Table of Contents

Most of the primary copper produced in the United States is derived from porphyry-type ore deposits located in Arizona, Montana, Nevada, New Mexico, and Utah (Intermountain States). In milling these low-grade ores to produce a smelting-grade concentrate, enormous tonnages of finely ground tailings are discarded. The vast accumulation of these wastes from past operations and the current annual production of over 125 million tons of tailings are actual and potential contributors to air and water pollution. In addition, these tailings are often eyesores.

The Bureau of Mines is engaged in a broad investigative program to devise and develop effective methods for stabilizing and utilizing the wastes of the mineral industry. Because of the enormous tonnages of tailings accumulated from past operations, major emphasis is directed to a study of stabilization techniques. However, because the tailings are discharged as finely ground and thick slurries composed chiefly of quartz, feldspar, clay, and sericite, an investigation was made to determine if this waste could be utilized as a raw material for producing building bricks.

The possibility of making ceramic structural products from a variety of solid mineral wastes has been studied by several research groups. Under sponsorship of the Department of the Interior’s Office of Coal Research, West Virginia University developed a process for making building bricks and other structural units from fly ash. Stanford University, under a Bureau of Mines grant, studied the feasibility of using siliceous gangue from California gold mine tailings as raw materials for calcium-silicate-bonded bricks. The Colorado School of Mines, also working under a Bureau grant, conducted investigations aimed at making building bricks by the extrusion and steam-curing methods from various mine and mill waste accumulations located throughout Colorado.

About 25 million tons of clay is used annually in the United States for the manufacture of building brick, paving brick, sewer pipe, draintile, and kindred products. Although the mill tailings, if convertible to building bricks, represent an abundant and cheap raw material, this resource is located in the Intermountain States, whereas the principal market for bricks is in the large population centers at considerable distance from the resource. At present, the manufacture and sale of building bricks depends on local raw materials, usually siliceous clay or intermixed shales and sandstone, and on nearby markets. Hence, a large-scale brickmaking operation using porphyry copper mill tailings would have to produce a quality brick at a low enough cost to cover the cost of shipping to population centers, such as Denver, Phoenix, Los Angeles, San Francisco, Portland, and Seattle, which are 100 to 750 miles from the tailing material sources.

Brick Specifications and Manufacturing Methods

There are no established specifications for raw materials for brickmaking. In general, suitability is determined by tests that simulate the brickmaking process employed. Building bricks are designated as grades SW, MW, and NW according to ASTM specification C62-66 (1-2) :

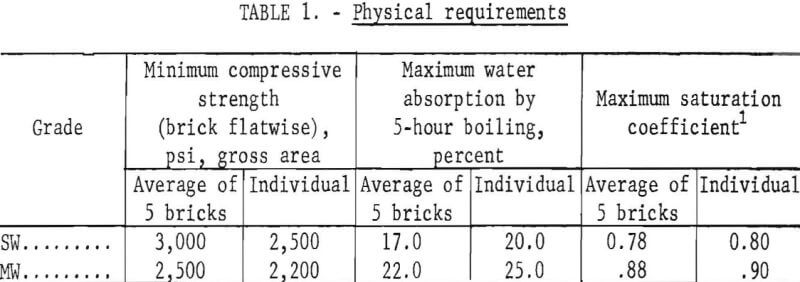

Grade SW brick “is intended for use where a high degree of resistance to frost action is desired and the exposure is such that water permeating the brick may be frozen.” Grade MW brick “is intended for use where exposed to temperatures below freezing but unlikely to be permeated with water, or where a moderate and somewhat nonuniform degree of resistance to frost action is permissible.” Grade NW brick “is intended for use as backup or interior masonry.” No attempt was made in these investigations to produce NW-grade brick. Physical requirements for grades SW and MW are given in table 1.

The Syllabus of Clay Testing states, “Brick, especially the common varieties, are made from a wide range of clays and shales. As a result, brick show an equally wide range of properties, colors, and qualities. The building brick industry is the most localized of all ceramic industries. Brick used for facing, which are of much higher quality, in general, command high prices and are often shipped considerable distances.” For the latter reason the production of satisfactory facing brick became the primary objective of the investigation.

