Cyanide Training

Proper care and handling of Sodium Cyanide

Why the need for training?

- To help ensure that Team Members are not exposed to harmful concentrations of cyanide through proper handling procedures.

- To assist all Team Members in understanding how cyanide is used safely and the environment is protected.

- To ensure all Team Members are trained in the proper procedures to deal with an incident involving cyanide from notification, evacuation, response, and remediation.

International Cyanide Code

Principals of the code

PRODUCTION: Encourage responsible manufacturing by only using cyanide produced in a safe and environmentally protective manner.

TRANSPORTATION: Protect Communities and the environment during cyanide transport.

HANDLING & STORAGE: Protect workers and the environment during cyanide handling and storage

OPERATIONS: Manage cyanide process solutions and waste streams to protect human health and the environment.

DECOMMISSIONING: Protect communities and the environment from cyanide through development and implementation of decommissioning plans for cyanide facilities.

What is Cyanide?

- Chemical Name : Sodium Cyanide

- Chemical Symbol: NaCN

Cyanide Uses

- The use of cyanide in the mining industry is only one of the many industrial uses of cyanide

- NaCN is also used in a variety of processes including the production of plastics (such as acrylics and nylon) and pharmaceuticals (ibuprofen and naproxen), processing of food (decaffeination of coffee and as an anti-caking additive in table salt), and for electroplating and hardening of steel.

Cyanide Shipping and storage

- 100Kg Drums

- Cyanobrik

- 4 drums/pallet

- UN 1689

- Hazard class POISON 6.1

- Label: Toxic

Cyanide Storage

- The NaCN used at the Wolverine Mine is stored in a locked container.

- The container will be located a minimum of 50 meters from any acid storage areas.

- Access to the storage container is limited to authorized and trained personnel only.

- Personnel will sign out: how much removed, date removed, time of day, and signature.

- Sign out sheet will be audited weekly by the Mill Supervisor/Manager.

- In the plant the NaCN is stored in the mix station room until it is prepared, which is a separate room inside the plant with restricted access.

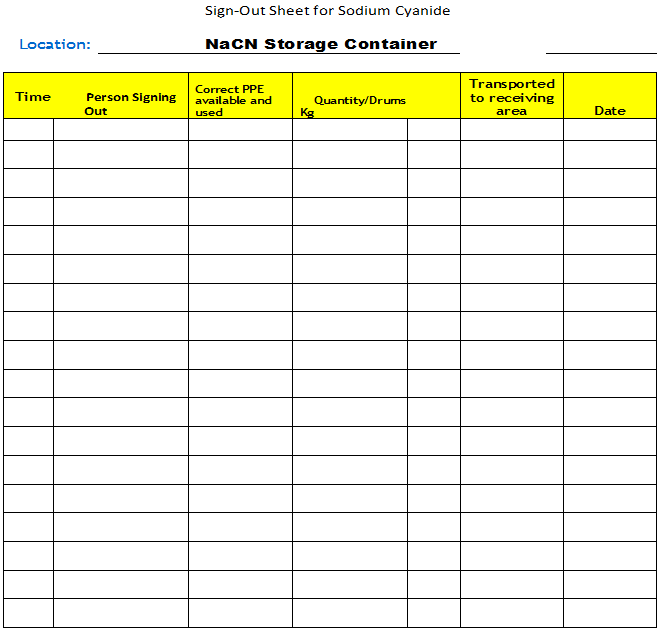

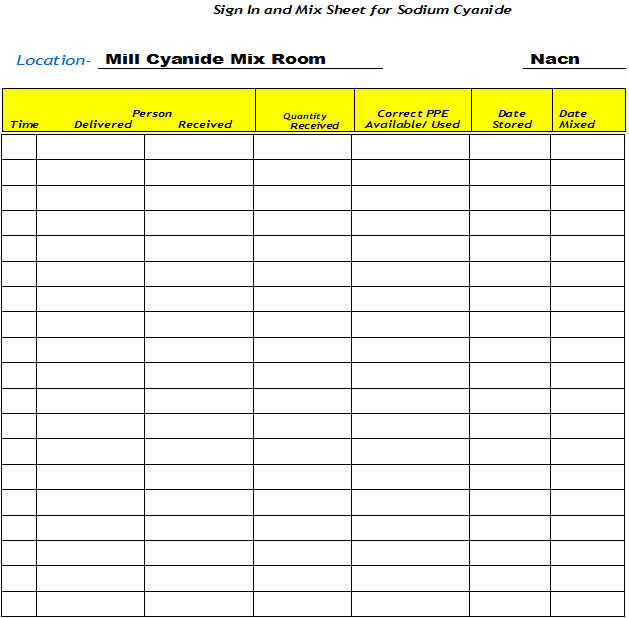

Sodium Cyanide (NaCN) sign out procedure

The cyanide sign out and transportation procedure is in place to ensure we have safety method of storing, accessing, handling and transporting the NaCN to the Mill, and when delivered to the mill moved to the NaCN mix room.

