This ore processing plant is for the flotation of 2 base metals (Cu/Pb/Zn/Co/Ni/etc.) which may or may not contain precious metals. These ore deposits are called polymetallic by geologists and metallurgists. This system allows you to recovery by way of differential or sequential flotatio, the sulphide metals in 2 separate concentrates. Examples include: Copper, Lead, Zinc, Cobalt, Nickel, Molybdenum, Pyrite, Pyrite-Gold, Silver-Sulphides. This process will also recover silver and/or gold associated with sulphide minerals.

This simple metallurgical concentrator includes single stage crushing, conveying, primary grinding, hydrocyclone classification (optional spiral), slurry pumping, conditioning tanks, 2 rougher flotation circuits and 2 x 3 stages of concentrate dilution cleaning. For each or either metals, a regrind circuit can be added upon request.

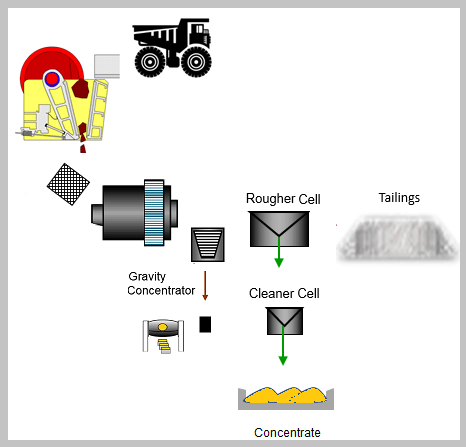

If you know coarse gravity recoverable gold is present in your mineral deposit, an iCON gravity gold concentrator (and refinery) can easily by introduced in this process plant.