Table of Contents

Cobbing, as used in this paper, refers to coarse dry magnetics separation. It is applicable when, by its practice, plant cost can be reduced or the value of its products increased by the removal of a barren or lean reject or a high grade final product. This paper attempts to describe cobbing as it is now being practiced, and also the problems that are of concern to the operator and design engineer. In preparation, 16 plants were contacted, all of which were very cooperative with their time and data.

Equipment

In the plants from which cobber designs were obtained, all were using conveyor belt magnetic head pulley machines. One plant, in addition, used an overhead magnetic pulley to remove high grade lump ore from a conveyor belt. Many designs have been tried and tested, but when treating coarse material none seem to offer any advantage over the simple conveyor-belt magnetic head pulley type.

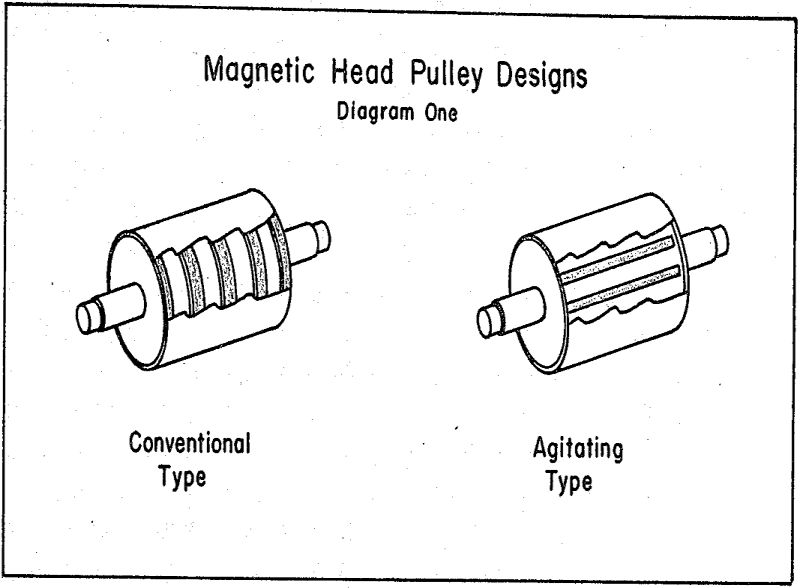

Two types of head pulleys are available for cobbing: (1) The head pulley in which the magnet revolves at the same rpm as the drum,called in this paper the “conventional” type pulley; and (2) The head pulley in which the magnet does not resolve at the same rpm as the drum, called in this paper the “agitating pulley.”

The design of cobbing pulleys must be such that there are no weak areas on the surface, of the drum as these will result in loss of magnetic material. One plant reports that it was necessary to skirt off sections of a new pulley for this reason. Fortunately the field strength had been guaranteed and the magnet was returned to the manufacturer for correction. When obtaining quotations from manufacturers, it is wise to request a plot of gauss meter readings. An order should specify minimum strengths at various distances from the pulley.

There are three generally used methods of obtaining D.C. power for electromagnets: (1) Motor Generator Sets, (2) Rectifiers, and (3) Convertors.

