This paper presents in a general manner some of the applications of the DorrClone (Dutch States Mines cyclone) in the metallurgical and heavy chemical fields. Technical or mathematical analyses of the design factors and of the mechanism whereby the cyclone effects its separation have been capably treated in a series of previous papers. Engineering and operational aspects of a few installations and laboratory tests have been chosen to emphasize the unique classification characteristics of the DorrClone and to illustrate its utility in certain difficult situations. Its use in coal washing and heavy-media operations are not considered.

Installation

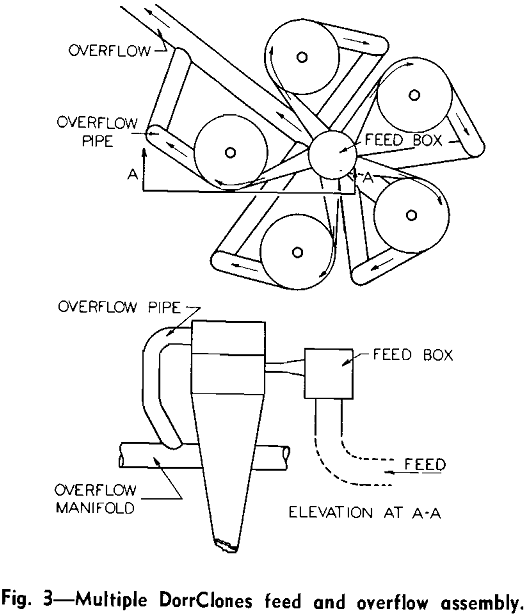

Where more than one cyclone is to be installed, best overall efficiency and ease of control are obtained with equal distribution of both pulp volume and weight of solids among the cyclones, and with the same pressure being maintained at each cyclone feed nozzle.

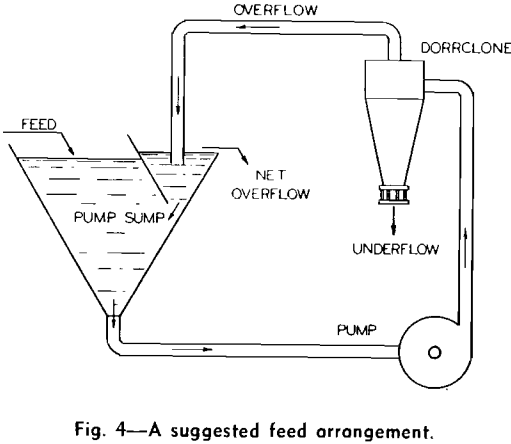

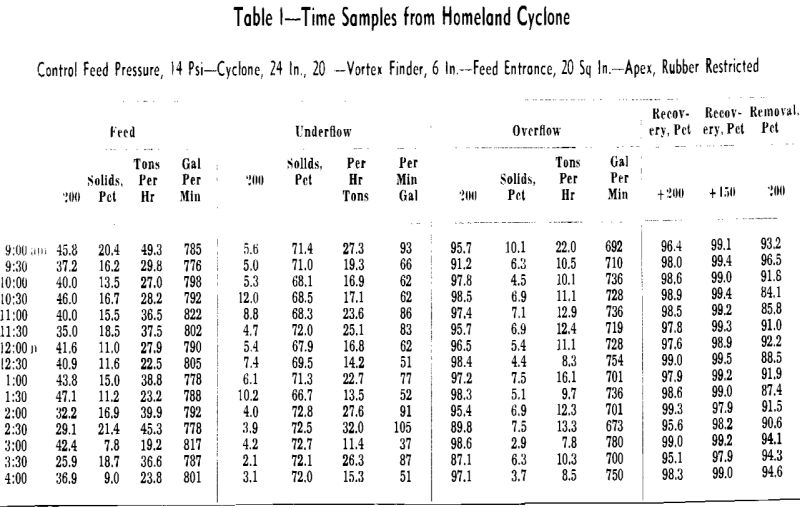

Feed, pressure control: Under normal operating conditions it is not unusual for some surge to exist in the feed that is to be sent to the cyclone. As will be discussed later, surges in the solids content of the pulp are usually not of great operational consequence, but surges in feed volume are a problem.

Several systems have been devised for absorbing surges in feed volume, each involving a surge tank. If the surges are small and fairly rhythmical, a tank of sufficient size might be installed to dampen out

the surge. If the surges are large or of long period, the pump speed should be changed by some control or regulator system, and the number of cyclones on the line should be varied to keep the inlet pressure relatively close to the optimum value.

