I desire to call the attention of the Institute to a novel system of dredging, which, it seems to me, may prove applicable, not only to river and harbor improvements, but also to certain varieties at least of alluvial and diluvial gold mining; that is, river-mining, bar-mining, coast-mining, and any other similar operations now carried on by means of coffer-dams or dredging machines.

The simple and effective method to which I refer is the invention of General Roy Stone, formerly an officer of volunteers, and at present a civil engineer, engaged under General Newton, of the United States Engineer Corps, upon the government works in New York harbor. General Stone has been, since September, 1878, in charge of operations upon Diamond Reef. This reef, lying between Governor’s Island and the Battery, is one of the most dangerous in the harbor. Its position in the highway of navigation, and the fact that it is dangerous only to vessels of considerable draught and at certain stages of the tide, combine to increase the serious nature of the disasters which it has caused. The reef consists partly of rock in place, and partly of deposits of glacial clay, boulders, and pebbles, over all of which lies, or did lie until it was removed, the ordinary silt and rubbish of the harbor. As the purpose of the present paper has nothing to do with the special dimensions and other circumstances of this particular work, I describe those features only which are connected with General Stone’s ingenious device.

Various attempts have been made to remove the upper portion of Diamond Reef and secure a navigable depth at low tide. Some years ago Maillefert undertook to accomplish this by firing charges of high explosives, simply laid upon the surface. He accomplished some good in the removal of projecting points and ridges; but as soon as the surface of the reef had become approximately level, his method was no longer effective.

After the work had been taken up by the Engineer Corps, the well-known drilling-scow invented by General Newton was brought into action; and, so long as holes could be bored and fired in solid rock, this process was effective enough. In the mixture of hard-pan and pebbles, however, boring proved impracticable. The suggestion of a pile-driver, to drive piles, which could be subsequently withdrawn to leave holes for blasting, appears to have been made by one of the officers employed, but never to have been carried out. Under the circumstances, I should hardly consider this plan worth a trial. Even if it could be executed, the most satisfactory results which could be expected from it would fall far short of the simple, rapid, and cheap performances of Stone’s apparatus.

By a thorough examination, General Stone found the whole upper portion of the reef to possess apparently one and the same character, that of an exceedingly compact indurated clay (hard-pan), filled with boulders, and containing occasional pockets of gravel and sand. The size of the boulders indicated that no bed-rock existed on this part of the reef, within the depth required for navigation. The clay was too hard to be removed by ordinary dredging, and, after some consideration, it was resolved to try the effect of a sort of hydraulic mining; that is, of the use of powerful streams of water from a force-pump. A strong Worthington pump was mounted on the scow, and divers were sent down with the hose-pipe, but they were unable to hold it against the reaction of the stream.

The next day, the pipe being lashed to a pole held from the deck and guided only by the divers, it was found that the hardest clay was rapidly penetrated and the earth and small stones were washed away. The effect of the streams appeared to be fully equal to that which they would have produced if directed against the same material on land. As the result of this successful experiment, simple means were devised to control and guide from the deck the hose and their nozzles at a depth of 30 feet, and in the most rapid tidal currents, when the divers could not remain below. The hose-pipes finally employed are of heavy iron, 2½ inches in diameter, and 12 to 16 feet long, contracted to 1 1/8 inch at the nozzle. These preserve the hose from contact with rocks on the bottom. At 3 feet from the nozzle, they are attached firmly to the ends of heavy spars, provided with steam tackle for lifting and lowering, and various other guys, braces, and tackle to hold the hose in position against the tide and move it as required, to hold it down against the reaction of the stream itself, and to rock and twist it so that the nozzle may work its way down among the boulders.

