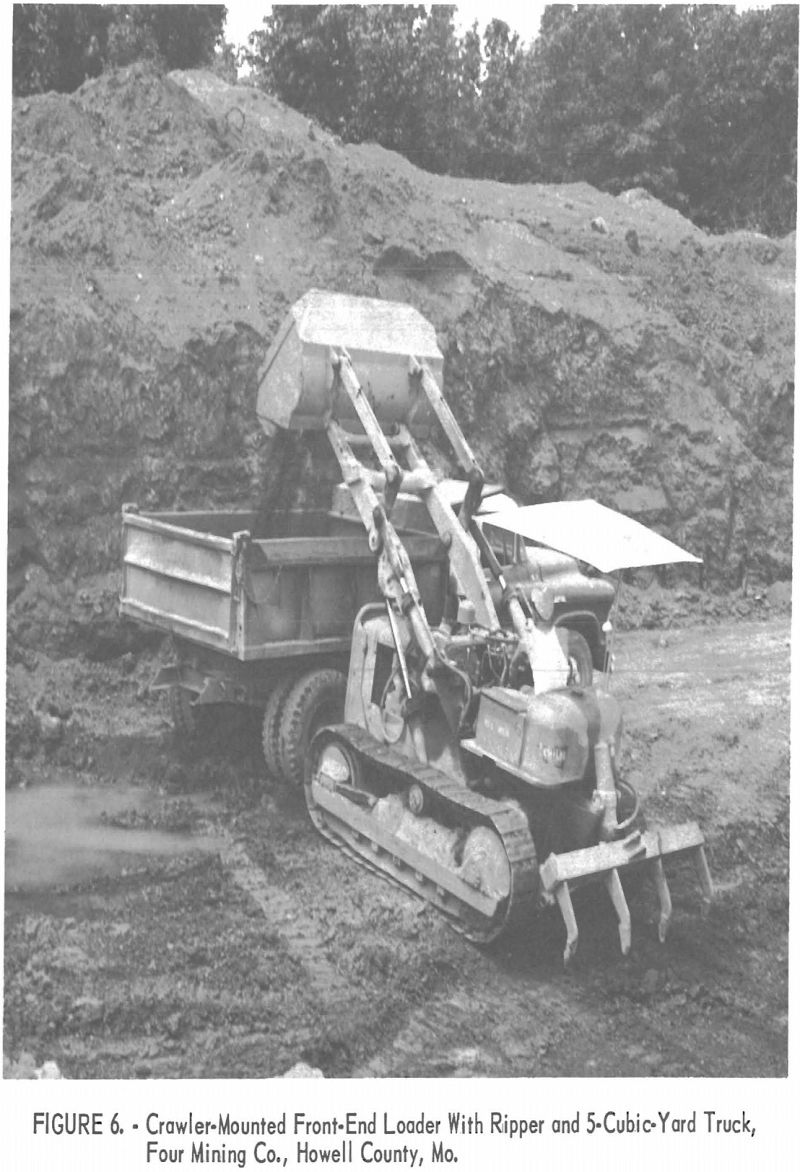

At the Fore mine, a power shovel with a 1 cu.-yd, dipper was used 40 pct. of the time, and a crawler-mounted front- end loader with a 1-½ cu.-yd. skip the remainder of the time (fig. 6). Front-end loaders normally operated on top of the deposits, working toward a bench of ore or country rock to facilitate filling the skip. Teeth on the lips of the skips, or rippers attached to the rear ends of the crawlers, loosened the ore for loading. Loading a 5-cu.-yd.-capacity dump truct required 3 to 5 min.

