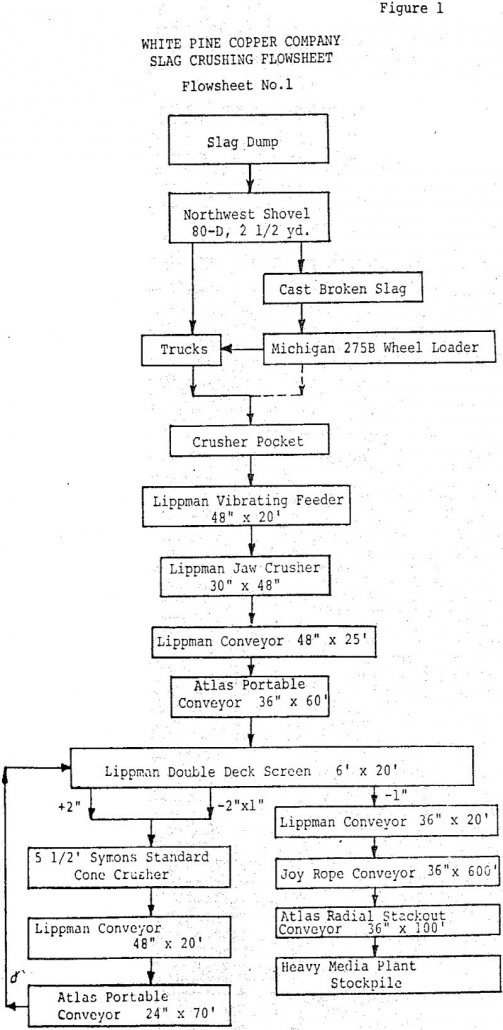

Copper Recovery from Reverberatory Slag

White Pine reverberatory furnace slags contained economically recoverable amounts of copper for a variety of reasons. Among them: White Pine concentrates yield extremely high matte grades (65+% Cu) and viscous slags. The viscous slags hinder matte settling causing matte “prill” entrapment in the slag. White Pine’s total refined copper output is accomplished through fire refining […]

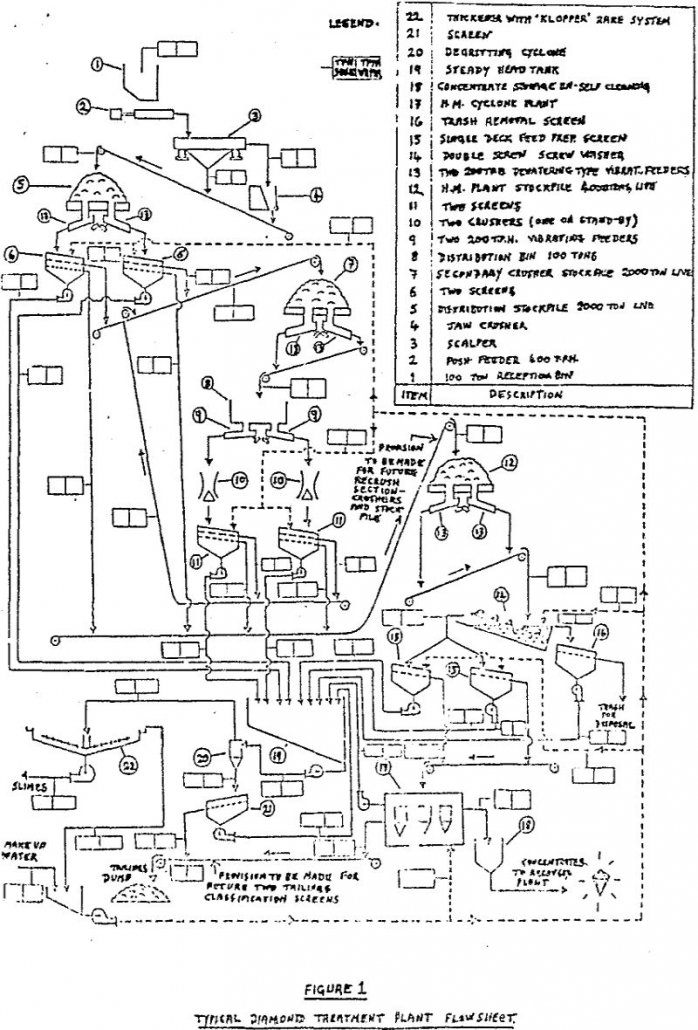

Process Plant Design

The radial system simplifies and improves control and supervision to a very considerable extent and can lead to a form of continuous plant operation with the separate sectors shutting down in succession for necessary maintenance while maintaining the overall plant operation. Radial Layout for Increased Treatment-Plant Productivity A great deal of time and trouble is […]

