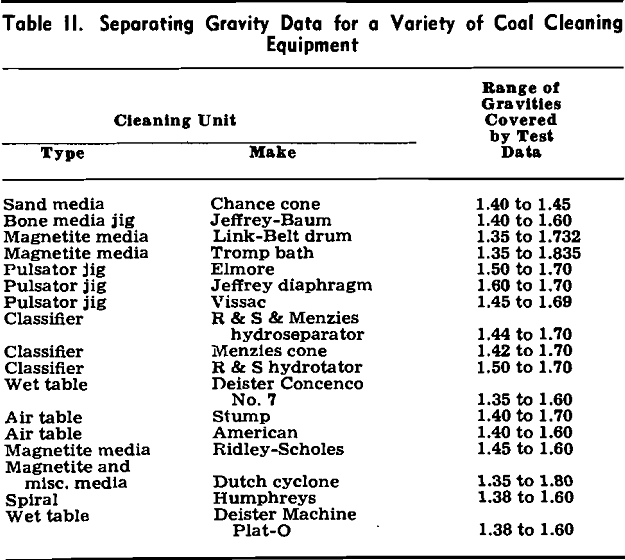

Table of Contents

The relative performance of coal washing equipment, or the effectiveness with which any type or make of equipment removes impurities from coal, has been most difficult to evaluate in the past. The most widely used yardstick is the Frazer and Yancey efficiency formula developed in 1922, but Yancey in a later article states that “washers treating coals of different density composition or operating at different densities of separation cannot be compared directly on the basis of this criterion.” Prior to and since 1922, a variety of other methods has been used for comparison purposes, including the distribution curve, the error area, and the “ecart probable” or probable error.

The Correlation Theory

The ideal coal cleaning process would treat all sizes and would make a perfect separation at any given specific gravity. All material lower in density than the desired value would report in the coal product and all material higher in density would report in the refuse product. Unfortunately, no known cleaning process achieves this goal and there seems little likelihood that any process yet to be invented will do more than approach it.

When coal is treated in volume under operating conditions, it is impossible to avoid mechanical entrapment, fluctuations in throughput and effective gravity of separation, and the creation of turbulent currents, even when a true heavy-liquid bath is used and the feed is closely sized and contains little intermediate gravity material. This being so, it is possible to appreciate the difficulties inherent in trying to obtain a perfect separation when treating a wide range of sizes and a feed containing high percentages of intermediate material, using turbulent currents to help create the effective separation gravity, under operating conditions which normally tend to be on the overload side.

