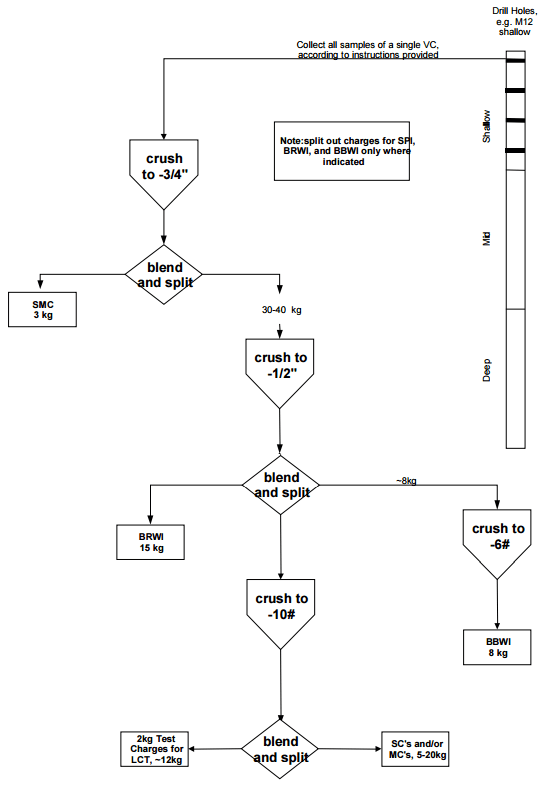

Sample Preparation Flowchart

The samples set aside for the Super Composites (SC) were blended to form the four composites used for the initial flowsheet development program. Each SC was crushed to 100% passing 10 mesh and rotary split into 2 kg charges and a reject fraction. A flowchart summarizing the sample preparation procedure is presented here below. Eighteen […]

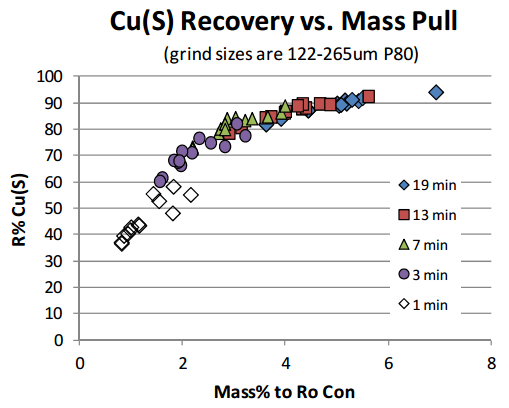

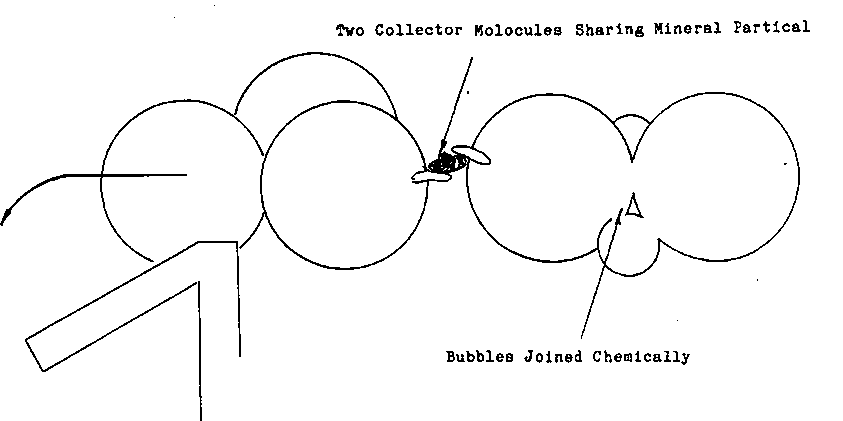

Selective Flotation

Who would think that Selective Flotation of copper, gold, zinc or any metal would required that one must be able to feel pain and recognized and/or admit when it hurts. Flotation mass-pull is a process that is often misunderstood; a learner’s mistake made by non-operating types. You do not need to pump anything in the […]

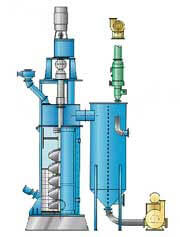

Lime Slaking Equipment

A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation circuits. A pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit. Other lime […]

Concentrator Troubleshooting -From Grinding to Flotation

Let me sum this up in two or three sentences. Start solving a problem at the effect. Reduce the effect as much as possible when it is losing money or making a mess. Check all of your mechanical and operational variables to discover the cause. You know what the equipment and process is supposed to […]

Concentrators Sample Collection – When and Why

What is the purpose of SAMPLING? Where do you need to collect samples in a plant for good operation and correct metallurgical accounting? Samples give the operating staff and crew all of the information that is necessary to operate the concentrator plant. Samples may show when equipment is almost worn out, when circuit performance is […]