Facing brick must meet grade SW or MW standards and are divided into three types–FBA, FBX, and FBS. The FBA designation covers brick used to obtain special architectural effects. Type FBX is for general use in exposed exterior and interior masonry walls where a high degree of mechanical perfection, narrow color range, and minimum permissible variation in size are required. Type FBS brick, made in this investigation, is for general use in exposed exterior and interior masonry walls and partitions where wider color ranges and greater variations in sizes are permitted than are specified for type FBX. Because copper mill tailings vary in content of possible coloring minerals (such as pyrite), considerable latitude in color is offered for production of facing brick.

Building bricks are made by three principal methods–the soft mud process, dry pressing, and the stiff mud process. Most of the bricks are made by the latter method, in which clay is mixed with water to a stiff plastic condition and is then extruded, cut to size, and fired. Clay or shale starting materials must have a reasonable degree of plasticity for this process. Because most tailings are relatively low in plasticity, dry pressing was selected for testing.

Tailing Materials

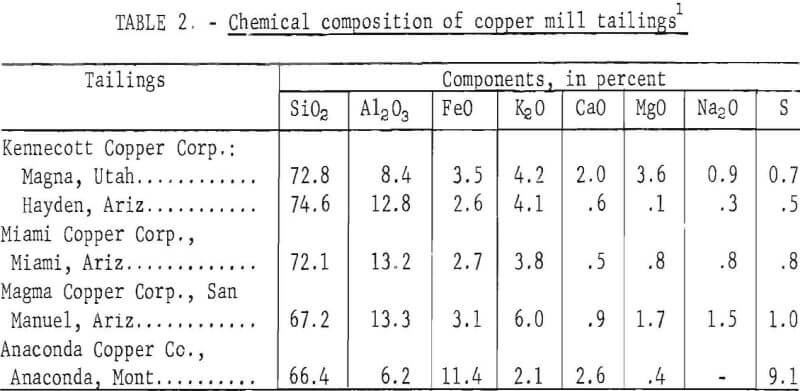

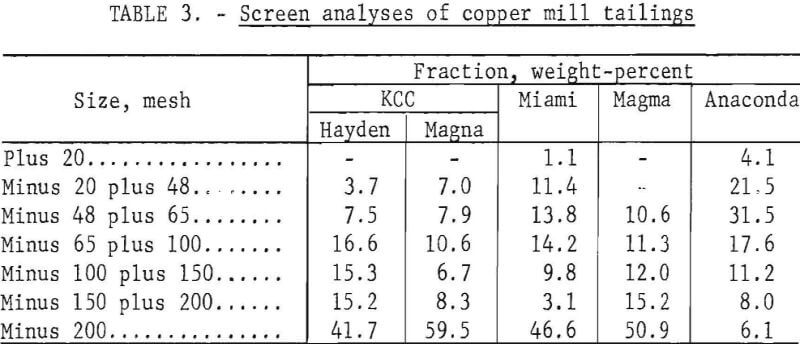

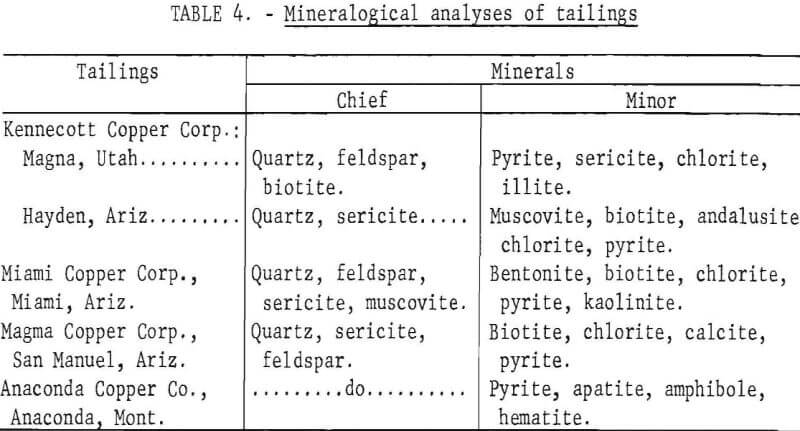

Copper mill tailings from five sites-Hayden, Miami, and San Manuel, Ariz., Anaconda, Mont., and Magna, Utah were obtained for this study. These samples varied somewhat in composition, chiefly in pyrite content, and were representative of the types of waste tailings being discharged by the western porphyry copper producers. The samples were dried and split to furnish representative head samples for chemical, size, and mineralogical analyses. The results are given, respectively, in tables 2, 3, and 4.

Laboratory Test Procedures

The production of building bricks from copper mill tailings by the dry press method encompassed drying, screening, mixing with color modifying and binding additives, adding water, forming, firing, and cooling. A general description of the process follows:

Tailings were dried in an oven at 110° C and screened through 20 mesh to break up lumps. To facilitate mixing and to attain a homogeneous mixture, the additives were also dried and screened through 20 mesh before being blended with the tailings. For green strength, 0.5 percent calcium lignosulfonate was added; and, if desired for color variations, 7 percent pyrolusite or dolomite was added.

