This is a general safety information regarding Bruker’s handheld X-ray fluorescence XRF analyzers. Proper training is vital for compliance, safe operation and understanding of the operator’s responsibilities associated with handheld XRF analyzer use. The term radiation is used to describe forms of energy emitted as particles or electromagnetic waves. There are two types of radiation: non-ionizing and ionizing. Non-ionizing radiation is radiation without enough energy to remove tightly bonded electrons from their orbits around an atom. Examples include visible light, radio waves, microwaves, infrared radiation and ultraviolet light. Ionizing radiation is radiation that has enough energy to remove electrons from an atom in a process called ionization. There are four types of ionizing radiation: alpha particles, beta particles, gamma and X-rays, and neutron particles. The process of ionization is important because it affects chemical and biological functions of the cells of the body and can be used to detect radiation.

X-rays are the type of radiation emitted from an XRF analyzer. They are a type of electromagnetic radiation that consists of photons or individual packets of energy. They have a neutral charge and no mass. X-rays originate from the electron shells outside the nucleus and travel many feet through the air. Several units are used to describe radiation measurements. X-ray and gamma ray exposure is often exposed in units of Roentgen. The Roentgen or R unit refers to the amount of ionization present in the air. Absorbed doses that measure the amount of energy absorbed per unit of mass of material. When radiation transfer energy to material, the material absorbs some or all of the energy resulting in an absorbed dose. This is expressed in units of Rad in the United States and Gray, abbreviated as ‘Gy’ in the international community. Absorbed dose does not take into consideration the effect of different types of radiation on living organisms. We must use other units known as Rem in the US and Sieverts abbreviated Sv in the international community to express the dose equivalent or equivalent dose respectively. This value is defined as energy absorbed per unit mass times a quality factor times other modifying factors. The quality factor accounts for the varying levels of biological damage caused by the different types of radiation. For X-rays and gamma rays the quality factor is 1. So you can assume 1R = 1 rad = 1 rem = 1000 mrem or 1R = 10 mGy = 10 mSv. Since this is the case, we simply refer to the dose equivalent, equivalent dose or absorbed dose as dose or radiation dose. Most dose values are so low that they are expressed in mrem or mSv. 1 mrem = 1/1000th of a rem. 1 mSv = 1/1000th of a Sievert. 1 Sievert = 100 rem.

Everyone is exposed to background radiation from both man-made and natural sources. According to the National Council of Radiation Protection and Measurement the average background radiation dose received by individuals in the United States is 620 mrem per year. Naturally occurring sources of radiation include cosmic radiation from space, terrestrial radiation from soil, air and vegetation and radioactive material that is part of your body, such as potassium 40. Man-made radiation includes medical and diagnostic procedures, consumer products, tobacco, building materials and the nuclear industry. The largest contributors to background radiation dose are radon, boron and medical procedures.

Regulatory dose limits for occupational radiation workers are based on data compiled on the biological effects of ionizing radiation by national and international professional and scientific organizations. These limits are set to minimize the likelihood of these effects. Administrative limits and as low as reasonable achievable or ALARA goals established by companies and some government agencies further reduce the occupational dose received by radiation workers. Occupational dose does not include the dose received from background radiation. In the US, the maximum dose allowed to a radiation worker is 5 rem per year or 5000 mrem per year to the whole body. The dose limit for extremities such as hands and arms and the skin is 50 rem per year, or 50,000 mrem per year. Members of the general public and minors are limited to 0.1 rem per year, or 100 mrem per year. The developing human embryo or fetus is extremely sensitive to ionizing. Since this is the case, a declared pregnant worker is limited to 500 mrem during the time she is pregnant. Female workers who become pregnant are encouraged to declare their pregnancy in writing to their employer. Internationally the dose limit to the whole body is 20 mSv per year. And the limit for the declared pregnant worker is 2 mSv for the term of the pregnancy. Limits to the extremities, the limbs and the eye, the skin, organs or tissues and the general public are identical to those in the US. The dose received by X-ray workers is typically between 0-100 mrem per year or 0-1 mSv per year.

