Testing Method Mine Anchorage Roof Bolts

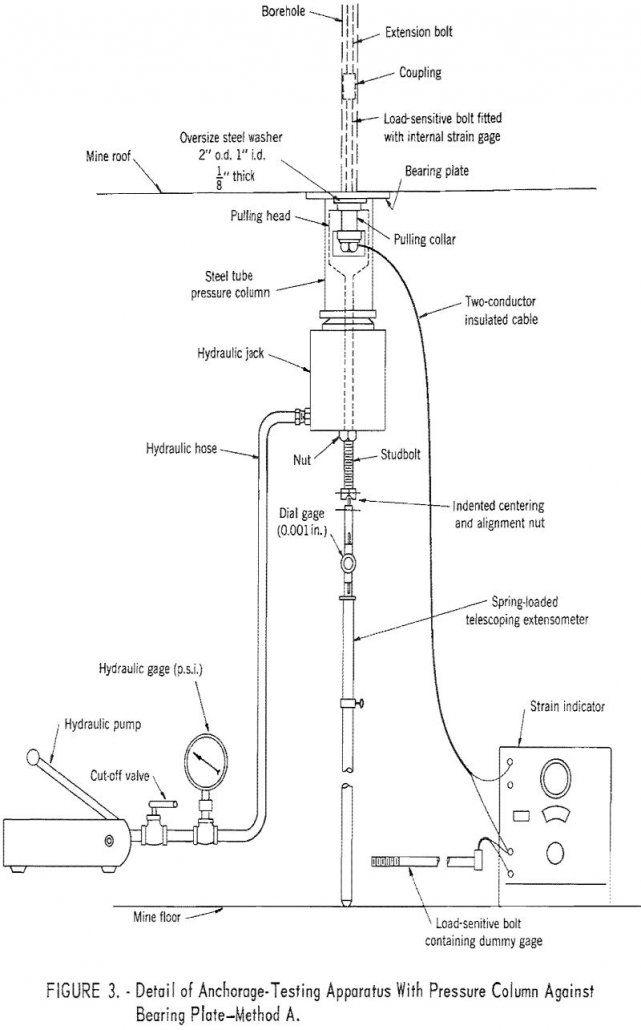

Two methods of testing anchorages of headed expansion-type mine roof bolts were investigated by the Federal Bureau of Mines to determine whether they are acceptable for general use. In both methods a load was applied to a tightened bolt with a hydraulic jack. A total of 80 tests, 40 using each method, was conducted in […]

High Speed Camera in Rock Blasting

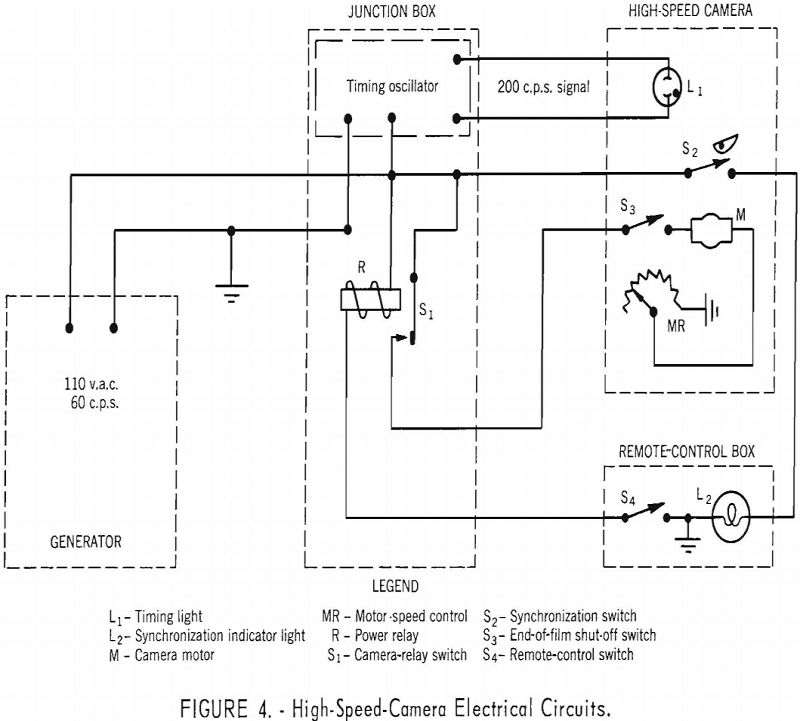

The breaking of rock by explosives occurs so rapidly that the details of the phenomenon cannot be observed by the unaided eye. High- (frame-) speed motion pictures offer a means of slowing down the blasting action so that the various phases of the process can be observed and studied. During the last 10 years, both […]

