Thickener Selection Parameters

A bewildering number of continuous thickeners and clarifiers are used in mineral industries and other heavy industries. General types are: Conventional Thickeners Thickeners with Flocculating Feedwells Solids Contactors Tray Thickeners Lamellas Conventional Thickeners with Lamellas High Flow, Fluid Bed Thickeners These units must be adapted to varied applications. They must provide operating flexibility to meet […]

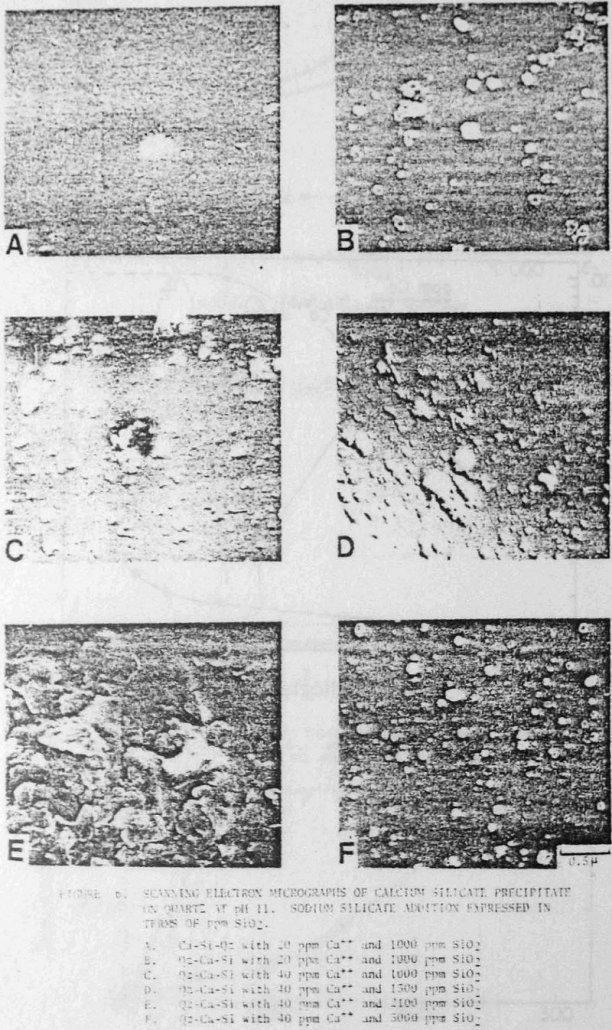

Use Sodium Silicate as Dispersant in Selective Flocculation

In the upgrading of finely-disseminated iron ores, selective desliming is the critical step which must be controlled in order to achieve efficient flotation. A prerequisite for selective desliming is a properly-dispersed pulp; sodium silicate is commonly used as a dispersant. The mechanism by which sodium silicate acts as a dispersant in the presence of calcium […]

