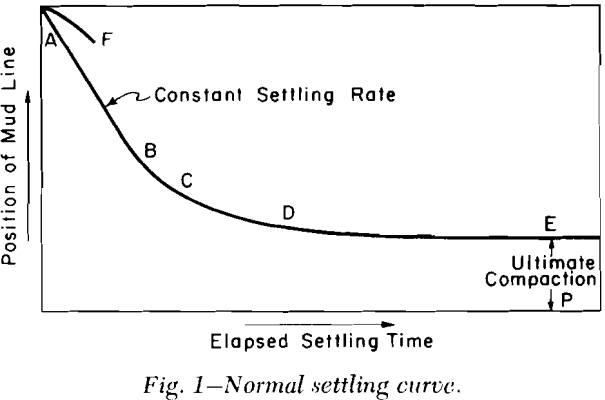

The two principal attributes of a thickener pulp are its settling rate and the ultimate pulp density of the thickened mud. Testing for evaluation of thickening attributes of a pulp has usually been done batch-wise by placing the pulp in a one-liter glass graduated cylinder and noting the position of the boundary between clear liquor and mud as a function of time. Refinements in testing have included repulping a thickened mud to various dilutions and evaluating the settling rate on these various repulped muds. This is considered to make possible an estimate of the settling rate as a function of pulp density and therefore to pinpoint the slowest settling pulp which ought to be critical from the standpoint of thickener plant design.