Conveyor Design for Mining Machines

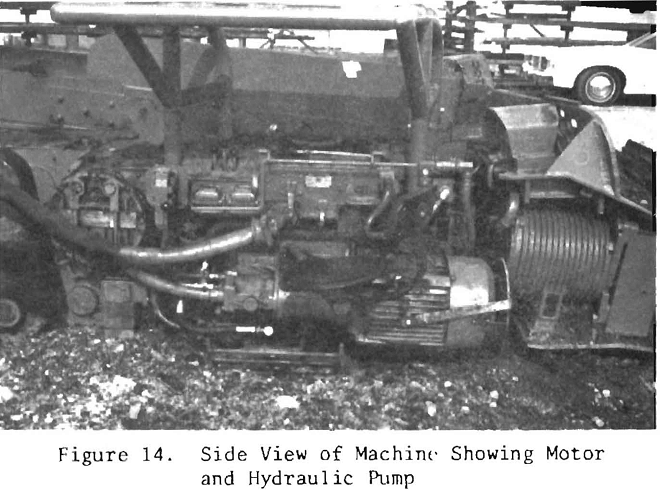

It does not appear likely that this conveyor-system function requirement can be avoided. The emphasis on the continuous miner performance is necessarily such that the conveyor system must be required to handle any material that is provided by the cutting head. Hence, a slowing down in the rate of advance of the miner to produce […]

