In most industrialized countries, the largest element of the mining industry in physical volume is that devoted to the extraction and processing of materials for use as construction aggregates. These materials come from four main sources:

(a) Excavation of unconsolidated deposits of sand and gravel

(b) Stone quarrying.

(c) Processing of slags and other mineral wastes.

(d) Manufacturing from clays and shales by heat fusion.

They are classified as fine aggregates (natural and manufactured sands, generally less than ¼” in size), coarse aggregates (round and crushed gravels, crushed stone, crushed slag, and fused clays and shales, in sizes generally from ¼ to about 1″, but sometimes used up to 6″ or so), and unseparated pit-run or crusher-run materials. T

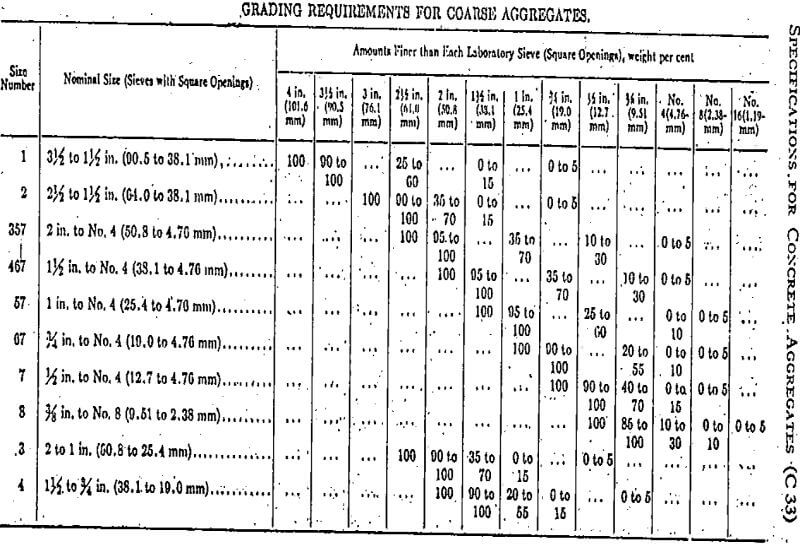

In crushing to produce specification aggregates, on the other hand, not only is it necessary to reduce all the feed to a given top size – say 1″, but also to have the amounts of the fractions in the succeeding sizes – ¾”, ½”, 3/8″ and so on – fall within certain fairly tight limits. An examination of the table shown here, “Grading Requirements for Coarse Aggregates”, taken from A.S.T.M. Specification C33-66 “Standard Specification for Concrete Aggregates”, indicates this point clearly.

Many specifications introduce a requirement on particle shape. Often materials produced from rounded gravel will be required to have at least 50% or 6o% crushed particles. These may be defined in the specification as particles having at least one fractured face, or two such faces, or something like that. Whether crushed or round, flat or elongated pieces are often required to be less than some limited percentage of the total product.

In primary crushing, large gyratories in the 42″ to 60″ range are frequently used in the larger crushed stone operations. Jaw crushers in all size ranges from small to medium are very common in gravel plants, where boulder size is not usually above about 12-15″, and up to very large sizes in crushed stone if the rock is not too slabby.

In secondary crushing, cone, crushers, standard and short head, are the most common choice, although they are criticized for producing a poor particle shape. Rolls crushers are good in product shape, but maintenance problems and low ratio of reduction make their selection very infrequent in permanent plants.

In fine crushing – say, below ½” – short head cones are most frequently used. For the less abrasive applications, hammer mills may be found occasionally, and specialized forms of impactors like cage mills. Rod or ball mills are used where sand production is desired.