All personnel handling the NaCN will receive training in the safe handling of NaCN.

The NaCN is stored in a locked container at all times at the storage area, it is stored in 100 Kg sealed drums. Only the Mill Shift Foreman, Mill General Foreman, Mill manager or the Metallurgist are authorized to request that NaCN be delivered to the mill.

When the request comes from the mill for NaCN to be picked up and transported to the Mill. The crew transporting it to the mill will coordinate with the crew in the plant the time for the delivery so as it is brought it can be moved immediately to the NaCN mix room.

Before entering the locked storage container

- No eating, drinking of fluids or smoking is permitted.

- Proper PPE including Neoprene or rubber gloves and a portable HCN monitor.

- After opening the container a visual inspection of the drums will be made looking for any spilled or loose NaCN on the drums or on the floor of the container.

- Any spills are to be reported to the Safety Department, Environmental department and Mill department immediately and all work stopped until the spill is contained/dealt with.

- A visual inspection of the drums is to be also completed to ensure that the seal on the drum is intact and in pace and it is clearly marked.

- There is a sign out sheet that will be filled out stating the person or persons working, time in and amount to be moved to the mill.

- The drums will then be moved from the container to the receiving area in plant and container will be locked.

- Upon delivery to the mill, the person who delivered the NaCN will sign it off to the mill crew who will also sign to receive it and then move it immediately to the NaCN Mix room for storage/mixing.

Personnel Protective Equipment

What is required when working with Cyanide?

PPE

- Hardhat

- Full Face Respirator

- Rubber gloves

- Chemical resistant suit

- Rubber boots

- Personal HCN gas detector

- Hearing protection

Inside mixing room

- Good air flow/ventilation

- Fixed HCN monitor

Reagents operator’s PPE:

- Safety hat

- Safety glasses

- Chemical resistant suit

- Full Face Respirator

- Safety rubber boots

- Rubber gloves

- Ear protection etc

NACN mixing procedure are as follows:

Before mixing commences the control room will be called to inform them that NaCN is being prepared, a check will be completed of the equipment used in the NaCN mix room, that the ventilation system is functioning and a visual inspection of the tanks, piping, pumps meters and all equipment used in the mixing process.

- Start the NaCN solution mixing agitator

- Add the fresh water to the determined set level in the mixing tank

- Add the NaOH to the NaCN solution mixing tank, increase the solution pH to a minimum of 12 pH

- Add the NaCN to the NaCN mixing tank continuously, until the whole reagent is discharged into the mixing tank

- Add fresh water to the determined set level in the mixing tank.

- It requires 40-60 minutes to completely dissolve the NaCN into a well mixed solution

- Stop the agitator and transfer the mixed solution to fill up the NaCN solution holding (distribution) tank, and ready for use and distribution;

- Collect the package(s) and take it to the reagent package’s cleaning area, clean and place in the designated area for appropriate disposal/or treatment.

Cyanide Safety

Mixing room

- The locations where NaCN is stored, mixed, and all additional points between those areas are clearly marked with signs.

- There is an HCN fixed monitor/alarm at the location where the NaCN is mixed

- At the two locations where NaCN is added to the circuit, the Pb conditioning tank and the Pb regrind mill pump box there are HCN monitors/alarms in place, These have a safety function in addition to a high HCN alarm, if the HCN rises the pumps will automatically stop pumping.

