In considering the use of a coal or a coal blend for the production of metallurgical coke, the fact is often overlooked that laboratory data can be most effectively used to determine coke plant operating conditions conducive to maximum output as well as to predict the quality of coke produced.

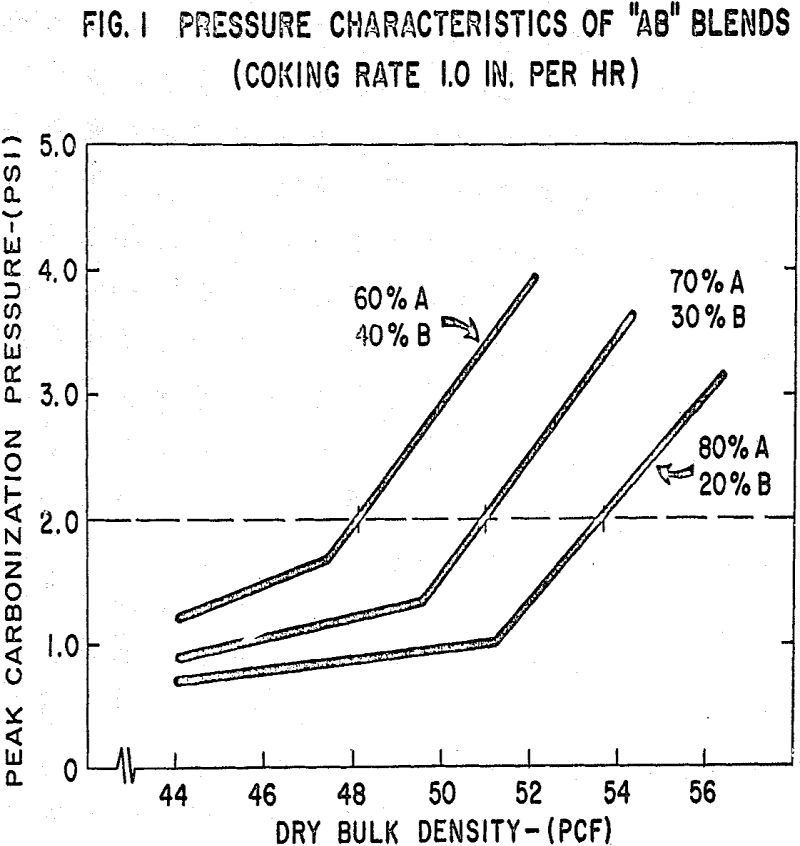

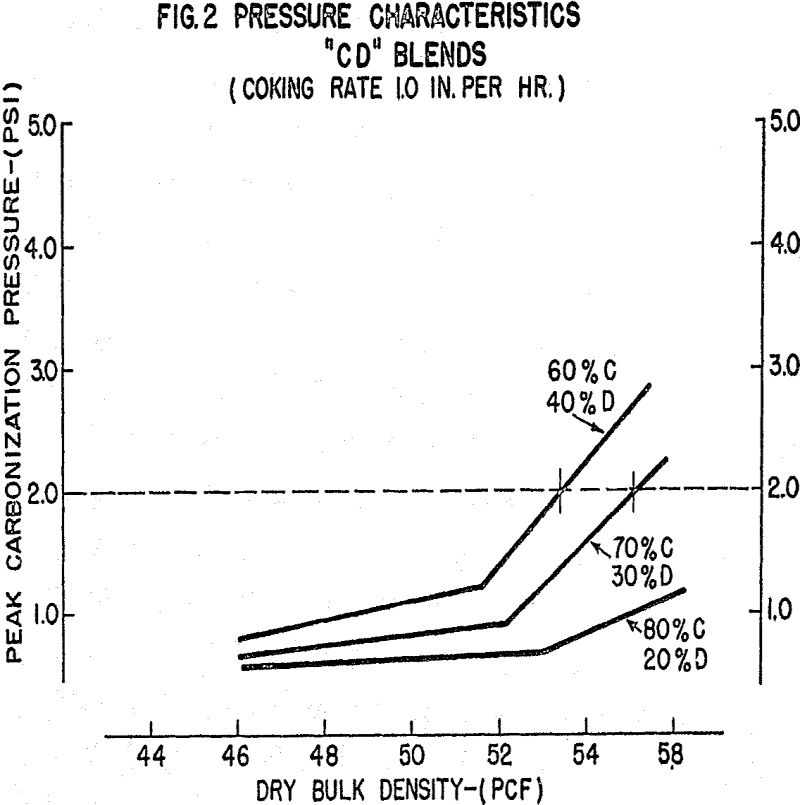

The basic property of any coking blend which must first be given attention is its tendency to generate pressure during the coking cycle. Despite the fact that experience has tabulated some disastrous instances where unsuspecting coke plant operators have found their oven walls distorted from excessive carbonization pressures, the safe upper limit to be placed on this pressure is still a controversial subject. (1) In this particular analysis a pressure of 2.0 psi (as measured in the laboratory) at average operating bulk density is considered the danger point, hence the upper pressure limitation.