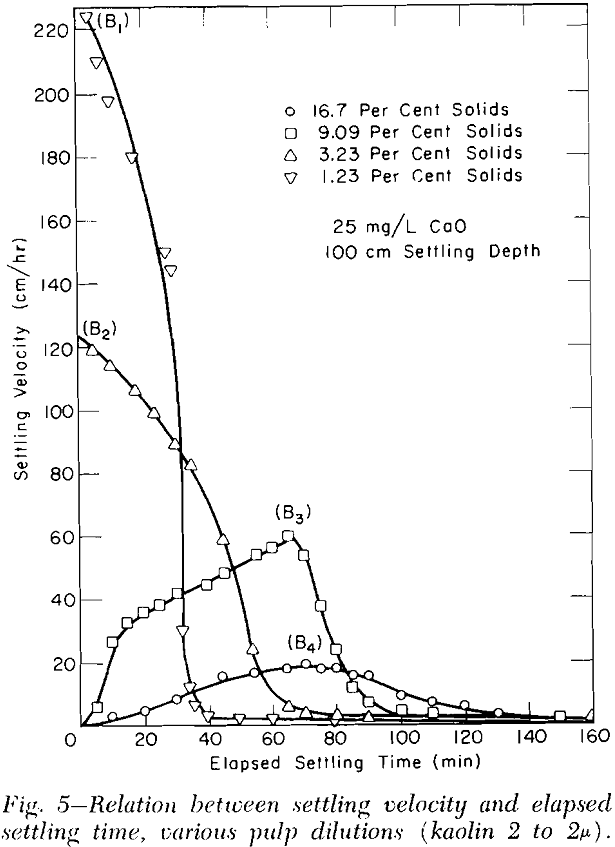

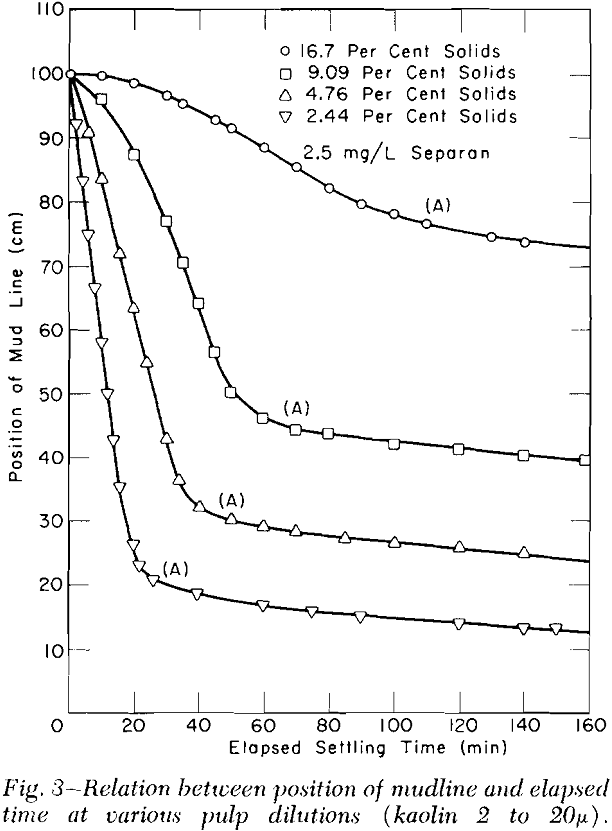

The effects of pulp dilution on sedimentation behavior on pulps ranging from 2.44 to 16.7 pct solids initial pulp density, flocculated with Separan and charted in the traditional manner. At least two of the lines appear nearly straight in their early sections, but neither of the others does. Each of the curves in this figure includes a region labeled (A) in which the settling changes radically, becoming relatively slow.

The time required for condition A to appear is shortened as the pulp is made thinner. The appearance of condition A is marked by formation of volcanoes at the mudline from which small flocs erupt, as noted by Coe and Clevenger.

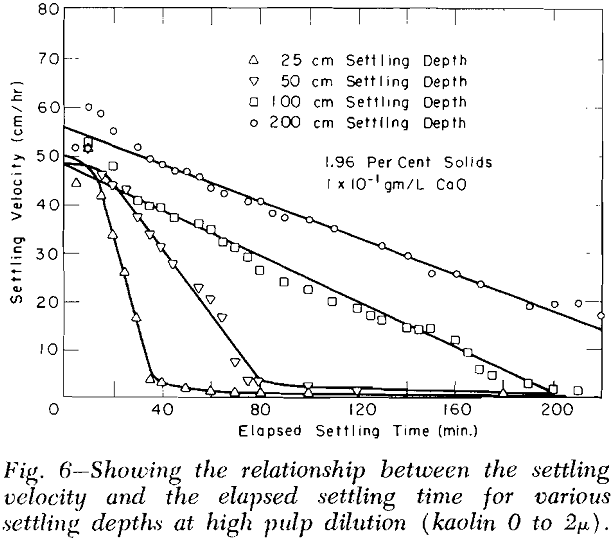

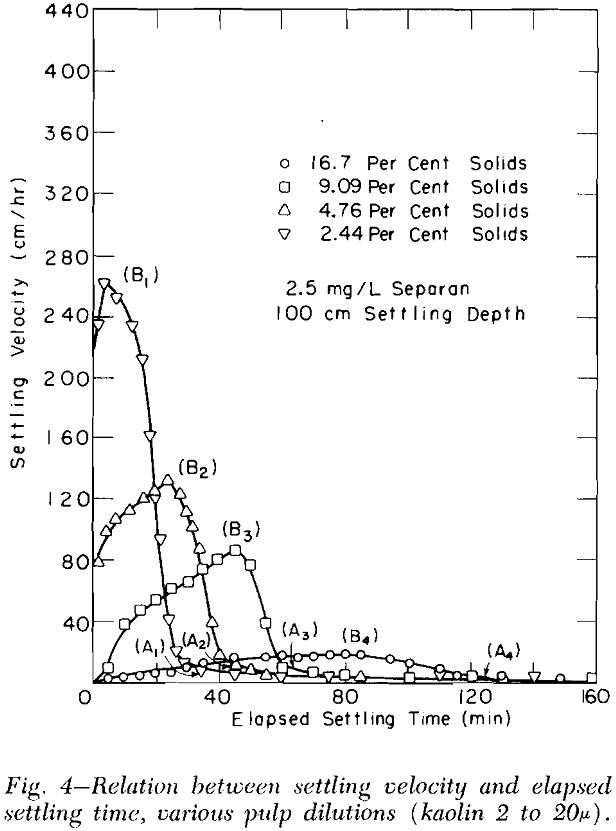

Settling depth has heretofore not been regarded as a factor in the behavior of batch-settling thickener pulps. Tall settling columns (100 and 200 cm in height) as well as settling columns of more usual height (25 and 50 cm) were used in this study.

When dilute pulps are under consideration, maximal settling velocity is substantially independent of settling depth (points B). Also, maximal settling velocity is attained early in the sedimentation period and occurs at almost the same time for all settling depths. The shorter the settling depth, the more rapid the rate at which settling velocity decreases after the maximum is attained.