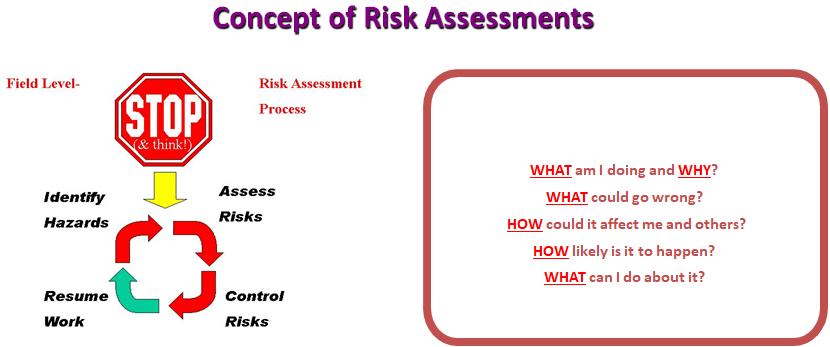

- INDIVIDUAL

- TEAM

- FORMAL

Routes of entry

- Skin – flush with water for up to 5 mins after contact or suspected contact (generally sufficient to effectively remove from skin)

- Eyes – flush with water for up to 5 mins while holding eyelids apart. Do not try to neutralize. Continue to rinse and further evaluation will be required

- Ingestion – Give patient activated charcoal slurry if conscious

- Inhalation – if consciousness is impaired, 02 and amyl nitrite should be administered

- In the event that NaCN comes in contact with clothing:

- If wet remove all contaminated clothes immediately, use emergency shower

- If dry brush off as much chemical as possible, remove all contaminated clothing immediately, use emergency shower if required

- If either wet or dry and it has been in contact with skin wash with copious amounts of water

Cyanide Safety

Risk assessment

No Eating, Drinking, or Smoking around Cyanide Working Areas!!

Things to think about:

- Potential Areas for Exposure

- Fast Acting Poison

- Routes of Entry

- HCN Exposure Limits

- Symptoms of Cyanide Poisoning

- First Aid Procedures

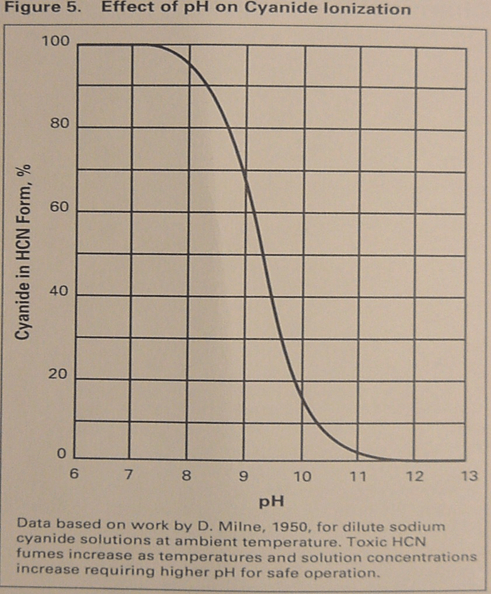

HCN Production

The Higher the pH of the Solution the Less HCN Produced.

DO NOT mix acid with cyanide at any time!

Fires involving Cyanide

- Cyanide is not combustible but upon contact with acids it will release highly flammable and toxic Hydrogen Cyanide gas (HCN)

- DO NOT USE WATER IF CYANIDE IS PRESENT it will produce HCN as well

- The Cyanide we use is in a solid form (Cyanobrik) it is soluble so fighting a fire with a stream of water will put the cyanide into liquid form creating an environment with an additional environmental hazard as well as introducing water with a lower Ph such as potable water in the Ph 7 range creating HCN gas.

- Fighting a fire involving Cyanide requires Personnel Protective Equipment (PPE) and approved self contained breathing apparatus (SCBA) in the pressure demand or positive pressure mode.

- Dry Chemical fire extinguishers ARE THE ONLY ONES TO BE USED to fight any fire at site.

- You can use water to control surrounding fires being very careful of any fire containing cyanide

- If water is used to control surrounding fires all water will be contained with a trough or berm and collected for decontamination.

REMEMBER

- NaCN can react with water to produce highly poisonous and flammable cyanide gas and in that produces a very high risk of explosion

- Do not use carbon dioxide extinguishers or foam extinguishers that may contain acidic compounds

Spills involving Cyanide in solid form

- AVOID over reaction

- Always wear proper PPE prior to clean up

- Shovel or sweep up dry spill

- Place into a drum, pail, spill container, etc and cover

- Keep spill area dry, cover if needed and barricade off

- Report incident to Supervisor

- Decontaminate with hypochlorite

- Proper disposable must be in a high Ph area of plant

Emergency Response Plan

- In the event of a NaCN spill or incident, work in the area will cease and personnel in the area will be evacuated immediately to a distance of 50 meters.

