Anodic Dissolution of Zinc Sulfide Suspensions in Aqueous Solution

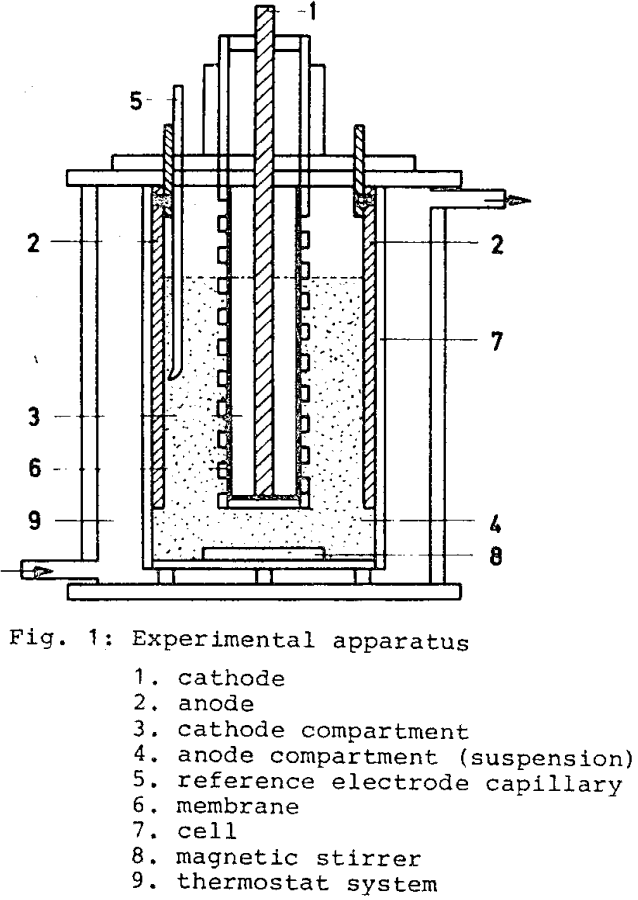

A new suspension electrolysis method has been developed, which enables without any gas or dust pollutants a direct anodic extraction of zinc from zinc sulfide concentrates, while simultaneously oxidizing sulfide sulfur to elemental sulfur. The investigations were performed in a laboratory scale electrolytic cell with suspended zinc sulfide concentrate particles with or without graphite powder […]

How to Recover Zinc from Zinc Chloride by Electrolysis

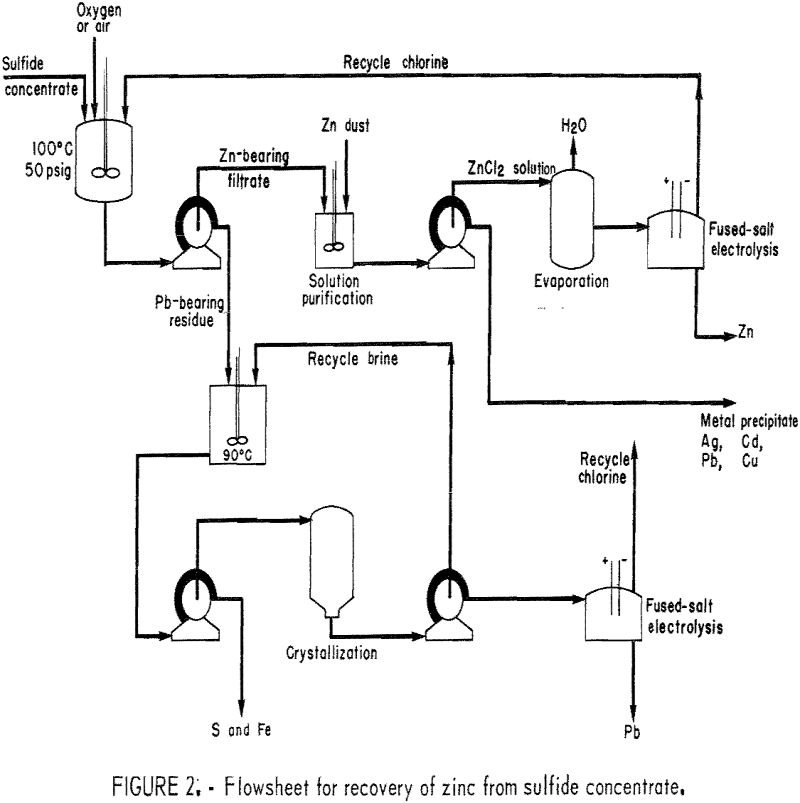

The closure of zinc plants has reduced smelting capacity in the United States from 1,300,000 tons in 1969 to approximately 700,000 tons in 1974. At the same time, U.S. consumption of zinc has increased, as shown in figure 1. As a result, the United States must import over 50 pct of its zinc supply from […]

