Table of Contents

Moisture in coal must be considered as an impurity, just the same as ash, from the standpoint of utilization of the coal. Being incombustible, it reduces directly the heating value of the coal, and in addition absorbs heat for its evaporation. Its presence means useless expenditures in handling and transportation. In coke plants, extra moisture reduces capacity and may cause damage to brick work and equipment.

Accordingly, the removal of extra moisture can be considered just as important as the removal of other impurities, such as ashes, in the modern coal preparation plant.

Moisture, which can be removed by heating the coal up to a temperature of 100°C, may be retained in various forms:

- As a film, on the surface of each coal particle, and in the interstices between particles, retained by capillary forces.

- Or “occluded” inside the coal particles. This occluded moisture may be either free moisture (as in a sponge), or hygroscopic moisture which varies with atmospheric conditions, (also called “regain”).

Dewatering

If we reserve the name of drying to the removal of water by evaporation, we must consider the initial phase of the mechanical removal of free moisture as a distinct operation covered by the term dewatering.

In all cases the free water carried over the surface of the coal particles or in their interstices, or in their pores, is retained by capillary forces. Dewatering is accomplished by breaking or counteracting these capillary forces; removal of as much water as possible by dewatering methods is usually advisable, as the cost of these operations is generally much less than by evaporation.

Heat Drying

In the final phase, the remaining moisture must be evaporated. Coal and water must be brought up to the chosen temperature of evaporation, and heat must be supplied to fill the requirements of the latent heat of evaporation of the water to be removed.

Accordingly, drying becomes largely a problem of heat transfer, and drying methods can be classified accordingly, namely:

- Radiant transfer.

- Transfer by surface contact and conduction.

- Transfer by hot gas contact.

The mechanism of complete drying is really very complex—several phases are involved:

- The constant rate period.

- The uniform falling rate period.

- The varying falling rate period.

Volume of Gases Required

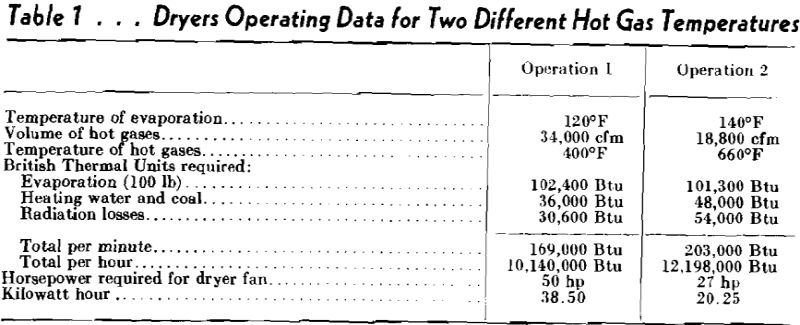

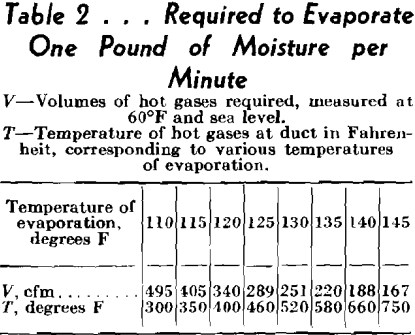

A feed of 60 tons per hour is 1 ton, or 2000 lb per minute.

The moisture to remove is 5 pct of 2000, or 100 lb per minute (dry basis).

Assume evaporation at 120°F (temperature of gases at dryer’s exhaust) and 60°F as outside temperature.

1 cfm of air carries:

at 120°F and at full saturation 0.005 lb water per cfm and at 60°F a difference of 0.001/0.004

And if we assume a 75 pct evaporation,

1 cfm of hot gases will re-remove 0.003 lb of water

Accordingly, the air required on the basis of evaporation alone is: 100/0.003 or 33,333 cfm (measured at sea level, and 70°F).

Furnace Required

Total heat required = 170,000 Btu’s per minute.

or with coal at 12,600 Btu and at 75 pct combustion efficiency

170,000/0.75 x 12,600

or 18 lb of fuel per minute

or 1080 lb per hour at 42 lb per sq ft.

The required grate area is 26 sq ft. Combustion space at 50,000 Btu per cu ft per hour required = 200 cu ft or 7.7 arch.

Cold Air Ducts

Required 18,000 cfm of cold air (see furnace calculations).

Hot Gases Ducts

Volume at 70°F sea level is 33,333 cfm at 400°F at 4000 ft elevation volume is:

33,333/0.858 x 0.616 = 63,000 cfm.

Desired speed about 2000 fpm.

Section required about 30 sq ft.

Proposed area 5 x 6 ft.

Regeneration

The cooling off by water of the exhaust gases from say 120°F down to 60°F will recover, with a volume of 35,000 cu ft at 0.06 lb per cu ft.

35,000 x 0.06 x 0.25 x (120 – 60) = 31,500 Btu

The circulating water of a washery operating in a closed circuit is used for this purpose; this regenerated heat is used to preheat the coal before it is fed to the dryer.

In addition to their technical value, cooling and regeneration offer many material advantages:

- Cooling reduces the danger of spontaneous combustion, decreases sweating of loaded coal.

- Regeneration assists in the heating of the preparation plant, the thawing of frozen coal, and its mechanical dewatering (by reducing surface tensions).

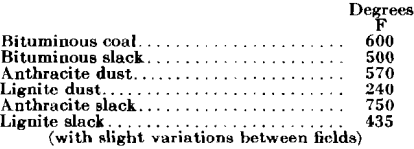

From the above discussion it appears desirable to operate a coal dryer at low temperatures, in order to obtain not only the maximum efficiency, but also the best safety of operation; in this connection, it will be important to keep in mind the following kindling temperatures:

Drying Characteristics

Before the proper layouts and selection of equipment can be made, we must first of all determine the drying characteristics of the coal to be treated; in other words, establish the relative drying difficulties of the coals or sizes of coals to be treated.

These preliminary studies can be done easily even in the most elementary laboratory. Our method consists in plotting the drying curves of the tested coal, just as washing curves are established for a coal cleaning problem.

Drainage factors are established first; the coal fully saturated with water is allowed to drain over a certain period of time. If, for instance, a certain size of coal is drained down to 6 pct in one hour, its drainage factor will be 1; if a slack coal is drained down to 10 pct in 12 hr, the drainage factor will be 12. In each case the final moisture contents considered are based on practical experience, coal characteristics, and actual requirements.

Drying factors are established in the same manner; coals are allowed to dry in a heated laboratory under certain constant conditions of evaporation. If it takes 3 hr to dry a certain size from its final point of drainage, say 5 pct moisture, to the required point of drying, say 2 pct, the drying factor of this coal will be 3.