- When a spill or incident occurs the Safety/ERT Team, Mine Manager, Mill Manager or designate and Environmental Superintendent will be notified.

- Access to the area will be closed and entry into the area will be controlled by the ERT captain to prevent unauthorized access to the area.

- Personnel accessing the area will be equipped with full Hazmat gear as well as self contained breathing apparatus. The spill will be monitored for HCN.

- In the area surrounding the spill: the wind direction will be monitored and the surrounding area will be evacuated, the spill quantity will be evaluated by the ERT.

- for a small spill a minimum of 200 feet in all directions will be isolated, additionally if the spill has come in contact with water or HCN is present the area 0.4 Km downwind will be isolated.

- In the event of a large spill an area of a minimum of 390 Meters will be evacuated in all directions, additionally if the spill has come in contact with water or HCN is present the area downwind a distance of 1.3 Km during the day and 4.9Km during the night will be isolated to protect people .

- If possible the area around the spill will be built up with sand or earth to contain it.

- If the spill is in liquid, or HCN is detected lime or soda ash will be used to maintain a Ph of 9 or above.

- The spill will then be immediately contained and then collected and placed in well marked containers or bags and covered, if raining the spill will be covered to prevent contact with rainwater, water flowing from the area will be collected via berm or trough for collection and all material or liquid collected treated with Hypochlorite to neutralize it. It can then be disposed of in the process plant through one of the high Ph circuits.

- The spill area will continue to be monitored and tested for any free cyanide and any additional material collected, treated and disposed of.

- All equipment used in the response will be decontaminated in the plant in a controlled area with Sodium Hypochlorite or high Ph water with the flows returning to the circuit, no water from the decontamination will enter the drain.

- In the event of fire dry chemical or dry sand will be used to control the fire, no water stream will be used to fight fires involving the NaCN containers, water may be used to fight surrounding areas but all water must be stopped from flowing from the area, collected and treated.

- Move the containers if they can be moved safely out of the area.

NaOH

Emergency Overview: Corrosive to all body tissues contacted, harmful if inhaled or swallowed.

Routes of Entry: Inhalation. Ingestion.

Potential Acute Health Effects:

Eyes: Causes burns and permanent injury to the eye tissue.

Skin: Causes severe burns and permanent skin damage.

Inhalation: Harmful if inhaled. Can result in death. Causes burns to the respiratory tract and permanent damage to the nose, throat and lungs.

Ingestion: Swallowing may be harmful or cause death. Causes burns and permanent damage to the digestive system, including the mouth, throat, stomach and intestines. Symptoms of exposure may include severe abdominal pain, vomiting of blood, low blood pressure and shock.

Medical conditions aggravated by overexposure: Pre-existing skin or eye disorders

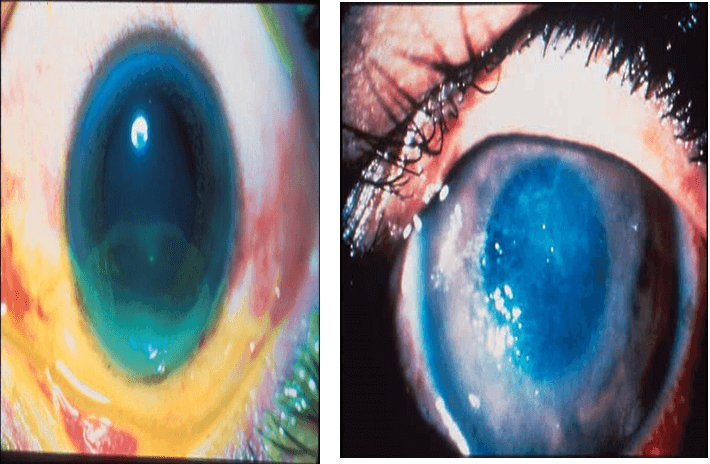

Chemical Injuries

- Alkali burns are frequently more disastrous than those caused by acids, as alkalis saponify the lipids of cell membranes & produce total disruption of cells. eg. burns caused by lye, fresh lime, ammonia etc

- Acids quickly precipitate tissue proteins & are therefore less penetrating.