Mixing was carried out for 15 minutes in a 1-gallon glass container. The blend was dumped into a bowl, where the material was prepared for pressing by slowly adding water and mixing by hand to prevent lumping. The amount of water added, generally about 6 weight-percent, was sufficient to cause the mixture to stick together when compressed by hand. Specimens measuring 1-½ by 3 inches in cross section and between 1 and 1-¼ inches thick were pressed at 5,000 psi on a 12-ton capacity Carver laboratory press.

Firing of the specimens was done by heating in a small (5 by 5 by 15 inches) Globar electric muffle furnace at a rate of 200° C per hour for approximately 6 hours and soaking for 2 more hours at the firing temperature. Generally, the firing temperatures ranged between 1,120° and 1,230° C. On completion of the firing cycle, the kiln was turned off and the samples were left in the kiln overnight to cool slowly. After cooling, the linear shrinkage, water absorption, and compressive strength of the specimens were determined.

Preliminary Testing

The mill tailings from Kennecott Copper Corp., Magna, Utah, were used in preliminary tests designed to define the effects of varying the brickmaking conditions. For these tests the tailings were dried, screened through 20 mesh, mixed with 3 percent sodium silicate, moistened with 5 percent water, dry-pressed at 3,000 psi into 3- by 1-½- by 1-½-inch specimens, and fired for 6 hours to reach selected temperatures ranging between 980° and 1,230° C. The bricks were held at test temperature for 1 to 3 hours. The laboratory bricks showed that bonding did not occur at firing temperatures below 1,150° C, and at 1,205° C the specimens were deformed.

Test Variables

Subsequent tests were made to further study the effects of varying forming pressures, curing times, and additives. Pressures were varied between 3,000 and 5,000 psi, firing times between 1 and 8 hours, and heating rates between 100° to 500° C per hour. Sodium silicate, calcium lignosulfonate, hydrated lime, and soda ash were incorporated in amounts ranging between 0.1 to 5.0 percent as bonding agents. Calcium lignosulfonate in quantities between 0.5 and 1.0 percent produced firm bonding and was selected as the preferred bonding agent for all subsequent tests. Pyrolusite and dolomite were added to produce color variations.

