The transportation or transportable moisture limit is defined as:

It is the limit of a cargo which may liquefy, represents the maximum moisture content of the cargo, which is considered safe for the carriage in ships not complying with the special provision. It is derived from the flow moisture point (flow table test) or from data obtained from other test methods approved by the appropriate authority of the port state as being reliable.

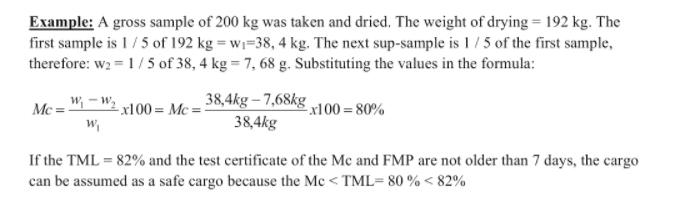

The transportable moisture limit (TML) = 90% of FMP. If the FMP and the MC is known, the TML can be calculated by the ship command.

The IMSBC Code requires that the shipper shall provide the master with a certification to confirm the TML and the actual moisture content of the cargo prior to loading. The cargo cannot be assumed as safe for transportation if the moisture content is not less than the transportable moisture limit (IMSBC code, section 7.3.1). If the moisture content is equal to the TML or is exceeding the TML, the cargo must be declared unsafe. The certification presented to the master should not be older than seven days. If the certificate is older than seven days, the test for the moisture content of the cargo must be renewed and the cargo can only be loaded if the new certificate, approved by the authorities, states that the moisture content is below the TML.