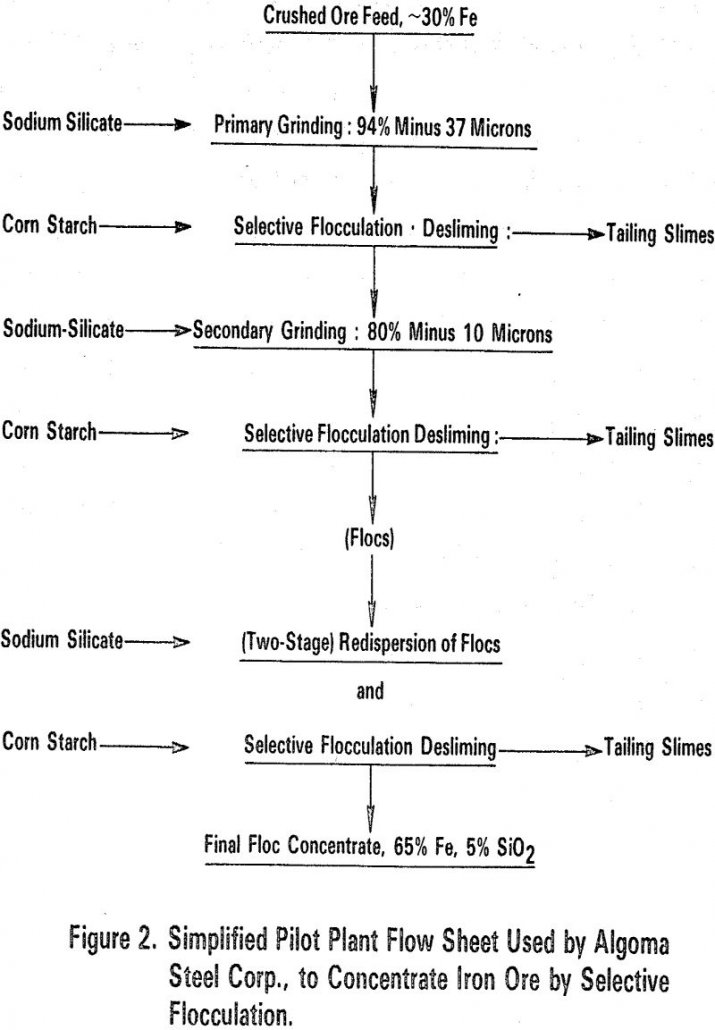

Selective Flocculation

Selective flocculation utilizes the differences in the physical-chemical properties of the various mineral components in the mixed suspension. It is based on the preferential adsorption of an organic flocculant on the particular solids to be flocculated, leaving the remainder of the particles in suspension. In order to understand the mechanics of this process, selective flocculation […]

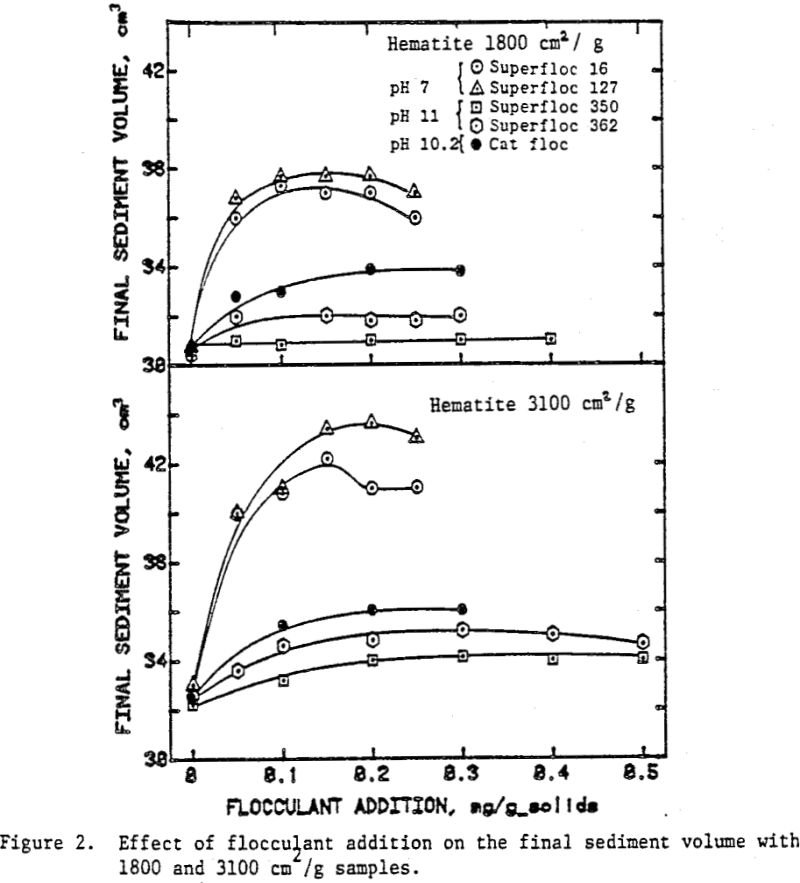

Influence of Flocculants on Filtration of Iron Concentrate

Experiments were conducted with the addition of several types of flocculants and surfactants. The filtration response of the slurries was studied in terms of the cake formation rate and the residual cake moisture. An analysis of the results is presented in ascertaining the role of flocculants and surfactants during filtration A specular hematite concentrate (67% […]