Acid Dissolution of Metal & Mineral Samples by Microwave

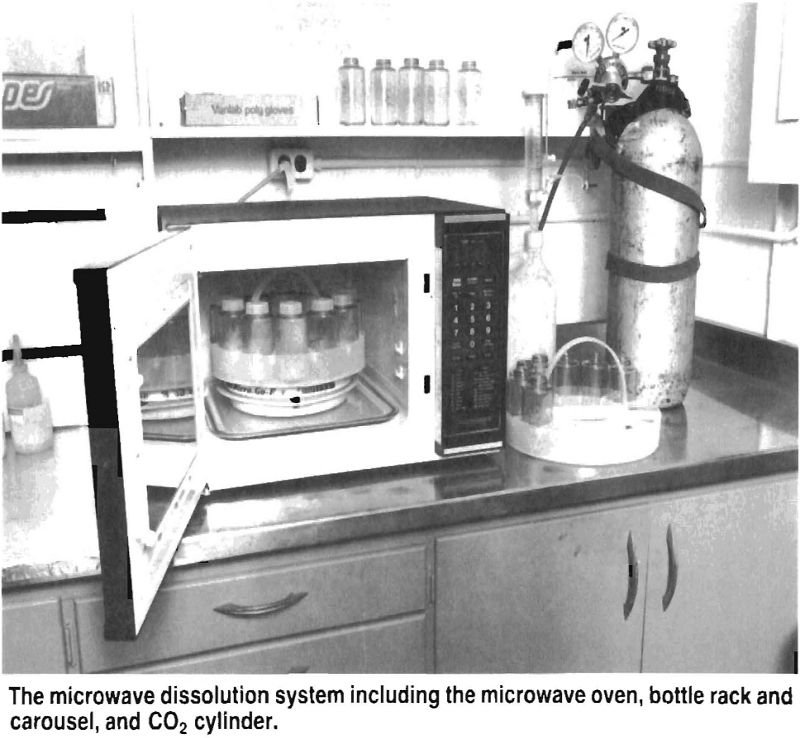

Objective Reduce the time, complexity and expense of dissolving metal and mineral samples in solution in preparation for chemical analysis. Approach In earlier research, the Bureau of Mines developed a rapid and inexpensive method for the dissolution of mineral and metal samples in plastic pressure bottles heated in a boiling water bath. Using this technique, […]

Effects of Impurities on Electrowinning of Lead

Lead is one of the oldest metals known to man and has been used for hundreds of years. The method for producing lead from galena has changed very little. A lead concentrate is mixed with fluxing agents, roasted to remove sulfur, and heated to about 1,000° C with carbon to obtain an impure metallic product, […]