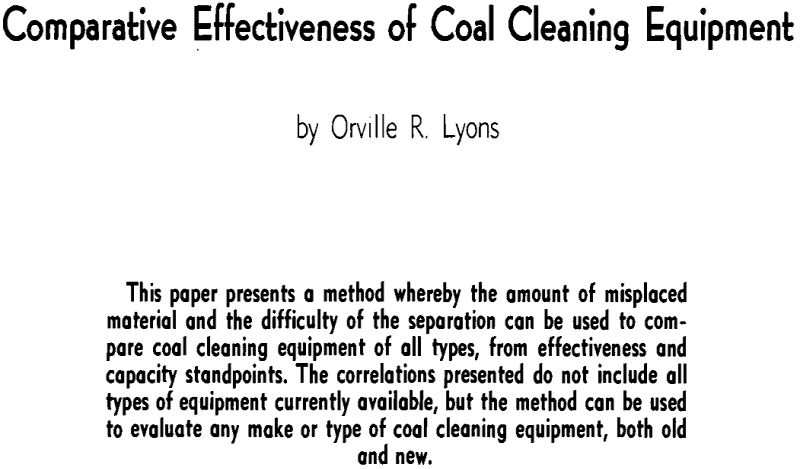

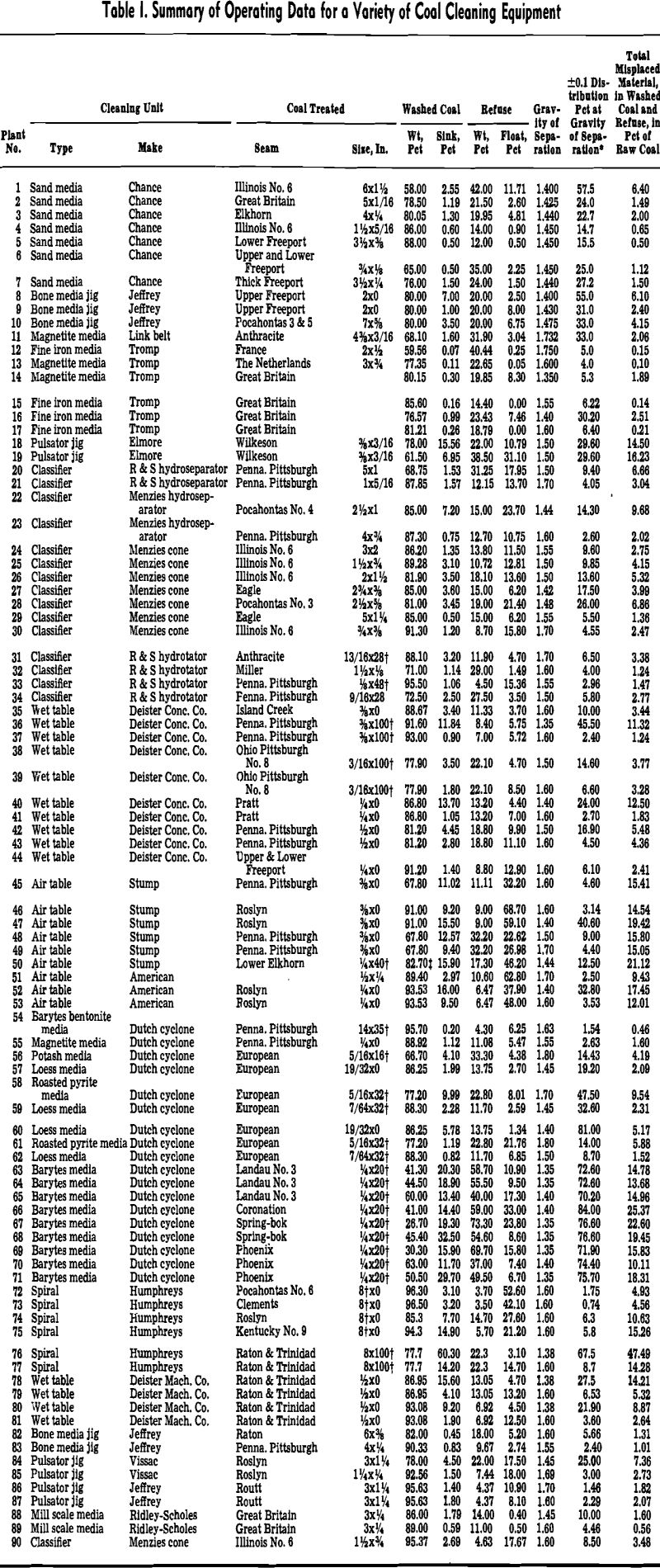

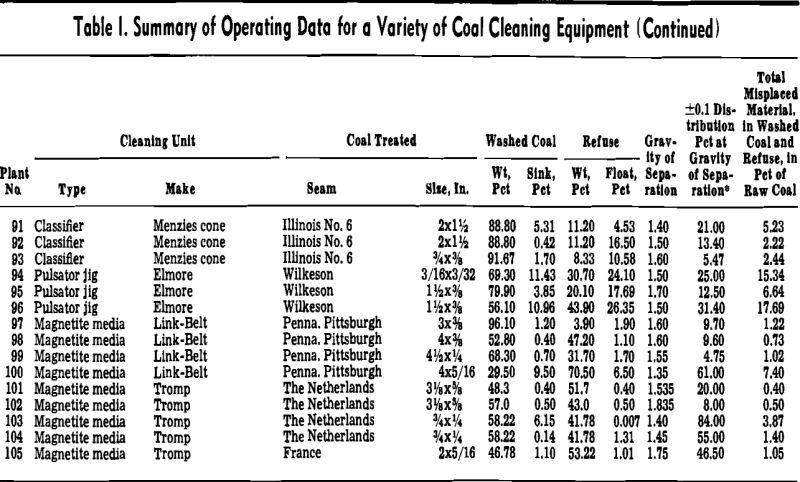

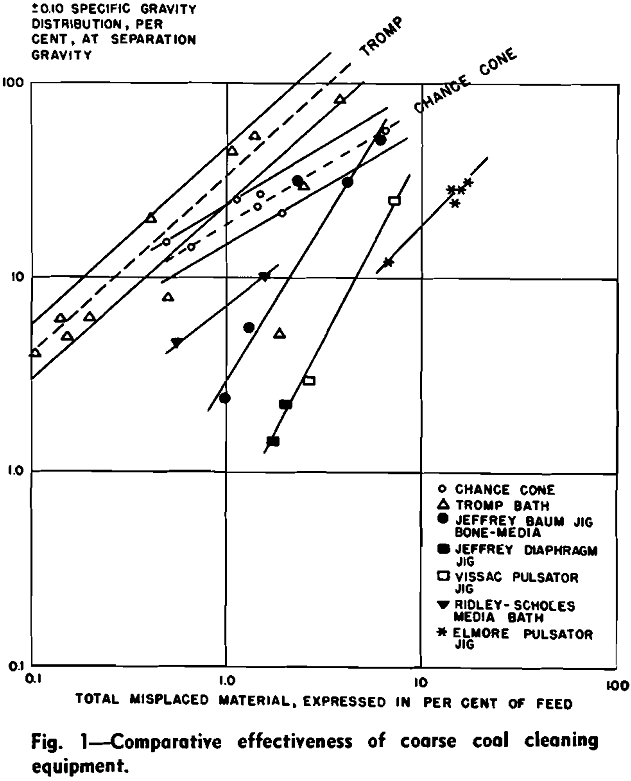

The Correlation Data

These data were obtained from the literature, from operators and equipment manufacturers, and from tests conducted at preparation plants of Republic Steel Corp. The major portion of the data represents tests conducted at preparation plants under normal operating conditions. The remainder of the data is for tests conducted on a pilot-plant scale. In so far as could be determined, all the tests represent careful sampling and accurate analyses. All the raw coal float-and-sink data were replotted and the ±0.1 near gravity values adjusted to compensate for the amount of sink 2.0 specific gravity material in the feed, thus placing all of the data on a common basis.

Of all the equipment for which test data were obtained, the Tromp dense-media bath is the most effective separator of coarse refuse from coal. The Chance cone is just as effective as the Tromp bath when treating feeds containing less than 7 pct ± 0.1 near gravity material but is less and less effective as the difficulty of the separation increases.

The Link-Belt dense-media drum is slightly less effective than the Chance cone and Tromp process when treating feeds containing less than 20 pct near gravity material. It is just as efficient as the Chance cone but not so efficient as the Tromp bath when treating feeds containing from 20 to 50 pct near gravity material, and is slightly more effective than the Chance cone but not so effective as the Tromp bath when treating feeds containing in excess of 50 pct near gravity material.