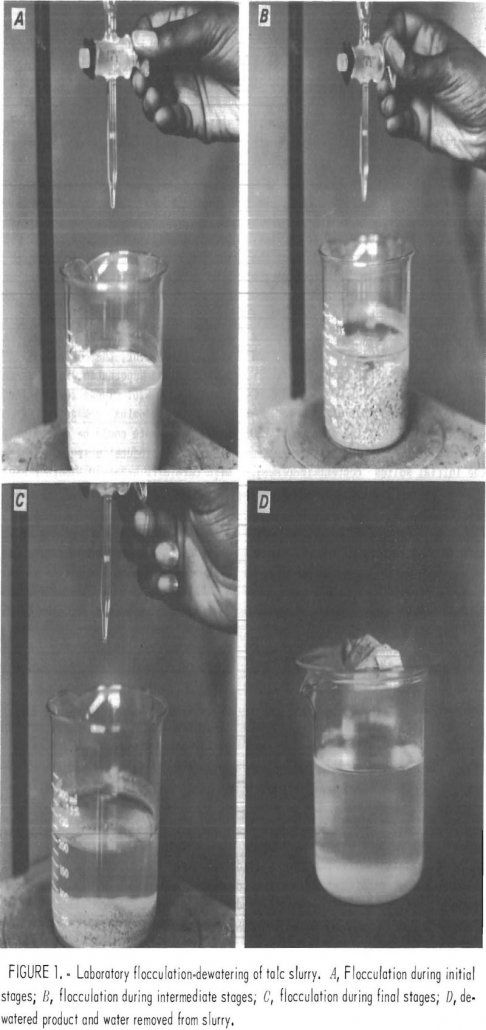

Dewatering Talc Slurry

Talc, a hydrated magnesium silicate, is a major constituent of soapstone, which is used in the manufacture of thermal and electrical insulators. Talc also finds applications as filler for use in the paper rubber, and textile industries, in the preparation of soap, cosmetics, lubricating and special polishing agents, as well as in the paint and […]

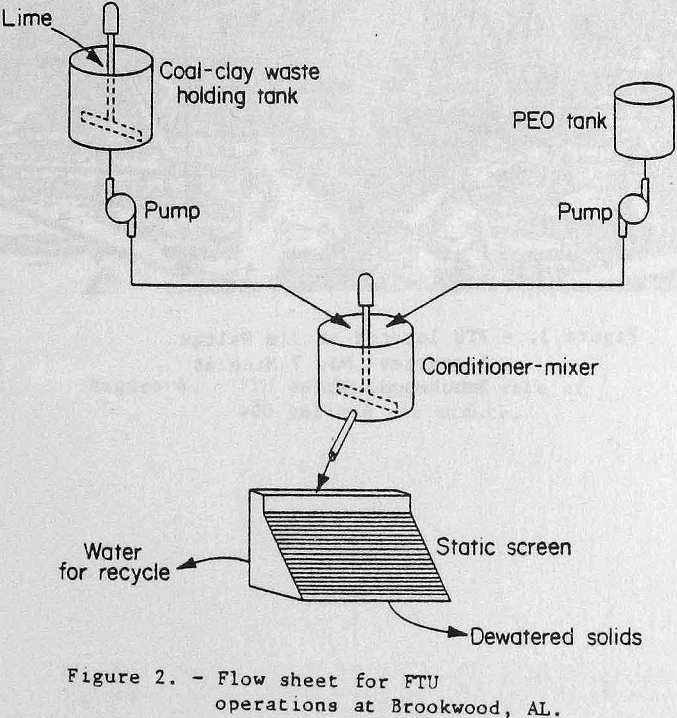

Dewatering of Fine Particle Clay Waste with Flocculant

The processing of ores for the recovery of minerals such as phosphate (U.S. Bureau of Mines, 1975), potash (C. E. Jordan, 1977), bentonite (S. G. Amplan, 1975), and coal (R. E. Zimmerman, 1978) generally results in the production of ultrafine waste materials, which respond poorly to conventional physical separation and dewatering techniques. In many cases […]