Open Pit Equipment Selection and Maintenance

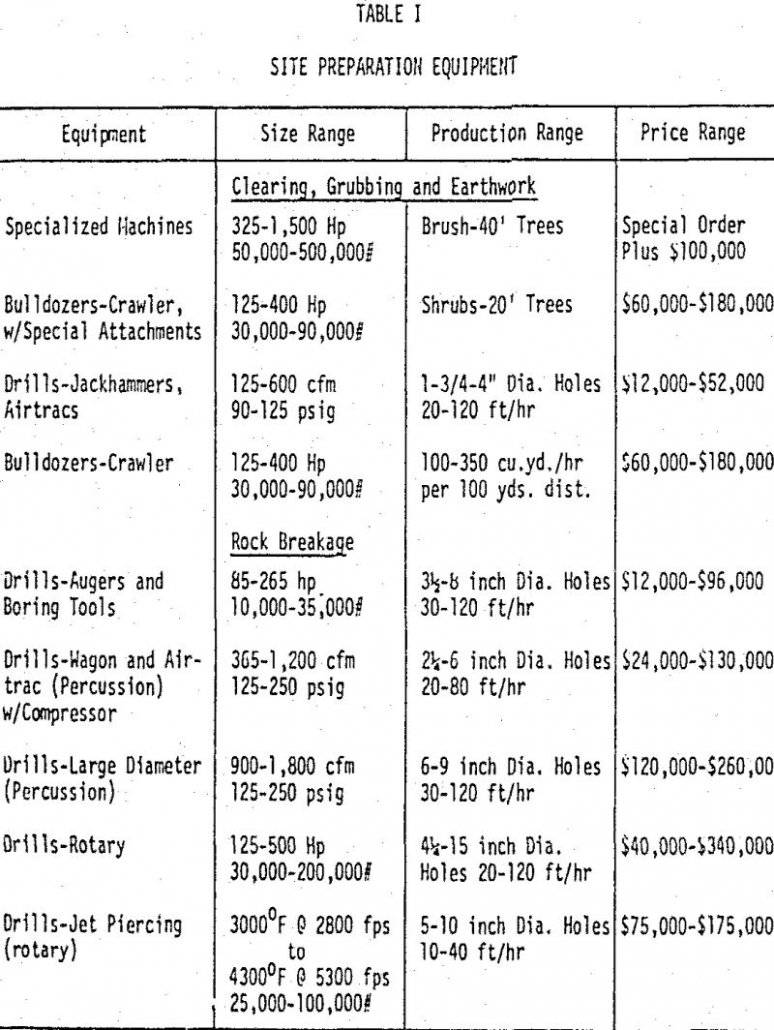

Principal factors influencing equipment selection can be grouped into five basic categories. Tonnage Requirements, Ore and Waste, Topography and Property Line Considerations, Ore Control Requirements, Physical Characteristics of Ore and Waste, and Climatic Conditions. Site Preparation Specialized Machines: This type of equipment generally operates on the principle of leverage uprooting and mechanical breakage of fallen vegetation. It is used in […]

Hydraulic Excavator

First, the hydraulic excavator enjoys tooth forces of the shovel because the dipper is attached to the machine with a dipperstick and boom, and can often actually realize greater tooth forces than a shovel because of the prize action of the dipper in hard digging. Digging range can be as deep as 35′ while dumping […]

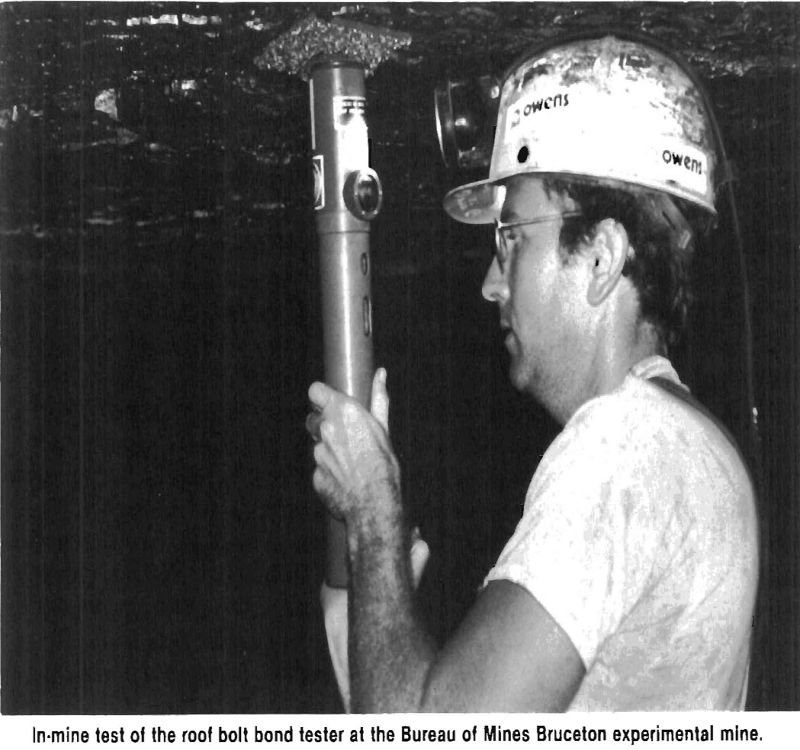

Roof Bolt Bond Tester

A measured pulse of energy is sent into the bolt by a piezoelectric transducer, and the instrument listens for reflected energy. Where the bolt is properly bonded, the energy passes from the bolt, through the resin, and out into the rock mass. Where proper bonding does not exist, a portion of the energy is reflected […]