Chemical Eye Injury

Cyanide 24 Hour Emergency Response Numbers

- Chemtrec 1-800-424-9300

- Dupont Emergency Response 1-800-444-2043

- Memphis NaCN Plant (CYANIDE HOTLINE) 1-901-357-1546

- Dupont Medical 1-800-441-3637

- Dupont Product Information 1-800-441-7515

Regional Emergency Numbers:

Exposure effects

- 2-5 ppm odor threshold

- 4.7 ppm TLV (-TWA) with a 10ppm ceiling (Cyanide Code limit)

- 10 ppm MSHA Permissable Exposure limit

- 20-40 ppm slight symptoms after several hours

- 45-54 ppm tolerated for 30mins – 1 hour without immedicate or delayed effects

- 100-200 ppm fatal in 30mins – 1 hour (without tx)

- 300 ppm rapidly fatal (without tx)

Symptoms of poisoning

MILD EXPOSURE

- Red eyes/skin

- Headache

- Nausea

- Giddiness

- Difficulty breathing

- Heart palpitations

- Weakness in arms/legs

SEVERE EXPOSURE

- Gasping for breath

- Loss of consciousness

- Cardiac arrest

- Possible death

Medical Treatment Facilities

- The nearest Hospital is Watson Lake approx 3 hours drive time from camp, staffed by 1 doctor and 5 nurses 24/7.

- The Company will have an industrial Ambulance on site and fully stocked for the transport of all patients to hospital and can transport up to 3 patients if required.

- If there is a cyanide incident and a patient/patients are transported to the nearest hospital one Cyanide Antidote kit will be transported with the patient for use by the medical staff.

- We have an airstrip on location and if required we can call the local Territorial Air Ambulance for transportation to Whitehorse as required. We have been in contact with the Air Ambulance and have a verbal agreement for transportation as required.

- No hospital staff are familiar with Cyanide poisoning due to it’s lack of use in the Territories, but the site medical staff will be with the patient at the hospital and will inform and assist hospital staff in the proper use of the Antidote Kit.

Medical Treatment at Site

- 1 Advanced Care Paramedic

- 1 Primary Care Paramedic – IV endorsed

- Both have the training and licensure to administer Cyanide Antidote Kit

Medical Treatment

- CYANIDE ANTIDOTE KIT from ABO Pharmaceuticals

- 3 kits will be available on site

Each kit contains:

- Contents of Antidote kit:

- 2 vials Sodium Nitrite Injection USP 300mg/10ml of sterile water

- 2 vials Sodium Thiosulfate Injection USP 12.5g/50ml of sterile water.

- 12 Ampoules Amyl Nitrite Inhalants USP every 5min (0.3ml)

- 1 sterile 10ml syringe with 22 g needle

- 1 sterile 60ml syringe

- 1 sterile 20 g needle

- 1 stomach tube

- 1 non sterile 60ml syringe

- 1 tourniquet

- The kit comes complete along with proper treatment instructions for cyanide poisoning

- Your safety is most important!

- Remove yourself or patient from contaminated area if possible

- Inform Supervisor or initiate Emergency Response which will inform First Aid of incident

- Decontaminate with copious amts of water if possible

- Amyl Nitrite kit stationed just outside of the mixing room (12 ampules)

REMEMBER TO REMAIN CALM

AMYL NITRITE PROCEDURE :

- If semi-conscious break AMYL NITRITE ampule (at neck of amp) with gauze pad provided

- If in a drafty area, provide some kind of coverage for vapors

- The objective is to get the patient to breath in and get the vapors to the lungs

- Avoid inhaling vapors yourself to avoid becoming dizzy and losing consciousness

- Lay patient down or in a semi laying position as the amyl nitrite dilates blood vessels and lowers blood pressure

- Hold under nose for 15 secs then remove for 15 secs DO NOT OVERUSE

- Continue this procedure until Medical Aid arrives

- Each Amyl Nitrite amp MUST be replaced every 3 mins

- Caution: Amyl Nitrite is highly volatile and flammable

Cyanide Treatment Protocol

- Cyanide poisoning may occur as the result of accidental exposure in the occupational setting. There are no distinct signs and symptoms suggestive of cyanide poisoning other than the odour of almonds on the patient’s breath, yet this is frequently absent even in case of severe poisoning. The patient seldom survives many hours. The prevention of death demands a quick diagnosis and the prompt use of specific antidotes. Fortunately the most important aspect of treatment is the administration of 100% oxygen.

- Cyanide poisoning is rapidly fatal.

- SYRUP OF IPECAC WILL NOT BE USED (under most circumstances)

Basic Life Support:

- Remove the victim to an uncontaminated area. Rescuers should wear appropriate protective clothing (PPE) and breathing apparatus (SCBA).