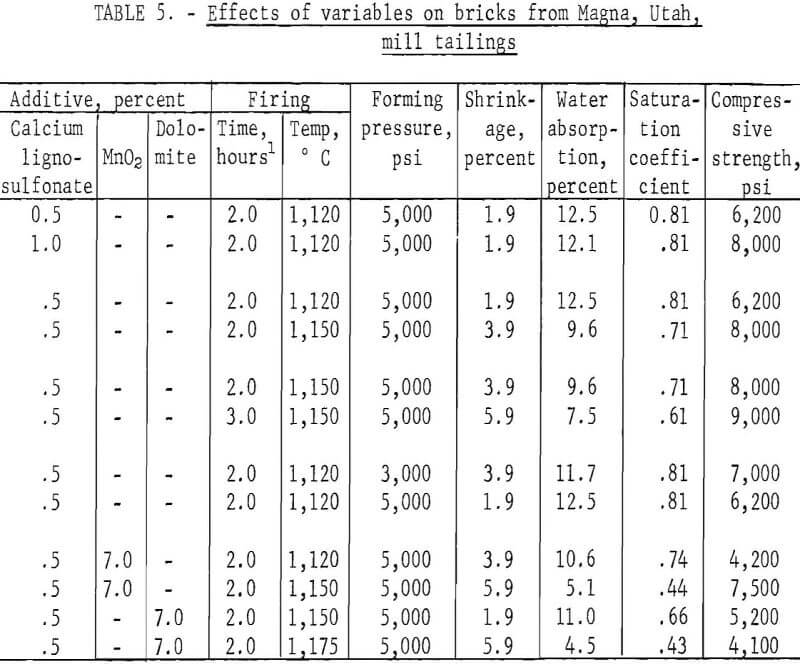

An investigation of the effect of the rate of heating the bricks to the firing temperature showed that if the rate were held to about 200° C per hour-products could be obtained from tailings containing less than 1.0 percent sulfur without bloating or blistering. The slow heating evidently allowed time for oxidation and volatilization of the sulfur before vitrification occurred. The variables tested were amount of bonding additive, maximum firing temperature and time held, forming pressure, and amount of color modifier. Results of tests made with Magna, Utah, tailings are presented in table 5.

These results show a soaking time of 2 hours at a maximum firing temperature of between 1,120° and 1,175° C to be satisfactory. A forming pressure of 5,000 psi is preferable to 3,000 psi, and incorporation of color additives is not overly detrimental. All of the bricks produced using 99.5 percent tailings and 0.5 percent calcium lignosulfonate at the foregoing conditions met the following ASTM Standards:

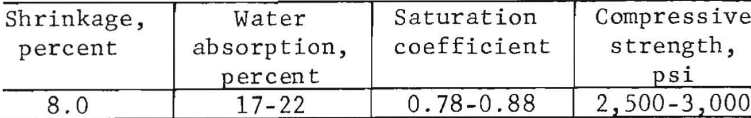

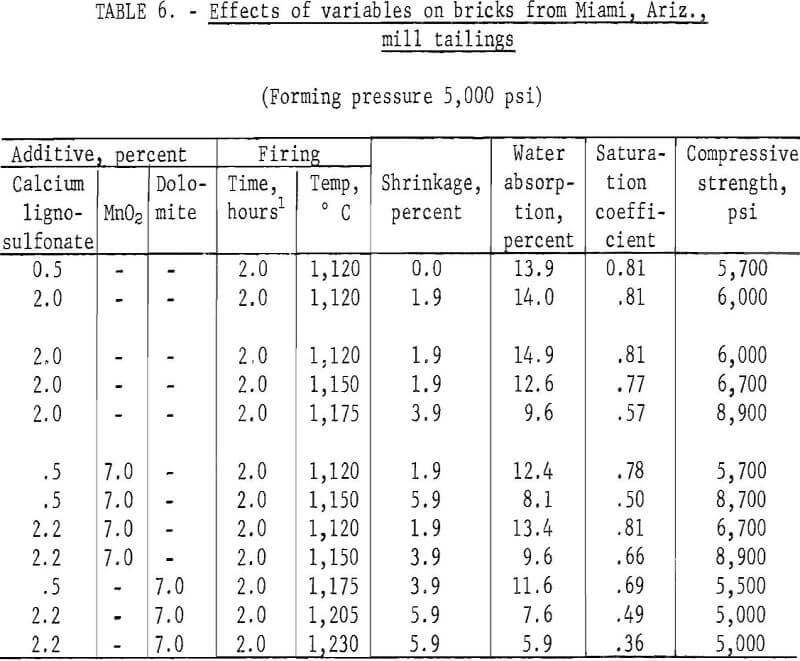

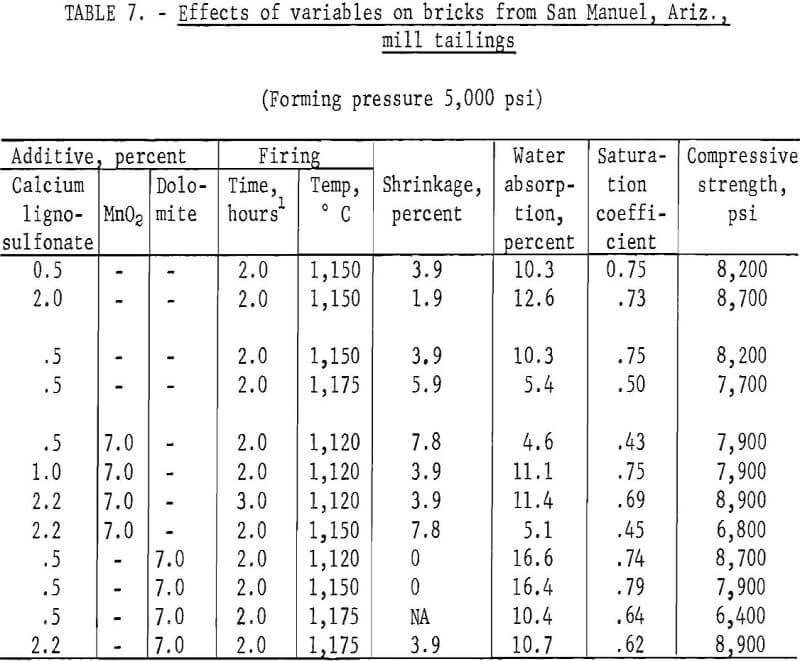

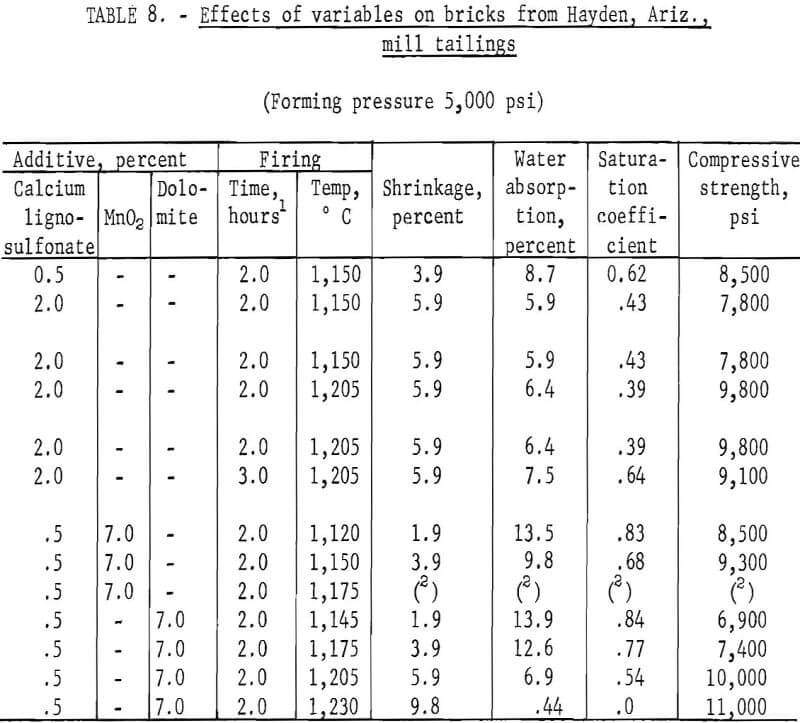

Further tests proved that the conditions established as best for the Magna, Utah, tailings were equally applicable for making bricks from the other mill tailings, except for the Anaconda sample which contained over 9 percent sulfur. Data resulting from the tests are presented in tables 6 through 8.

