Pelletizing Characteristics of Iron Ore Concentratesc

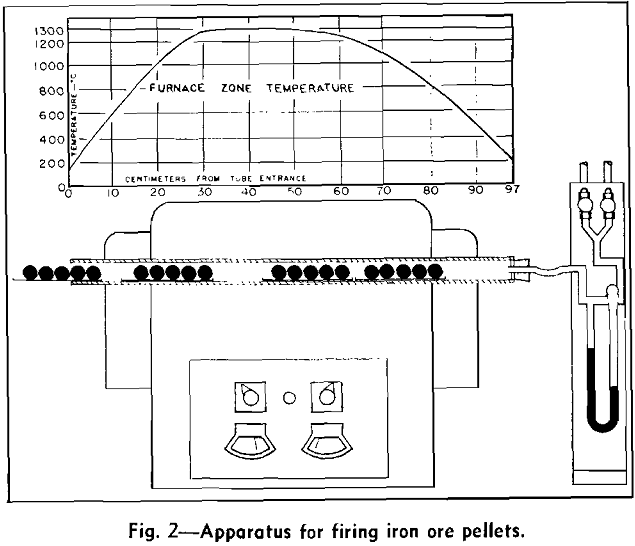

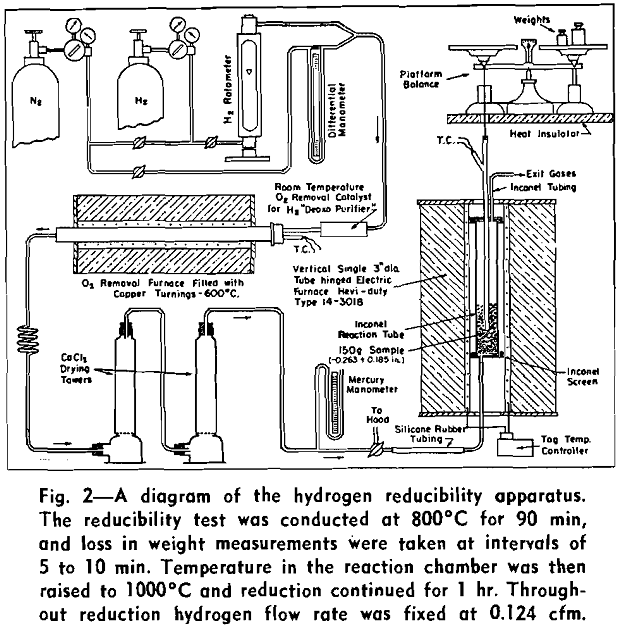

In most routine experimental work on products and processes, methods of operation and product evaluation are established from accurately controlled laboratory tests. With particular emphasis on the pelletization of fine iron ore concentrates, standardized procedures of laboratory production and product testing have been established at Cleveland-Cliffs Iron Co. Research Laboratory at Ishpeming, Mich. A program […]

Steel Ingot Solidification

Steel has been chosen as the metal whose solidification will be used to tie in the principles discussed in the previous papers. Although steel is the most important practical example that could be chosen, its solidification is complicated by the presence of many elements added either intentionally or present as impurities. The liquid steel bath […]