DorrClone Underflow Control

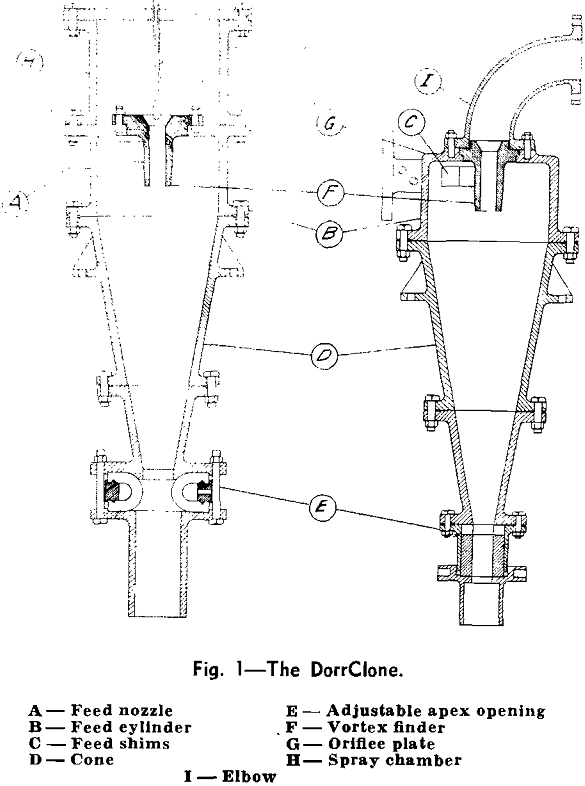

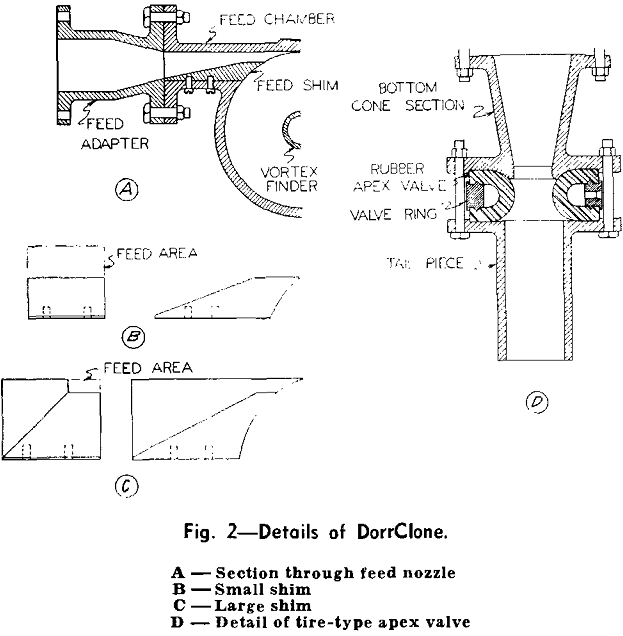

If full advantage is to be taken of the ability of the DorrClone to produce a dense underflow, some method must be adopted whereby physical adjustments of the cyclone are made automatically in response to the normal operating variations in feed composition. The density of the underflow from the cyclone has been shown to be a function of the apex orifice diameter if the feed rate and analysis are fixed and, as a corollary, the density of the underflow may be controlled by adjusting the apex orifice opening as the feed rate and composition vary. By decreasing the apex orifice opening, the density of the underflow is increased.

The adjustment of the apex orifice to control underflow density should be made in a manner that will minimize disturbance of the normal flow pattern of the cyclone. The most convenient device now known is an adjustable aperture.

The DorrClone can be equipped with any type of sensitive nonhunting control instrument capable of operating in response to a 0 to 10 or 0 to 20 in. of water control range. It is preferable to have manual adjustment for both proportional band and reset time.

Applications and Limitations

The mechanism whereby the cyclone makes its separation is generally considered as the settling of discrete particles under the influence of centrifugal force. The high shearing stresses in the cyclone tend to break up and prevent the reformation of any floes that exist in the pulp. At the same time, the high centrifugal forces acting on the particles suspended in the pulp will give sufficient force to even the extremely small particles to enable them to exceed the yield point of the pulp and settle through it. Following are mechanical features of the unit: 1—The elimination of flocs through shearing forces, 2—the increase in the acceleration with which particles act against the restraining force (yield strength) of the pulp, and 3—the reduction of effective viscosity through increased rate of shear. These features enable classification in the cyclone free from the undesirable effects of flocculation, even without dilution or the addition of chemical dispersing agents. This makes the cyclone especially attractive for fine separation with pulps that are naturally flocculent.

The cyclone has produced separations in which the top size of the fine product range from 10 to 150 microns; the exact separation being a strong function of the specific gravity of the solids and the plasticity of the pulp. In any given case the cyclone will not require nearly as much dilution water to achieve the fineness of separation as a hydroseparator. In addition, the underflow from the cyclone may be delivered to the process at only slightly lower per cent solids than the rake product from a classifier and at much higher per cent solids than the normal hydroseparator underflow, even when operating on a thoroughly dispersed pulp. This makes the cyclone useful for desliming ahead of flotation, where a high density conditioning is essential.

Desliming

The DorrClone is especially applicable to desliming. The mechanical dispersion of the pulp eliminates settling of floes (thickening) into the underflow. The dense underflows produced by the cyclone minimize the void volume in the underflow, thereby eliminating a maximum amount of the slimes that would be present in the pulp filling this voids volume. These two factors contribute to improved slime removals. The effect of centrifugal force to aid the small particles in exceeding the yield strength of the plastic pulp will allow high recovery of valuables without dilution of feed pulp. It was the combination of these factors that made possible the 91.7 pct slimes elimination and 97.5 pct recovery of valuables previously listed..

Florida Pebble Rock Phosphate

Details of American Cyanamid’s Sydney units are given in a recent article by Crago. The feed to the cyclones is washer debris at 14 to 17 pct solids and 35 to 45 pct —150 mesh. This is pumped from the surge tank at a rate of 9000 to 9500 gpm to a feed manifold. Pinch valves contained in 8-in. lines led to each of ten cyclones.

The feed entrance to the cyclone is 4 in. wide x 10 in. high. The vortex finder is 8 in. diam and the maximum apex opening is 5½ in. The overflow is removed to slime settling areas without further treatment. The underflow drops at 50 to 60 pct solids into a collection launder leading to a surge tank from which the sizer feed is withdrawn to a 12-ft quadruplex HX rake classifier.

Fine Size Classification

The DorrClone is capable of producing separation in which the top size in the overflow is as fine as 10 microns. The top size in any specific instance is determined by the cyclone proportions and pulp densities but is easily varied and controlled. It can be used in almost any hydroseparation with the advantage that it produces cleaner and denser underflows than a hydroseparator and requires no chemical dispersing agent.