Table of Contents

A brief summary of the methods employed and the costs of prospecting and exploration has been presented in the preceding pages. The primary object of such work, as already stated, is to find ore and furnish information upon which to base estimates of its quantity and grade.

Estimates of ore grade are based on the assays of samples obtained from excavations in the ore, from drill holes, or both. The accuracy of the estimates will depend on the care taken in procuring the samples and the judgment used in deciding upon the sample interval required, the accuracy in assaying, and the proper weighting of the individual assays in combining them for determining average grades of individual ore blocks, especially the treatment of erratic high values. These are all matters that require experience and judgment on the part of the estimator.

Natural conditions affect the degree of accuracy possible; thus, the regularity of the deposit and the size and distribution of the particles of valuable minerals will limit the accuracy obtainable with a given pattern of samples. Also, there are practical considerations, such as the amount of money available and the degree of refinement required. In large low-grade deposits, a fraction of 1 percent difference in valuable mineral may be enough to determine whether the material is ore or waste. On the other hand, in a high-grade deposit, although a difference of a few dollars per ton in grade may make a large difference in the total profit recoverable from a deposit, such a difference may be relatively unimportant if the objective of the estimate is merely to determine whether or not development operations are justified. However, if the sampling is to form a basis for determining the price to be paid for the purchase of the property, obviously a high degree of accuracy is necessary.

In any event, sampling is an important operation, as much may depend on the care with which it is done and the intelligence shown in interpreting assay returns. It is obvious that correct conclusions cannot be reached from misleading samples—that is, from samples not truly representative of the material sampled. It is not always easy to obtain representative samples, and often they are reliable only when taken systematically in large numbers, so that errors in individual samples become compensating and not cumulative. Systematic sampling requires a procedure that will eliminate the human factor as far as possible.

A perfect sample would have the assay value of the block of ground from which it was taken. Since valuable minerals are distributed unevenly and are present in varying degrees of purity throughout the gangue material, a perfect sample can be obtained seldom if ever. Indeed, in erratic ores, assays of individual samples may vary widely from the actual assay value of even the small block they are supposed to represent. However, if each sample is taken mechanically in strict accordance with a system and the number of samples taken is large, the combined samples may and usually do approach much nearer the actual average ore than do individual samples to the different blocks of ore from which they are taken, the errors compensating, as above stated.

The questions to be decided in adopting a sampling procedure include the size of individual samples and the sample interval. A well-recognized principle is that the finer the size of the mineral particles (ore and gangue) and the more even the distribution of the ore-mineral particles in the matrix, the smaller may be the sample and the greater the space between samples. Conversely, the more irregular the distribution of the ore minerals and the larger the particles, the larger should be the individual sample (in weight per unit length of sample cut) and the closer the sample interval. The mineralization in some deposits is so erratic that only actual mill tests of relatively large bulk samples will give a reliable index to the grade of the ore.

The following discussion will cover, principally, the methods of taking small samples rather than bulk samples. It may be said at this point, however, that mill tests of large or bulk samples may sometimes be employed advantageously to check the results of small samples previously taken from selected blocks of ground. Thus, the mill tests may establish a correction factor that may be applied to assays of small samples to give more accurate results for the particular ore in question. Methods of sampling ore deposits may be classified as follows:

- Drill sampling with

(a) churn drills,

(b) core drills,

(c) hammer drills, and

(d) fish-tail and other types. - Face sampling:

(a) Pick or chip sampling,

(b) regular channel or groove sampling. - Grab sampling of broken ore.

- Bulk sampling.

Each of these methods has been discussed at some length by Jackson and Knaebel.

Drill Sampling

In churn drilling for sampling purposes, the cuttings from each unit length of hole are brought to the surface and constitute a sample of the formation at the interval of depth from which it is cut. When cable-tool equipment is used, the tools are raised to surface and cleaned of material adhering to them by washing it off into the hole. The bailer is then lowered and the cuttings are raised to surface, bailing being continued until the hole is clean.

When hollow rods are used instead of cable tools, as with the Mesabi-type rig, the water is pumped continuously through the rods, as in diamond drilling, the return water carrying the cuttings being caught in a series of tubs, barrels, or other suitable settling apparatus.