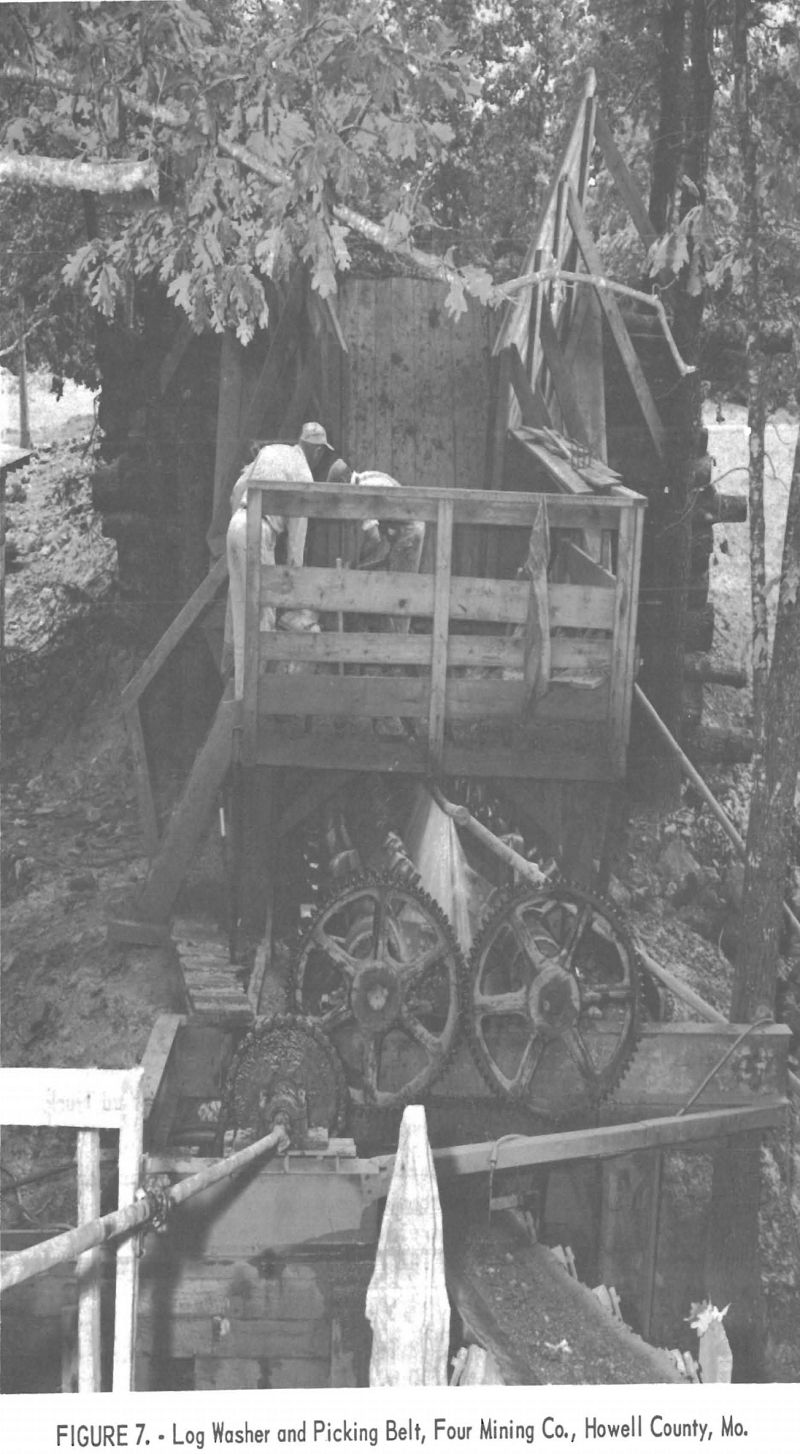

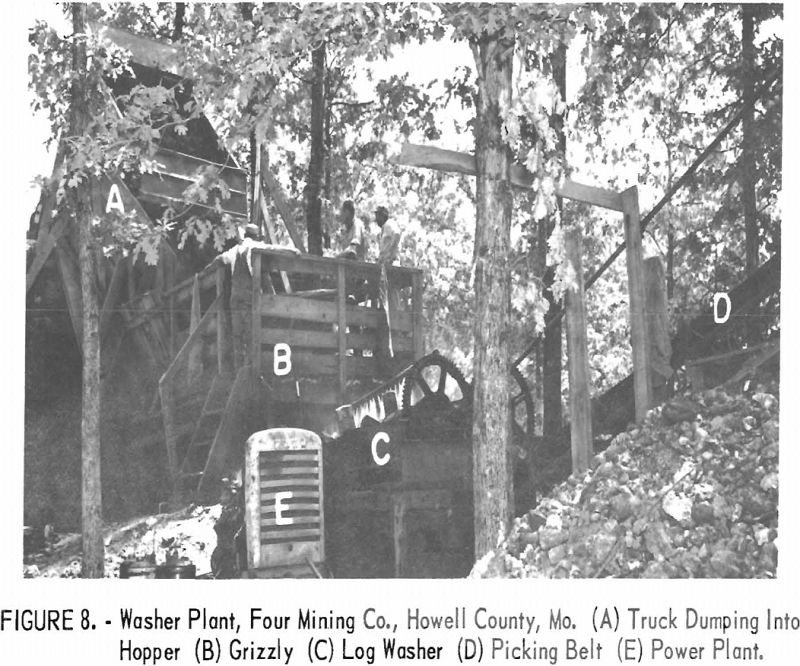

At both washing plants crude ore was upgraded by similar washing processes using log washers and picking belts (figs. 7 and 8). The crude ore was dumped from trucks into a hopper, from which it passed through a grizzly to the log washer. The feed from the hopper through the grizzly was controlled by being raked by hand or washed down with water under pressure from a nozzle. The grizzlies were constructed of T-rails set parallel with the flanges up and

spaced to pass 4-in. material. Boulders that did not pass were broken with a sledge hammer. The washed ore was dropped from the upper end of the washer onto a conveyor belt, on which it was elevated to the ore bin or stockpile. One or two men handpicked waste material from the ore as it was carried toward the discharge end of the belt.

Water for the washers was obtained from ponds formed by damming small nearby streams; the required 450 to 500 g.p.m. was pumped through 4-½-in.-diameter pipe for distances up to 500 ft. Tailings were collected in separate ponds to prevent steam pollution.

Transportation

Haulage at each mine was by 5-cu.-yd.-capacity end-dump trucks; five were used at the Sawyer mine and two at the Fore mine. The distance by road from the Sawyer mine to the washer at Williamsville is 11 miles; at the Fore mine the haul from the pit to the washer was about 500 ft. Haulage from the Sawyer mine was done with privately owned trucks on a contract price per ton; the trucks at the Fore mine were company owned and operated.