Desulfided Tailings

Excellent laboratory-size bricks were made from all as-received tailings, except those from Anaconda, Mont. The Anaconda tailings contained about 9 percent sulfur, and the excessive evolution of sulfur dioxide during the firing cycle caused blistering of the bricks. The emission of sulfur dioxide in excessive quantities as an air pollutant would also cause concern. Hence, the bulk of the pyrite and other sulfide minerals were removed from the Anaconda tailings sample by flotation. Additionally, the pyrite was floated from Kennecott’s Utah Copper Division tailings to determine if a lowered pyrite content would improve the quality of brick produced from those tailings.

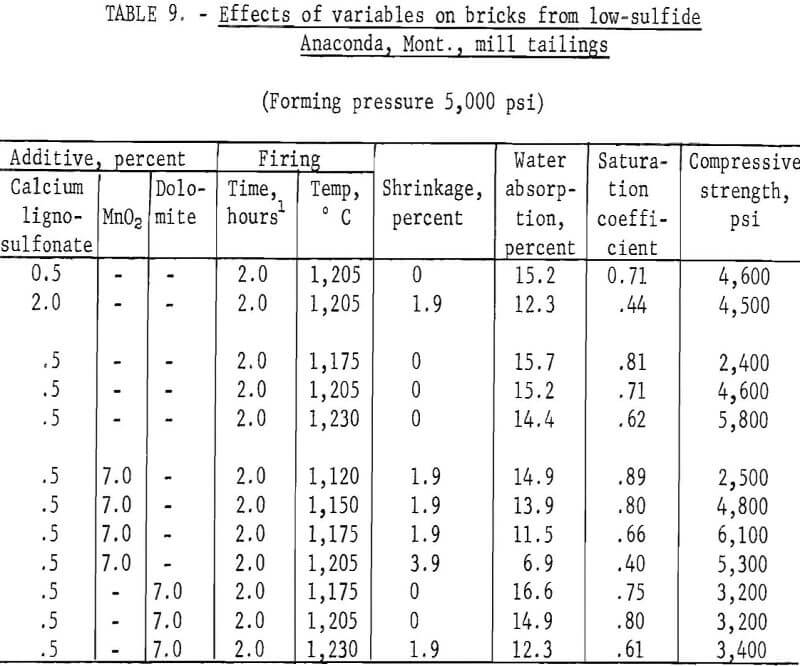

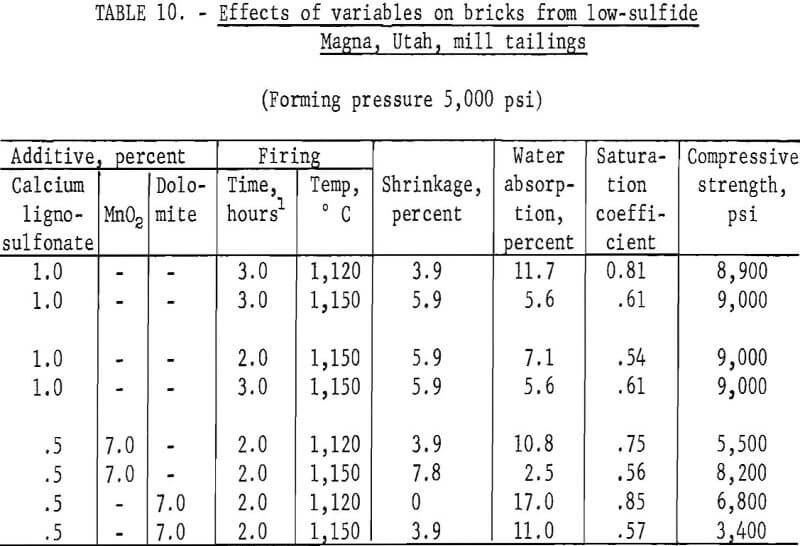

A simple flotation procedure was effective in reducing the sulfur content of the Anaconda, Mont., and Magna, Utah, tailings from 9.1 and 0.7 to 0.22 and 0.25 percent, respectively. The tailings of lowered sulfide content were made into bricks by the same procedure as used for entire tailings, and the results are shown in tables 9 and 10.