With cable tools, the hole usually is bailed at regular depth intervals until ore is reached. The cuttings are examined mineralogically, often being panned to separate the constituent minerals. Thus, a knowledge is gained of the different rock formations and the horizon at which each occurs. Information gathered from examination of the cuttings should be logged carefully on suitable forms. When rods are used, the same information is obtained by watching the sludge during drilling and taking occasional pannings for examination, especially whenever a change is noted in its appearance.

When ore is struck, it is usually desirable and often necessary to case the hole from surface to the top of the ore, setting the bottom of the casing firmly into the ore. This is done to avoid contamination of subsequent samples with material loosened from the upper part of the hole by natural caving, by the raising and lowering of drilling tools and bailer, or by the slap of the drilling cable or rods, as the case may be. After being cased, the hole is cleaned thoroughly, and as drilling proceeds samples are taken at regular intervals (usually 3, 4, or 5 feet) by successively drilling and removing the cuttings from corresponding depth intervals. Care must be taken to clean the hole thoroughly each time and to collect all the cuttings in the sample.

Erroneous samples may result from caving of the hole; from leaking of drilling water in dry ground through cracks and crevices, carrying sludge with it; from rock falling from upper sections of the hole, thus contaminating the sample by raising or lowering the assay value, depending on whether the contaminating material is higher or lower in grade than the portion of the hole being sampled; and from faulty handling and treatment of the sludge constituting the sample.

Any great increase or decrease in the weight or bulk of the sample per foot of hole usually can be detected quickly and indicates either that the hole is caving badly or that appreciable leakage has taken place. Lesser departures from average size of samples are not so easily explained or detected. A given size of bit will cut holes of slightly different diameters in different rocks, depending largely on the hardness of the rocks, and small variations in size of samples from equal footages need not, as a rule, be looked upon with suspicion.

A large increase in size can usually be attributed to caving at the sample horizon or to sloughing from above, and assay results may require correction. Thus, if a sample weighs or assays appreciably more or less than the samples next above and next below it, serious contamination may be suspected. The procedure will then depend on conditions and previous experience with other holes in the deposit. It may be satisfactory to average the assay value of the vitiated sample with that of the two adjacent samples and assign the average to it, or to disregard the assay entirely, assigning to the sample the average of the two adjacent samples if they appear to be accurate.

Sludge samples from the larger holes are very bulky and usually must be cut down and dried at the drill. Generally, the first cuts or splits are made on the wet sample when cable-tool equipment is used.

At one time the senior author was employed on a churn-drill sampling job at Ray, Ariz., where holes were drilled with cable-tool rigs, starting with an 8¼-inch bit and followed, successively, by 6¼- and 4¼-inch bits when it became necessary to case and recase the hole. The samples from the larger diameters were bulky, especially in soft ground, and each bailer was dumped into a sample box, from which