Roads in and within a few hundred feet of the pits were built with local material and were not surfaced; they become slippery when wet and were the cause of shutdowns during rainy weather. All-weather, gravel-surfaced access roads, less than a mile long, extend from the pit roads to hard-surfaced highways.

Haulage costs averaged 6.25¢ per long-ton mile.

Production Rates and Percentage of Extraction

Sawyer Mine

During 1957, the Sawyer mine operated one 8-hr. shift per day for 192 days. Crude ore, estimated by the operator to contain 38 pct. iron, 0.05 pct, phosphorus, and 3.88 pct. insoluble material, was mined at an average daily rate of 205 wet long tons per day. Total output from the mine during 1957 was 39,270 wet long tons of crude ore, which produced 17,000 dry long tons of shipping-grade ore averaging 58 pct. iron, 0.05 pct. phosphorus, and 4 pct. insoluble material. The data indicate a recovery of 66 pct. of the iron in the crude ore.

Fore Mine

During 1957 the Fore mine operated one 8-hr. shift per day for 200 days. Daily production averaged 310 wet long tons of crude ore estimated by the producer to contain 35 pct. iron, 0.04 pct. phosphorus, and 5 pct. insoluble material. Total output from the mine during the year was 62,448 wet long tons of crude ore, from which 20,816 dry long tons of shipping-grade ore was recovered averaging 50 pct. iron, 0.06 pct. phosphorus, and 8 pct. insoluble material.

All material estimated to contain enough iron to be profitably handled was mined and washed.

The data indicate a recovery of 47.58 pct. of the iron in the crude ore.

