The effects of rare-earth metals on the properties of sand-cast magnesium were discussed in some detail in earlier paper by the author. The present paper deals with the effect of the same alloying elements on the properties of extruded magnesium. This investigation also had as its aim the development of a wrought alloy having a better combination of room-temperature strength and ductility and elevated-temperature strength and creep resistance than is found in magnesium-Mischmetal-manganese alloys, which have been reported earlier. The only known attempt to study wrought magnesium alloys containing pure cerium instead of Mischmetal was made by Mellor and Ridley. They found that in the form of rolled bars there is a definite, optimum cerium content for creep resistance at 200 °C and that the creep resistance of these alloys at 200 °C is significantly improved by heat treatment at 550° to 580°C.

The alloying ingredients used in preparing the alloys described herein are the same as those reported in the earlier paper. Cerium-free Mischmetal is the rare-earth mixture remaining when the cerium is removed from Mischmetal, which contains all the rare-earth metals as they occur naturally in monazite sand, the ore from which Mischmetal is produced. Removal of both cerium and lanthanum from Mischmetal leaves what is commonly called “didymium,” consisting predominantly of neodymium and praseodymium.

The alloys were extruded into ½ in. diam rod on a 500-ton direct-extrusion press using a 3 in. container. The details of the extrusion step are: billet preheat, 925 °F (2 hr); container temperature, 900 °F; die temperature, 900 °F; extrusion speed, 10 ft per min; reduction ratio, 36:1; and percent reduction, 97.3. The lower melting point of alloys containing didymium necessitated reduction of the extrusion speed to 5 ft per min in order to prevent hot shorting during extrusion.

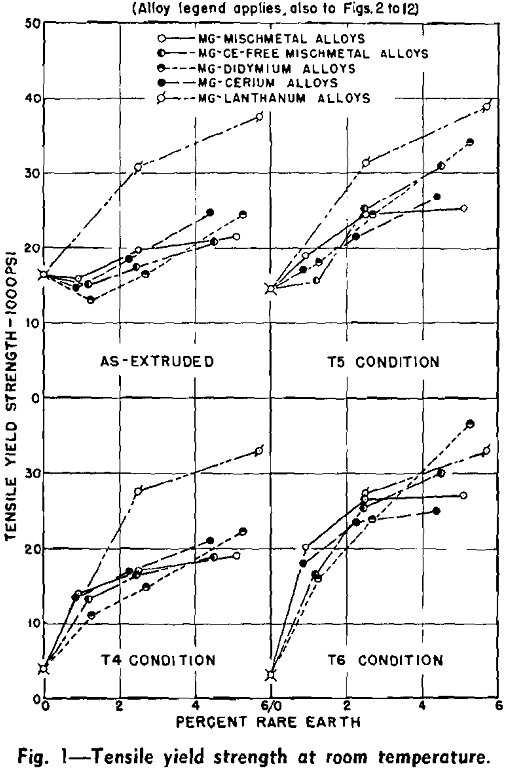

Effect of Extrusion Speed and Temperature: In order to obtain the optimum properties, it is necessary to extrude the alloys under carefully selected conditions. The two most important variables in this process are temperature and speed. Reduction also has some effect on the properties of magnesium extrusions; however, in the case of extruded round rods, the properties are relatively insensitive to reduction over a wide range—as from 16:1 to 144:1. The reduction used in these experiments falls well within this range.

Thus, it is apparent that in order to develop the maximum creep resistance and strength at elevated temperature in extruded magnesium-rare-earth alloys, the extrusion must be performed at 900 °F or higher and the alloys must be heat treated and aged. Lower heat-treating temperatures produce proportionately lower properties. Increasing the heat-treating time beyond 4 hr does not produce any further advantage.