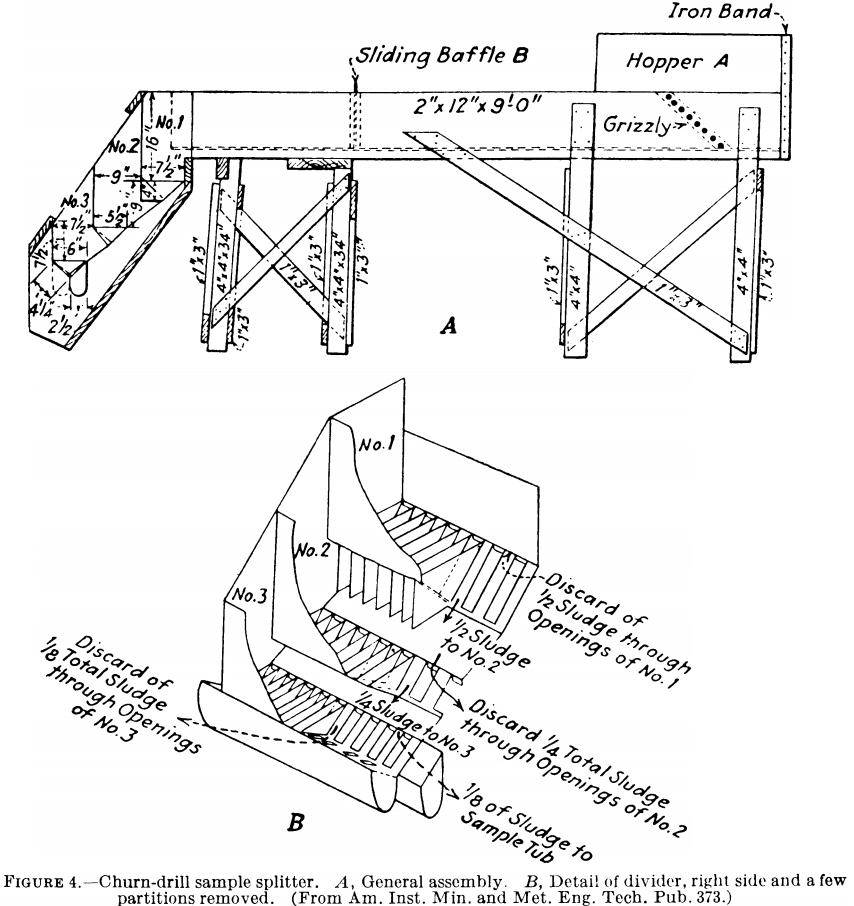

the water and cuttings passed through a sample splitter of the Jones type (fig. 4). The cutters were arranged in three tiers in such a manner that 50, 25, or 12.5 percent or all of the sludge could be caught as desired.

The final sample is then dried and sacked. In drying, it is important to avoid burning it or heating it to such a high temperature that chemical changes take place in the mineral constituents, particularly if sulfide minerals are present.

When churn-drilling is done with rods, the return water and sludge are discharged into suitable settlers, from which clear water overflows or is siphoned off, leaving the sludge in the settler. Whatever the arrangement used, it is important that the waste water shall not carry slimes away with it and thus remove fine material from the sample. This may be accomplished easily with some types of ore, but with those that contain clayey or other colloidal material it may be necessary to provide large capacity to allow a considerable time interval for settling.

Accuracy Of Churn-Drill Samples

In the Tri-State zinc and lead district, churn-drill samples have been used extensively for estimating tonnages and grades of ore in advance of actual mine development. The ore minerals are principally sphalerite and galena. According to Netzeband, the experience of one large company in this district is that the ore mills out about 10 percent better than the estimates based on the churn-drill samples.

Keener states, also, that in this district the estimates based on churn-drill samples are lower than actual mill-run tests.

Joralemon states, with respect to cable-tool drill sampling of the disseminated-porphyry deposits, that “with careful work, involving-casing below all caving ground, assays from churn drilling can be depended upon in nearly all cases to within 0.1 percent copper.”

In referring to samples in the schist ore bodies at Miami, Ariz., Maclennan has stated:

The original churn-drill sampling was checked by:

- the usual channel samples, which were cut across the direction of the major seams every 5 feet of drifts;

- cuttings from dry stoper-drill holes drilled across the major seams at 2.5-foot intervals;

- samples of broken ore taken as the cars were loaded when driving the drifts;

- a few check samples of 6 to 8 tons of ore shot down from the back of drifts over a length of 25 feet and carefully quartered down;

- one 1,500- ton sample mined from a narrow shrinkage stope and put through an automatic sampler at the mill.

This stope was sampled at the same time by the other methods. The conclusion reached was that the churn-drill samples were accurate, the stoper-drill samples the most accurate samples for small drifts, and the channel-sampling average 13 percent too high.

Sampling With Core Drills

Sampling with Hammer Drills

Face Sampling

Grab Sampling

Cutting Down Samples

Summary Of Sampling

The accuracy of the samples themselves—that is to say the extent to which they truly represent the material actually sampled—should not be confused with the accuracy of ore-reserve estimates based upon assay results. Samples may very accurately represent the grade of the ore sampled; but in mining, the grade of the ore sent to the mill may be considerably lower, due to dilution in stoping operations because of inadvertent inclusion of wall rock or because of deliberate mining of ore of lower grade than that sampled. The necessity for eliminating the human factor in taking samples has been stressed, and the advantage of making the sampling operations as automatic as possible for this purpose has been pointed out. By adhering to rigid standards for the spacing of samples and the method of taking them, size of samples, relationship of sample size to particle size in cutting down, the mathematical probability is greater that errors in individual samples will be compensating. Interpretation of sampling results in estimating grade of ore reserves, on the other hand, is a matter requiring the exercise of judgment.