Flowsheets

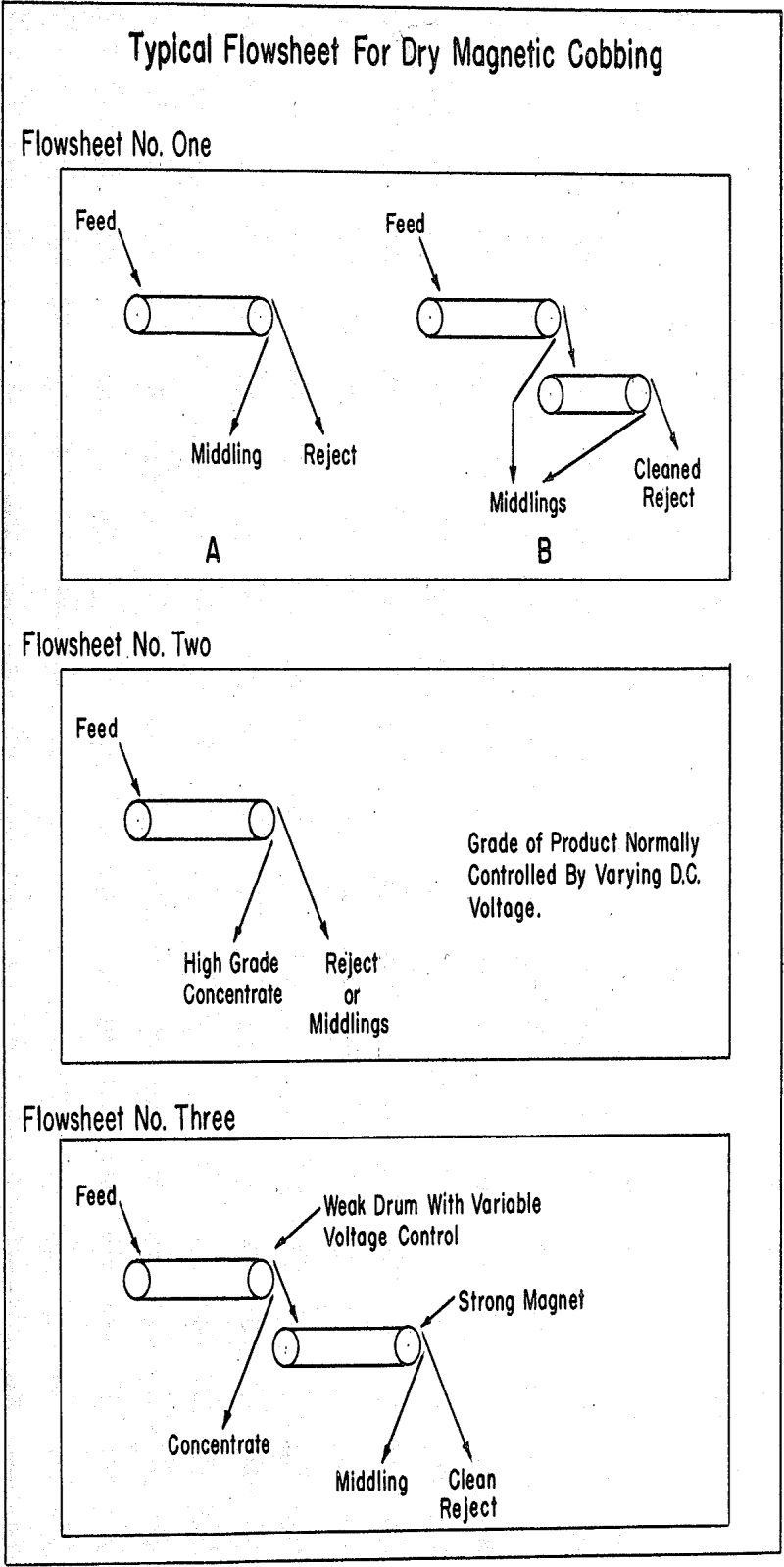

There are three general flowsheets used in cobbing, and they may be divided according to the type and number of products.

- Probably the most common is Flowsheet One. It produces a final, clean reject and a low grade concentrate. A variation of this flowsheet is also shown. The retreatment of the initial reject as shown on the diagram is necessary where high magnetic iron recovery is desirable, and especially when separations are made at a large size, say plus 3″.

- Flowsheet Two is one in which the two products are a finished concentrate and a reject or middling as the case may be. In this circuit it is advantageous to have a method of varying the strength of the magnetic field, making the use of electromagnets desirable.

- Flowsheet Three is a combination of the above two, the rejected material from a weak primary drum being retreated on a strong secondary drum, the latter producing a clean reject and a middling.

Capacities of Cobbers

For efficient cobbing the belt should be loaded-uniformly and preferably one particle deep, eliminating entrapment of reject. Using this belt loading, one way to determine capacity is to take a representative sample of the material, weigh and spread it out oh a flat surface, and determine the area it occupies. The capacity per minute then is the weight of material per square foot times the number of square feet per minute delivered by the belt.

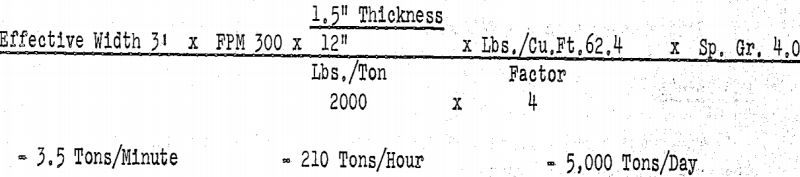

An approximate estimate may also be made by emulating the weight of a solid band of ore (no voids) of average thickness that would pass the head pulley in one minute, and then dividing by a factor of 4 to allow for voids. For instance, a three foot effective belt, width a speed of 300 feet per minute on -2″/1″ material with a specific gravity of 4 would calculate as follows:

Speed and Strength of Magnet vs. Size of Material being Treated

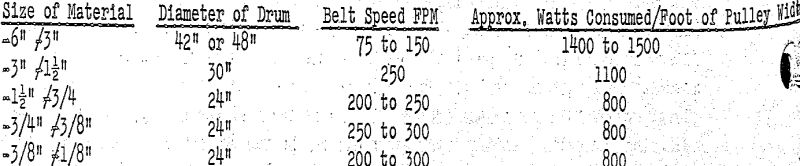

As can be seen in Table One, cobbers are operated under greatly varying conditions, and it is difficult to determine from the table what, speed and diameter of pulley are best for any particular size of material. Therefore, one manufacturer’s recommendation is given below as a guide in design.

Metallurgical Problems

Evaluation of the benefits of cobbing may or may not be simple. Cobbing is usually justified:

- When a high percentage of the crushing plant feed can be rejected at a coarse size with little loss in values.

- When a final product perhaps premium priced, can be removed from the circuit at a coarse size.

- When an increase in production in an existing plant is important.

Cobbing may be uneconomical:

- When it is impossible to produce a sufficiently clean reject.

- When the amount of reject is small.

When fine-grained magnetite is the only mineral of value and there is a minimum of dilution rock and barren material in the ore, elimination of cobbing in the crushing plant in favor of wet rougher magnetic separation in the grinding circuits should be considered.

Sampling of a cobbing plant is always difficult when treating coarse material. Because of this, metallurgical data is often based upon large grab samples rather than upon continuous sampling.

Related: Magnet Fishing Kit