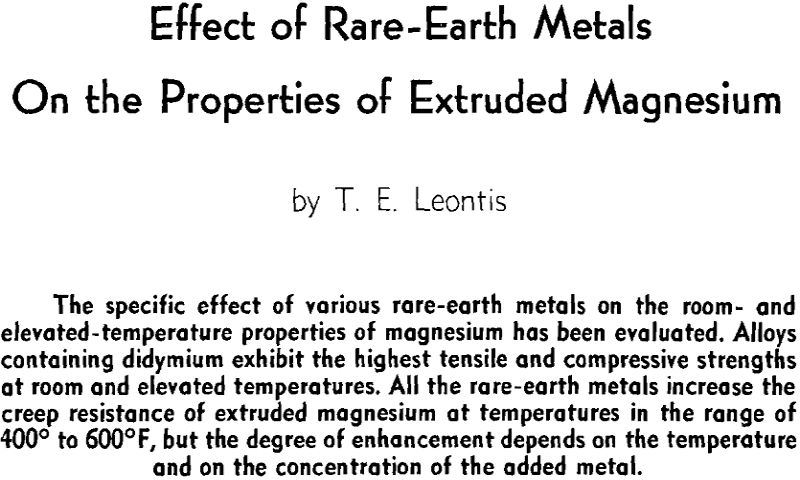

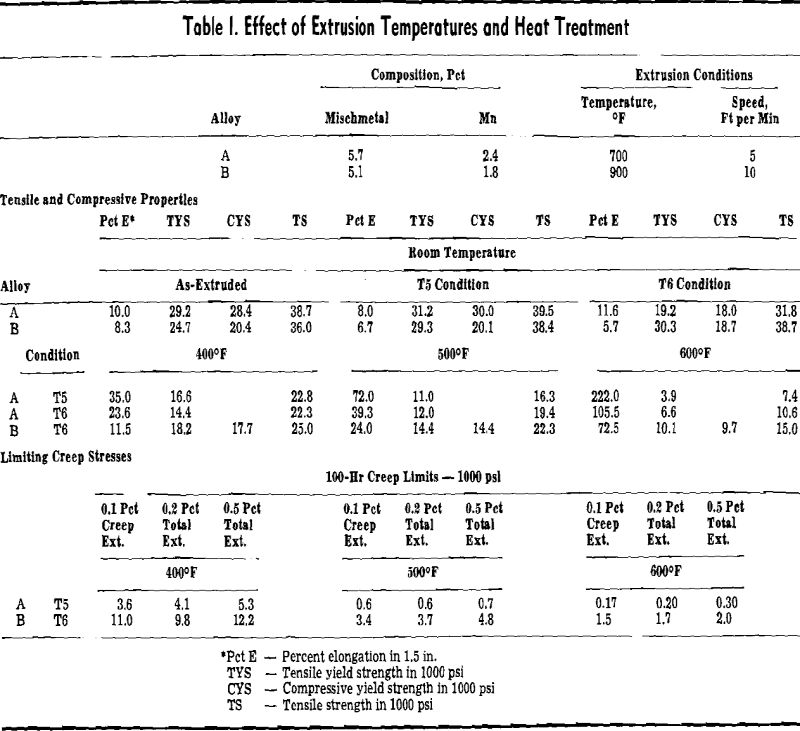

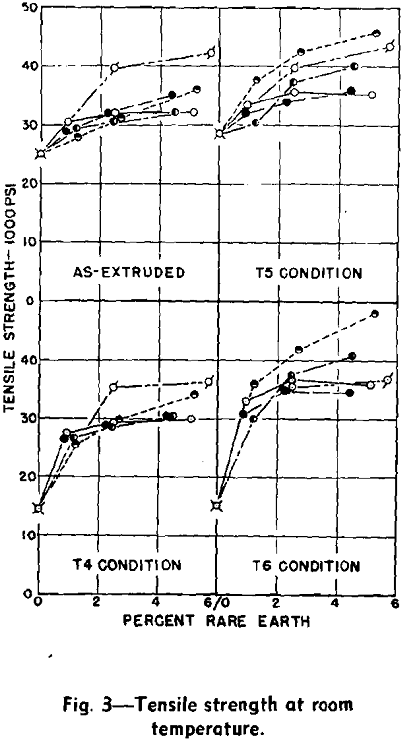

Tensile Properties of Mg-Rare-Earth Alloys: Complete tensile properties at room temperature, 300°, 400°, 500°, and 600°F have been determined on the five magnesium-rare-earth alloy systems as a function of composition.

The elevated-temperature tensile and compressive properties of magnesium-rare-earth alloys present a more straightforward picture. At all temperatures investigated in the range of 300° to 600 °F, the alloys fall in the following order of decreasing strength: 1—magnesium-didymium. 2— magnesium-cerium-free Mischmetal. 3—magnesium- Mischmetal. 4—magnesium-cerium. 5—magnesium- lanthanum. The spread in the strength properties of the alloys increases with increasing alloy content. The low strength of magnesium-lanthanum alloys is associated with very high elongation. The other magnesium-rare-earth alloys do not show very great differences in ductility at elevated temperatures.

Effect of Manganese on Magnesium + 5 Pct Rare-Earth Alloys: In general, the addition of 2 pct Mn to magnesium + 5 pct rare-earth alloys increases the strength properties by 1000 to 2000 psi at all temperatures. The room temperature tensile properties of the binary magnesium + 1.85 pct Mn alloy, extruded under the same conditions as the magnesium-rare-earth alloys, are comparable to those of the latter alloys. However, the compressive yield strength of the binary magnesium-manganese alloy is much lower. Magnesium + 1.85 Mn alloy, however, does not exhibit the same degree of temperature resistance that the rare-earth alloys show.

Electrical Conductivity: The results of conductivity measurements show trends similar to those found in the sand-cast alloys. The low solubility of lanthanum in magnesium is again demonstrated by these data. No special significance should be attached to the maxima in the curves for magnesium-lanthanum alloys. Two possible explanations that might be proposed for this phenomena are: 1—differences in impurity content, and 2—differences in degree of preferred orientation.