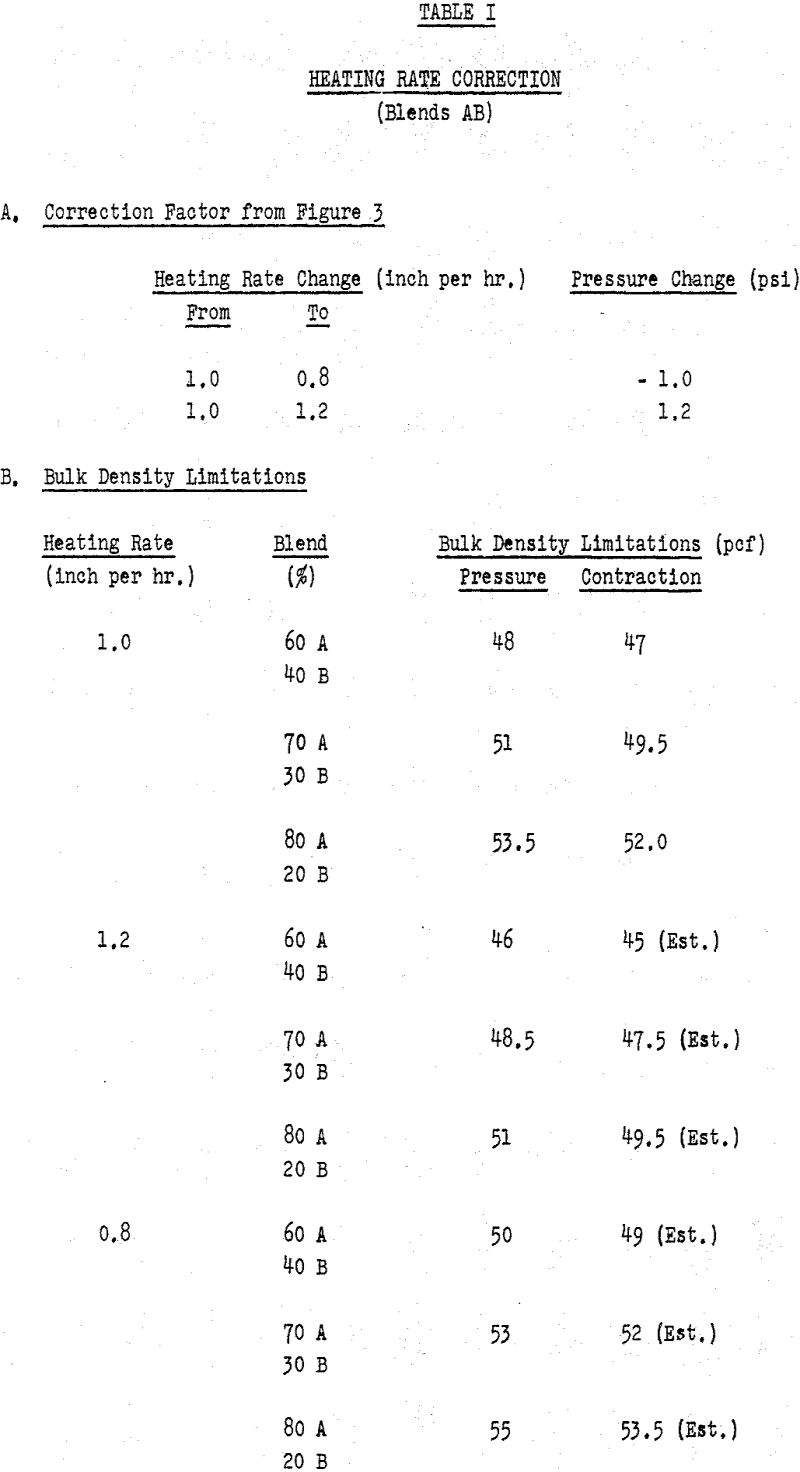

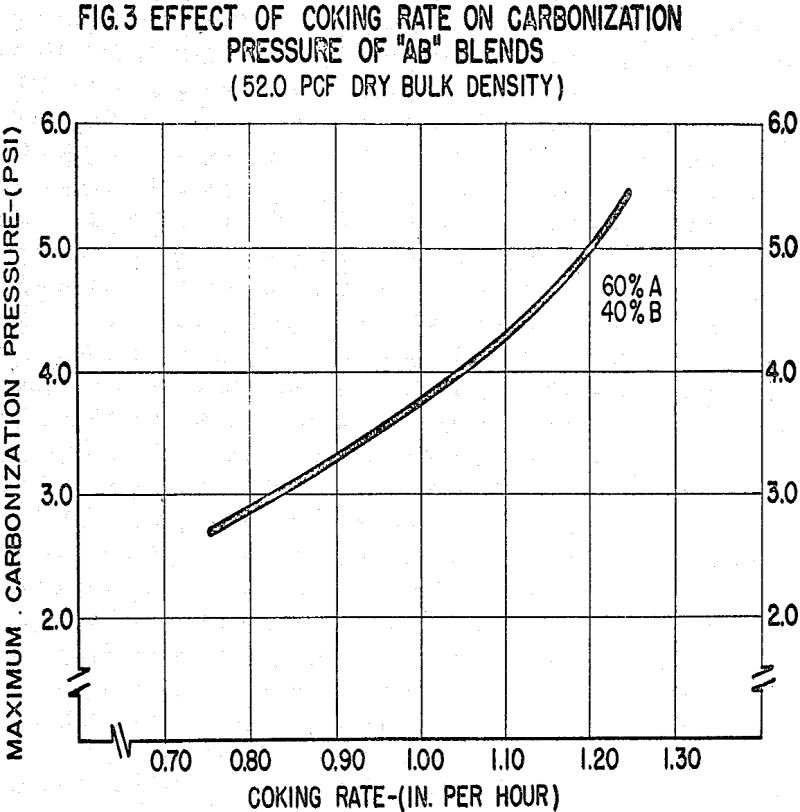

The data shown cover the pressure relationships at a normal coking rate of approximately 1.0 inch per hour. However, because coking rate is one of the main variables to affect coke plant productivity, it is necessary that some information be available concerning changes in blend carbonization pressure as the coking rate is lowered or raised. Because the effect of coking rate on the pressure generation of coking charges is many times overlooked, the safety of coke oven batteries is often imperiled. In considering this aspect of coke plant operations, therefore, it is prudent, in the face of a lack of reliable data, to introduce a relatively high safety correction factor when coking rates are to be drastically increased.