- Remove any contaminated clothing and shower or wash thoroughly any areas of contaminated skin.

- If there are no symptoms, no treatment is required.

- If symptoms or signs of cyanide poisoning develop such as:

Nausea, tachypnea, shortness of breath, dizziness, confusion, sleepiness, general malaise, breathing may be rapid then slowing rapidly to gasping, increased pulse, vomiting, cyanosis can be a late sign.

Administer 100% 02 - If consciousness becomes impaired administer 100% 02 and amyl nitrate.

- If breathing stops administer 100% 02 and amyl nitrate by positive pressure resuscitator (BVM).

- If the practitioner is at the level of EMT who has completed the PCP bridge or has successfully completed a learning module approved by the Medical Director, the practitioner may insert a King LT airway device if the patient is apneic.

Advanced Life Support:

- Follow above procedures, administering BLS skills/tx first.

- Monitor cardiac status, V/S every 3-5 mins

- Make critical interventions as needed, intubation (ET intubation, King LT, LMA), assist resps, begin CPR, follow ACLS protocols, and be prepared for cardiac arrest, seizure activity, and cardiac arrhythmias.

- Administer Cyanide Antidote as directed below.

CYANIDE ANTIDOTE

- Actions: Sodium Nitrite reacts with haemoglobin to form methemoglobin. The latter removes cyanide ions from various tissues and couple with them to become cyanmethemglobin, which has a relatively low toxicity.

The function of Sodium thiosulfate is to convert cyanide to thiocyanate. The combination of Sodium Nitrite and Sodium Thiosulfate is the best therapy against cyanide and hydrocyanic acid poisoning. - Warning: both Sodium Nitrite and Amyl Nitrite in excessive does induce dangerous Methemoglobinemia and can cause death. The doses in Cyanide Antidote packages are not excessive for an adult when used correctly.

- Personnel should acquire some skill in the proper method of administering the contents of the antidote package prior to an emergency.

- Instruct assistant how to break an ampoule of Amyl Nitrite, one at a time, in a handkerchief or cloth and hold it in front of the patient’s mouth for 15 seconds, remove for 15 seconds, and this cycle should be repeated continuously using a new ampoule every 3 minutes. The Amyl Nitrite should be continued until the patient regains consciousness OR up to a max of six ampoules. Making sure the individual administering the Amyl Nitrite avoids inhaling substance as it may cause drowsiness.

- Record V/S after each ampoule of Amyl Nitrite, constant monitoring of cardiac status.

- While the above process is being administered draw up 300mg (10ml of a 3% solution) of Sodium Nitrite and inject IV at a rate of 2.5 – 5ml/min.

- Immediately thereafter, inject IF 12.5g (50ml of a 25% solution) of Sodium Thiosulfate.

- The same needle and vein can be used.

- If the poison was taken by mouth, gastric lavage should be performed as soon as possible, but this should not delay the treatments outlined above. Lavage can be done concurrently by a third person if possible.

- The patient should be transported to hospital as quickly as possible.

- If the patient can not be transported to hospital they must be watched closely for 24 hours post treatment. If signs of poisoning reappear, IV injection of Sodium Nitrite and Sodium Thiosulfate should be repeated. The dose will be decreased by half of the original dose.

- Sodium Nitrite IV injection 2nd dose 150mg (5ml of a 3% solution)

- Sodium Thiosulfate IV injection 2nd dose 6.25g (25ml of a 25% solution)

Contents of Antidote kit:

- 2 vials Sodium Nitrite Injection USP 300mg in 10ml of sterile water

- 2 vials Sodium Thiosulfate Injection USP 12.5g in 50ml of sterile water.

- 12 Ampoules Amyl Nitrite Inhalants USP every 5min (0.3ml)

- 1 sterile 10ml syringe with 22 g needle

- 1 sterile 60ml syringe

- 1 sterile 20 g needle

- 1 stomach tube

- 1 non sterile 60ml syringe

- 1 tourniquet

Things to remember

- Always wear proper PPE

- Dry Cyanide when mixed with even a small amt of water/moisture will begin to release HCN gas

- Is not volatile

- Do not use water when fighting a fire involving NaCN (ONLY dry chemical extinguishers)

- Always THINK before you do something!

MSDS

- 1 in Control Room

- 1 outside of Mixing Room