The goal of the ALARA program is to keep radiation dose as far below the occupational dose limits as possible. The success of the ALARA program is linked to the clear understanding and compliance with policies and procedures for the protection of workers. ALARA is the responsibility of workers, managers and the radiation protection organization. Three basic ways to reduce the routine external dose potentially received from X-ray producing devices are time, distance and shielding.

Total dose is the dose rate in mrem per hour multiplied by the time spent near the source of the radiation. For example, a person in an area for 2 hours with a dose of 5mrem per hour will receive a dose of 10mrem. To minimize the total dose you receive, limit the time you spend near the source of the radiation by planning ahead. The less time you are exposed to the source of the radiation, the smaller the dose you will received. Increase your distance away from the source of radiation whenever possible and keep others away. The radiation exposure is inversely proportional to the square of the distance from a point source. This is called the Inverse Square Law. When the distance is doubled, the dose rate is reduced to 1/4th of its original value. When the distance is tripled, the dose is reduced to 1/9th of its original value. Shielding is based on the ability of materials to stop radiation particles or photons by absorbing their energy. As you put more material between you and the source, the dose will decrease. The decrease is proportional to the density of the material. For this reason, lead and tungsten are routinely used to shield X-rays. The design of your analyzer incorporates substantial shielding to reduce the dose outside the analyzer to a minimum.

In cases where the sample is of low density, for example aluminum, or is thin, some of the source radiation may penetrate the sample and produce a high radiation dose rate. This is one of the main reasons that no personnel should be in the line of the useful beam even when a sample is present. Similarly, if the sample is a liquid or a powder there is a significant chance that the source of radiation will penetrate the sample and exit the back side. In order to compensate for small samples which do not completely cover the measurement aperture, thin samples and liquid or powder samples an optional small sample cover is provided which will satisfy the infrared safety interlock and shield the user from primary beam radiation coming from the analyzer. It is recommended that the cover be used whenever the sample geometry allows its use.

Users of X-ray equipment should be aware of the signs and symptoms of accidental exposures to large amounts of radiation. Exposure of the extremities to an open, high-intensity gamma ray or X-ray beam can result in severe radiation burns in a matter of second. Radiation burns or aerothermal are the principal hazard associated with the use of analytical XRF equipment. These burns heal poorly and on rare occasions have required amputation of fingers or surgery to remove affected flesh. The burn symptoms may require from one to several weeks to develop, depending on the dose. An acute dose of approximately 600 rad or 6 Gray to a part of the body causes a radiation burn equivalent to a 1st degree burn or mild sunburn. Typically, there’s no immediate pain like with a thermal burn, but the sensation of warmth and an itching occurs a few hours after exposure. An initial reddening or inflammation of the affected area usually appears several hours after exposure and fades after a few more hours or days. The reddening may appear as late as 2-3 weeks after the exposure. A dry scaling or peeling of the irradiated skin is likely to follow. And acute dose of approximately 1000 rad or 10 Gray to a body part causes serious tissue damage similar to a second-degree thermal burn. Reddening and inflammation occur followed by a swelling and tenderness. Blisters will form within 1-3 weeks and will break open leaving raw, painful wounds that can become infected. Hands exposed to such a dose become stiff and finger motion is painful. An acute dose of approximately 2000 rad or 20 Gray to a body part causes severe tissue damage similar to a scalding or a chemical burn. Intense pain and swelling occur within hours. Partial body exposure to approximately 3000 rad or 30 Gray destroys tissue and surgical removal is necessary. If the user believes they were exposed to the primary beam and develops any of these symptoms, seek immediate medical attention. This is why it’s imperative that operators of XRF analyzers keep any part of their body out of the primary beam while it is energized.

The threshold dose for radiation-induced cataracts is 200 rad or 2 Gray delivered to the lens of the eye in a single occurrence. For fractionated or prolonged exposures a larger dose is required to cause cataract formation. The onset of cataract formation depends on the dose received and the duration of the exposure. The latency period is about 8 years for doses 250-650 rad but cataracts may form anywhere from 6 months to 35 after exposure. Warning: do not look into the primary beam of the XRF handheld analyzer. If the unit is used in accordance with manufacturer’s instructions, acute radiation effects will not occur.