Sinter Testing

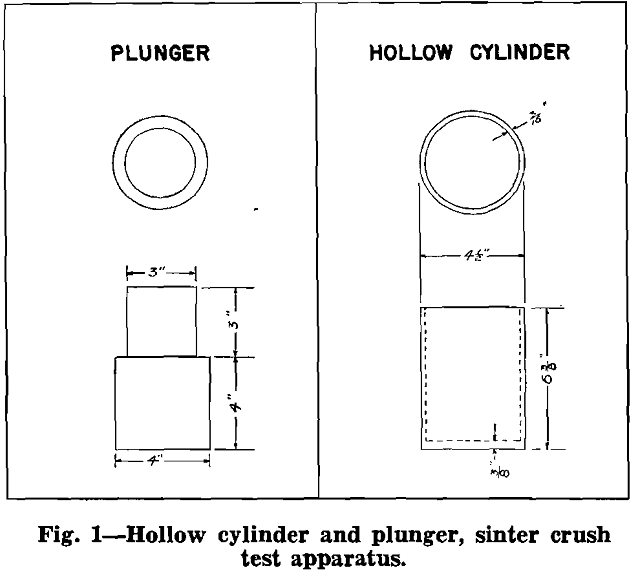

This report to the American iron and steel industry marks the completion of a 1949 survey of blast-furnace sinter practice sponsored by the Sub-committee on Agglomeration of Fines of the American Iron & Steel Institute. The use of sinter in blast furnaces, sinter properties, raw materials, and sinter plant operation have been reported recently. Each […]

Sponge Iron

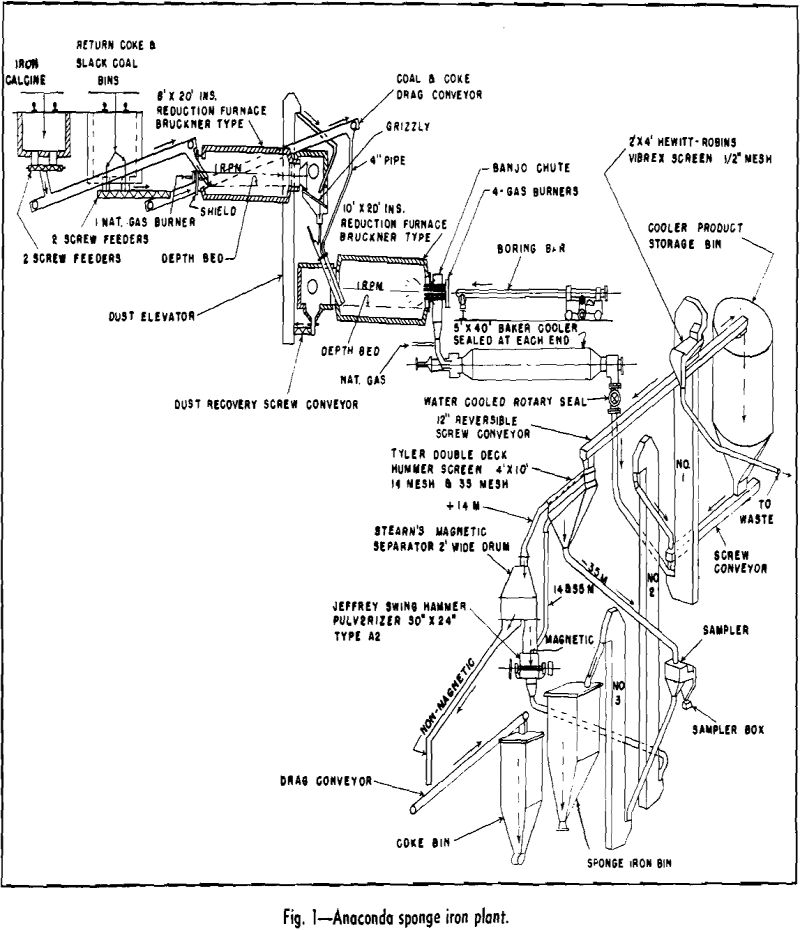

Sponge iron as produced at Anaconda is a fine, —35 mesh, impure product, about 50 pct metallic iron, obtained from the reduction of iron calcine at a temperature of 1850°F by use of coke resulting from slack coal. The metallic iron particles are bulky and spongey and precipitate copper readily and rapidly from a copper […]

Laboratory Studies on Iron Ore Sintering and Testing

Some of the variables encountered in the sintering of iron ores and their effect on sinter properties have been investigated at the Jones and Laughlin Ore Research Laboratory in Michigan. Ores requiring agglomeration before blast furnace utilization may be classed as coarse, intermediate or fine. Coarse iron ore is considered similar to a —¼-in. Mesabi […]

Physical Metallurgists

During the past year there have been a number of significant investigations that have furnished evidence on the driving forces governing grain growth and on the role played by boundary impurities. Thus Burke has shown that in high-purity alpha brass the rate of grain growth in the earliest stages is approximately inversely proportional to the […]