Five or six men are required to each spar, and one at the pump. A pressure of 150 pounds to the square inch is used. This will penetrate the level surface of hard-pan at the rate of one foot per minute, making a “pot” from three to five feet in diameter, in which boulders of 20 pounds weight boil up and remain suspended until the stream is withdrawn. On a slope, it is still more effective, and in sand the pipe sinks almost as if in water. The accumulation of larger stones in the hole usually stops the descent of the pipe at about 5 feet, the spar being too large to penetrate among them when they are jammed in the smaller section at the bottom. On face-work, a somewhat greater depth may be reached, but the stones roll to the foot of the bank and impede the pipe and spar there so that it is necessary to rake them away. This is done by the divers at slack water, and at other times with a long-handled rake guyed against the tide, and guided by hand and hauled forth and back by steam-tackle. The rake is worked by about the same number of men as a stream, and is fairly effective when it does not encounter rock too large for it to move.

Beyond the fact thus demonstrated, of the effectiveness of a sub-aqueous jet, the proceedings of General Stone up to this point have no special bearing upon mining operations, in which it is required that the excavated material shall be brought to the surface for further treatment. The first operations according to the method above described washed the sand and earth from the edges of the reef away into deep water, leaving the larger stones to be removed by grappling ; but as soon as a flat surface had been formed by the cutting and filling, the material began to lodge and to return at the next tide. It was evidently necessary to devise a method of carrying it athwart the tide into the deep water alongside the reef, whence it could not return.

The customary methods of dredging and dumping, whether with the ordinary dredges or by pumping, seemed extravagant when the material needed to be moved so short a distance and not to come to the surface at all. In lieu of these it, was suggested to lay a pipe along the bottom and throw a jet of steam into it to create an induced current (as in the steam siphon) sufficient to move the gravel and sand; but this would involve a considerable loss by radiation in the passage of the steam, however well it might be protected, and a very great loss by condensation when the steam strikes the water in the pipe.

The only remaining method which occurred to General Stone as practicable was to create an induced current by water instead of steam, a method for which the scow was already provided with the necessary appliances, except the large pipe for the bottom.

Before obtaining a large pipe, General Stone experimented with the drill-pipes on the scow. Into a vertical pipe 6 inches in diameter, suspended in the water so as to leave 2 feet of water standing in it, a 5/8-inch stream under a pressure of 150 pounds per square inch was thrown from beneath. When the nozzle was placed 6 inches below the bottom of the pipe no effect was seen. When placed at the bottom, the water in the pipe was raised 3½ feet; placed 10 inches above the bottom, it raised the water 4½ feet and the injected stream did not penetrate the 14 inches of water above it so as to rise above the surface.

A pipe with bell-mouth was then sent down and laid horizontally on the bottom. A 5/8-inch nozzle was inserted one foot beyond the bell-mouth, and one of the divers used a similar stream to stir up the sand and stones near the bell-mouth, while the other observed the stream emerging from the pipe and endeavored to get samples of it in strong glass jars. But the current swept him away from the pipe, and stones as large as his fist came through with such force as to bruise his hands. He came up with his hands bleeding and his jars broken ; and the other diver confirmed his statement of the force of the stream by saying that his arm had been drawn into the mouth of the pipe with great force.

The pipe was then brought near the surface, and the stream injected with intent to measure the velocity of the current through the pipe, but the length of the pipe (10 feet) was not sufficient to get any appreciable space of time in the passage of an object through it.

When the large pipe, 15 inches diameter and 64 feet long, was received, a successful measurement of velocity was made. The injected stream was through a 1¼-inch nozzle, under pressure of 150 pounds, with a volume of about 400 gallons per minute. The velocity in the large pipe was 10 feet per second, giving a discharge of 5500 gallons per minute, from which, deducting the injected 400, leaves 5100 gallons per minute as the volume of induced stream.

For the foregoing facts I am indebted to the courtesy of General Stone, who, besides answering fully my inquiries, placed at my disposal his official report of progress. The important question, how much solid matter can be transported by the induced stream, is not yet precisely answered. In the operations at Diamond Reef, from 24 to 32 feet under water, the pipe removes all that the stirring-jet outside can dig up, and it is the latter which limits the capacity of the whole apparatus. The stream there carries from 2 to 5 per cent, of its volume in the form of solid material. But when the material to be removed is already loose, such as sand or gravel, and does not need to be bored into and dug up by a hydraulic jet, the induced current seems to carry 20 to 25 per cent. A basket or coarse grating over the mouth of the pipe prevents the entrance of boulders of excessive size. But stones larger than one’s fist are frequently carried through.