How to Make Lead Metal by Molten Salt Electrolysis

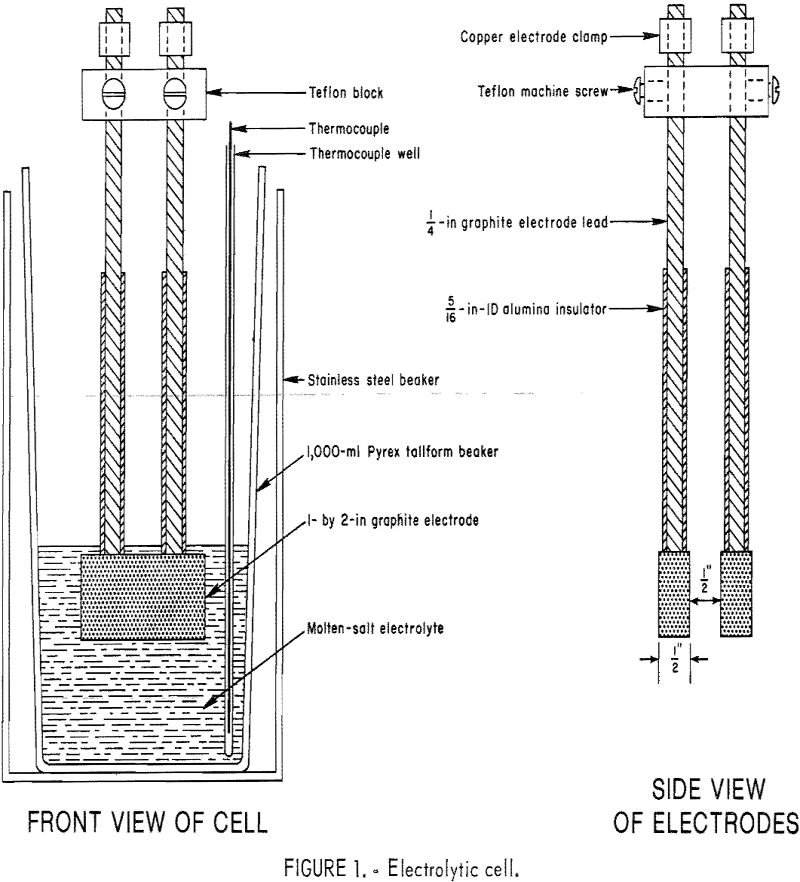

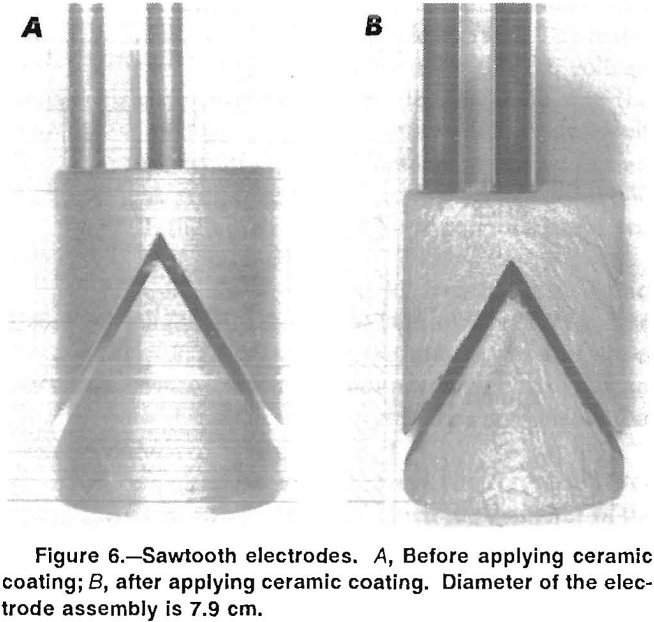

Molten-salt electrolysis of lead chloride is an integral unit operation in a ferric chloride leaching process that was developed by the U.S. Bureau of Mines for treating galena concentrates as an alternative to smelting. Prior to the Bureau’s work, several other investigators had studied molten-salt electrolysis of lead chloride. As part of the Bureau’s research […]

Precipitation of Mercury in Cyanide Gold Leaching

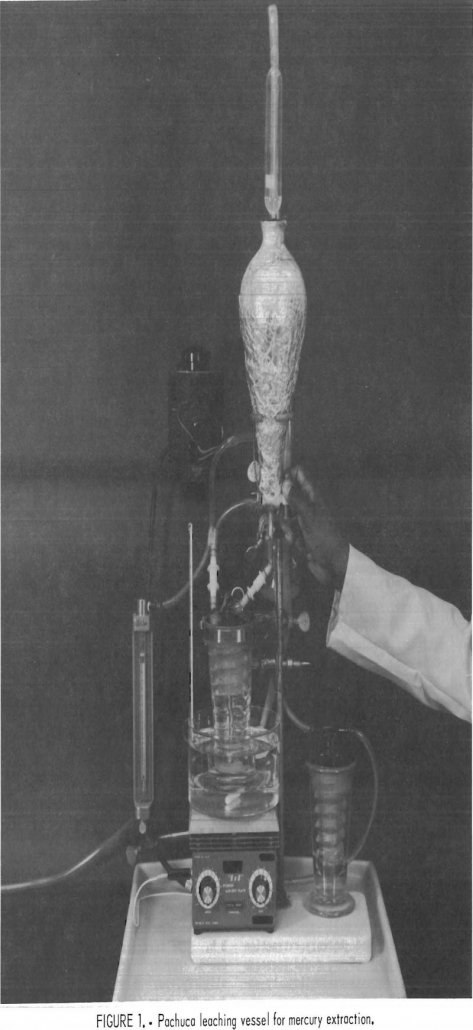

Numerous low-grade gold-silver ore deposits are being mined and milled throughout the Western United States. In addition to gold and silver, many deposits contain as much as 15 ppm of mercury. During cyanidation, 10 to 30 pct of the mercury and 85 to 90 pct of the gold are typically solubilized. The reactions for gold […]