Radiation cannot be seen but it can be measured. Survey meters are used to detect radiation, check shielding and measure dose rate in real time. In some cases regulatory agencies require users to own survey instruments and conduct radiation surveys as part of the radiation safety requirements. Instrument selected for the measurement and/or detection of radiation should be appropriate for the type of energy of the radiation. Survey meters used for X-rays should have the capability to detect low energies. Radiation instruments must be sensitive enough to detect radiation doses on the order of mrem per hour or micro rem per hour. Some survey meters are more appropriate for laboratory use versus outdoor operations where components may be damaged. Radiation instruments should be calibrated prior to the initial use and periodically thereafter.

There are a number of commercially available survey meters that are appropriate for X-ray radiation detection and measurement. Ion chambers, thin window Geiger Mueller GM survey meters, thin-window sodium iodide or NaI TI scintillators. These survey meters as well as detecting radiation leakage can be calibrated to provide an indication of a worker’s dose. The two most commonly used meters are the GM survey meter and the ion chamber survey meter. The GM meter has excellent sensitivity for detecting low levels of radiation. Unless the meter has been calibrated for the radiation energies expected, GM meters should be restricted to the detection of radiation only, rather than the quantitative assessment of a dose rate. The ion chamber survey meter is preferred for measuring the amount of radiation emitted, principally because of its accuracy. Equipment manufacturers can be helpful in choosing the correct meter. Be as specific and detailed as possible about the radiation type and your intended use of the meter.

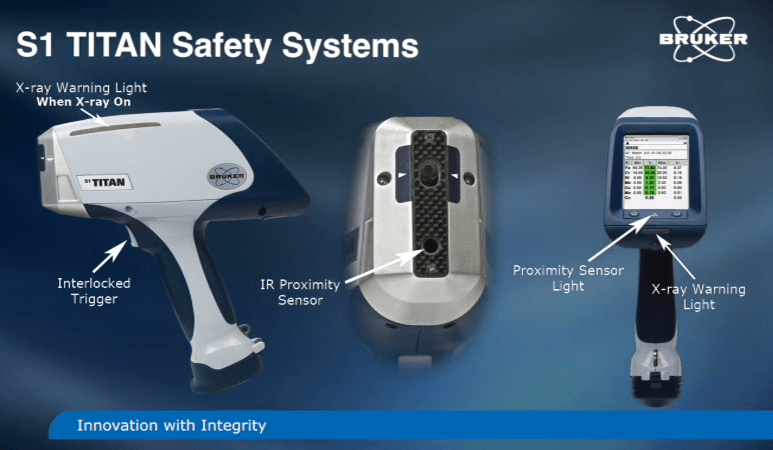

Personnel monitoring devices called dosimeters are used to measure the dose a person receives from external sources of radiation. Regulatory agencies in most cases require use of whole body and/or extremity dosimeters when working with X-ray producing devices. Whole body dosimeters include thermoluminescent dosimeters or TLDs, optically simulated luminescence dosimeters or OSLs and film badges. Finger rings and wrist badges are examples of extremity dosimeters. This slide shows examples of dosimeters commonly used for personnel monitoring. Starting at the left and moving clockwise, they are: the optically simulated luminescent or OSL dosimeter, the film badge, wrist dosimeters and finger rings. Bruker designs fail-safe systems and interlocks into the devices to prevent unauthorized or unsafe use of the analyzer. These include password protection, software X-ray warning, infrared proximity sensor, operator trigger interlocked, red X-ray warning light, minimum back scatter detection, X-ray enunciator, operator timeout.