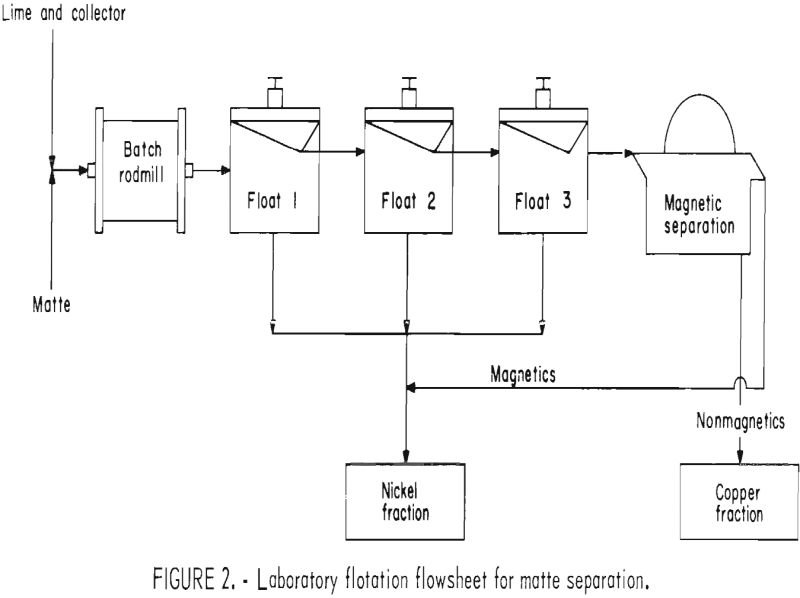

Separation of Copper-Nickel by Flotation and Magnetic Methods

As part of our mission to investigate technology options for the development of domestic mineral resources, conducted tests aimed at separating the copper-nickel values in bulk sulfide mattes into copper-rich and nickel-rich fractions. Resources in the Duluth Gabbro Complex are estimated to be 4.4 billion short tons of mineralized rock grading more than 0.50 pct […]

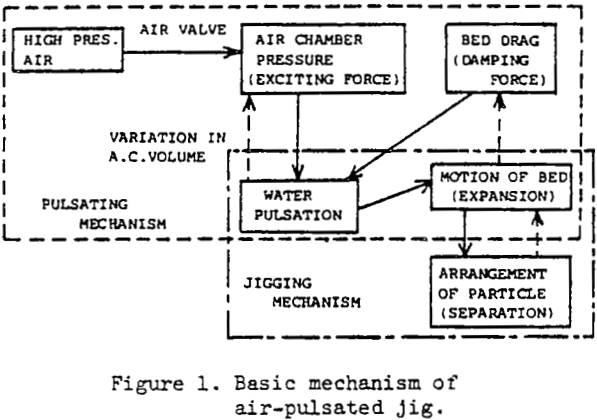

Air Pulsated Jigs

An air-pulsated jig has teen widely adopted as a main coal washer. It may be mainly because of its many technical and economic features such as large capacity, low running cost, long life, etc. However, the recent increasing demand of fuel coal requires a higher productivity and efficiency of the air-pulsated jig. To fill this […]

Jigs & Coal Preparation

Traditionally in coal processing jigs have been used to clean the coarse coal fraction, the +3/8″ or +¼” material. Today with the advent of modern fine coal jigs in the United States, its place was moved from the coarse to the intermediate coal circuit, the 3/8″ x 100 mesh. Recent theoretical performance and […]