Chelating Crosslinked Starches as Flocculation

One of the major technological problems associated with beneficiation of complex, finely disseminated ores is the generation of large quantities of fine minerals less than 10 µm in size. Fines are generally refractory to conventional low-cost beneficiation methods, and failure to recover this fraction can represent a significant, permanent loss of valuable minerals. In addition, […]

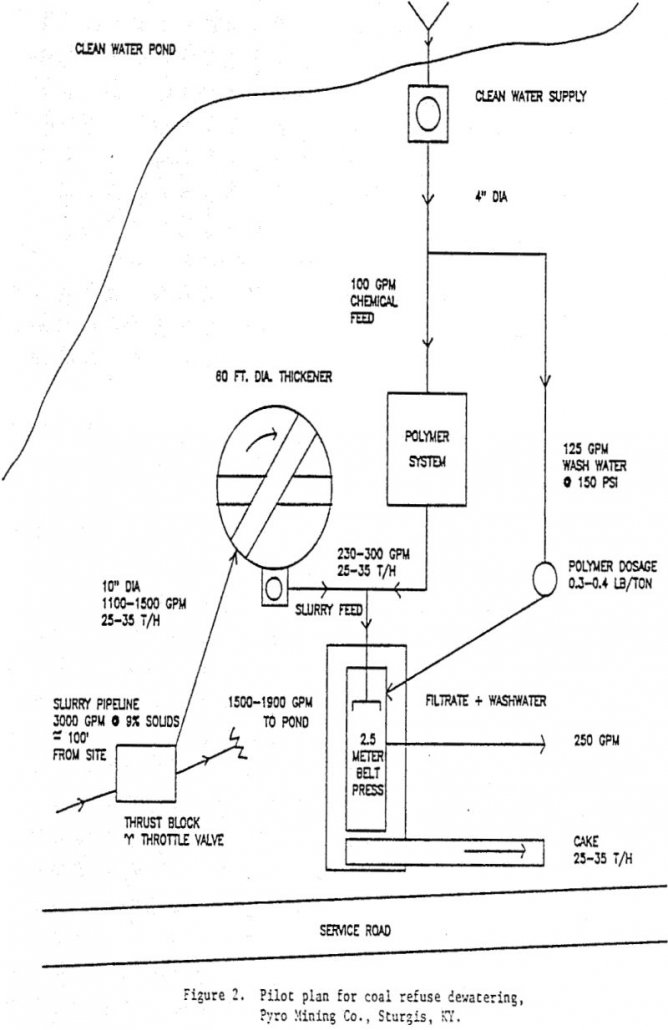

Slurry Thickening & Dewatering

Dewatering refuse tailings with a belt filter press has not been widely accepted by the Coal Industry. Part of the problem lies with the highly variable characteristics of the refuse solids themselves. The belt filter press, like other dewatering devices, is highly dependent on these dewatering characteristics. The purpose of this study was to examine […]

