The IGR 3000 Trommel type Gold Washplant was designed for a nominal 30 tons/hour feed rate based on an alluvial type material with moderate clay contamination.

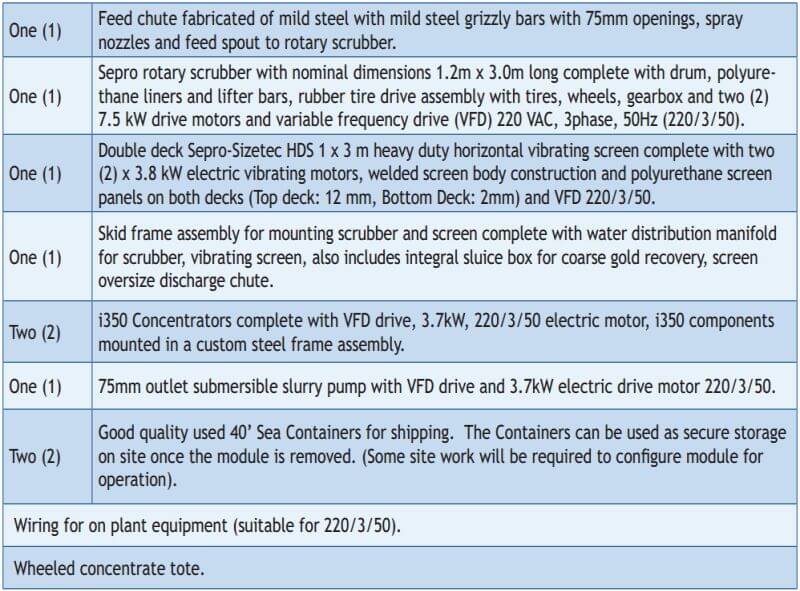

Material is loaded into the plant feed hopper through a static scalping grizzly with 75 mm bar spacing. Oversize is to be periodically removed manually from the grizzly. Undersize feed material is washed into the scrubber feed chute by water-jets strategically placed in the feed hopper and by a manually operated water monitor. Water is piped from an onboard water manifold system that supplies water to the complete plant from the customer’s primary water supply.

Material is scrubbed in this gold wash plant to let clays and silts dispersed into the slurry. Slurry is discharged over the double deck vibrating screen. Oversize (+10mm) from the vibrating screen is discharged via a chute to ground level where it can be removed by the customer’s mobile equipment or by the client’s conveyor system. Product from the bottom deck oversize (-10mm + 2mm) is discharged onto the sluice, complete with riffles and fiber mats, where coarse gold will be recovered.

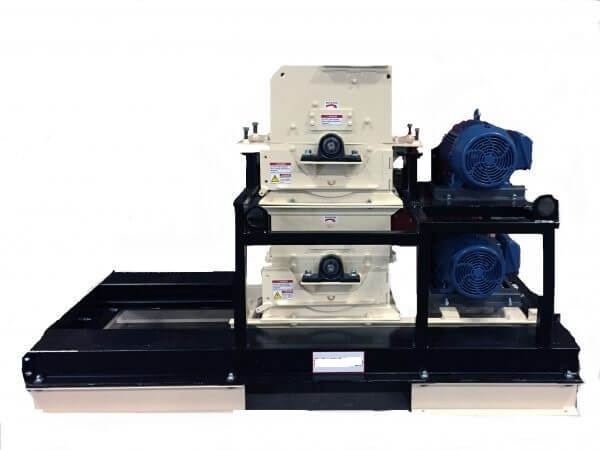

The screen undersize (-2mm) is pumped from the screen undersize hopper to the concentrator feed box/splitter. The concentrator feed box services a dual purpose as it regulates feed to the concentrators by flowing excess slurry directly to the sluice when required and it serves as a manual by-pass system during the concentrator rinse cycle. Feed from the concentrator feed box flows directly into the twin i350 centrifugal gravity concentrators.

Tailings from the concentrator are directed to the inlet side of the sluice to aid the oversize material (-10mm +2mm) in flowing down the sluice to the final tails area. Concentrate from the twin i350 concentrators is directed to a wheeled storage tote which can be easily removed and towed to a final location for final upgrading and smelting. Concentrates from the sluice need to be removed periodically washed and added to the gravity concentrate.

- 75 mm – passes the grizzly and into the scrubber

- 10 mm + is rejected by the top level of the vibration screen

- 2 mm + to 10 mm – is fed to the high-efficiency sluice

- 2mm – is distributed to 2 x i350 Concentrators