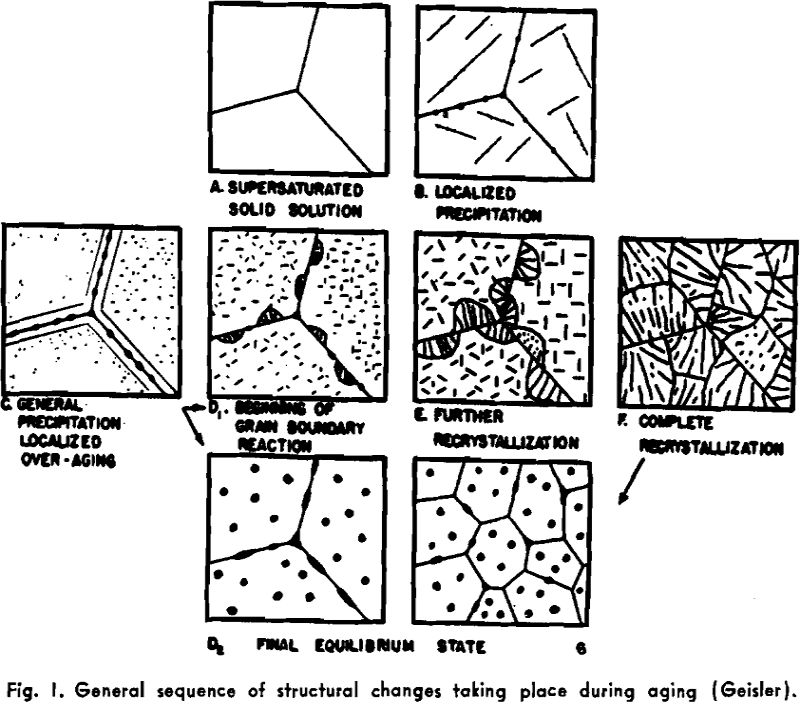

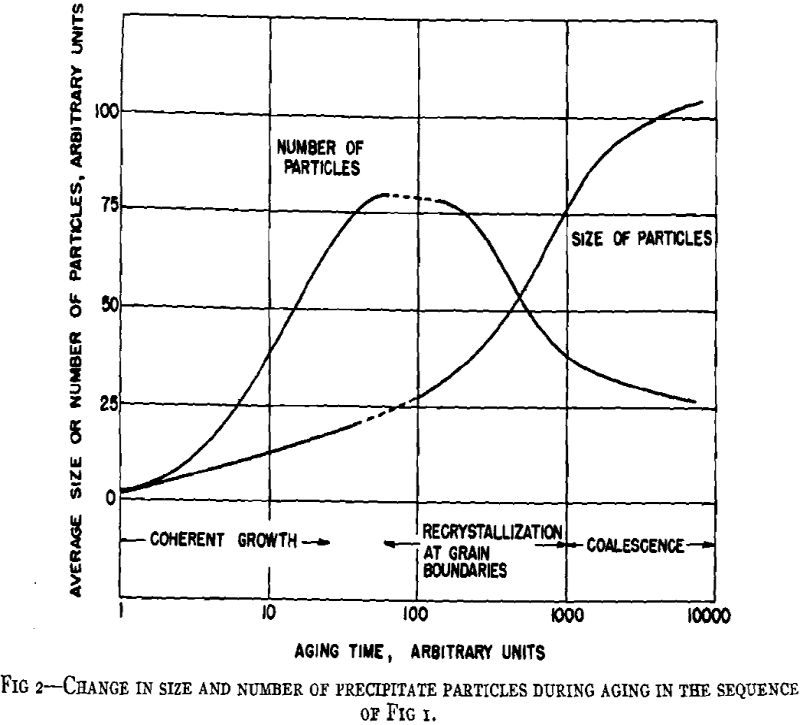

Metal Aging

The correlation of property changes during precipitation with structure has progressed, sometimes rapidly but other times more slowly, since the fundamental discovery of Merica, Waltenberg and Scott. The predominant factor that hampered the progress has been limitations imposed by the various detection methods. Refinements in X ray diffraction techniques and in metallographic methods, which have […]

