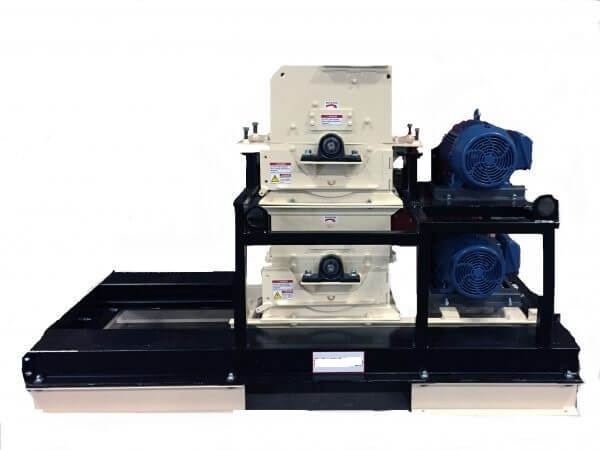

For HIGH REDUCTION RATION applications, our Electronic Shredders are made of Dual Stage Hammer Mills  featuring two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine fully shredded consistency, and grinding free-flowing material to an ultra-fine finished particle size.

featuring two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine fully shredded consistency, and grinding free-flowing material to an ultra-fine finished particle size.

Disintegrate your solid-state hard-drives to a super-fine scrap electronic power of under 2mm.

The energy resulting from the dual revolving rotors produces a suspension zone that provides additional size reduction. As a result, a finer grind is achieved in one pass through the dual-stage mill, than can be achieved in multiple passes through a single hammer mill.

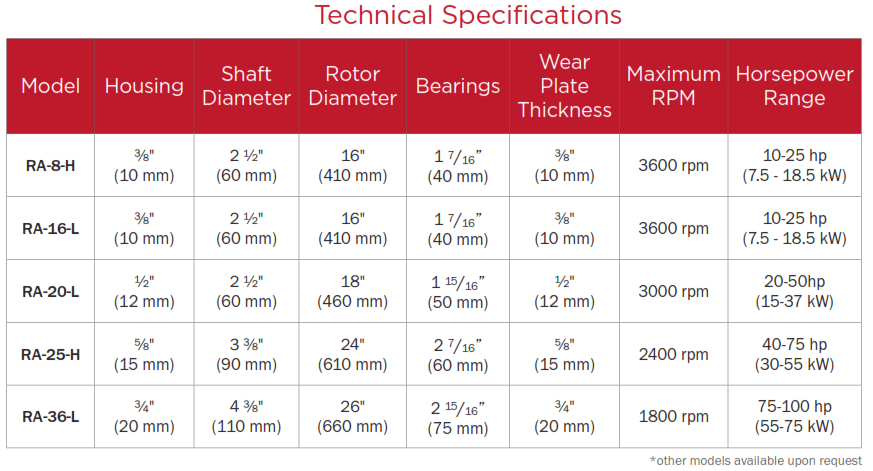

- The Electronic Shredders are available in 5 standard sizes

- Space-saving stacked design features a slide-out rail for ease of maintenance

- Option of carbon or stainless steel construction plate

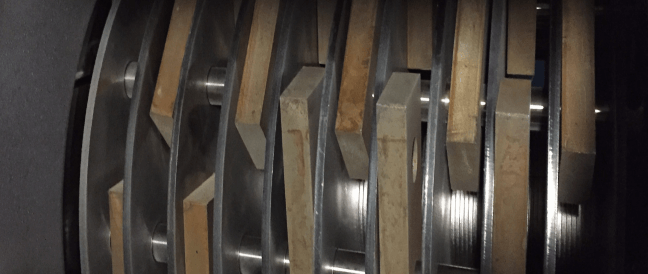

- Multiple hammer styles and sizes

- Reversible hammers maximize wear life

- Replaceable abrasion resistant wear plates protect mill housing

- Interchangeable heavy-duty bar grates or perforated screens made from abrasion-resistant steel

This Electronic Shredder is a Monster Hammer Mill capable of pulverizing most anything to dust!