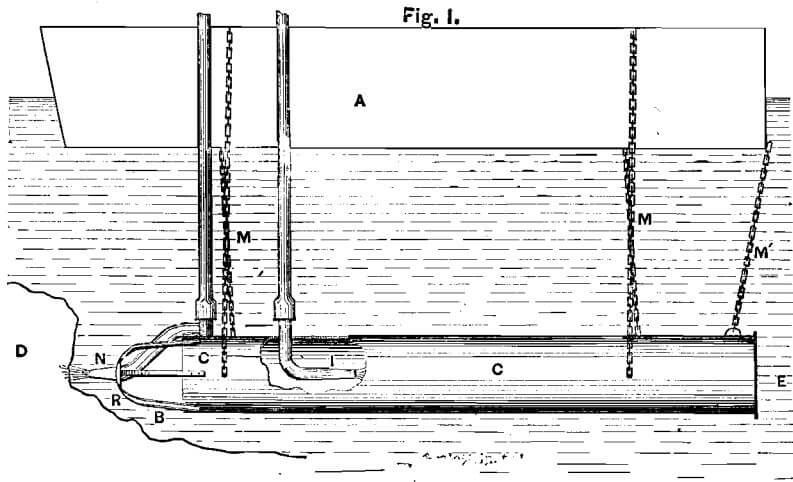

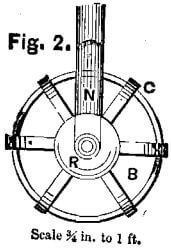

In the illustrations herewith given, Figs. 1 and 2, the large pipe C is shown suspended by chains M M’ from the scow A. A basket-grating B prevents the entrance of large boulders into the pipe. I is the interior or propelling, and N the exterior or excavating jet, the latter being held in its place by the disk R, through which it passes, and which forms the  centre-piece of the basket. The pipe C is represented as horizontal, and the nozzle N as pointing backward, directly in the axis of the pipe. This would be the proper position for both, if the material to be excavated were standing as at D, and the object were to remove it horizontally and drop it into deeper water at E. But the direction given to the nozzle N may be varied according to the surface attacked, against which, for maximum effect, it should deliver its jet at a right angle. For instance, the pipe C being horizontal, and the surface of attack also horizontal, the nozzle N would be directed vertically downward. It is, however, in most cases best to incline the pipe C, so that its discharge may be above the surface of the water and continually open to inspection. In the apparatus now employed at Diamond Reef the pipe C is thus inclined, so that its lower end touches the reef, while its upper end projects a foot or 18 inches above tide, and can be observed from the deck of the scow. It is by watching the, discharge, and noting the quantity of mud, sand, and stones which it carries, that the work-men know when the jet N “takes hold” (usually about ten seconds after operations commence at a given spot), and when it ceases to be effective, either through obstruction in the pipes, or through the accumulation of stones before the nozzle. In the former case, the lower end of the pipe is easily brought to the surface for examination ; in the latter case, it is moved a short distance under water, to commence operations at another spot, and dredging is not resumed at the first spot until the stones have been removed by raking, grappling, etc. These operations are controlled by the periodical inspection made by the divers.

centre-piece of the basket. The pipe C is represented as horizontal, and the nozzle N as pointing backward, directly in the axis of the pipe. This would be the proper position for both, if the material to be excavated were standing as at D, and the object were to remove it horizontally and drop it into deeper water at E. But the direction given to the nozzle N may be varied according to the surface attacked, against which, for maximum effect, it should deliver its jet at a right angle. For instance, the pipe C being horizontal, and the surface of attack also horizontal, the nozzle N would be directed vertically downward. It is, however, in most cases best to incline the pipe C, so that its discharge may be above the surface of the water and continually open to inspection. In the apparatus now employed at Diamond Reef the pipe C is thus inclined, so that its lower end touches the reef, while its upper end projects a foot or 18 inches above tide, and can be observed from the deck of the scow. It is by watching the, discharge, and noting the quantity of mud, sand, and stones which it carries, that the work-men know when the jet N “takes hold” (usually about ten seconds after operations commence at a given spot), and when it ceases to be effective, either through obstruction in the pipes, or through the accumulation of stones before the nozzle. In the former case, the lower end of the pipe is easily brought to the surface for examination ; in the latter case, it is moved a short distance under water, to commence operations at another spot, and dredging is not resumed at the first spot until the stones have been removed by raking, grappling, etc. These operations are controlled by the periodical inspection made by the divers.