Mine Drainage

The floor of each pit was normally advanced upgrade to prevent the accumulation of water. Rainwater drained through the lowest pit opening, or was allowed to seep through pit bottoms.

Wages Operatives and Equipment

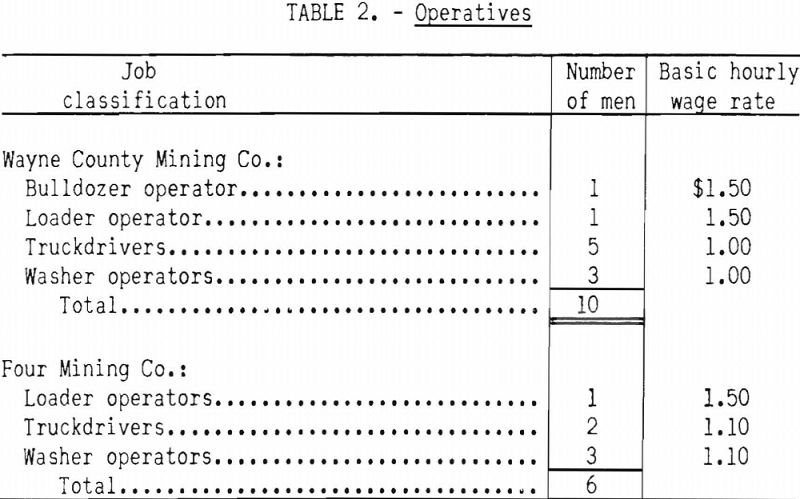

Prevailing wage rates in the brown-iron-ore mines of southern Missouri in 1957 ranged from $1.00 per hour for common labor to $1.50 per hour for heavy equipment operators. Much of the hauling and bulldozer work was done on a contract basis.

Job classifications, the number of operatives in each category, and the basic hourly wage of the two companies in 1957 are given in table 2.

Units of equipment employed by the two companies follows:

Wayne County Mining Co.:

Bulldozer (contract work)……………………………………………1

Front-end loader (2-½-cu.-yd. skip)…………………………….1

Front-end loader (1-½-cu.-yd. skip)…………………………….1

Dump trucks (5-cu.-yd. capacity)…………………………………6

Hauling ore from pit to washer……………………………………5

Hauling concentrate from washer to railhead……………….1

Washer with picking belt…………………………………………….1

Exploration churn drill……………………………………………….1

Four Mining Co.:

Dipper shovel (1-cu.-yd. dipper)…………………………….1

Front-end loader (1-½-cu.-yd. skip)………………………1

Dump truck (5-cu.-yd. capacity)……………………………6

Hauling ore from pit to washer……………………………..2

Hauling concentrate from washer to railhead…………4

Washer with picking belt………………………………………1

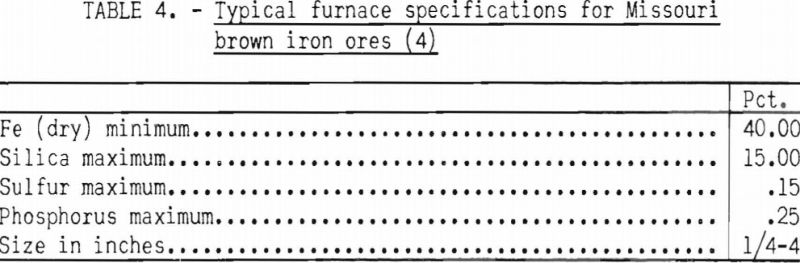

Marketing Ores

Brown iron ores produced in southern Missouri are normally sold to blast-furnace operators in Illinois and Alabama. The price is based on units (22.4 lb.) of iron per dry long ton, and the ore is sold under schedules submitted to the producers by individual purchasers. Table 3 gives a typical price schedule as of June 1957, and table 4 gives typical furnace specifications for Missouri brown ores. Penalties may be assessed or the ore rejected if the sulfur, phosphorus, or other objectionable elements exceed allowable quantities.