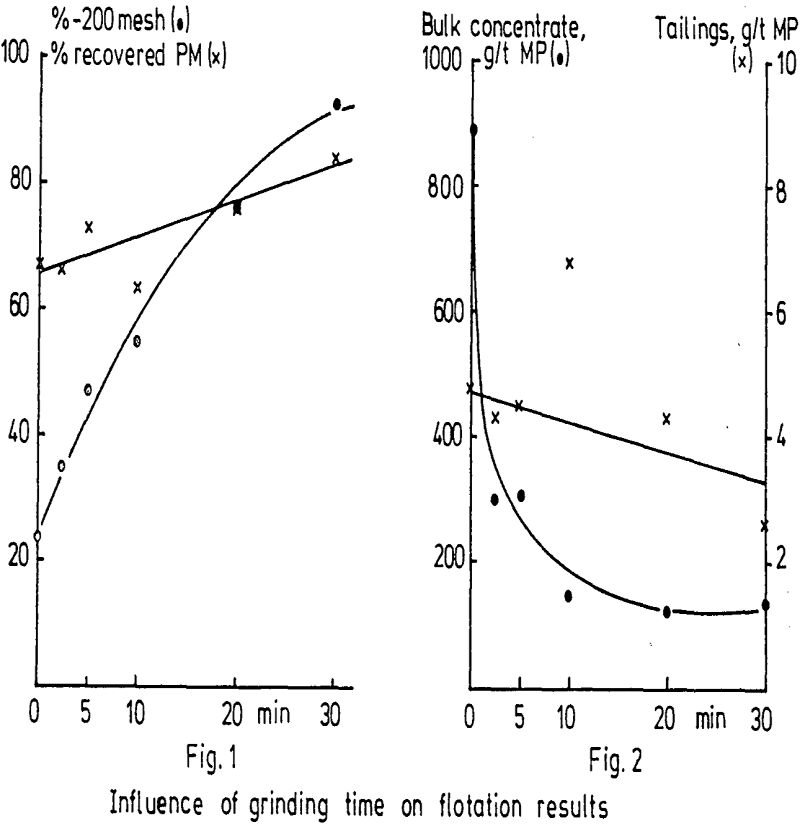

Reprocessing Gold Tailings by Gravity Methods

Tailings originating from the gravity concentration of a gold ore containing about 14 g/t Au have been treated by various beneficiation methods. These tailings have been screened on the 147 and 74 micron sieves and the two coarsest fractions have been separated on shaking tables with unsatisfactory results, but the concentrates have been examined in […]

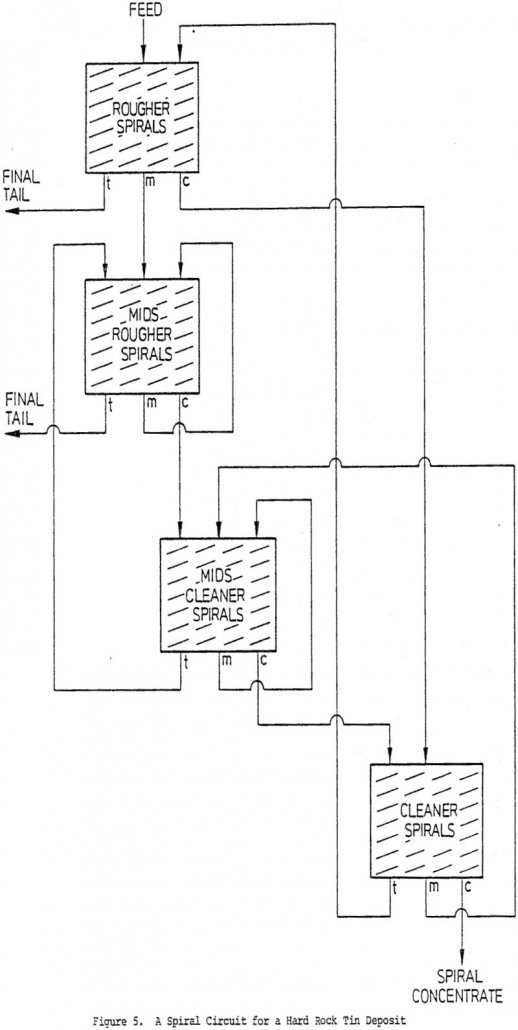

Gravity Concentrators

For some decades now, the use of gravity separation techniques to recover valuable minerals has been relatively neglected in comparison to the developments in flotation and hydrometallurgical technology. However, more recently, there has been a resurgence of interest in gravity separation, especially in utilizing its low cost to improve the economics of high tonnage and/or low […]

Dry Gravity Separation

The basic principle of this separation method was already defined in the middle of the nineteenth century. However, a change over for the treatment of minerals has followed from the construction of proper machines i.e. airjigs and airtables as late as in the twenties and thirties of this century. The main application of this technology […]

Classification & Concentration of Heavy Minerals

The recovery of heavy minerals by gravity concentration during grinding is practiced widely in the minerals industry. Studies have shown that the grade and recovery of the concentrate depends not only on the performance of the concentrator but also on the degree of liberation achieved in the mills and the scavenging action of the hydrocyclones […]

Laws of Gravity Gold

Ten Laws of Gravity Gold Recovery DO DON’T Try to Evaluate the Economic Impact of Gravity Recovery Get a Statistically Significant Sample of the Ore to Evaluate Gravity Response on a Size-by-Size basis Design the Gold Recovery Circuit with a Good Understanding of Gold’s Behaviour in Grinding Circuits When GRG Recovery Is Not Indicated, Look […]