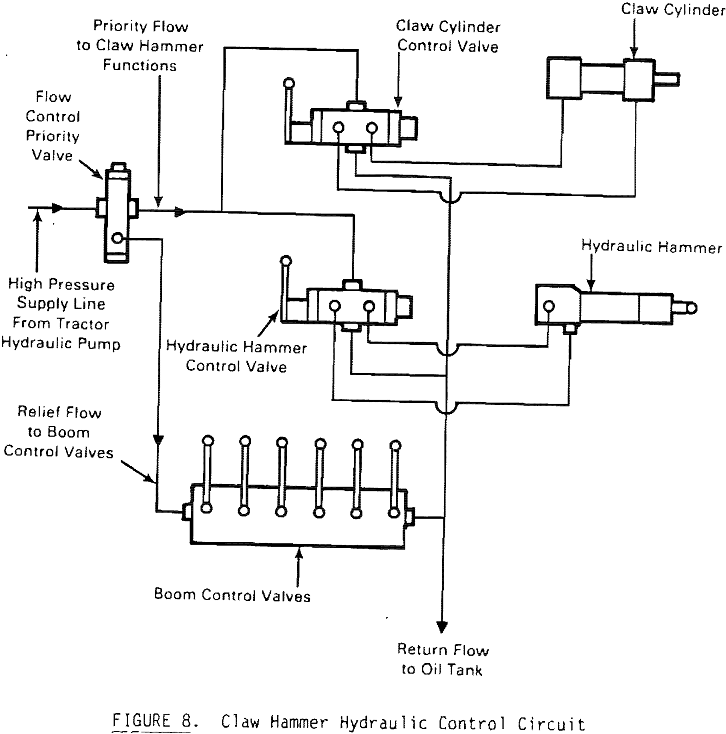

Claw Hammer Scaling Tool

Proper scaling is necessary for safe operation during any underground mining activity. This need is documented in the mandatory regulations for scaling found in 30 CFR 57. In many U.S. mines operating today, scaling is accomplished by manually barring-down the loose material from around the mine opening. Barring-down requires a great deal of physical strength, […]

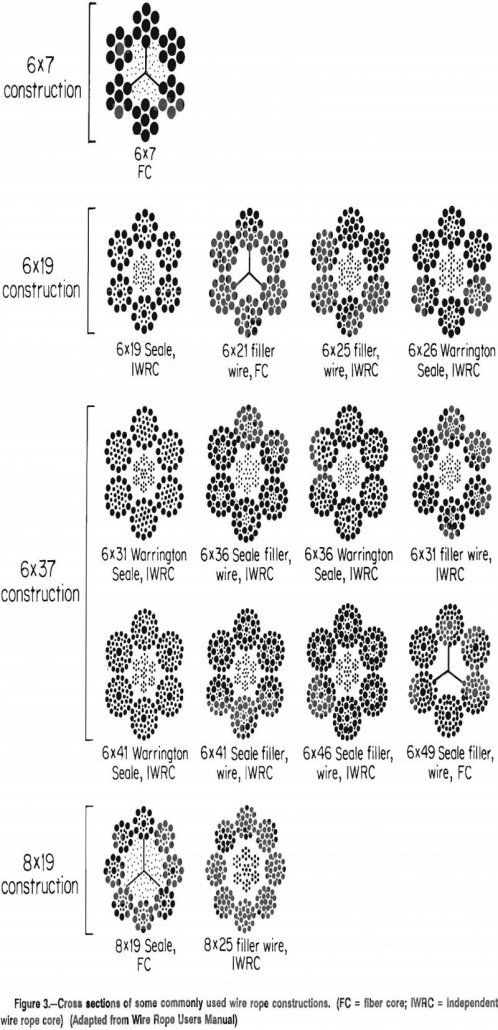

Wire Ropes & Mine Hoisting

Although wire rope has been in use for over 100 years, it is a complex structure that is still not well understood. Wire ropes are made in diameters from less than 1/32 to more than 7 in and can have as many as 900 individual wires. The mining industry uses a lot of wire rope, […]

Mining Equipment: Select, Buy & Maintain

Mining Equipment Selection Some basic parameters had to be defined at the time: Mechanical or diesel electric trucks. Number of shovels versus size versus number of pits in operation. Size (height and width) of shops and doors. Number of repair bays. Cranes capacity. Number of service equipments (graders, dozers, loaders). The maintenance shop was designed […]

Rock Cutting Equipment

Mechanical excavators were introduced for soft rock cutting at the time of the industrial revolution. The early machines date back to mid 1800’s and were developed for rapid excavation of tunnels and to increase production in the mining environment. The early radial or drag type tools were very primitive and made of hardened steel and […]