The first level of security is achieved by having a password-based login. The analyzer will neither operate nor generate X-rays without a password. It is important to maintain the security of the passwords by changing it often and providing it only to trained operators. After the operator is logged on, the infrared sensor is used to confirm that a sample is in place prior to generating X-rays. X-rays cannot be generated if the sensor does not detect an object. The operator trigger interlock requires the operator to pull the trigger in the manual mode to generate X-rays. If the trigger is released, the X-rays stop. Red X-ray warning signs illuminate on the side of the instrument and/or beneath the screen indicating the generation of X-rays. If the lights fail, X-rays cannot be generated. The count rate is continuously monitored during each measurement. If the count rate drops below the allowable threshold indicating the absence of the sample, a safety circuit will shut down the X-ray generation. An optional X-ray enunciator is available. When the trigger is activated, an audible alarm alerts the operator and those nearby that the unit is generating X-rays. If the analyzer remains idle for a set period, the program will require the operator to log back in restoring the previous sessions. These controls are designed into the XRF analyzers for your protection. Do not defeat or tamper with the interlocks or the failsafe systems.

Safety warning labels identify the analyzer as a radiation producing instrument. The manufacturer mounts radiation warnings at the factory. Each instrument contains the words ‘Caution: this equipment produces X-rays when energized to be operated only by qualified personnel’ and ‘Warning: high-intensity X-rays. Do not expose any part of the body to the beam’. Bruker’s name, address and telephone numbers are readily available under the analyzer housing, near the handle in case of an emergency, or other customer needs. A software X-ray radiation warning has been integrated into the design of the S1 Titan. You must pull and release the trigger acknowledging the warning before you’re allowed to proceed. Do not remove, deface or tamper with radiation warning labels.

Here are some examples of the manufacturer’s labels you will see on your X-ray analyzer. No one but the operator should be allowed closer than 3 feet from the S1 analyzer, particularly the beam port. Ignoring this warning could result in unnecessary exposure. Never hold the sample up to the X-ray port for analysis by your hand or other part of your body. Hold the instrument to the sample. Never look into the useful X-ray beam. This could damage the lens of your eye. The operator should never defeat the IR sensor in order to bypass this part of the safety circuit. Defeating the safety feature could result in the over-exposure of the operator. Place the S1 analyzer in contact with the sample whenever operating. Holding the analyzer away from the sample will result in excessive back scatter. The correct way to use the X1 analyzer is to place it on a sample which completely covers the front of the analyzer and is away from the operator’s body or other people in the area. At this time, pull the trigger and observe that the red light is on until the measurement is completed. In review, the common sense safety rules to remember are: do not place any part of the body in the primary beam in front of the analyzer while the red X-ray light is on. Operate the device according to the instructions and warnings in the XRF analyzer manual. Never pull the trigger without a sample in place or the radiation cover on. Keep an area of about 1 meter or 3 feet in front of the analyzer free of all personnel. Never point the device at another person or yourself. Only trained personnel should operate the instrument. Do not remove or deface manufacturer radiation levels. Never defeat or tamper with safety interlocks. Report any damage of your analyzer to the manufacturer. Never open or service the unit yourself. When in doubt, contact your supervisor or Bruker Elemental for assistance.

In cases of emergencies, if there’s any doubt of the operation of the analyzer or the safety of the source, immediately remove the power source. This can be either the battery or the line power supply. If there’s no power to the tube, there will be no radiation generated. The extent and nature of policies and procedures can range from the use of the manufacturer’s manual, to the implementation of the radiation safety program. Review and follow state, provincial and federal requirements set forth by applicable regulatory agencies. It is essential that you take responsibility for determining and following the registration requirements for analytical X-ray equipment. Customers should also report receipt and transfer of devices to the regulatory agency.

The employer has the responsibility to inform employees of the presence of radiation in the work place. Instruct users in the hazards or radiation, the procedures to minimize exposure and the applicable laws for radiation protection. Post or make available operating procedures. Post notices of violation of radiological working conditions. Advise personnel of their radiation dose annually. Follow regulatory requirements. The employee has the responsibility to comply with employer X-ray safety postings and requirements. Obtain applicable training before operating the XRF analyzer. Wear required dosimetry, maintain exposure ALARA. Know the procedures for any machine operated. Verify the X-ray beam is off before reaching into the primary beam area.