Bricks produced from Montana tailings met all ASTM Standards. Blistering was not a problem, and excellent bricks were also produced from the partially desulfided tailings. Removal of the sulfides from the Utah tailings did not produce better bricks than obtained from the original tailings.

Pilot-Plant Brick Production

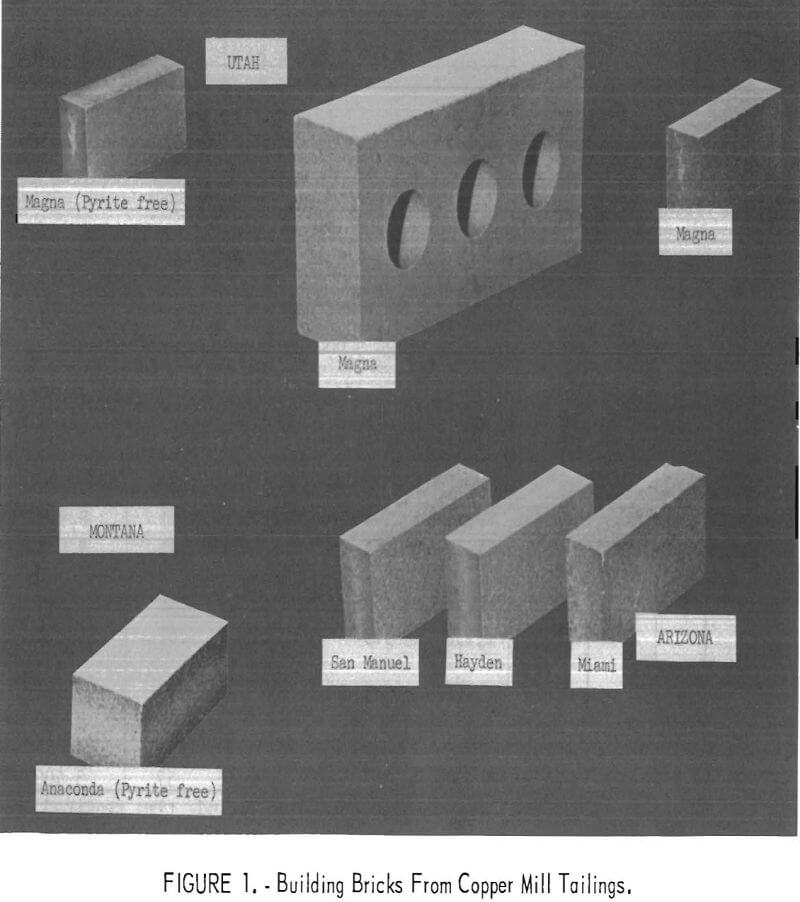

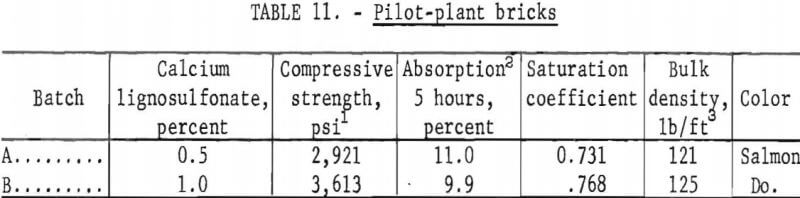

The successful production of bricks on a laboratory scale prompted a further investigation to determine if commercial-size brick could be produced in a dry-pressing pilot plant. To this end, 5 tons of as-received tailings was shipped to the West Virginia University Coal Research Bureau’s fly-ash pilot plant at Morgantown, W. Va. Pilot-plant runs were made using two differently prepared mixtures to produce standard-size brick, 2-¼ by 3-¾ by 8 inches in size. The first mixture tested consisted of 0.5 percent calcium lignosulfonate and 99.5 percent tailings; the second comprised 1.0 percent calcium lignosulfonate and 99.0 percent tailings. The bricks, formed by the dry press method, were fired at 1,150° C for 9 hours, and the products had an acceptable color (salmon) with excellent physical properties for such a relatively short firing period. Physical test results on five randomly selected bricks from each batch are presented in table 11. Standard- and laboratory-size bricks made from various mill tailings are shown in figure 1.

