Basic Principles & Variables Affecting Froth Flotation

The basic factors, principles and variables affecting froth flotation are enumerated in condensed form below: Ore. (a) Mineralogical character. (b) Fineness of grinding. (c) Method of grinding. Agents. (a) Principal flotation agent. (“Oil”) α Character. β Quantity. (b) Minor agent. α Character. β Quantity. Water. (a) Quantity with respect to solids, i.e. pulp thickness. (b) […]

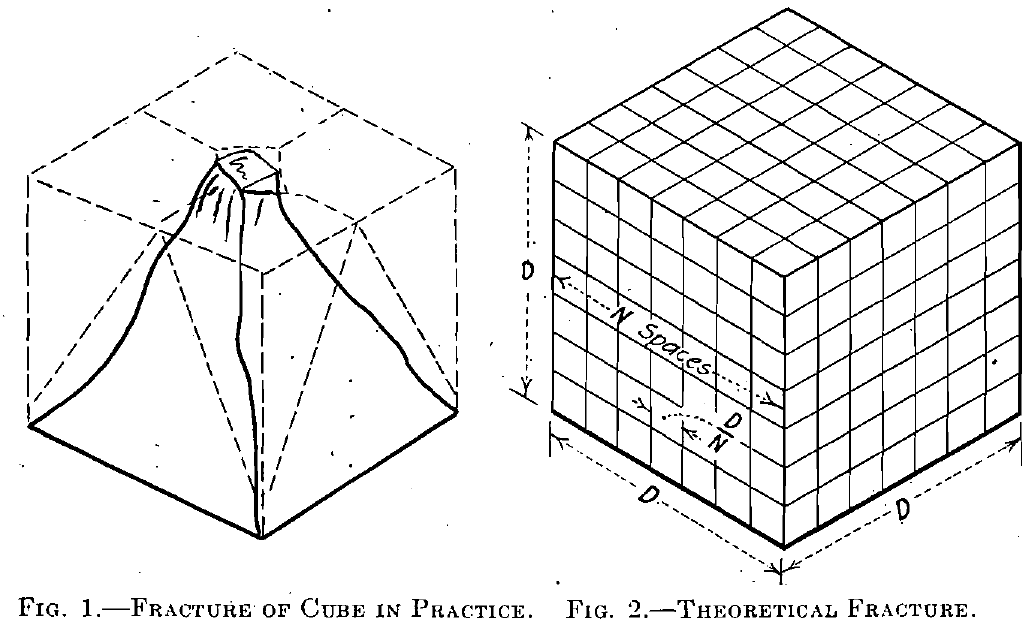

Rock Crushing Theory and Formula using Kick & Rittinger’s Law

Rittinger’s theory and law of the energy expended in crushing of rock is that the work of crushing is proportional to the reduction in diameter; or, as I have more fully expressed it: “The work done in crushing is proportional to the surface exposed by the operation; or, better expressed for this purpose, the work […]

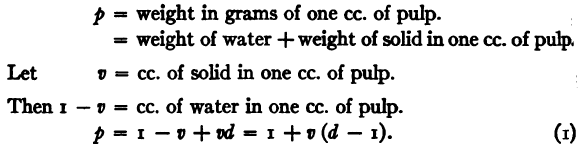

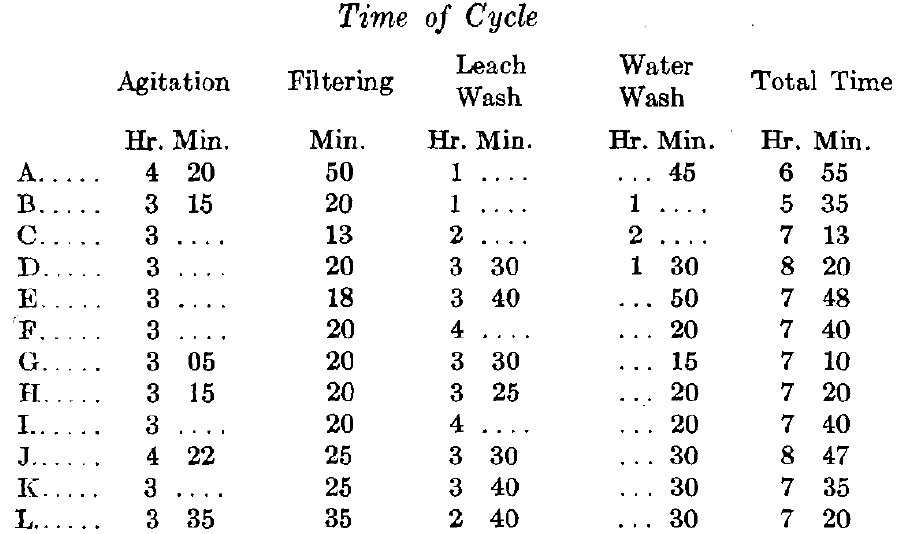

Pulp Formulas & Metallurgical Formulas

Definitions. “Pulp,” in flotation terminology, is a freely-flowing mixture of powdered ore and water. “Pulp density,” when the phrase is applied properly, indicates the specific gravity of the pulp. “Percentage of solids” means the ratio, expressed as a percentage, of the weight of the solids in a pulp to the total weight of pulp. “Pulp consistency” is the ratio, […]

