Lead Nitrate Safety

Lead nitrate is used in small quantities in the gold recovery circuit. Lead is extremely toxic. It is a cumulative poison and so a dangerous exposure level would not necessarily show an immediate result, but continuous exposure at this level would maybe show as serious problems after a month. View a lead nitrate MSDS. Ingestion of […]

Sodium Cyanide Safety – Poisoning – HCN Vapor

Almost all solutions in the plant contain cyanide, and in the absence of any other information it should be assumed that all solutions contain cyanide. Because of the toxicity of sodium cyanide, it is important that all persons coming in contact with it be completely familiar with and observe the established safety practices. Sodium cyanide […]

Good Concentrator Safety Guidelines & Practices

The following guidelines are considered good industrial practice: When any equipment or structure is dismantled in whole or in part, and subsequently re-assembled, it must be completely checked and found to be safe before it is started up. Whenever a person observes what appears to be an unsafe or harmful condition or act he should report it as soon as […]

The Density of Liquids and Solids

Density data may be used for obtaining relationships between density, chemical composition, thermal and mechanical treatments of materials, etc. This circular defines density and specific gravity, describes 11 methods (hydrostatic weighing, pycnometer, flotation, hydrometer, falling drop, balanced column, Boyle’s law. electromagnetic, elastic helix, ice calorimeter, and volumetric) for determinations of the densities of solids and […]

Mineral Processing / Metallurgy Rules of Thumb

Here is a list of General Rules of Thumb often used in Mineral Processing and Metallurgy: A concentrator (mill) requires up to 3 tons of water for each ton of ore processed. It is therefore important to operate with the maximum practical pulp density and minimum practical upward or horizontal movement. The basic philosophy requires movement over the […]

Standard Bond Ball Mill Grindability Test Method-Procedure

Here is the old Allis-Chalmers Bond Work Index Grindability Test Procedure. The standard feed is prepared by stage crushing to all passing a 6 mesh sieve, but finer feed can be used when necessary. It is screen analyzed and packed by shaking in a 1000-cc graduated cylinder, and the weight of 700 cc is placed […]

Maintenance Management KPI’s

Schedule Compliance Definition: “Schedule Compliance” measures scheduled maintenance jobs against unscheduled jobs. It is the total maintenance work hours scheduled divided by the total scheduled and unscheduled hours worked for a given period of time. Scheduled Work is defined as: Any maintenance job or task that has a start date and time formally agreed to by […]

Maintenance Management Systems & Procedures

Computerised Maintenance Management System (CMMS) DefinitionThe Computerized Maintenance Management System (CMMS) is a tool used to collect field data and convert it into useful information such that maintenance can determine work needs, control the work and measure effectiveness in carrying out. The CMMS has three basic functions: To determine what work must be accomplished […]

Basic Elements of Maintenance Management

The Mission of a Maintenance Group The mission of the Maintenance Team is to support and enhance the profitability of the treatment and infrastructure Facilities by the preservation of the physical assets and thus assuring their operability. This is accomplished through planned, scheduled, efficiently executed and quality controlled preventive and predictive maintenance of the equipment and […]

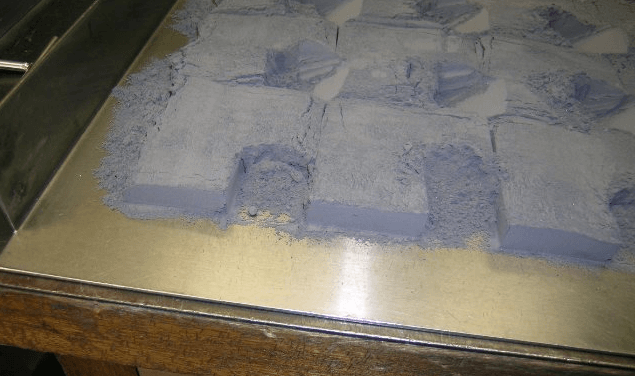

Sub-Sampling of Pulverized High Grade Gold Concentrates

The impressions in the second and third rows record a potentially biased sampling method. The Vee shaped cuts took most of their volume from the top, and almost nothing from the bottom of the pancake. This explains why periodic critical review of sampling at smelters is a good idea.