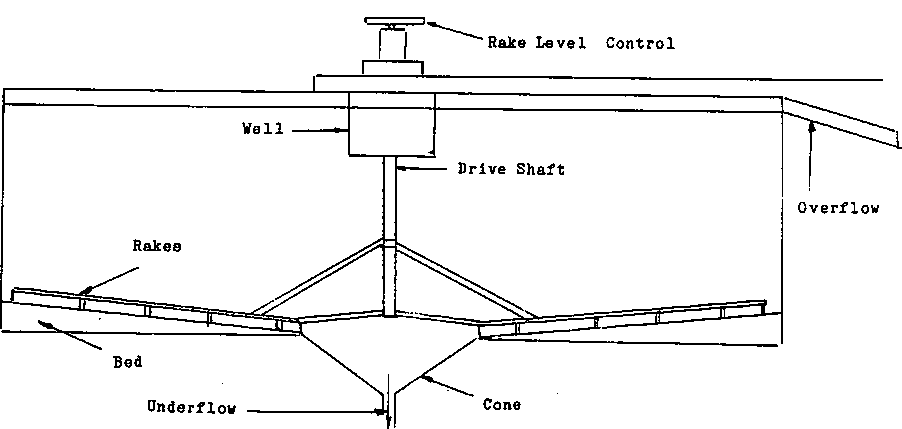

Concentrate Thickener Operation

In mining, when flotation is finished with the ore, and a final concentrate has been produced, often, both products will go to a concentrate thickener before it is dried for shipping. This is a very important step so here we discuss Basic Concentrate Thickener Operation. For the mine to get its concentrate to the smelter it […]

Adjusting Pulp and Air Levels to get good Froth Movement

Any time that you have an overloaded froth condition the OVERFLOW that is going over the side of the cell will slow down as the froth column begins to collapse under the weight of the mineral. The first corrective reaction is to raise the pulp level or add air to the cells to quickly increase […]

How to be a Flotation Operator – Job Description

The problem that most flotation operators have in learning their job (after reading the Job Description) isn’t with the flow sheet or the mechanical equipment. It is how to recognize the effects that the variables have on each other. The main operating tool that any operator has to use is their own five senses and a […]

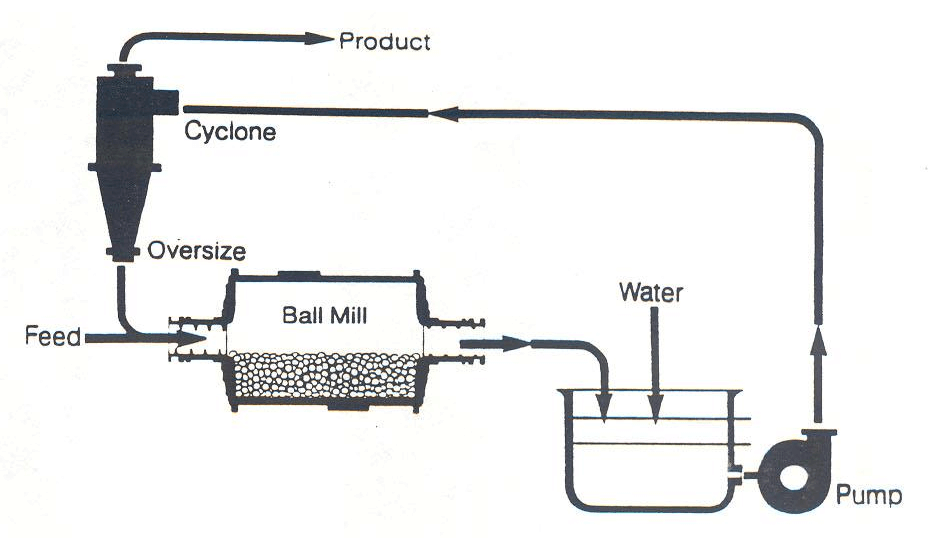

Operating and Troubleshooting a Grinding Circuit

In the operation of a grinding circuit you are managing several pieces of equipment as a single unit. If you make a change in the ore in the fine ore bin, that change will be reflected through the entire grinding process and beyond into the rest of the concentration system. The first thing that an […]

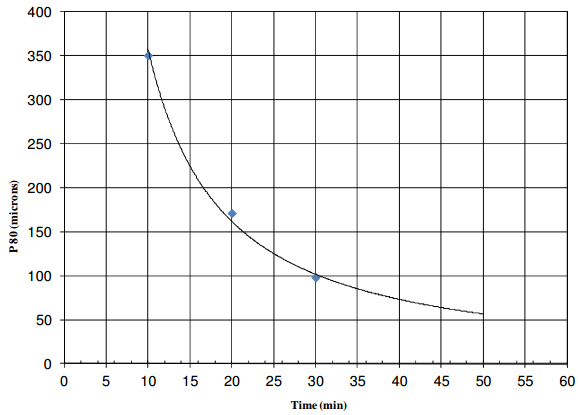

Grind Calibration Curve -Laboratory Test

Before doing multiple laboratory flotation bench tests in which you need P80 grind controlled or predicted, you need to build a Grind Calibration curve following this short procedure. You will consistently add sufficient water to the mill to achieve a pulp density of 67% solids (Example: 1 kg solids + 0.5 kg water or 2 kg […]