This form of the apparatus seems likely to be very useful in some kinds of gold mining. Since an interior jet of 1¼ inch diameter under a pressure of 150 pounds per square inch will carry a large column of water at least a foot above the surface, it is evident that in reasonably still water there would be no difficulty in causing the large pipe to discharge its contents into sluices floating upon rafts, or, even under some circumstances, into sluices set along the shore of a river. Increasing the pressure of the jet, or diminishing the size of the larger pipe, would increase the height to which the discharge might be raised.

On the coast of Oregon and Northern California there are, as is well known, deposits of auriferous sands, which exhibit, when washed up by the tide, placers of sufficient richness to repay mining. It is true, that these sands probably have their origin in bluffs on the shore which have been gradually eaten away by the ocean ; and it is questionable whether dredging under water along this coast would bring up material of sufficient richness to be profitably worked. But if such be the case, an apparatus of the kind I have described would be a very simple and effective means of raising the sands and loading them upon suitable barges.

A feature which particularly recommends this device for experimental use is the circumstance that it involves little loss in case of failure. The Worthington or other high-pressure steam-pump and boiler, the scow and tackle, and even the pipe and hose, are all useful and salable for other purposes; so that a machine of this kind would be by no means a dead loss if it should not in a given locality raise, from a river or ocean bottom, material rich enough for profitable working. The whole apparatus could either be towed or floated to another locality for further experiment, or it could be broken up and the parts sold separately for other uses.

I do not anticipate that the field in gold mining, for an apparatus of this kind, will be very large. The use of General Stone’s contrivance for dredging of rivers, harbors, canals, and the like will be far more important and extensive; but its simplicity, cheapness, portability, and effectiveness, as well as its novelty, seem to me to justify calling to it the attention of such mining engineers as may have to deal with the problems to which it is applicable.

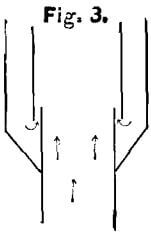

Concerning the novelty of this use of water, it ought to be noted that Captain Eads has employed, at the mouth of the Mississippi, a similar device in dredging. I have not seen either his contrivance or precise drawings of it.  I understand, however, that in that case the water under pressure is forced through an annular space into the dredging-pipe, somewhat as the accompanying imaginary diagram (Fig. 3) indicates. It seems to me that the central jet, as used by General Stone, would be more effective, since it would deliver the same amount of water with less friction ; the friction for a circular opening being less than for an annular opening of the same area. Whether there may not also be an advantage in the transmission of power from a central jet, as compared with the circumferential one, to the main column of water to be lifted, and whether, moreover, any difference in the effectiveness between the two plans could be great enough to make itself felt in practice, I am not prepared to say. At all events General Stone’s arrangement appears to be, for ordinary purposes, the simpler, and to have no serious defects.

I understand, however, that in that case the water under pressure is forced through an annular space into the dredging-pipe, somewhat as the accompanying imaginary diagram (Fig. 3) indicates. It seems to me that the central jet, as used by General Stone, would be more effective, since it would deliver the same amount of water with less friction ; the friction for a circular opening being less than for an annular opening of the same area. Whether there may not also be an advantage in the transmission of power from a central jet, as compared with the circumferential one, to the main column of water to be lifted, and whether, moreover, any difference in the effectiveness between the two plans could be great enough to make itself felt in practice, I am not prepared to say. At all events General Stone’s arrangement appears to be, for ordinary purposes, the simpler, and to have no serious defects.

I believe this invention has been made the subject of an application for a United States patent, and that the Patent Office having reported favorably upon it, the patent will shortly issue to General Stone.