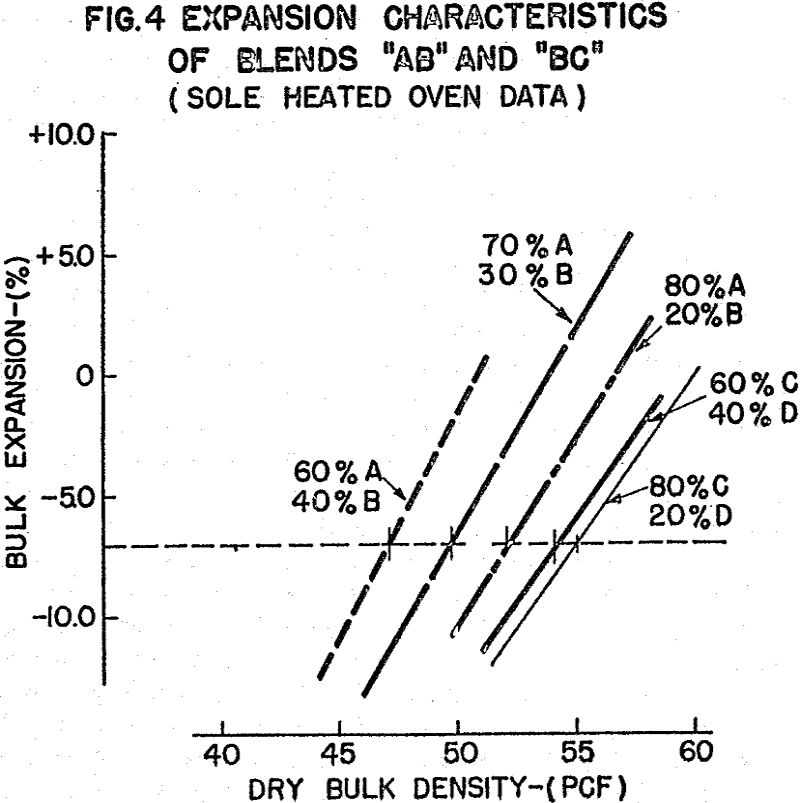

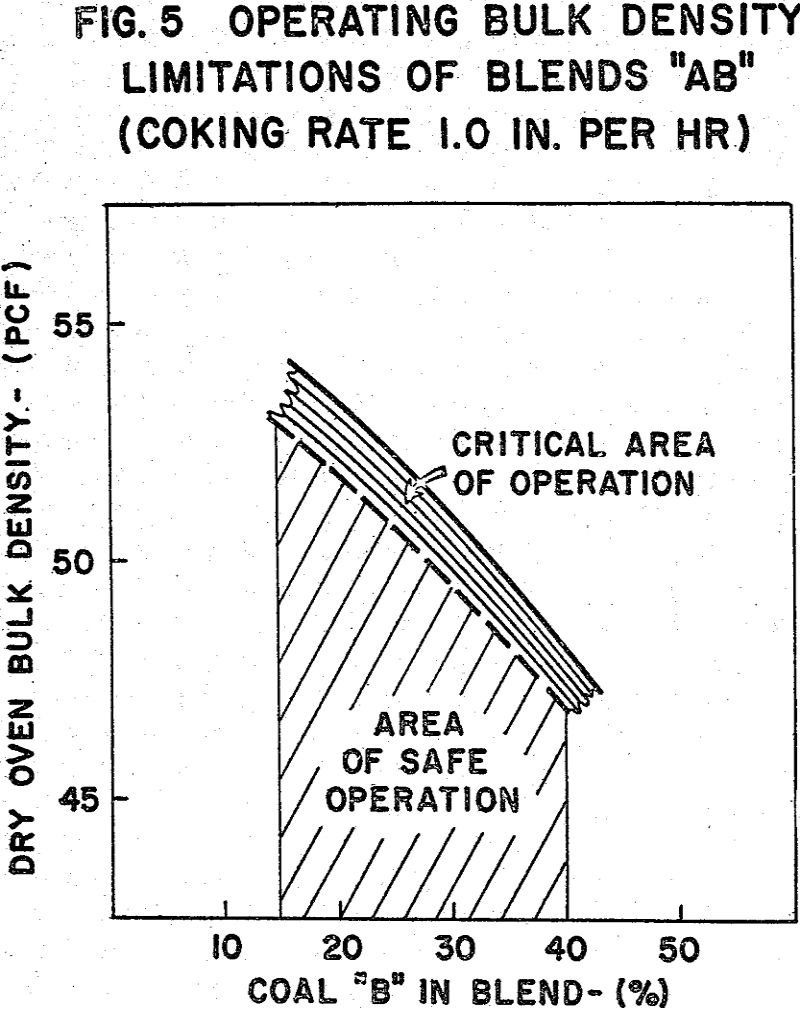

“Stickers”, for the most part, arise from insufficient contraction of the coking charge at the end of the coking cycle. Insight into this phase of the coking behavior of coal charges can be gleaned from expansion-contraction data as obtained from operation of the sole heated oven in the laboratory. Actual experience in one of the larger coke plants of the United States Steel Corporation has definitely indicated that a final blend contraction of 6 to 8 percent at actual average operating bulk density is required to avoid “stickers” from this source. In this analysis, therefore, a minimum contraction of 7 percent is used as the limiting value.

With information on the normal range ®f safe operating bulk densities, some knowledge of the coke yield-blend composition relationship and an indication of the effect of coking rate on both coking pressure and blend contraction, it becomes possible to develop a chart upon which can be projected the effect on coke plant productivity of the variables under discussion.

The general conclusion to be drawn from this discussion is that coking coal blends should be regulated in composition to permit operation at the highest permissible bulk densities consistent with high coking rates. To accomplish this end, it is fundamental that coals of low moisture content be used.