Economics of Brick Production and Marketing

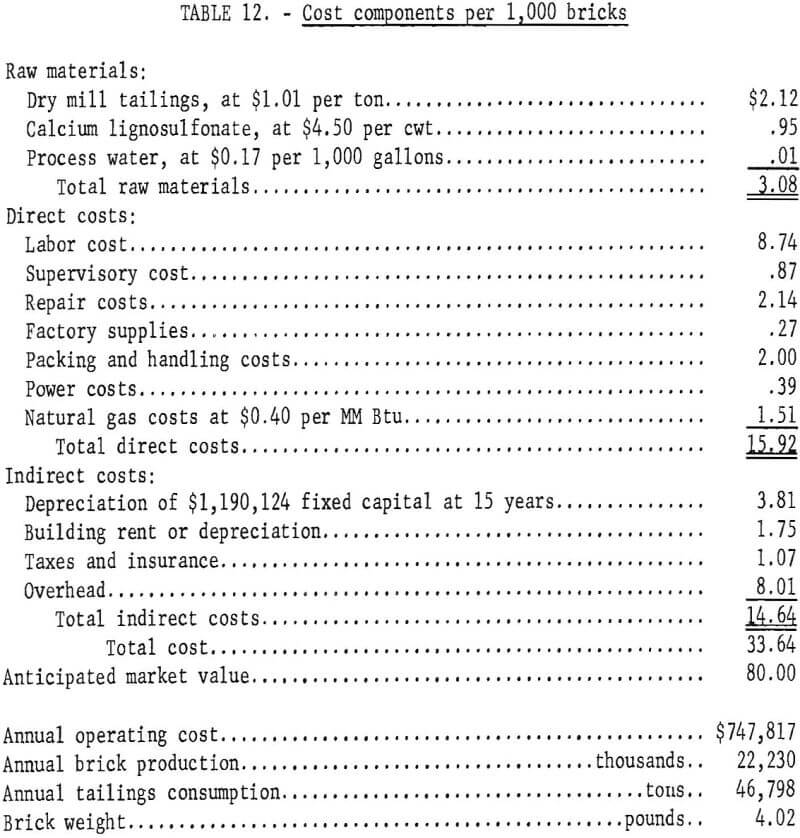

A production cost estimate prepared by the Coal Research Bureau of West Virginia University showed the estimated cost of producing 1,000 bricks from mill tailings to be $33.64. This was derived from the cost figures shown in table 12, which were obtained from pilot-scale production.

The postulated production cost of $33.64 when compared with an anticipated market value of $80 per 1,000 bricks indicates an attractive return on investment, but transportation costs of brick or tailings to urban centers must be considered. To evaluate the effect of transportation costs on return on investment, railroad freight rates were determined for brick between Salt Lake City, Utah, and Denver, Colo. (518 miles), and San Francisco Calif. (762 miles), based on shipment of at least 80,000 pounds (approximately 20,000 bricks). Quoted costs were $0.73 and $0.76 per hundredweight, respectively, to Denver and San Francisco. The freight costs of $29.35 to Denver and $30.55 per 1,000 bricks to San Francisco for 80,000-pound shipments would present total costs of bricks delivered to these localities of $62.99 and $64.19, respectively. Equivalent rates for shipment of tailings are not on current schedules but might be reasonably estimated at about half the cost of shipping brick.