The Jeffrey-Baum jig, and it should be emphasized that all of the test data are for jigs operated with a bone-media, is not so effective as the Menzies cone when treating coals containing from 0 to 3 pct ±0.1 near gravity material but is at least as effective and possibly more effective than dense-media equipment when treating coals containing 50 to 60 pct ±0.1 material.

The Deister Machine Co. Plat-O table and some of the data for the Deister-Concenco No. 7 table show less effective separations than those for the Dutch cyclones, Hydrotators, and the bulk of the No. 7 tables.

Capacity Comparisons

An operating man is frequently more interested in the capacity of a unit than he is in its separating effectiveness and is willing to sacrifice effectiveness to some extent if by so doing he can materially increase capacity.

A line of reasoning similar to that presented under the section on the Correlation Theory suggested that there should be a correlation between the difficulty of a separation, or the amount of ±0.1 material in the feed at the separating gravity, and the capacity for any make of coal cleaning equipment. Capacity was considered to be the tons of clean coal produced per hour per square foot of operating surface.

The Vissac pulsator jig and the Link-Belt heavy-media drum have the greatest capacity per unit area of all the coarse coal cleaning units. The Vissac jig was used to treat sized feeds, and its high capacity can be explained on that basis.

The Jeffrey-Baum jig can produce just as much washed coal per unit area as the Link-Belt drum when treating coals containing 60 pct or more of near gravity material but has a relatively lower and lower capacity rating as the difficulty of the separation decreases.