The 911MPE-JAC34 or 3″ x 4″ (75 x 100 mm) is our biggest Small Jaw Crusher. Handcrafted in Canada, is designed to crush rocks/ore of any type (gold, silver, copper, granite, cement, bricks, etc.) 2.5” (63mm) in size down to 50% passing its CSS closed side setting of 1/8″.

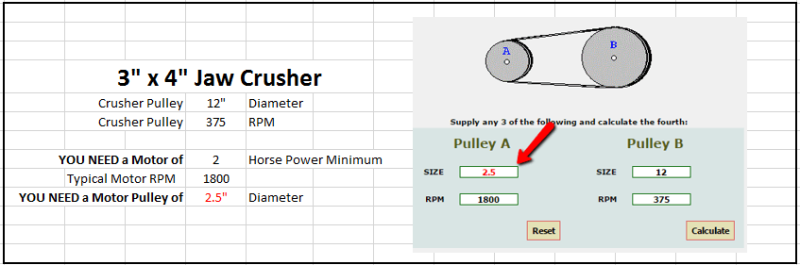

With a 375 RPM overhead eccentric, you would equip it with a 3 HP electric motor or 6.5 HP gasoline engine, to see this small primary rock crusher/breaker quickly have your hard rocks crushed to under 1/4″ and be ready for secondary crushing.

Use this jaw crusher ahead of a hammermill to preserve the life of the hammers and screens on the mill.

This jaw crusher (no motor, no frame) weighs 150 lbs.

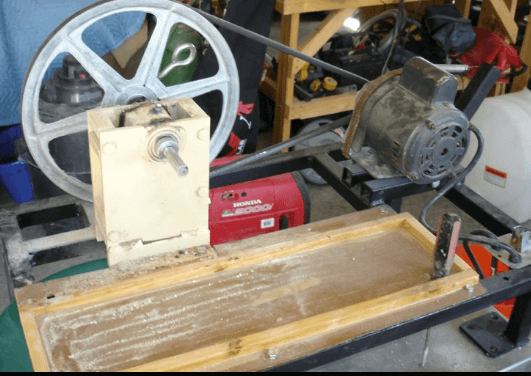

Simply add a 1/4″ or 3/8″ thick mild steel flooring to a heavy-duty garden wagon and bolt your 3 x 4 jaw crusher and motor to it.

Simply add a 1/4″ or 3/8″ thick mild steel flooring to a heavy-duty garden wagon and bolt your 3 x 4 jaw crusher and motor to it.