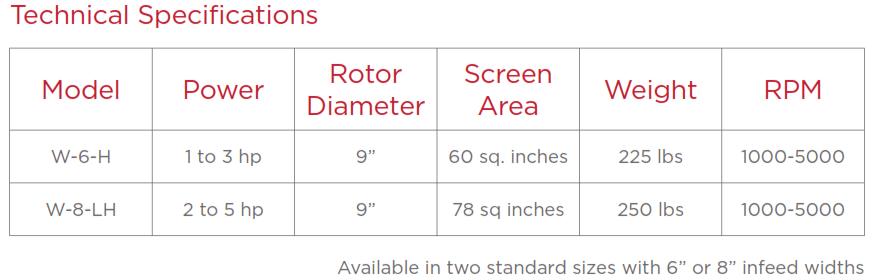

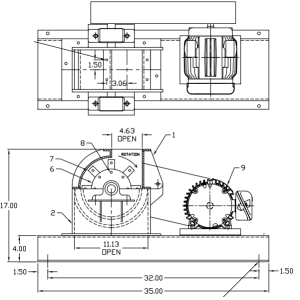

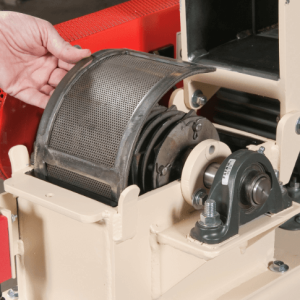

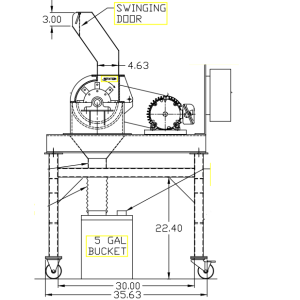

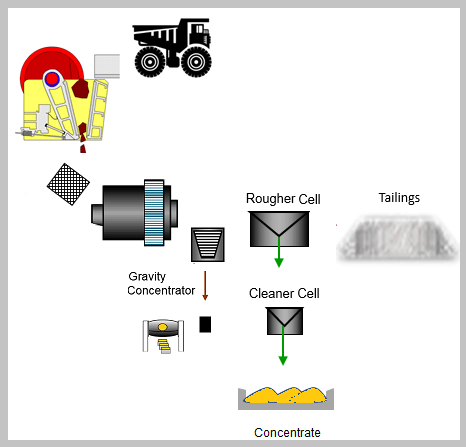

This rugged, yet compact, gravity discharge Laboratory Scale Hammer Mill features the same durable construction and long-wearing components of production scale models. Lightweight, low noise, and suitable for small production, batch, or pilot projects. The 6” and 8” wide laboratory scale mills are capable of processing a variety of materials to a granular or powder consistency with scalable results.

Key Features:

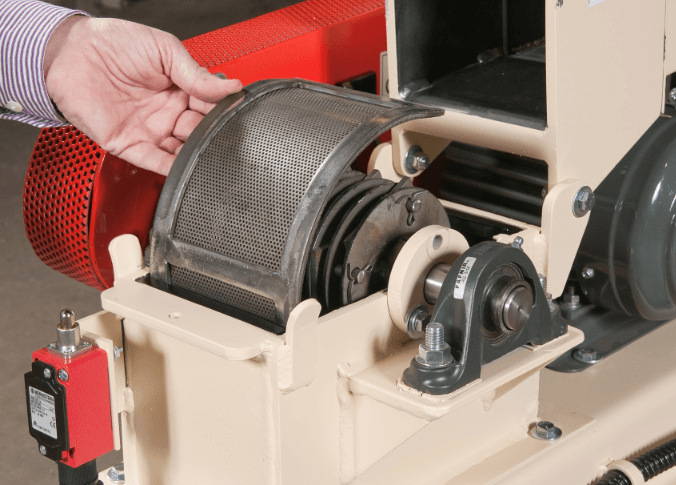

- Option of replaceable internal wear plates for processing abrasive materials

- Choice of carbon or stainless steel construction

- Wide selection of four-way reversible hammers,

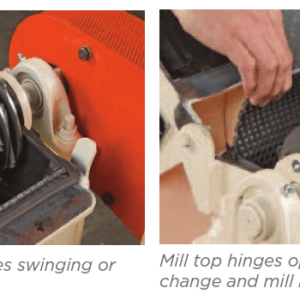

- Numerous, easily changeable screens for the exact desired finished particle

Additional Options Include:

- Single-phase motors

- Variable Frequency Drive

- Custom designed support stands, infeed, and discharge chutes

Typical Installations Include:

- Pilot plants

- University labs

- Government testing facilities

Production rate:

- Will process 50-150 pounds per hour depending on the type of material (Printed circuit boards or other)

- Not for Hard Drive

- The product size is as required by choice of screen size installed and hammer speed

- Grinds to under 1mm