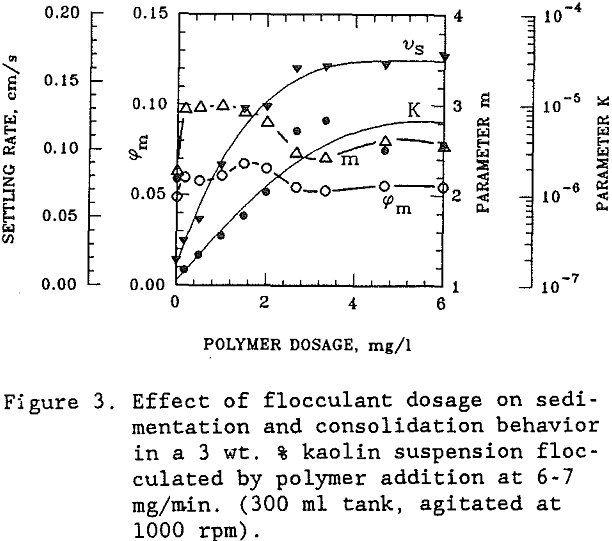

Sediment Compressibility in Thickening of Flocculated Suspensions

Polymeric flocculants are widely used to enhance particle sedimentation in the application of thickening processes to slurry dewatering. When properly applied, these flocculants promote the formation of large flocs which settle rapidly and provide for effective water clarification through the efficient capture of fine, suspended solids. However, the flocs formed are generally of very low […]

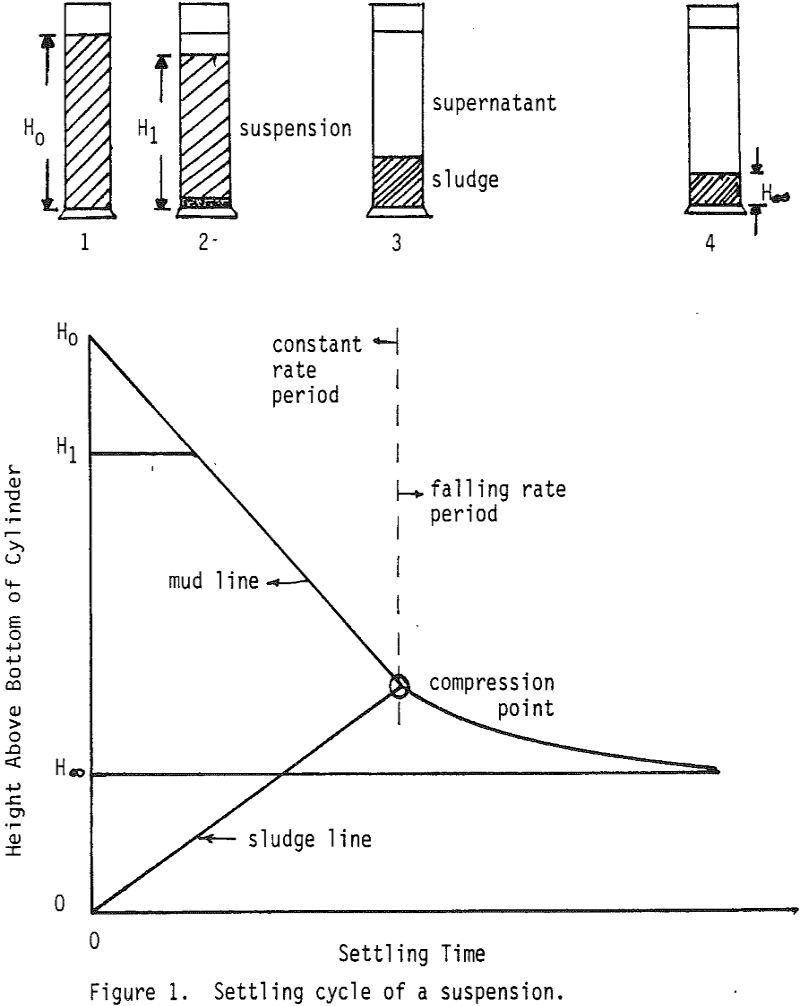

Solid Suspensions Settling Modeling

Sedimentation is used to clarify process effluents or to thicken process slurries. The sedimentation cycle of a suspension is presented as a settling curve. This curve is simply a plot of the height of the interface between the settled suspension and clear liquor versus time. The interface between the supernatant and suspension is termed the mud […]