Electro-depositing PGM Platinum Group Metal Coatings

The Bureau of Mines has evaluated the substitution of platinum-group metal coatings for bulk platinum-group metal objects as a means of reducing the consumption of the platinum-group metals. The Bureau has conducted several studies of the electro-deposition of the platinum-group metals from molten alkali metal cyanide baths during the last two decades. The major incentive […]

Tin Electrolytic Stripping

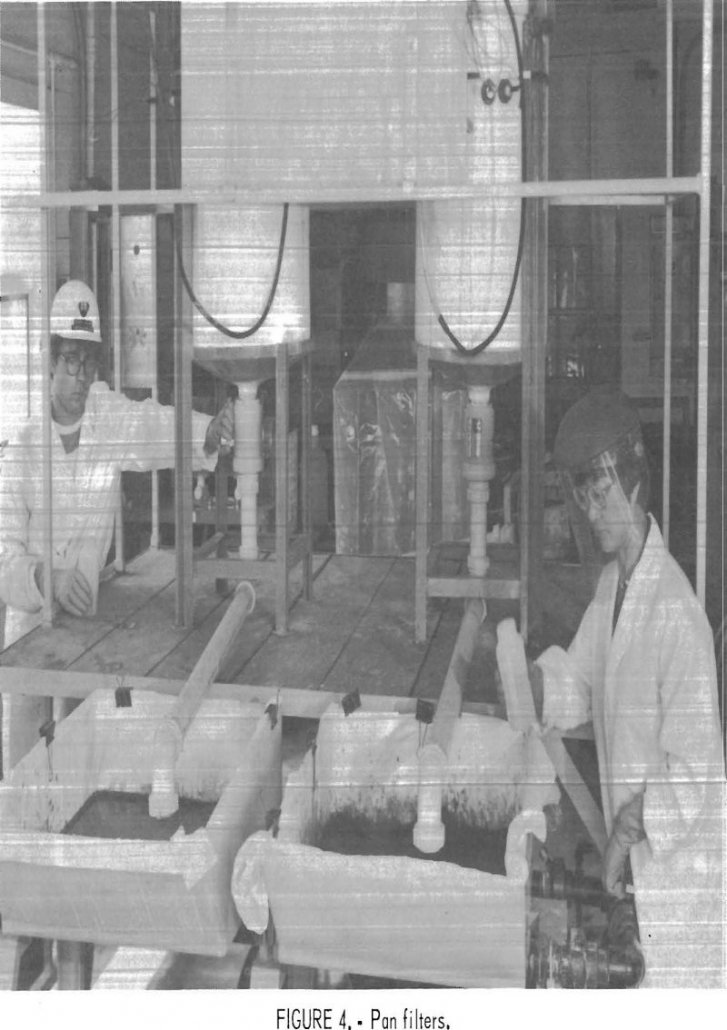

At present, in the United States, municipal solid waste (MSW) is generated at a rate of 3 to 5 lb/d per person. It contains about 8 pct ferrous metallics. Projections indicate -11 MMton/yr of this valuable ferrous scrap is being discarded Discarded MSW magnetics are equivalent to approximately 15 pct of the total U.S. 1982 […]

How to Recover Lead from Scrap Batteries

The Bureau of Mines has investigated an electrolytic recycling process to recover lead from scrap batteries as part of the effort to improve secondary recovery of metals, minerals, and other values from waste products. This process eliminating sulfur dioxide (SO2) generation and minimizing particulate lead emissions, is an acceptable alternative to the pyrometallurgical processes currently […]

Copper Electrowinning

The very survival of the U.S. copper industry is presently tied to the leach SX-EW process, a technology which 15-20 years ago was considered too radical and far fetched to be accepted by the industry. It came to life rather dramatically with the Ranchers Bluebird Mine and shortly thereafter with the Cyprus Bagdad plant. All […]