Ammonia-Carbon Dioxide Ore Treatment

Most metallurgists appreciate the great need of a process for the extraction and recovery of valuable metals from complex ore, where the presence of one metal increases the cost of extracting the other metals to such an extent that not any of the metals can be extracted at a profit. We need only refer to some […]

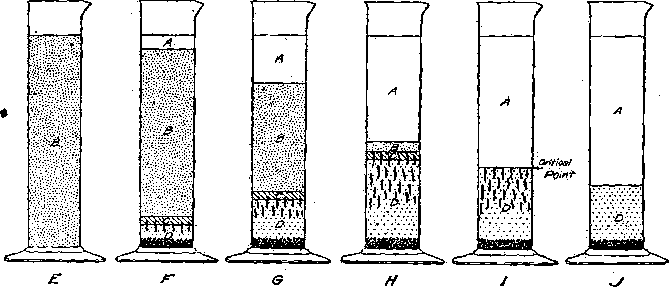

Measuring Settling Rates and Calculating Thickener Capacity

In order to develop rational methods of measurement and laboratory testing, it becomes necessary to study the general phenomena of settling rates. Since it was desired to give the public the benefit of these methods at as early a date as possible, together with the knowledge of the general principles of slime settling necessary for a […]

List Gold Metallurgical Tests

In order to have a preliminary idea about the metallurgical performance of the samples, some scoping tests have to be performed. They can be carried out in the prospective mine site and/or special metallurgical laboratory. The final election is based on the equipment availability and gold mineralization. Test to be done include; concentration by gravity, […]

Basic Gold Prospecting & Exploration Methods

Prospecting and exploration that is a search for precious metals deposits is not a simple process because big deposits were discovered a long time ago. There are several places with important content of precious metals waiting for skill prospectors. The large mining companies of the world are focused in big deposits and the small deposits […]

Estimation of Free Cyanide using Iodine and Potassium

The process of estimating free cyanide depends upon the fact that when a solution of iodine in potassium iodide is added to a solution of a simple cyanide, the reddish-brown color of the iodine solution disappears so long as the cyanide is in excess, since the reaction results in the formation of an iodide of […]

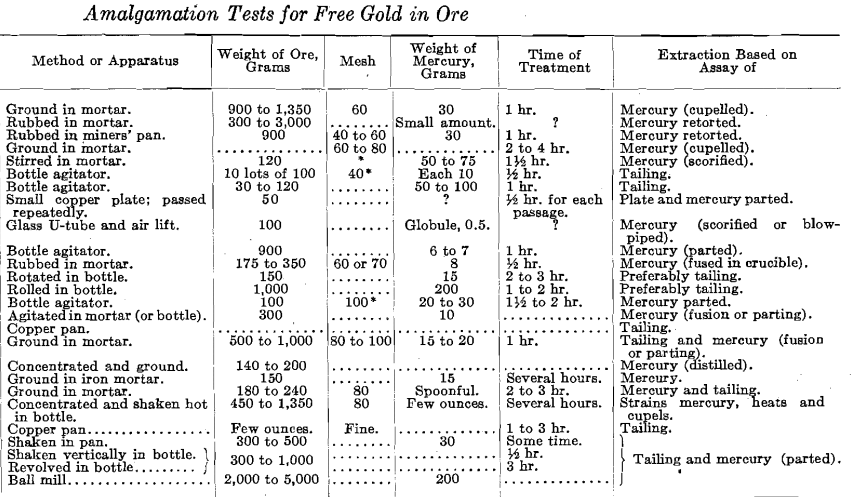

Free Gold Content by Amalgamation Assay Test

The amalgamation assay consists in subjecting a weighed sample of ore to the action of mercury, and separating the latter after the gold is presumed to have become amalgamated. Preferably the original ore or “heads,” the “tails” after amalgamation, and the mercury which has been separated, are all three assayed, as the results then check […]

Flux

Methods of Precipitate Refining FLUXES FOR METALLURGY Recovery of Precious and Secondary Metals from Electrolytic Copper Refining PRECIOUS METALS REFINING PRACTICE CALCULATING-DETERMINING SLAG DENSITY Flux SLAGS AND FLUXES IN PYROMETALLURGICAL PROCESSES