What is Metallurgy

Oh, please tell me what is metallurgy? There is no better way of paying tribute to the memory of a scientist than by developing and carrying forward those ideas which he has contributed to science and which are for us the very essence of his immortality. For a lecturer who has not had the great […]

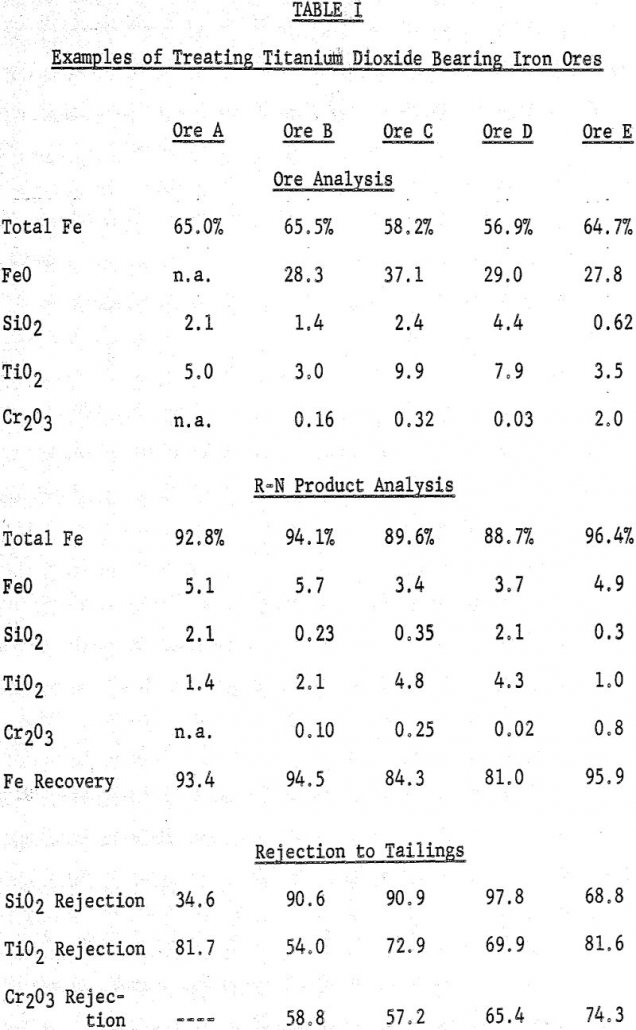

Recovery of Iron Ores Containing Titanium Manganese Chromium and Alkali Metal Sulfates

Most iron ores treated by the R-N direct reduction process yield metallic iron products considerably lower in titanium, manganese, and chromium oxides and alkaline metal sulfates/sulfides than were contained in the original ores. These metallic iron products are suitable as feed stock for the open hearth and electric steel-making furnaces. The elements which are rejected […]

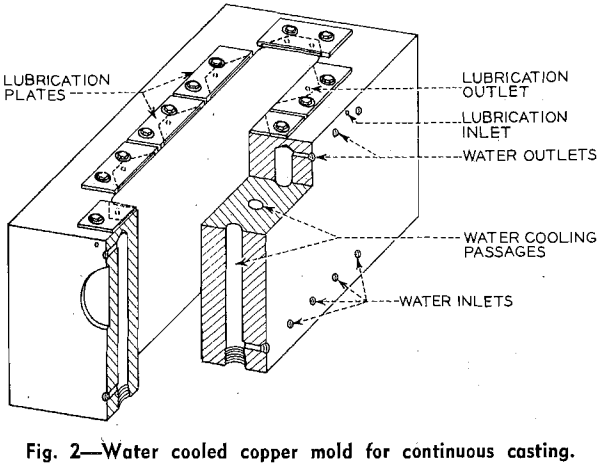

Low Carbon Steel Continuous Casting

Recognition of the benefits to be gained from the continuous casting of molten steel into finished or semifinished products has been given by scientific minds since the very beginnings of steel plant technology. In fact, Sir Henry Bessemer is credited with the first of a long list of patents issued by the U. S. Patent […]